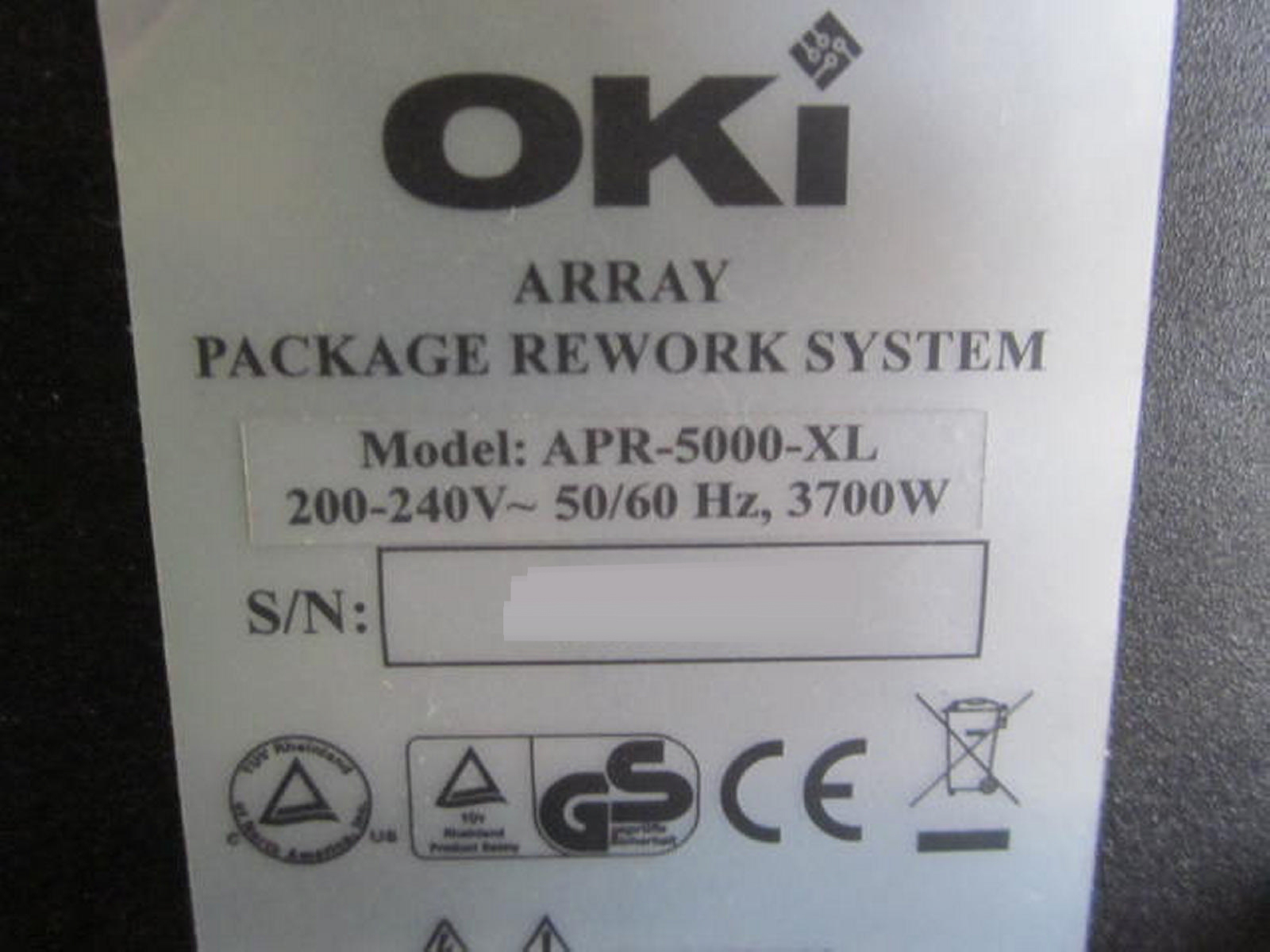

Used OKI APR-5000-XL #9111344 for sale

URL successfully copied!

Tap to zoom

ID: 9111344

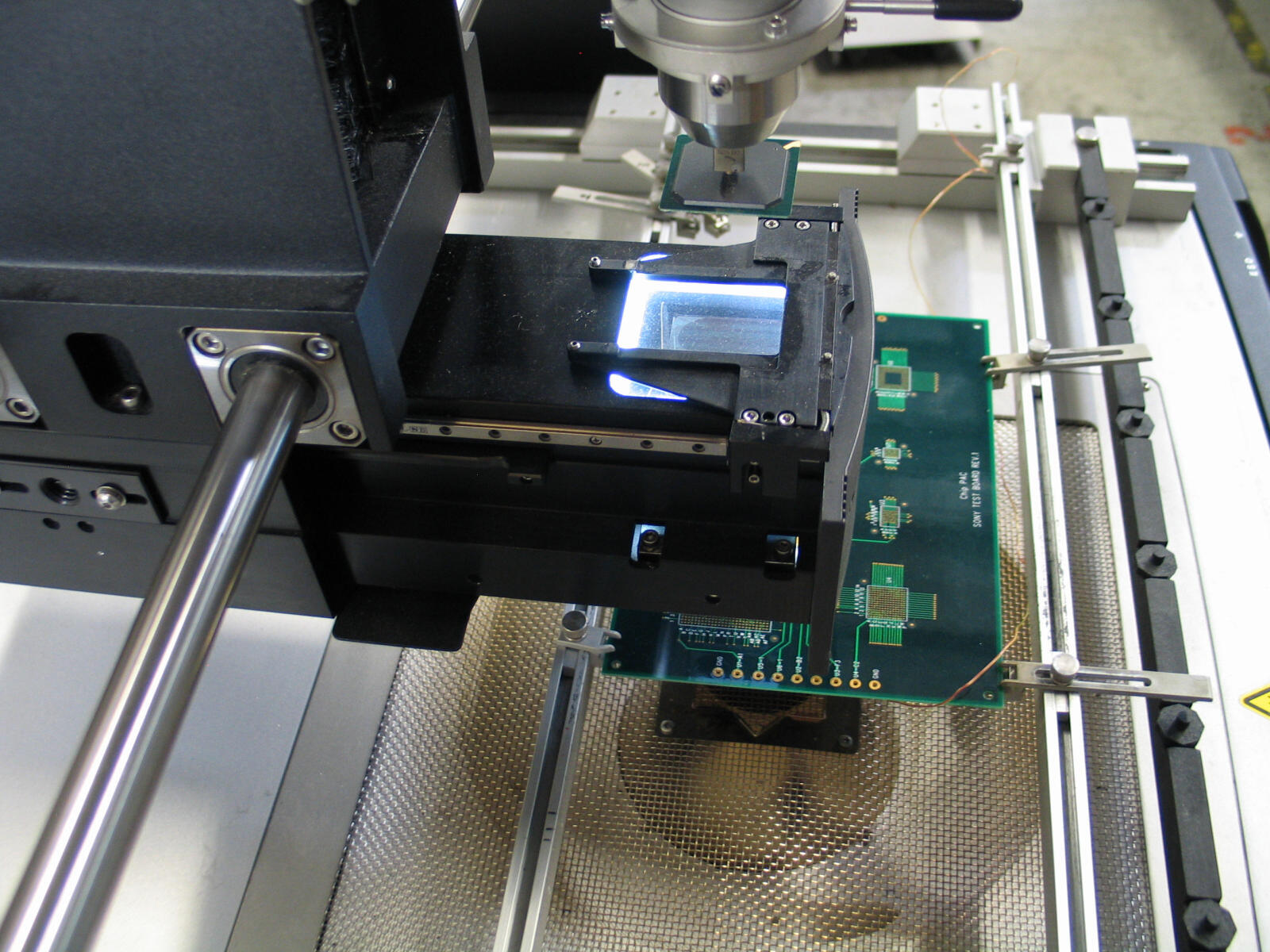

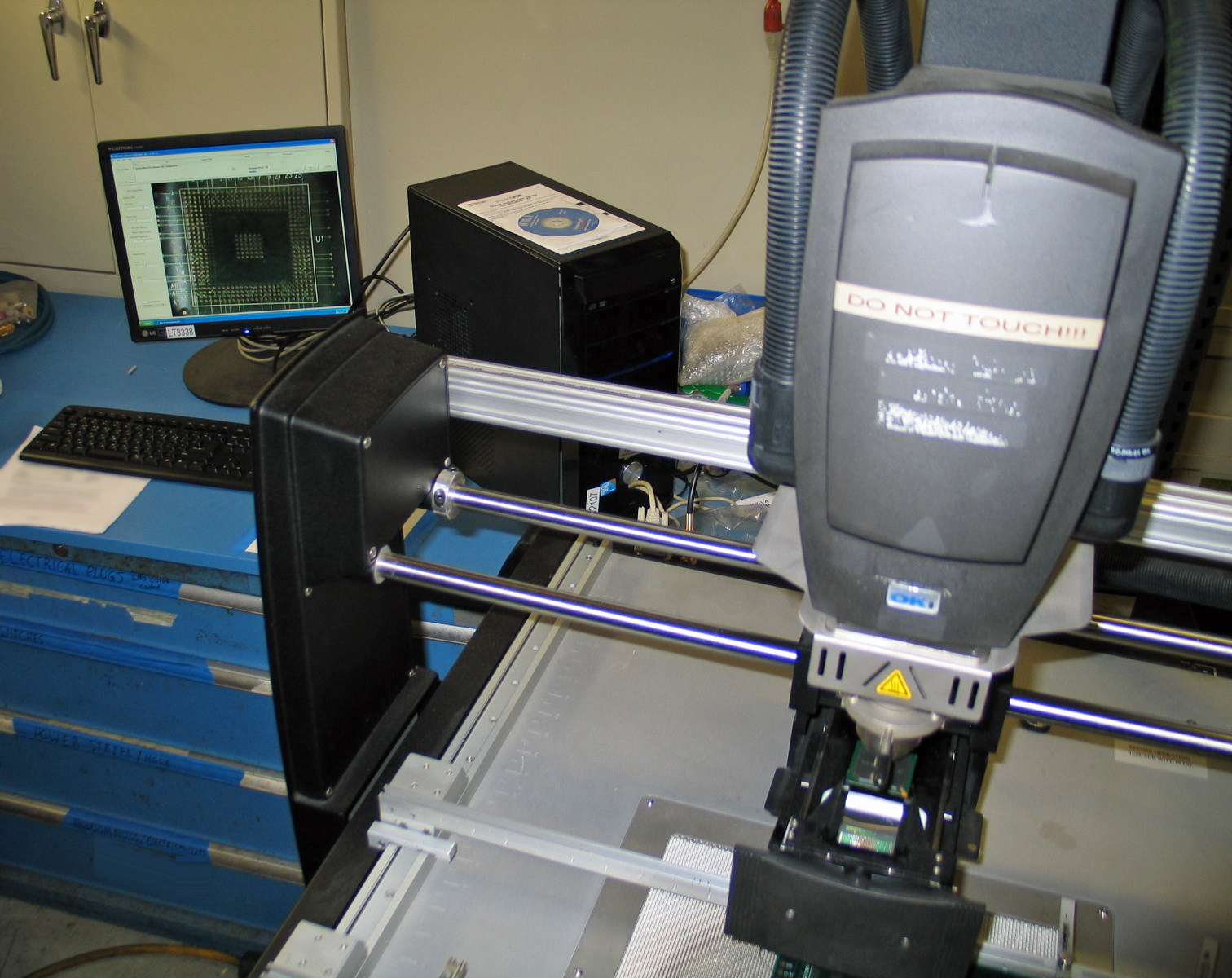

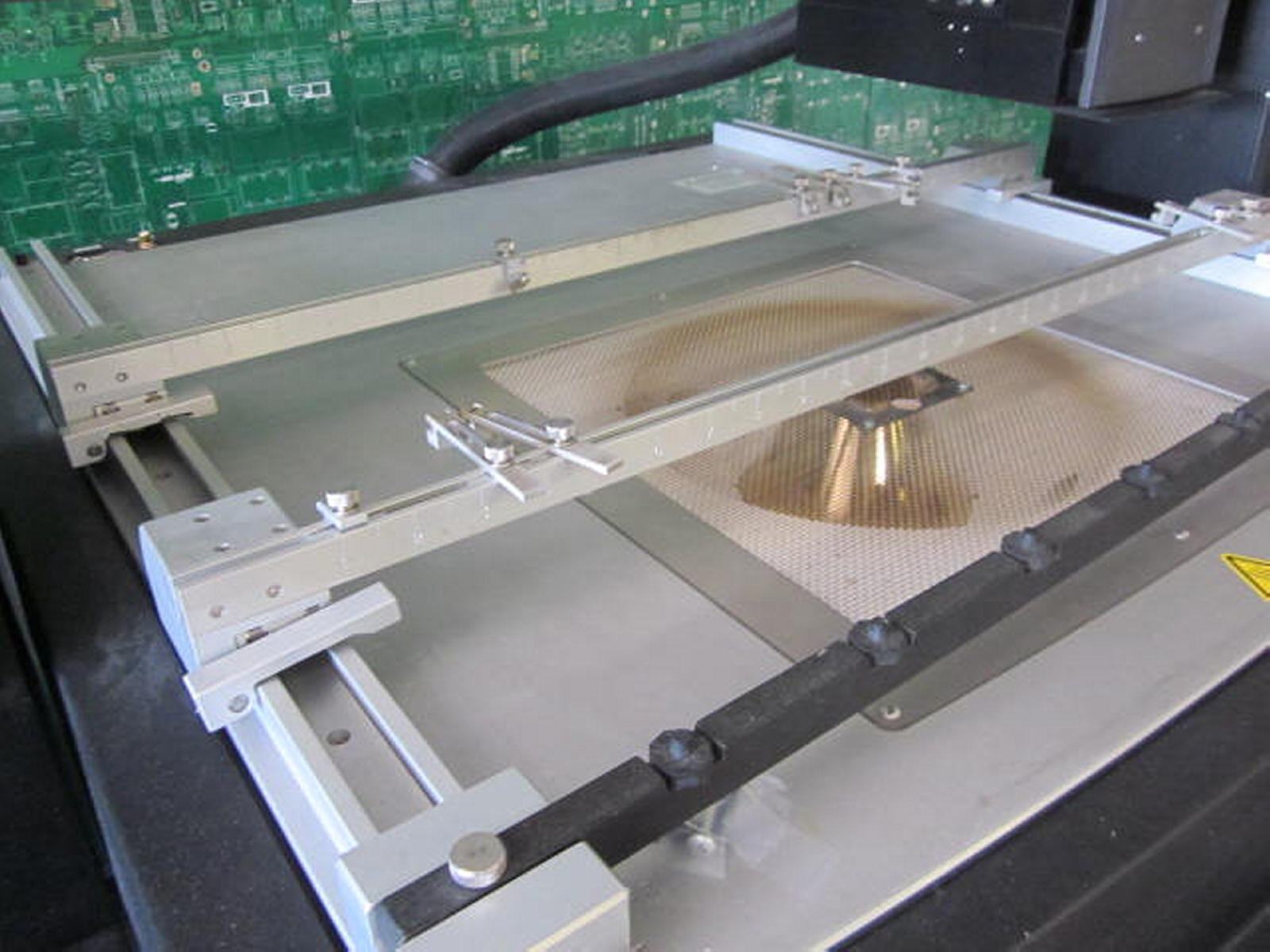

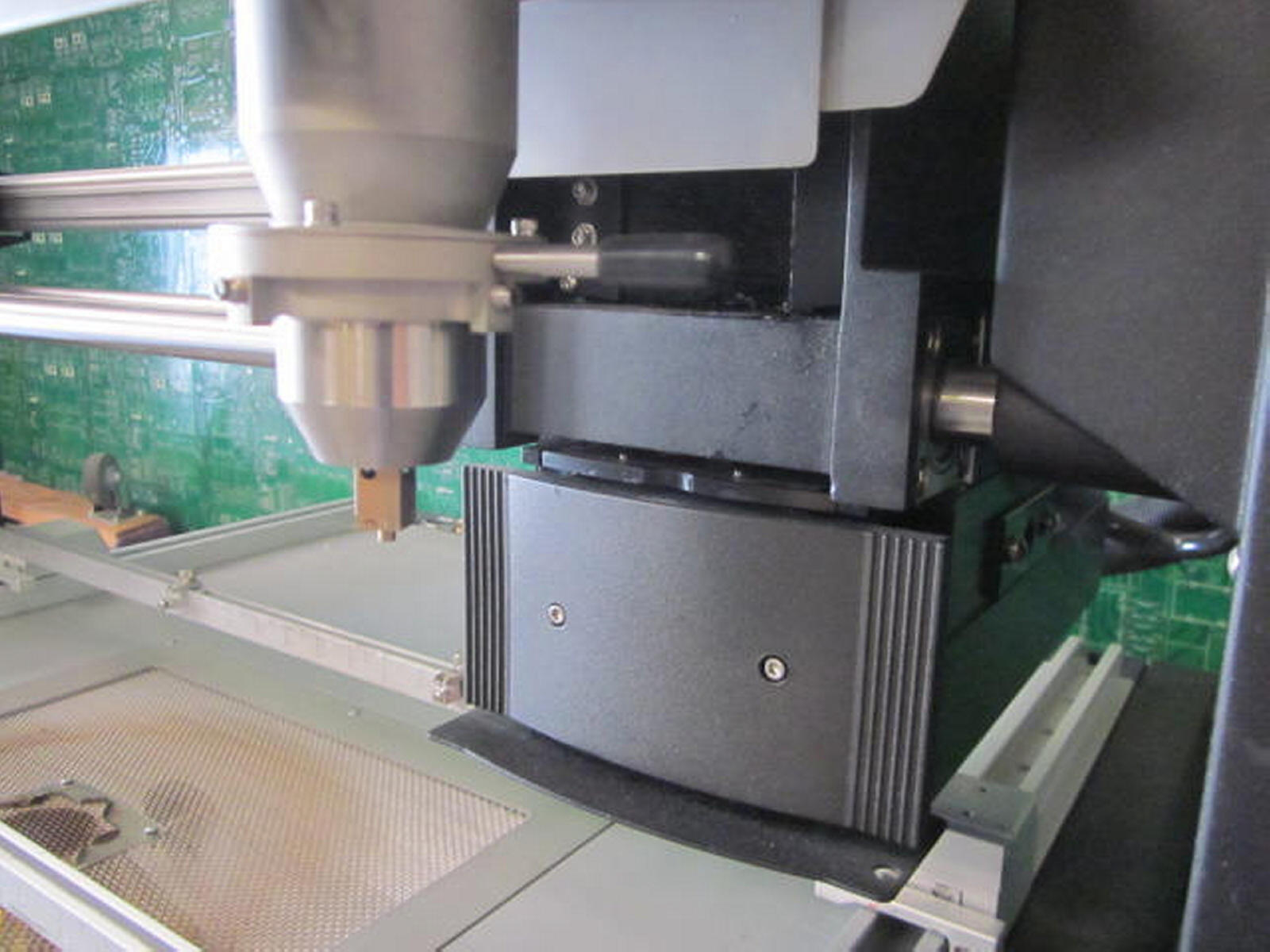

Array package rework station

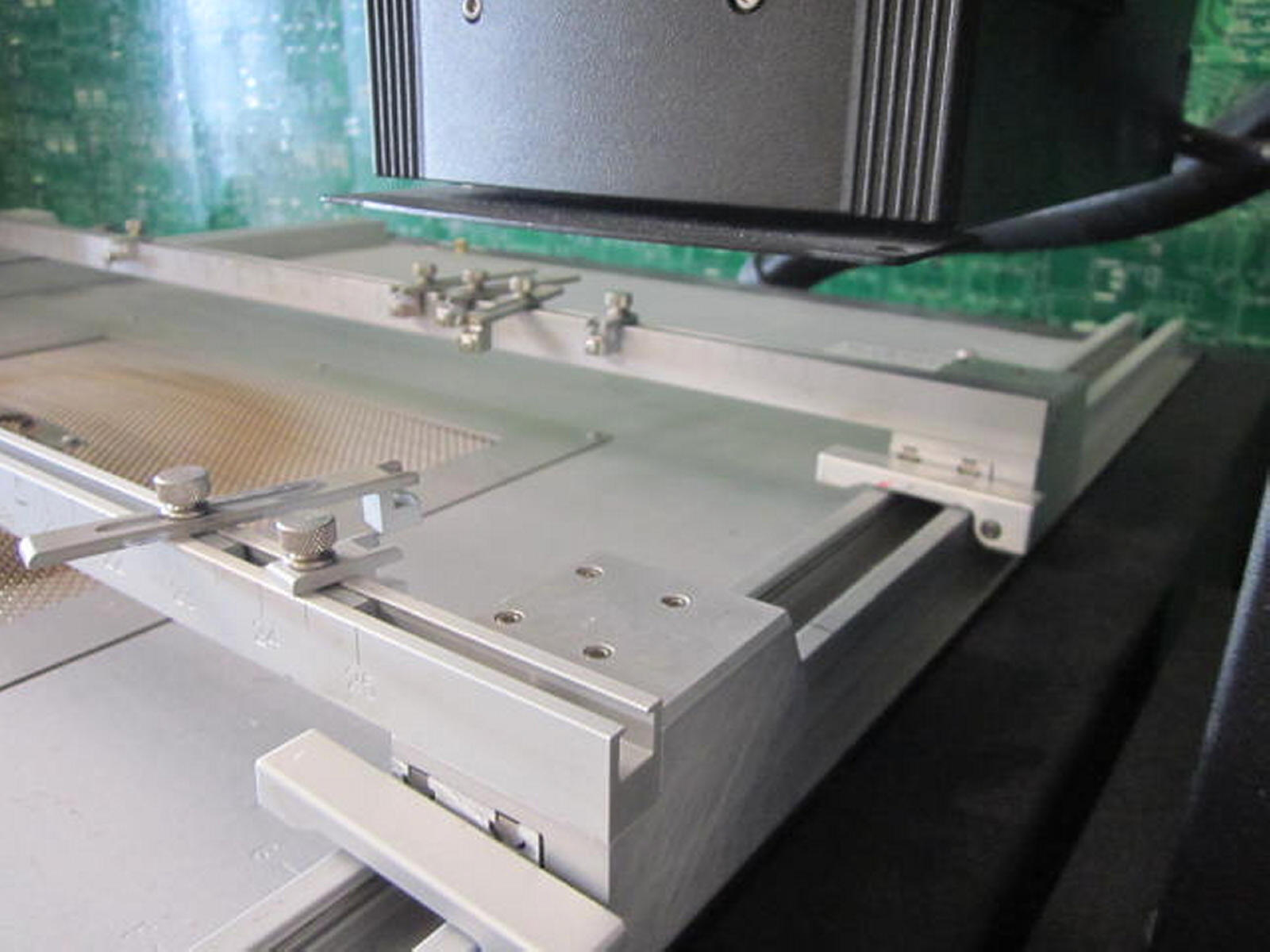

Board size max.: 24.5" x 24.5"

Board size min.: 0.020" x 0.010"

Motorized X,Y,Z adjustments speed placement

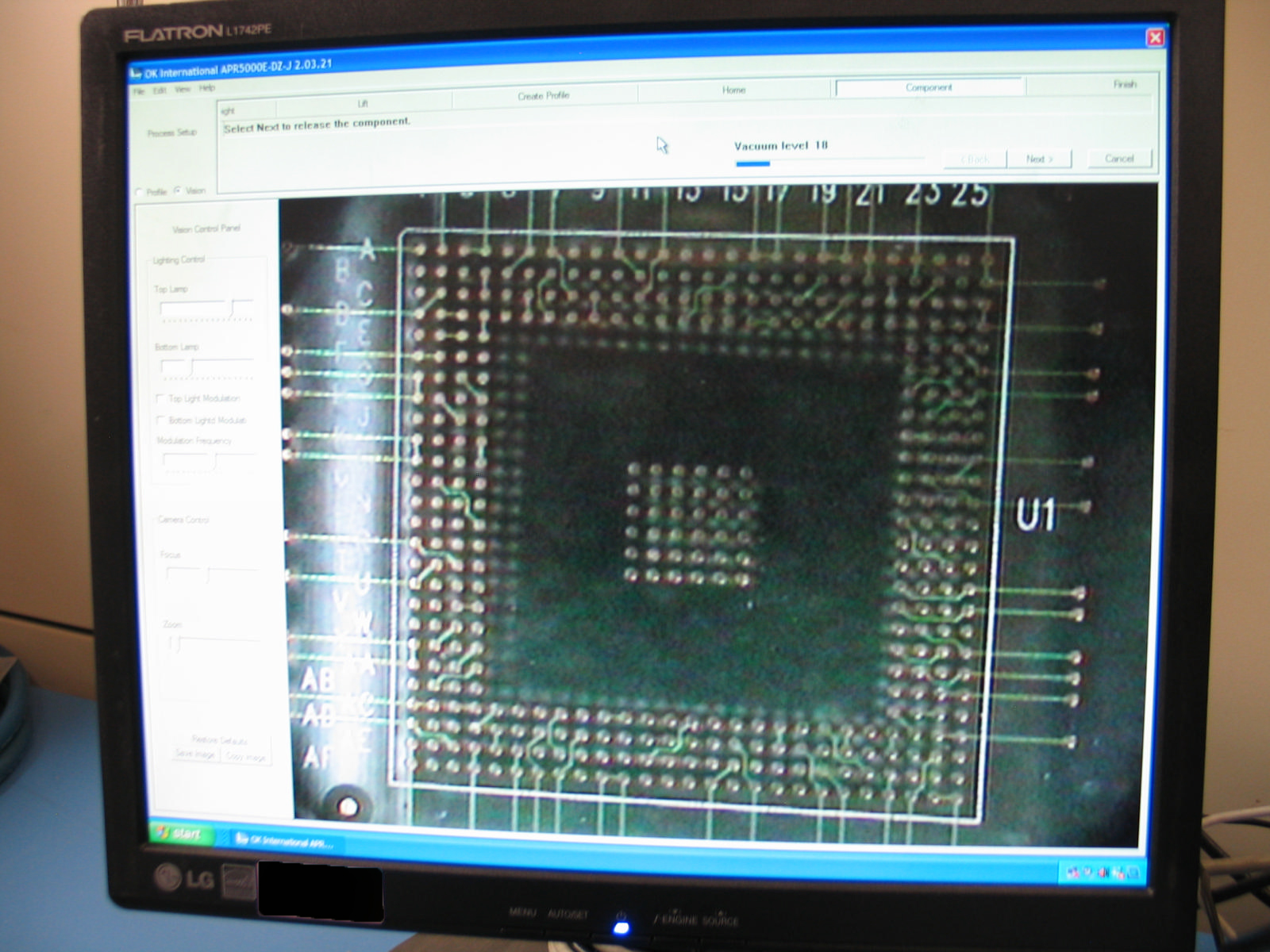

Theta axis: 360° rotation.

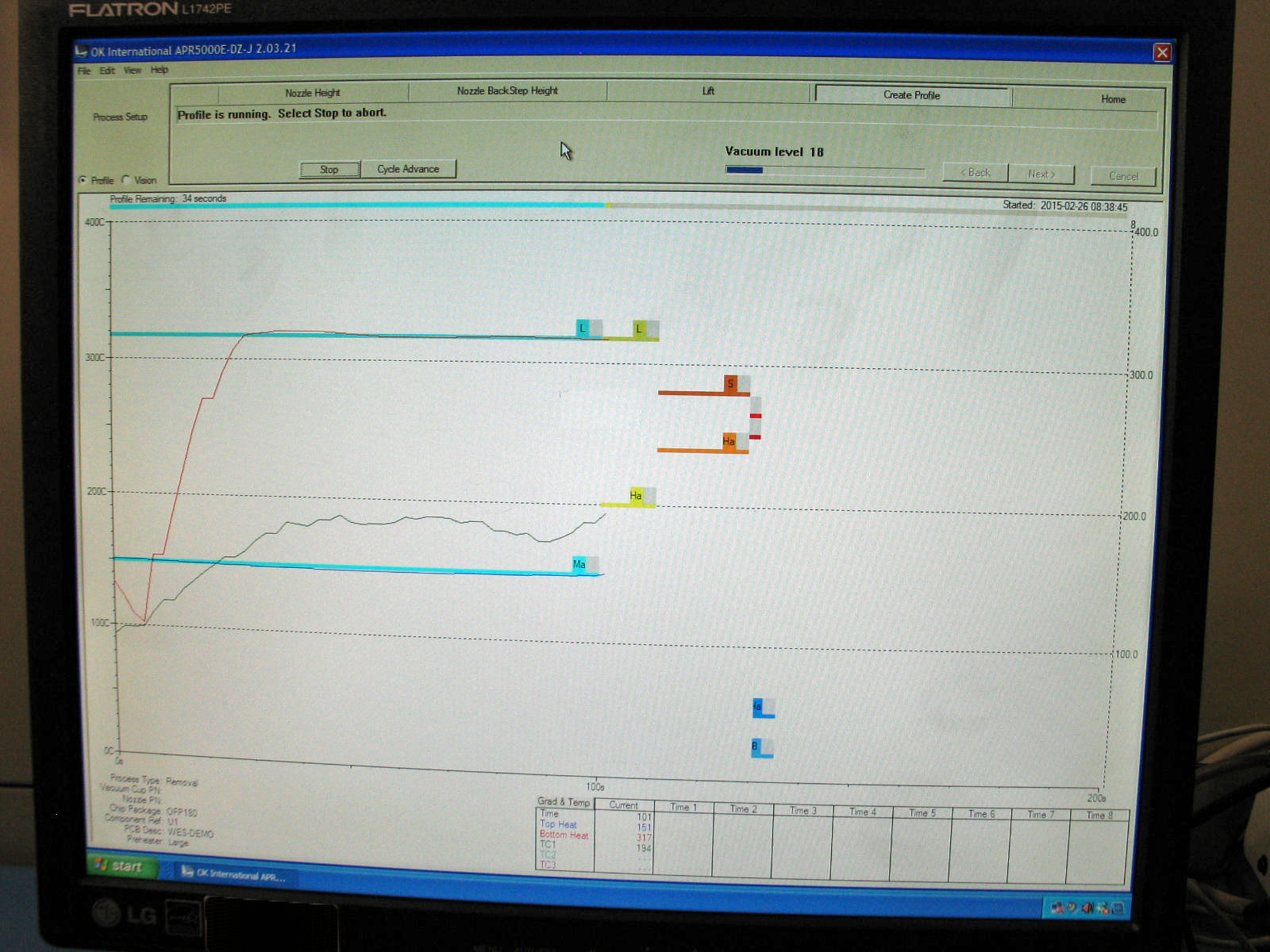

OKI APR-5000-XL is a PC board assembly and manufacturing equipment designed for high-volume applications. It is a compact, automated solution that is ideal for placing components such as chips, capacitors, and resistors onto printed circuit boards (PCB). The system is capable of both manual and automated component placement, providing a cost-effective solution for high-speed production of high-quality circuit boards. APR-5000-XL utilizes dual-head servo-driven pick-and-place technology to quickly and accurately place components onto the board surface. Each of the two pick-and-place heads is able to place components at up to 150,000 components per hour (450 pick-and-places per second). The unit is driven by a high-speed om-control machine, enabling an incredibly precise placement accuracy of ±0.04mm. To maximize accuracy, OKI APR-5000-XL features a camera profiling tool for each board to properly align the pick-and-place heads. This feature ensures high placement accuracy even if the boards are slightly warped. The asset also offers a variety of vision inspection options such as barcode scanning, component scanning, and PCB registration to ensure board quality. The machine's advanced environmental protection ensures a clean environment for component placement. It features a positive pressure clean room model, which facilitates exacting dust prevention during high-speed operation. Additionally, APR-5000-XL includes a patented dust blowout equipment that utilizes a powerful vacuum to promptly remove dust from the component sources. Moreover, the system is equipped with a 40-port feeder design, providing a high component capacity. It is perfect for high-mix processing, as it offers a wide range of component sizes and shapes. For maximum production flexibility,Users can also integrate 3rd party feeders into the unit. In conclusion, OKI APR-5000-XL is an advanced PC board assembly and manufacturing machine that offers an accurate and flexible solution for high-volume applications. With its dual-head pick-and-place technology, camera profiling tool, vision inspection options, and environmental protection features, it provides a top-of-the-line manufacturing solution for even the most demanding industries.

There are no reviews yet