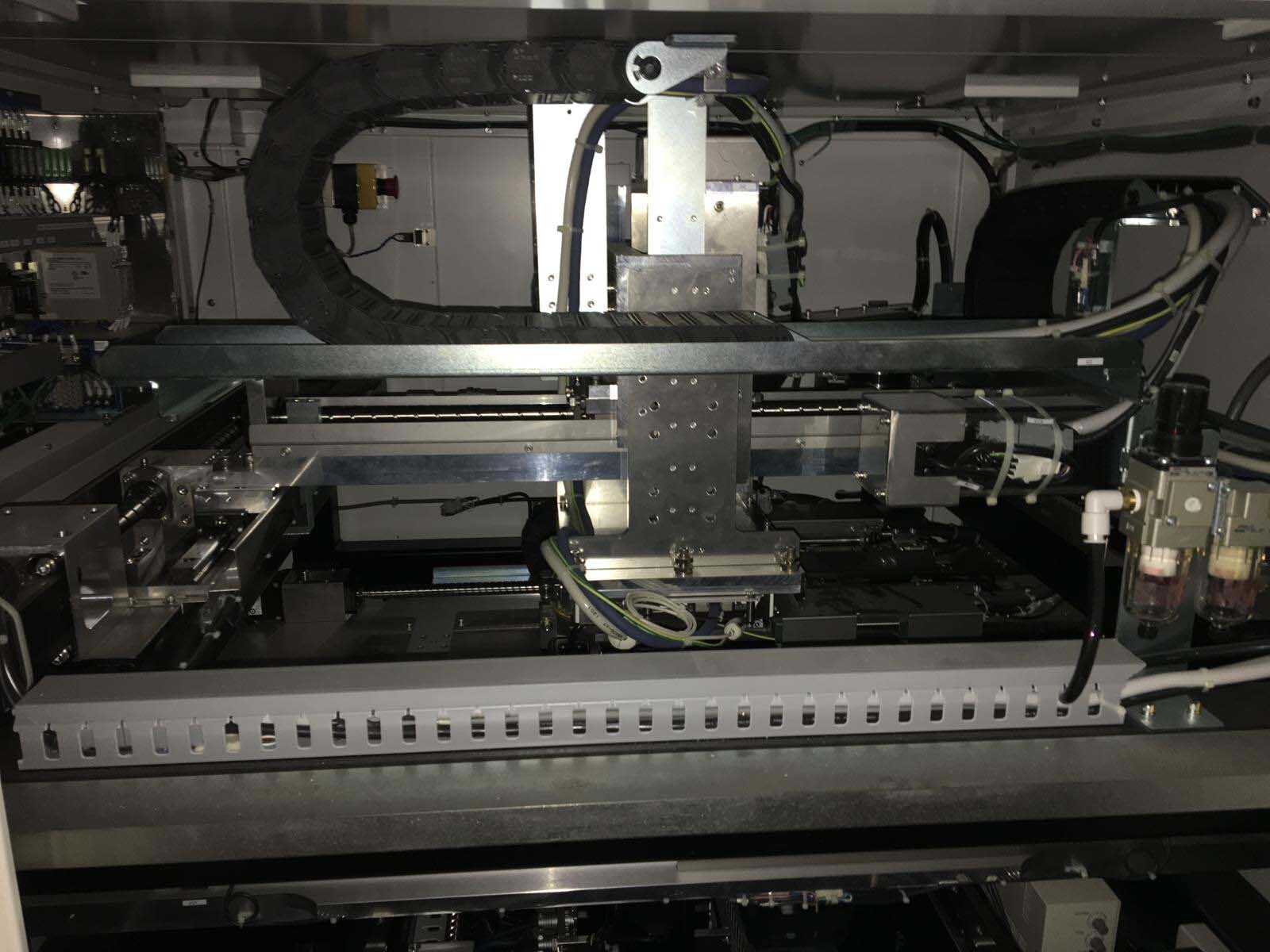

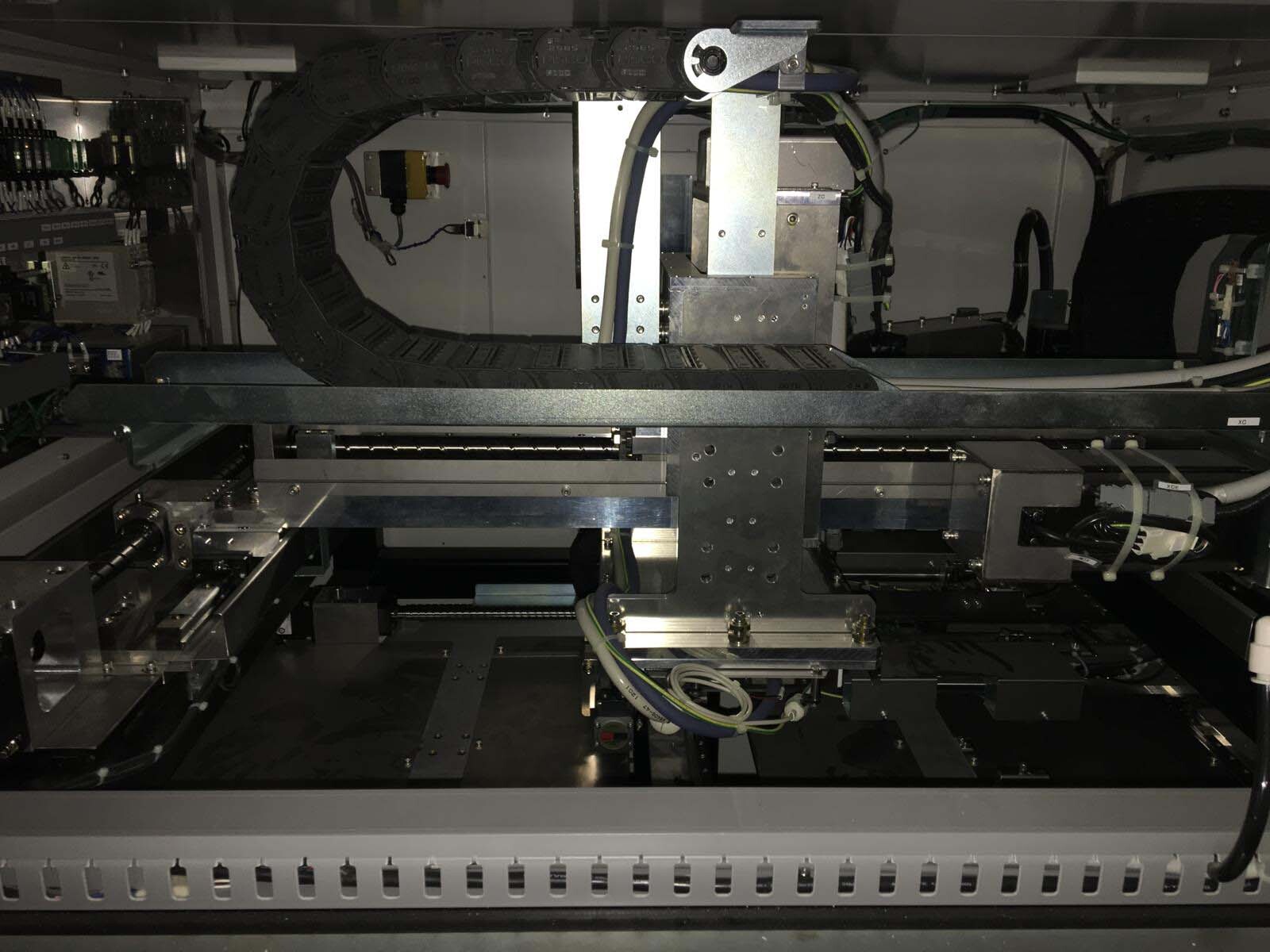

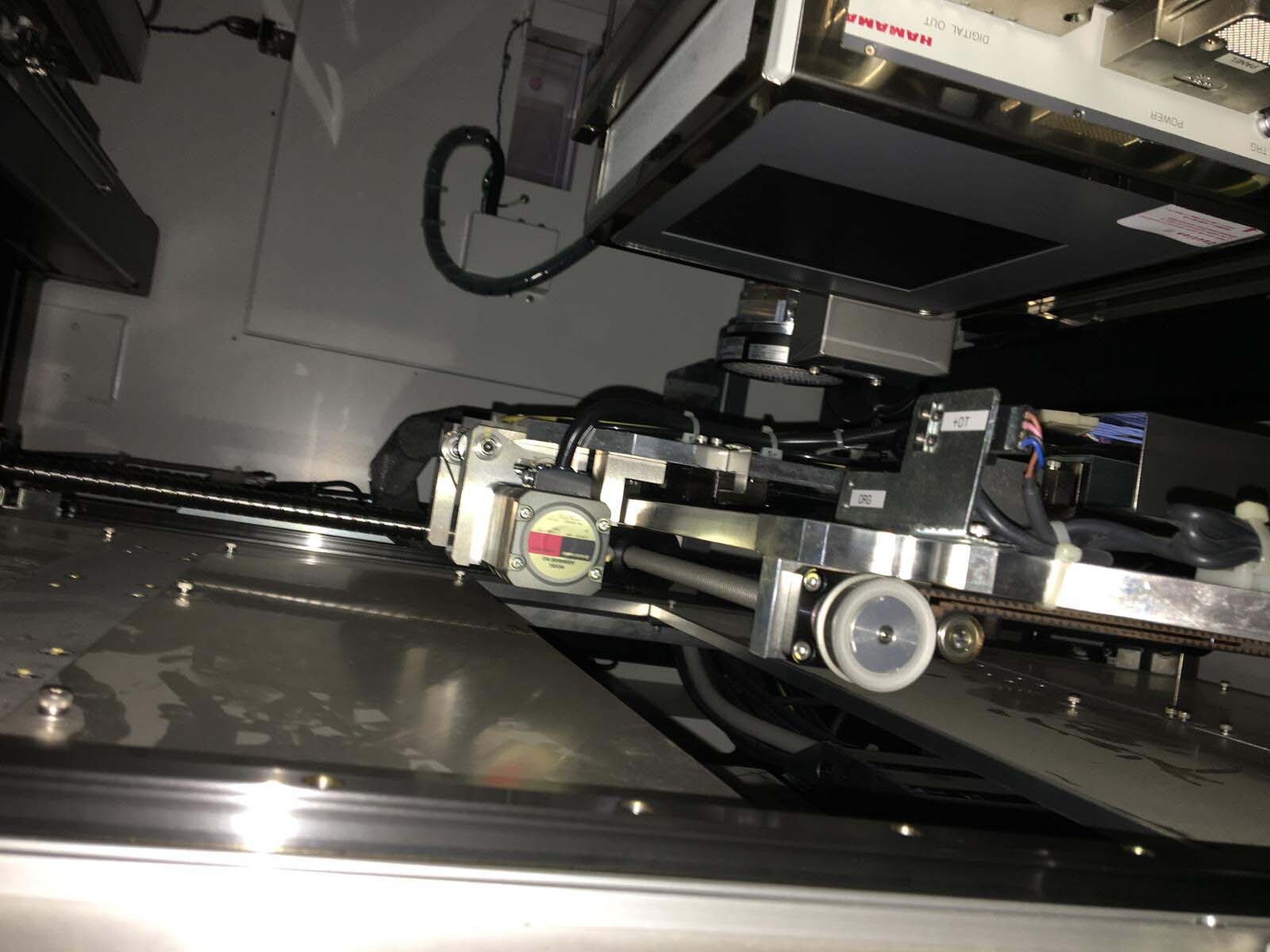

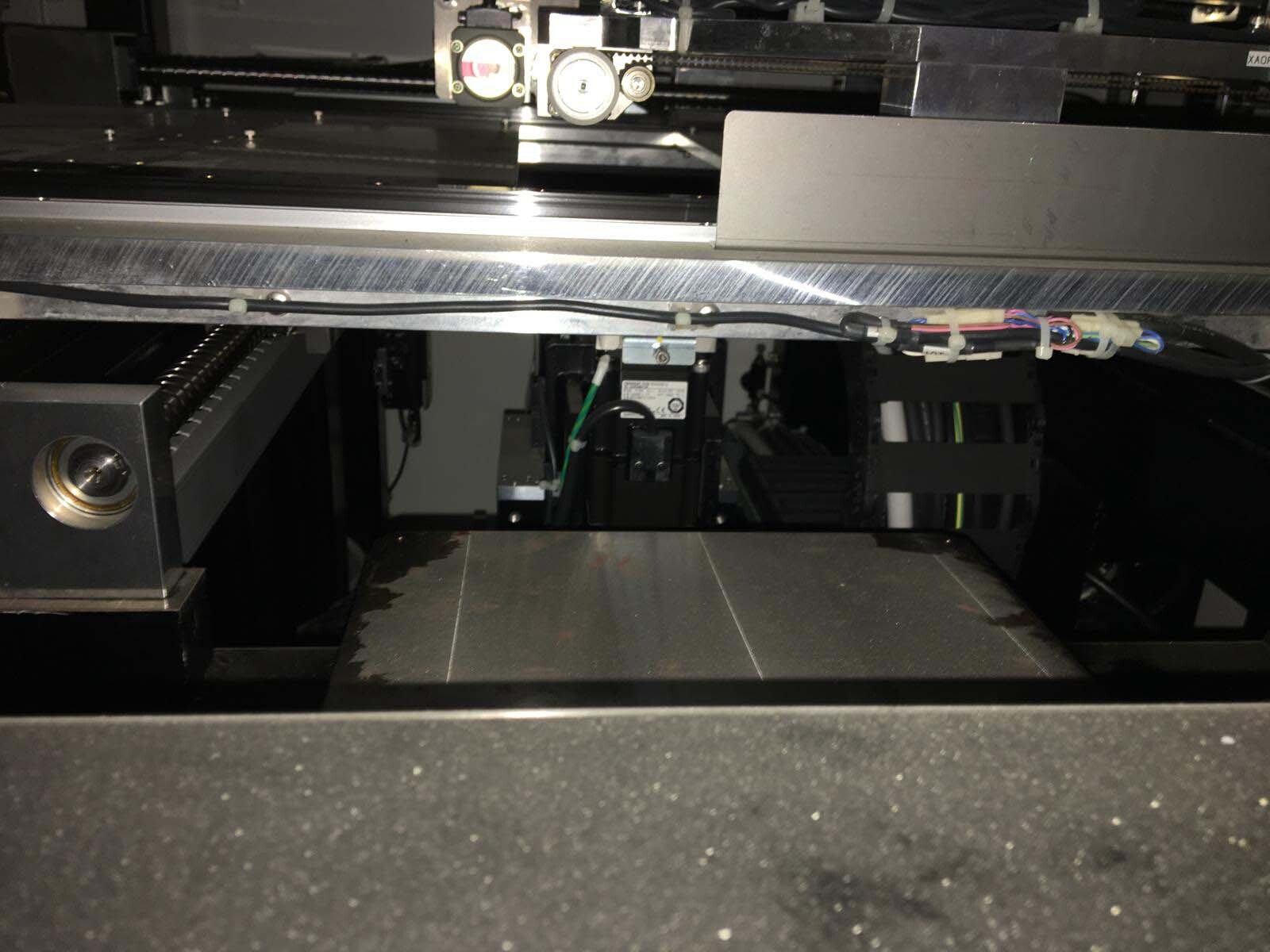

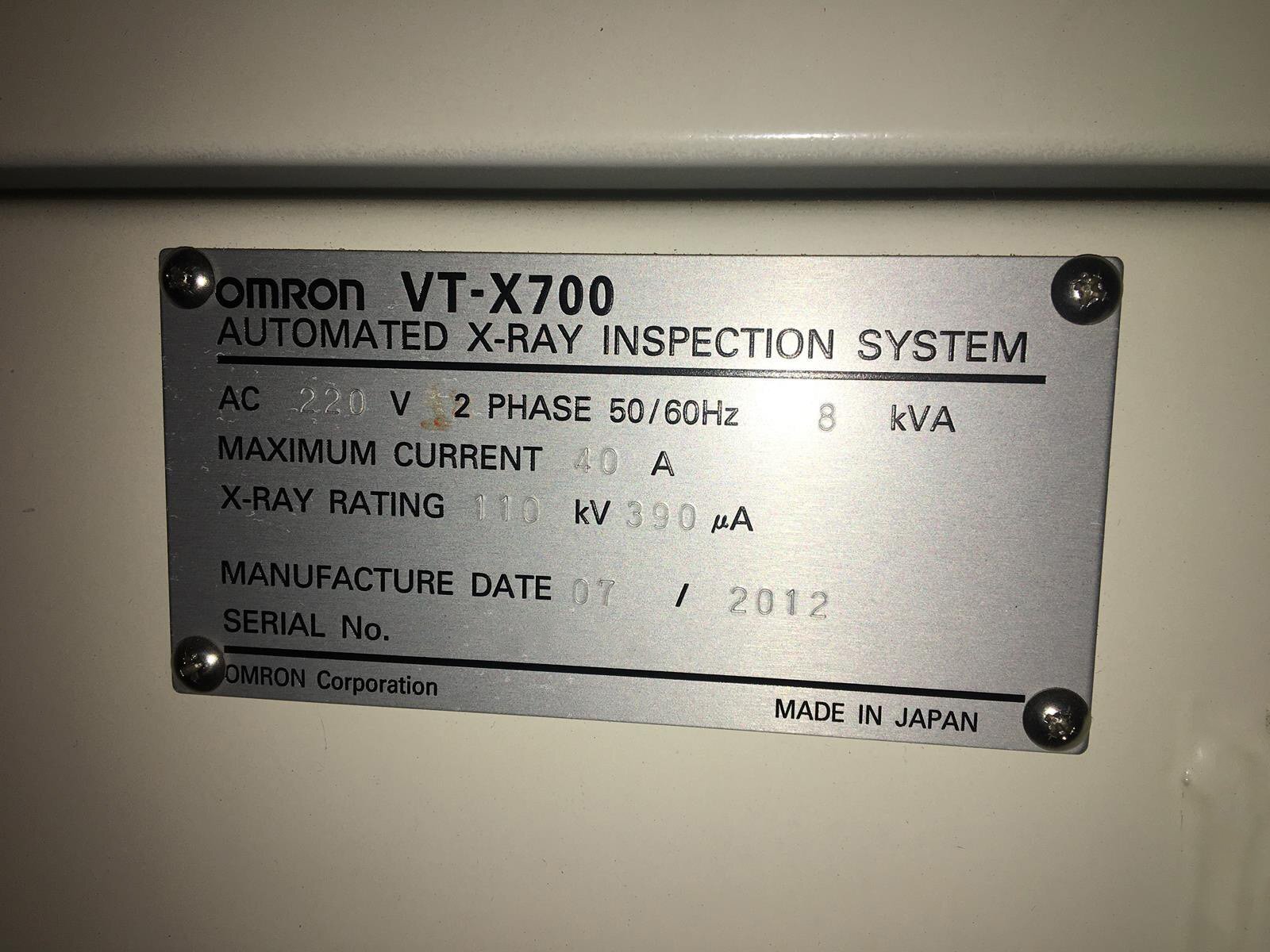

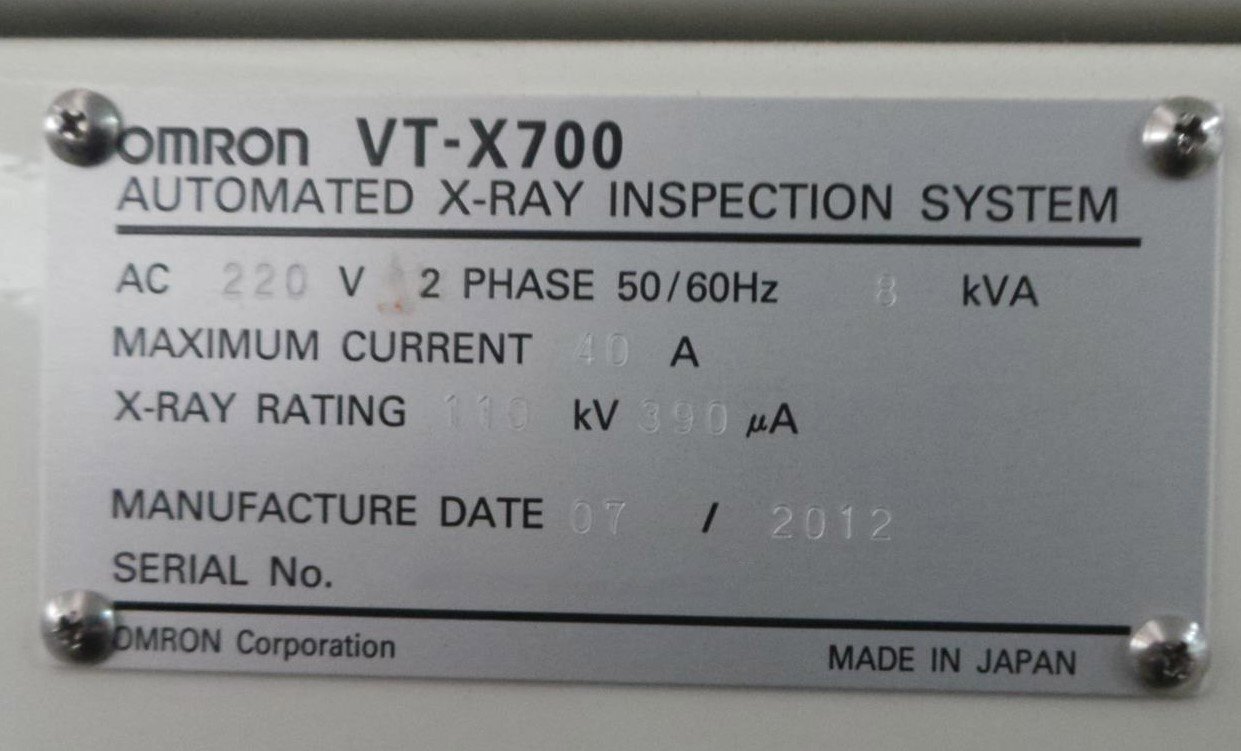

Used OMRON VT-X700 #9305873 for sale

URL successfully copied!

Tap to zoom

ID: 9305873

Vintage: 2012

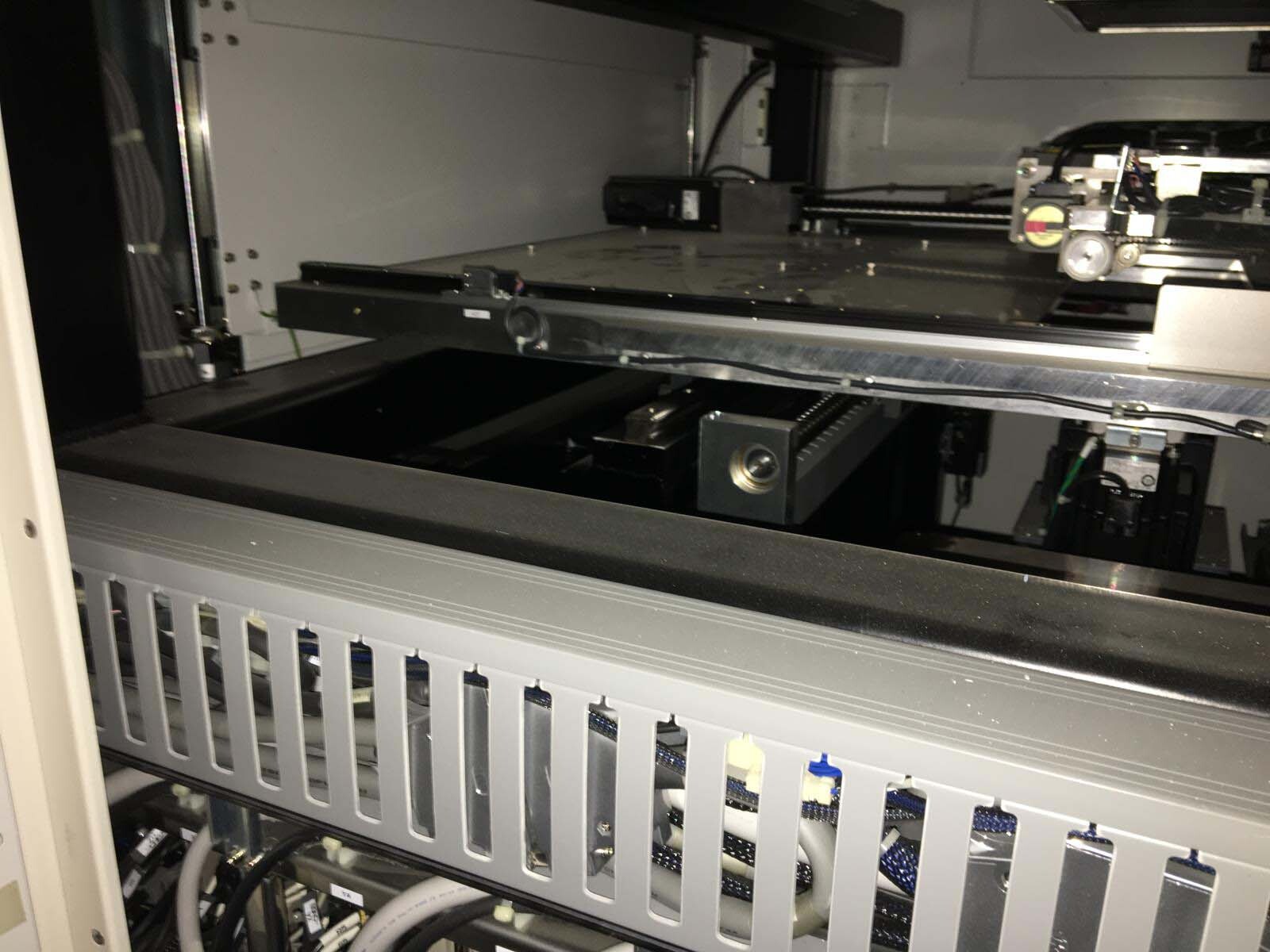

X-Ray system

Hours: 5,796

Inspected components:

BGA / CSP

Inserted components

SOP

QFP

Transistors

R/C Chips

Bottom-side terminal components

QFN

Power devices

Inspected items:

Openings

Non-wet

Solder amount

Shifting

Foreign object stuck

Bridging

Lead presence

Imaging specifications:

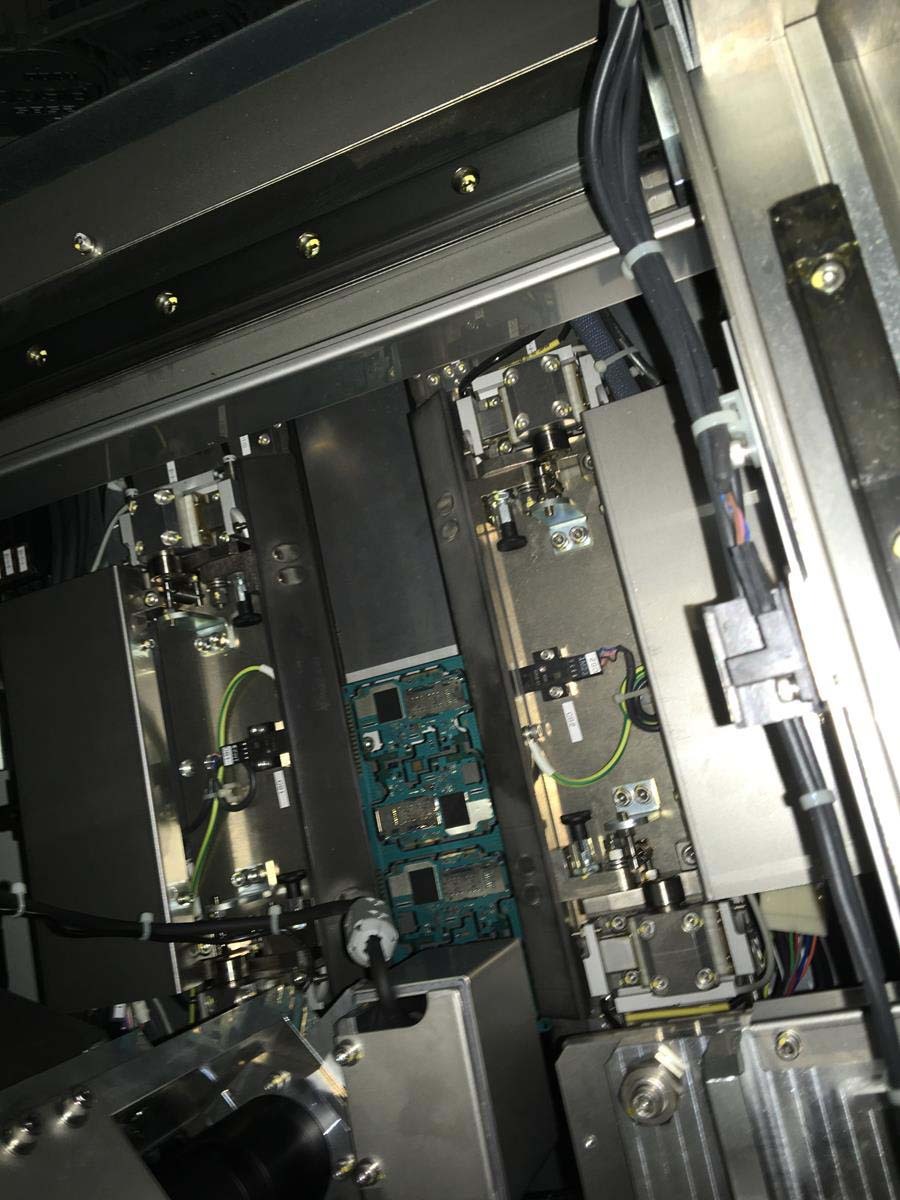

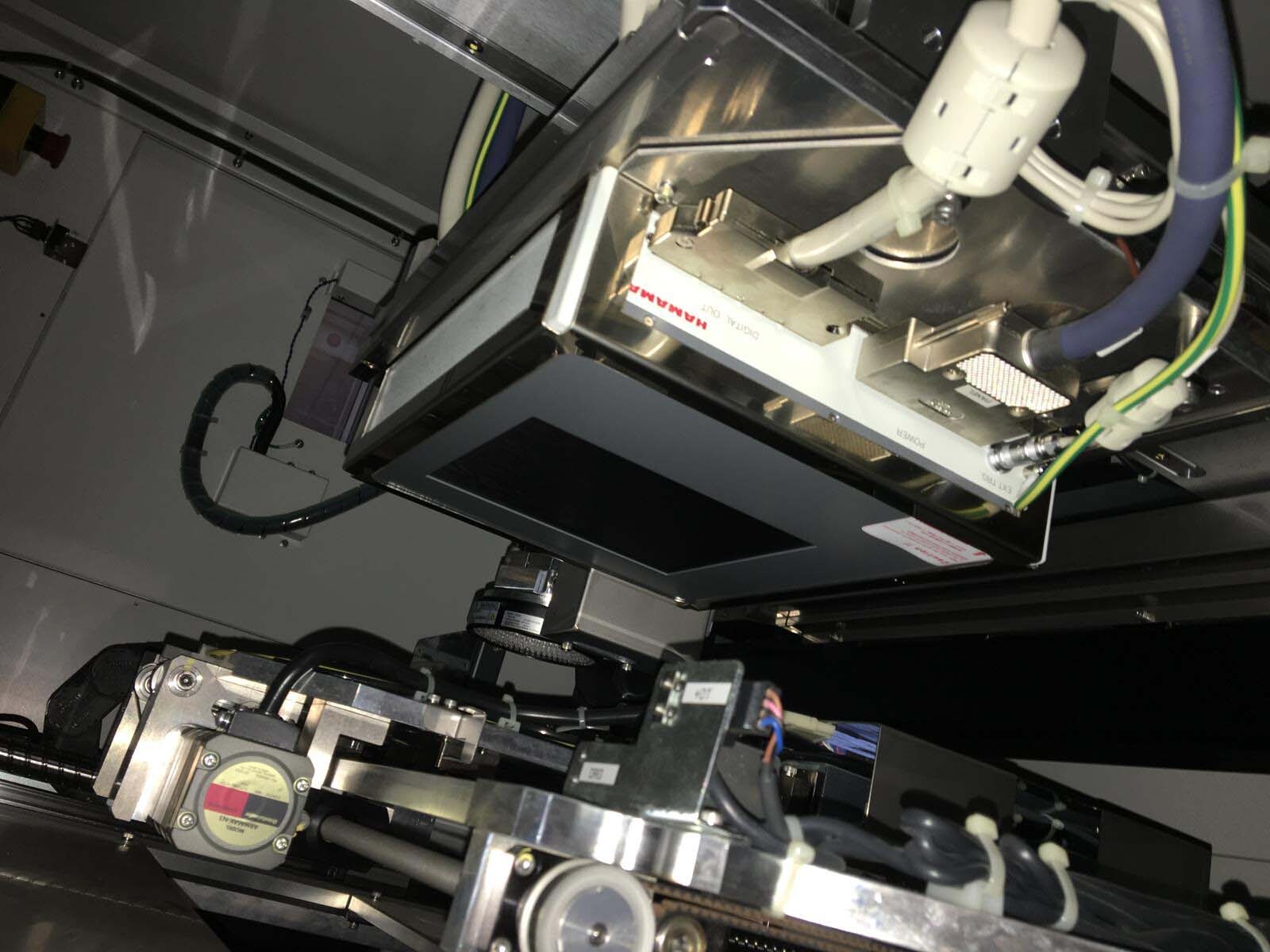

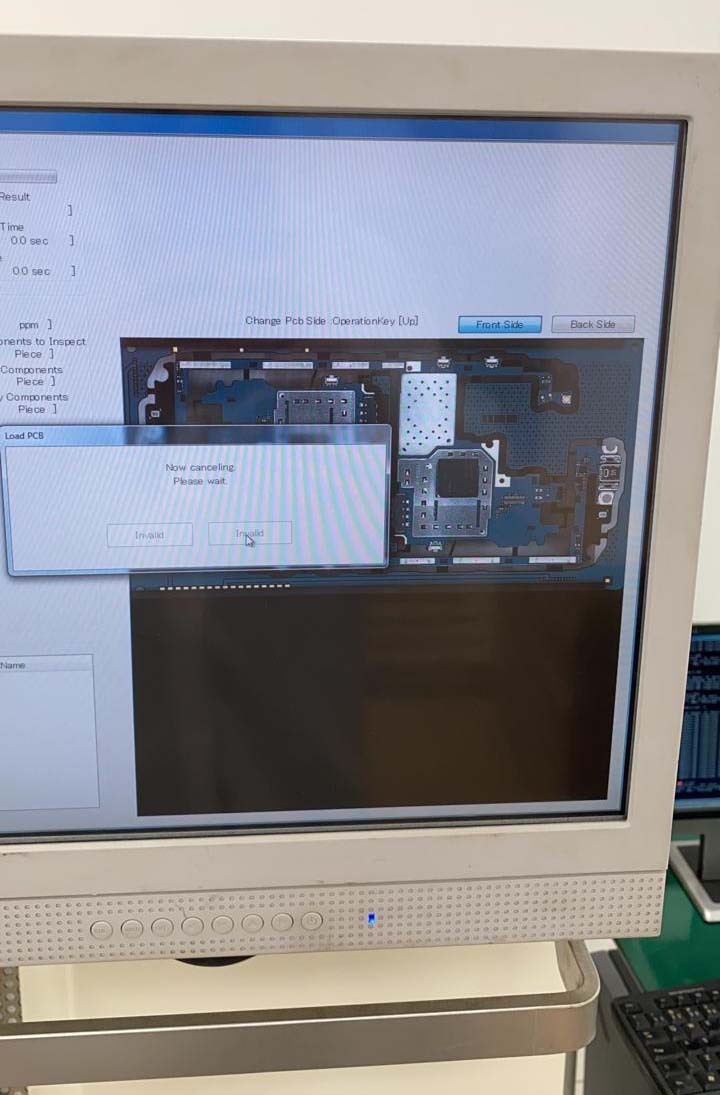

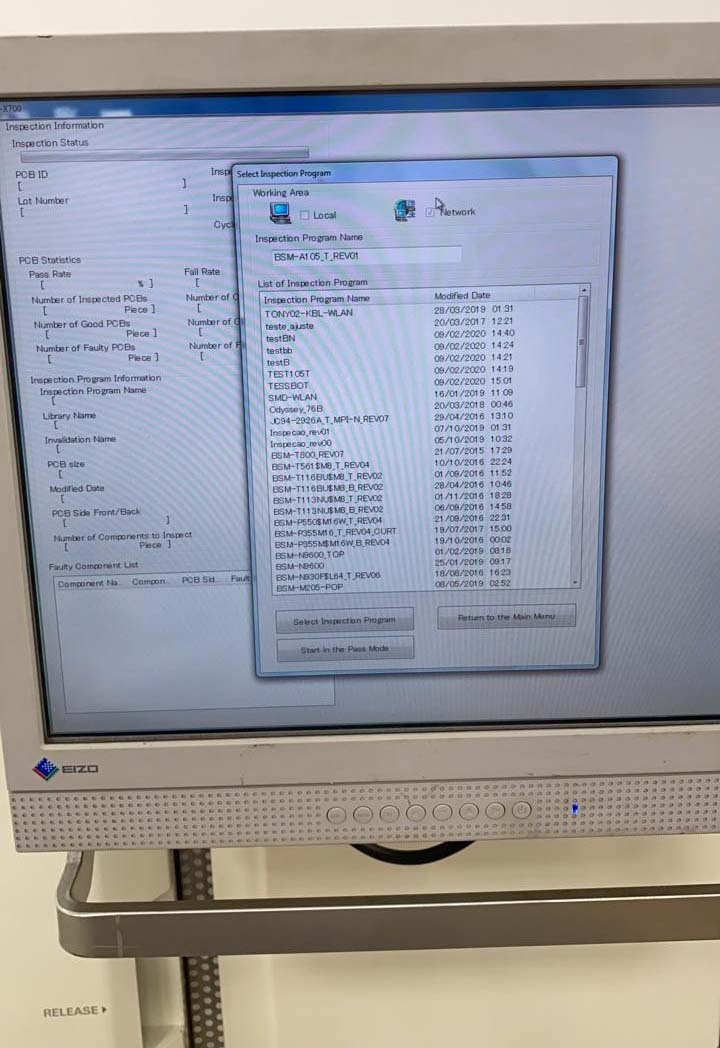

Imaging method: 3D Slice imaging using parallel CT

Resolution: 10, 15, 20, 25 or 30 μm (Selectable to suit detected item)

X-Ray source: Micro-focus closed tube (130 kV)

X-Ray detector: Flat panel detector

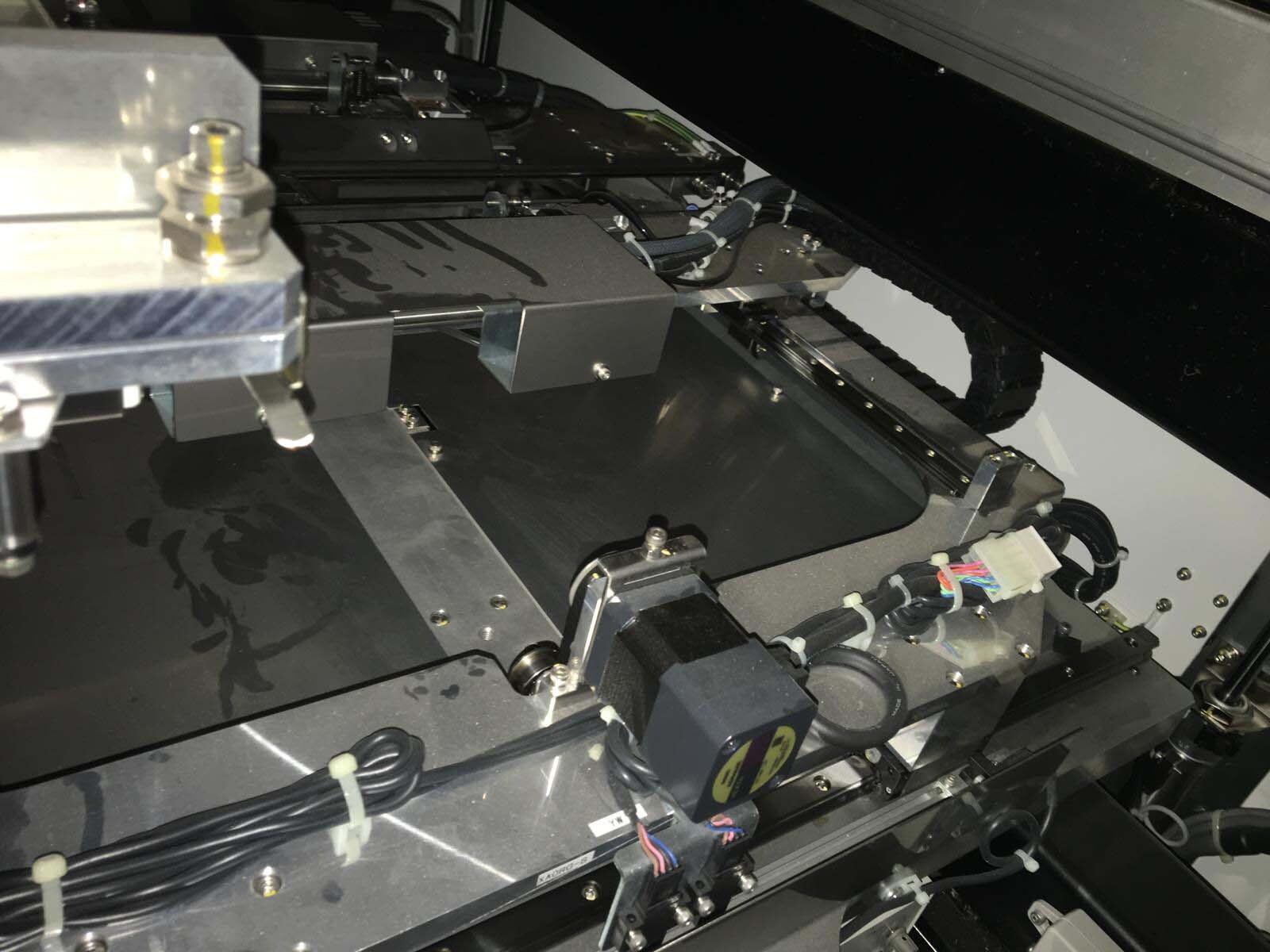

Mounted component height:

Top: 50 mm / Shorter

Bottom: 20 mm / Shorter

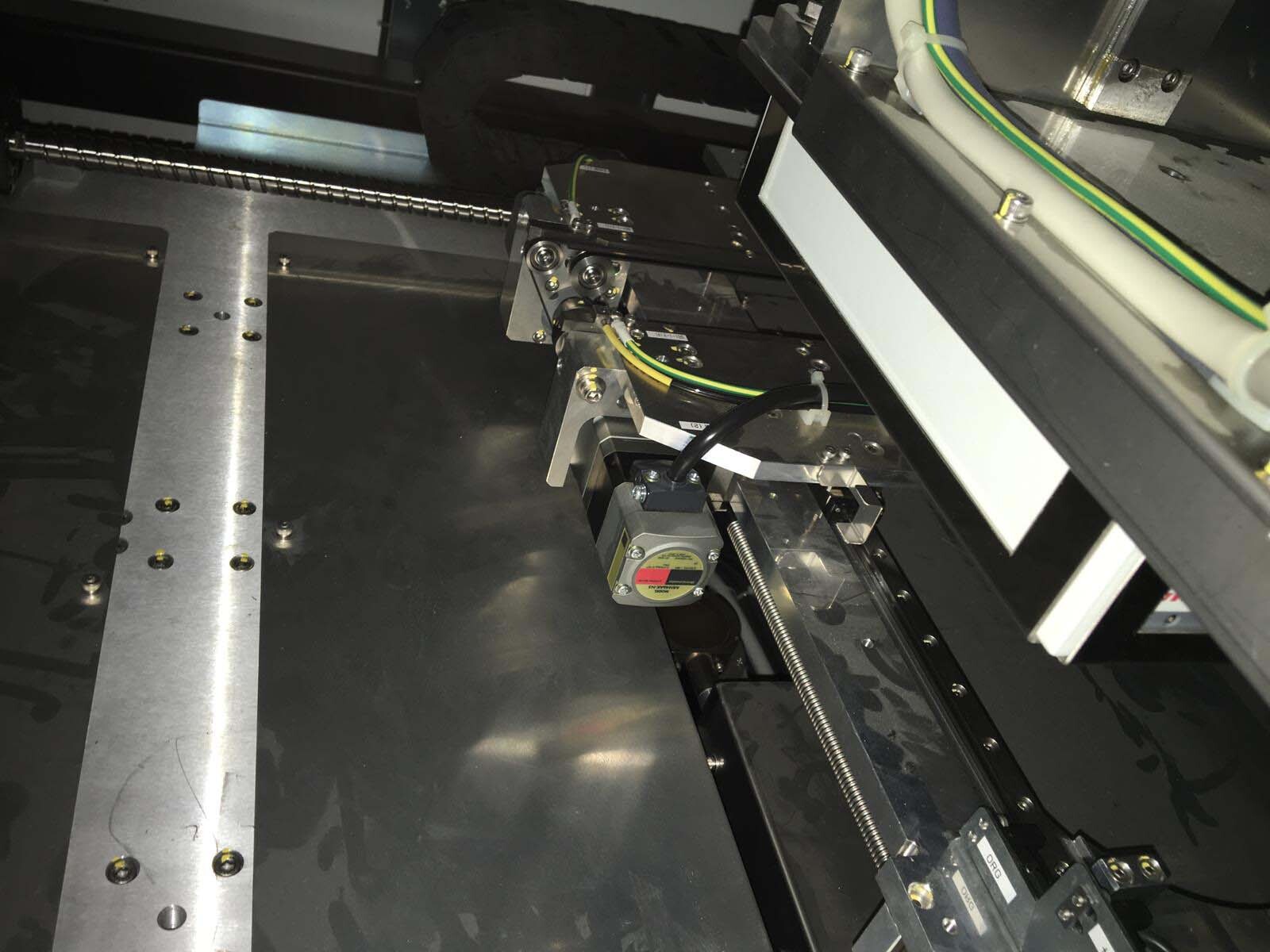

Device specifications:

PCB transfer height: 900 ± 15 mm

X-Ray leakage: Less than 0.5 μSv/h

2012 vintage.

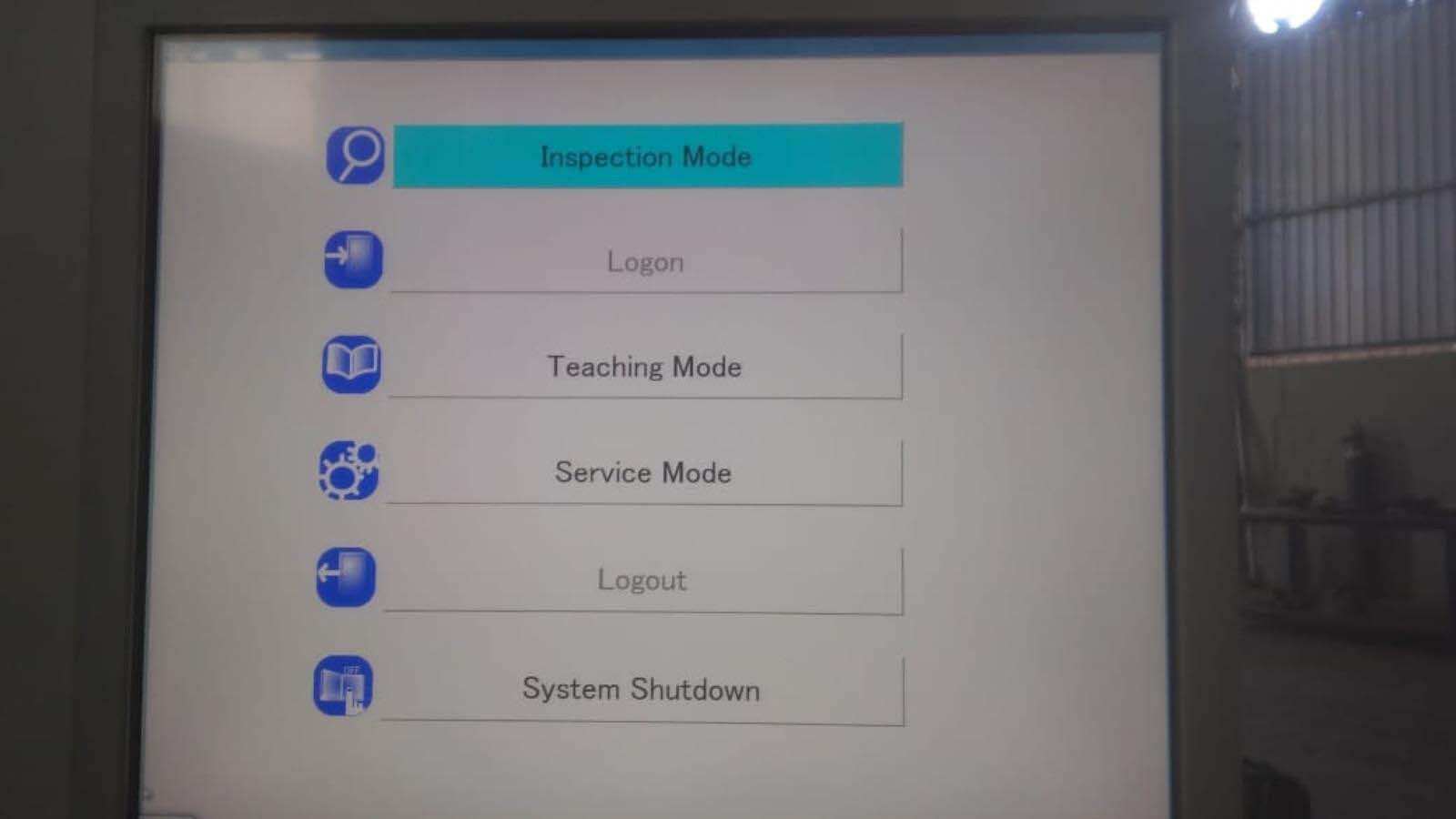

OMRON VT-X700 PC Board Assembly and Manufacturing Equipment is an interactive, high-speed, cost-effective production solution designed to streamline the manufacturing process. It provides an intuitive and easily operable interface, allowing production staff to program and monitor the production process. The integrated process sections allow for rapid set up and process changes for improved speed and accuracy. VT-X700 offers a range of options which can be tailored to the individual requirements of a given production environment. It is modular in design, allowing components to be added or removed as necessary. It also includes a software program which allows for the customization of board assemblies. This includes the ability to customize the placement of components on the board assembly, assign components a part number, create an assembly instructions, and track the entire manufacturing process. OMRON VT-X700 includes a number of features to ensure accurate and reliable production. It includes an image sensor that reads components on the board; a liquid crystal display (LCD) for displaying information on the production process; a memory card which stores production data; and a built-in bar code reader for tracking part numbers and other data. In addition, the system is designed to reduce downtime, as components can be quickly replaced if necessary. VT-X700 is designed to be energy efficient, and is capable of handling the most demanding production schedules. It is also designed to increase production accuracy by providing a process-controlled unit that can detect component defects and surface imperfections. Additionally, its selection of tools and equipment makes it capable of producing high-precision board assemblies. Finally, OMRON VT-X700 comes with built-in safety features to protect machines and operators from potentially hazardous situations. These include features such as overload protection and emergency stop functions. Additionally, the machine can also be set up to perform a series of tool checkup routines to scan components for defects and contamination. Overall, VT-X700 is an user-friendly, reliable, and cost-effective PC Board Assembly and Manufacturing Asset that is designed to improve production accuracy, minimize downtime, and enhance overall safety. It is an ideal production solution for a variety of applications.

There are no reviews yet