Used ONTEC RM-2500 #9058655 for sale

URL successfully copied!

Tap to zoom

ID: 9058655

Vintage: 2007

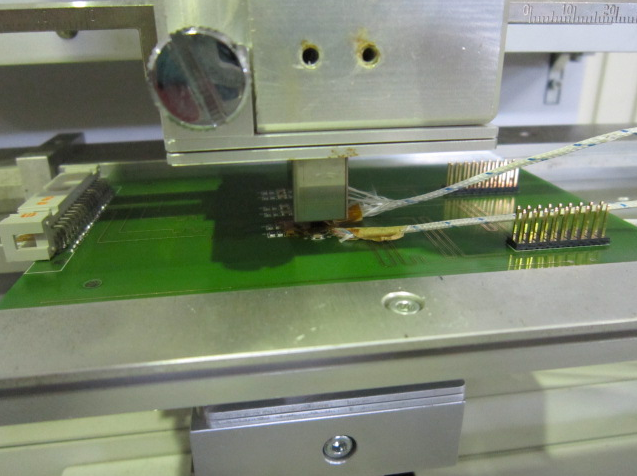

Rework machine

Temperature control

Upper spot heater: 1000W

Bottom spot heater: 1000W

Bottom area heater: 2000W

Control system: Independent PID control

Positioning

Stage: XYZ theta manual operation

Camera: Color CCD camera

Lightning:

Upper: White LED

Bottom: Red LED

Air pressure supply source : 0.5MPa (200L/min and more)

Power supply: 1 Phase, AC200V/220V, 50/60Hz

Electricity consumption: 4kVA

2007 vintage.

ONTEC RM-2500 is a revolutionary pc board assembly and manufacturing equipment that is designed to support all types of high volume communication industry applications, such as in cellular telephone, radio, and data communication systems. It offers high accuracy and reliability combined with excellent ergonomics and ease of use, allowing for improved productivity in the assembly and manufacturing process. At the core of RM-2500 system is its powerful, precision-engineered robotic technology, which allows it to effectively manage the entire assembly process with high accuracy and precision. The unit is designed with an ergonomic user interface, including a simple color LCD display, two-button keypad, or PC via a serial port connection, as well as numerous sensors and environmental control systems, allowing the unit to adjust parameters for optimal performance and efficiency. Additionally, it includes an integrated vision machine and adjustable grip arms, offering superior speed and accuracy when performing delicate operations, such as placing, soldering, and testing multiple components. ONTEC RM-2500 also features an advanced component feeder tool, allowing for up to 20 feeders to be fitted with components to assemble circuit boards with both SMD and THD components. It is capable of handling a wide range of components, from 01005 into large PoP components, with component accuracy to within 0.03mm. The setting-up, parameter adjustment, and storage of all process information is simple, and an automatically generated process report can be printed upon completion. RM-2500 is the ideal manufacturing asset for the pc board assembly process, offering exceptional performance and ease of use at an affordable price. It can process hundreds of components per hour, with up to 3000 components per hour available on multiple units. It is also designed to be energy efficient, with minimal noise, dust, and heat generated during operation. This model is a great choice for large, high-volume production environments.

There are no reviews yet