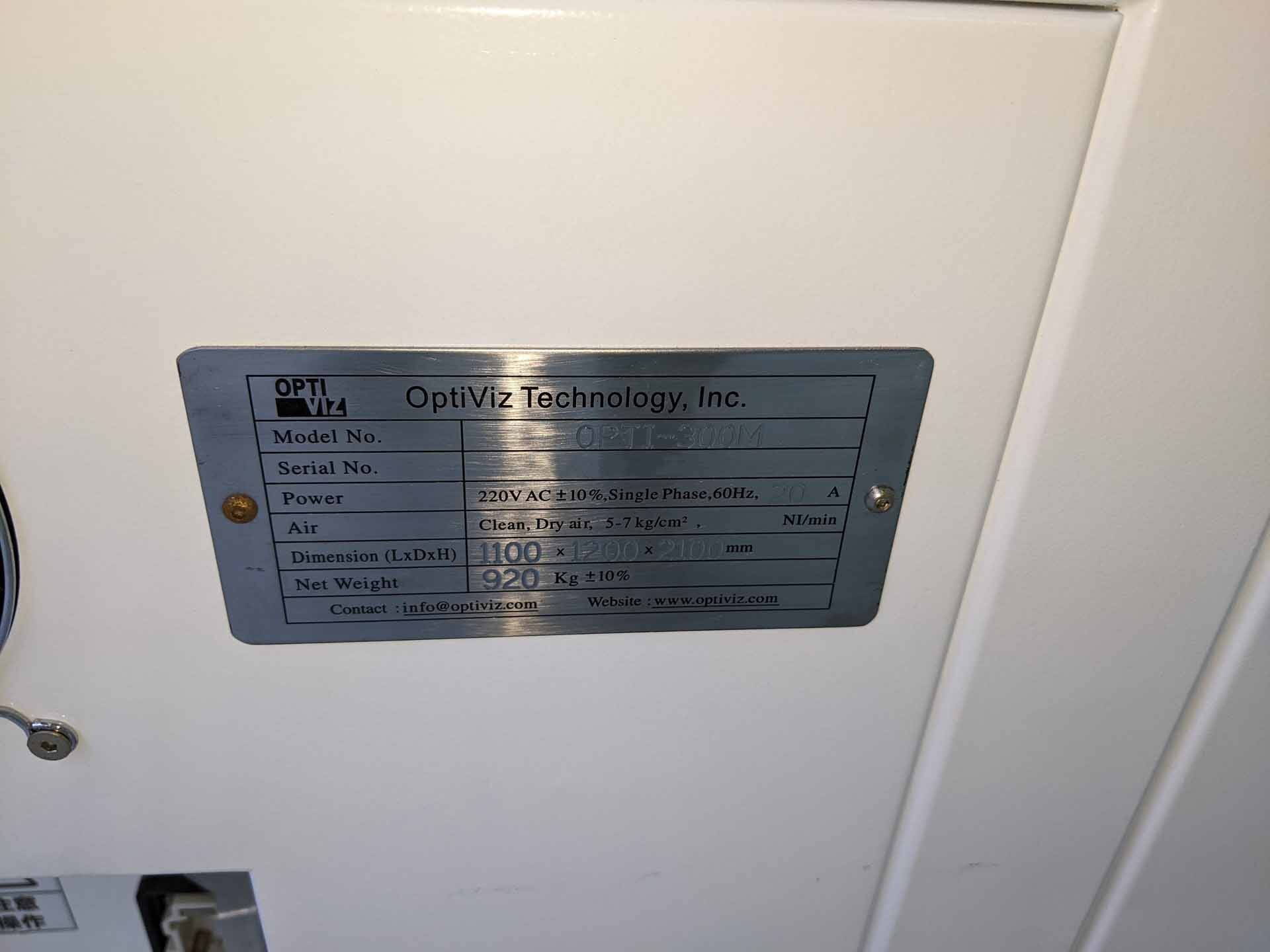

Used OPTIVIZ TECHNOLOGY OPTI-300M #293600763 for sale

URL successfully copied!

Tap to zoom

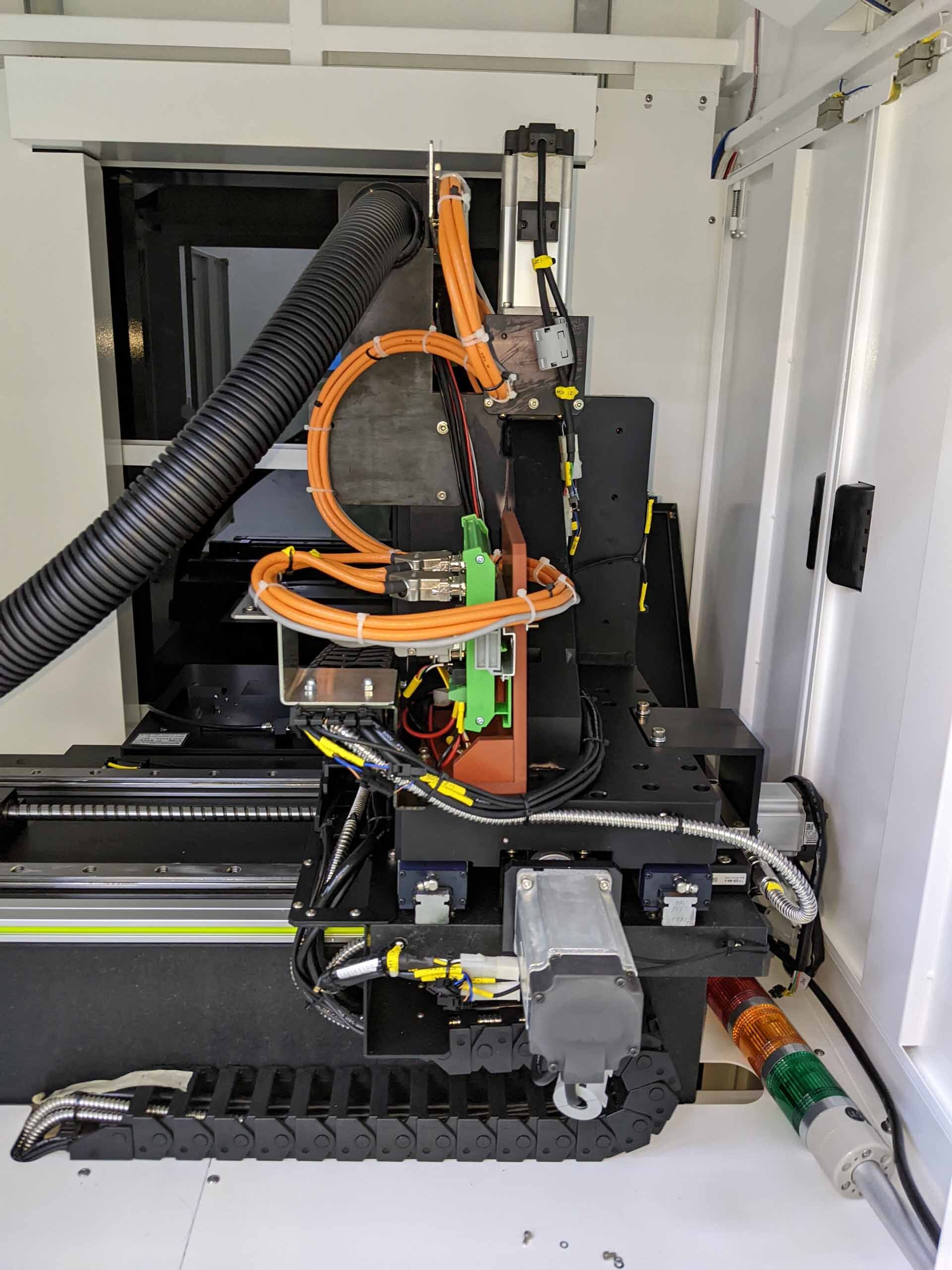

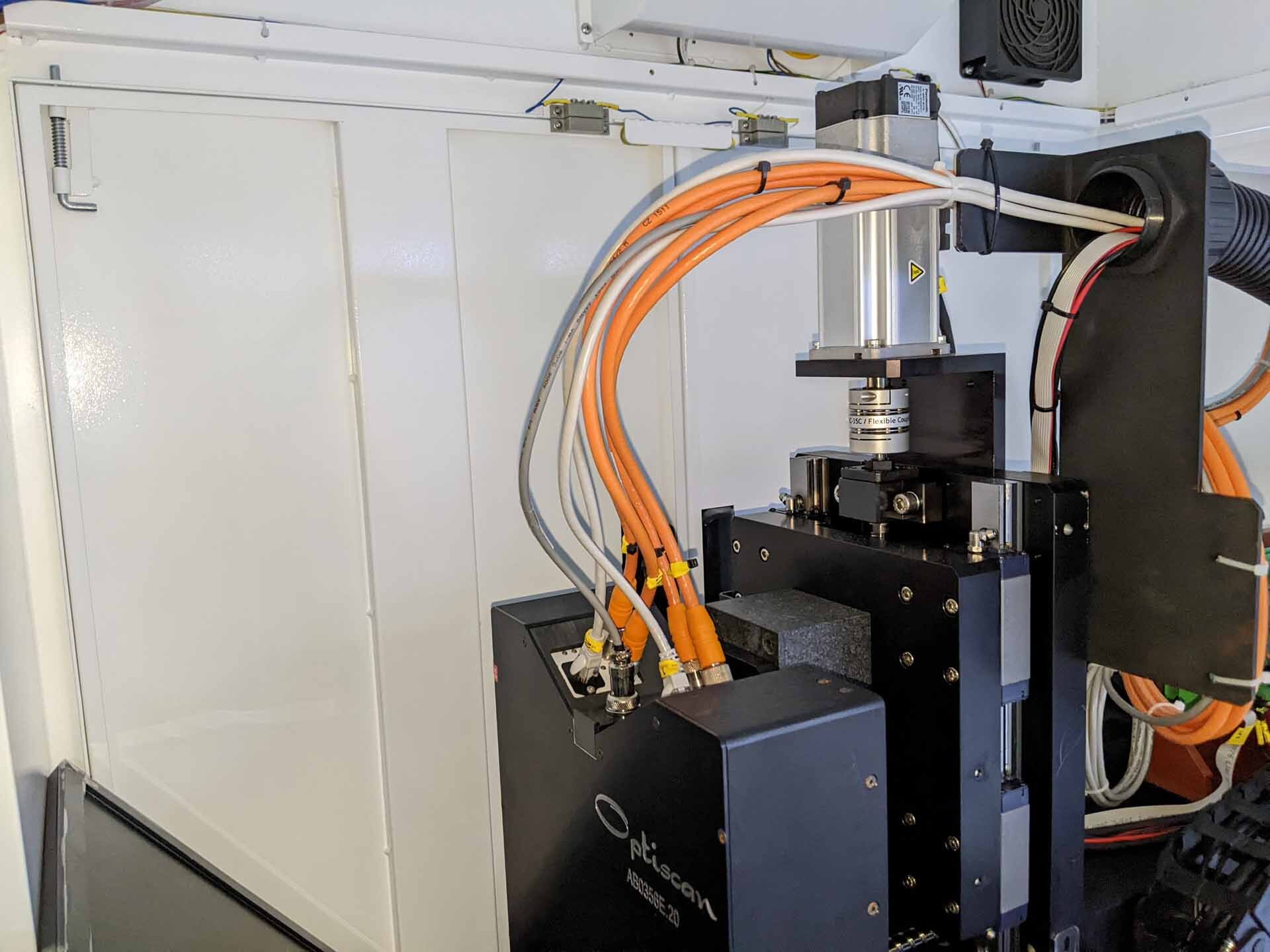

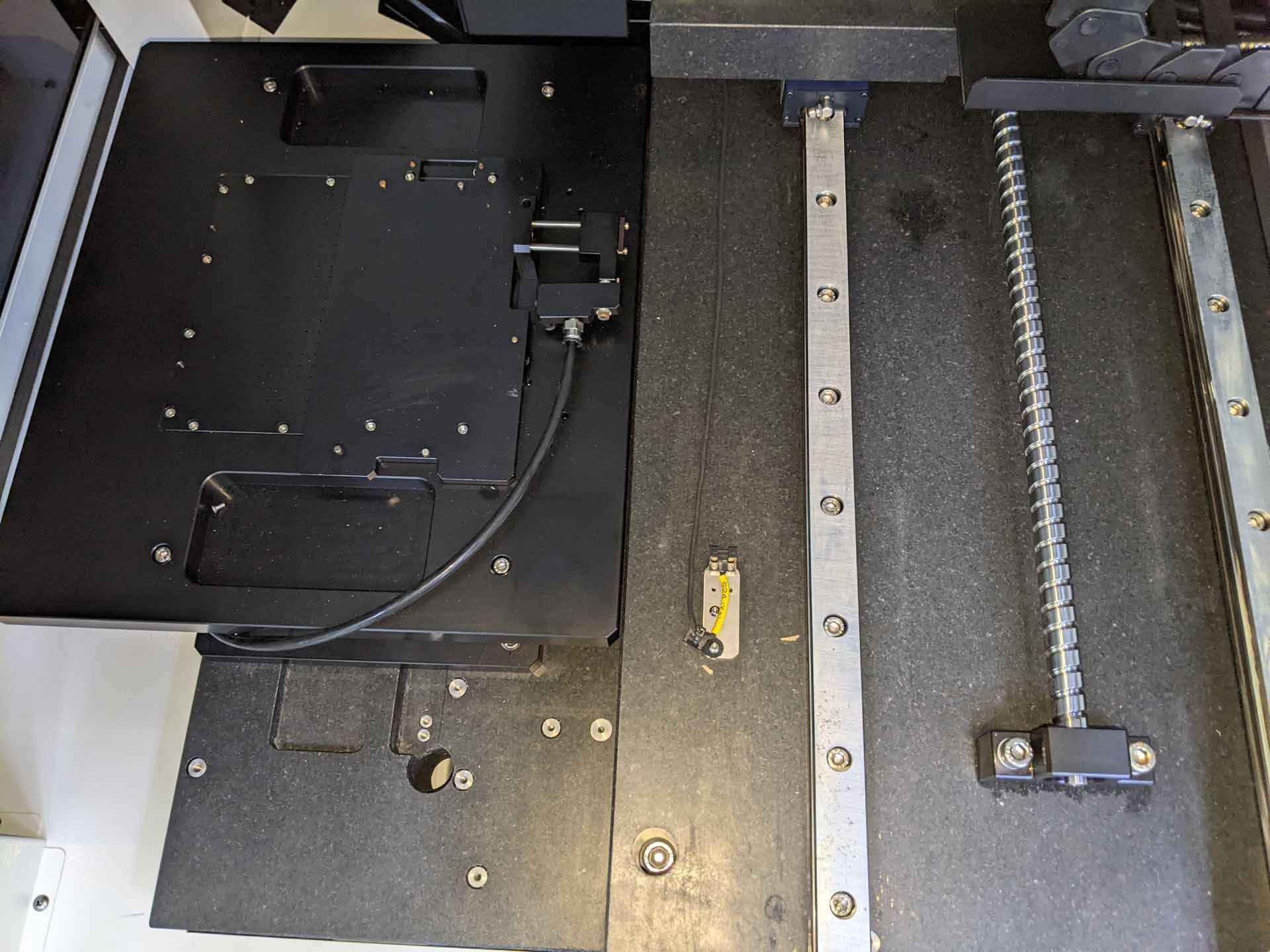

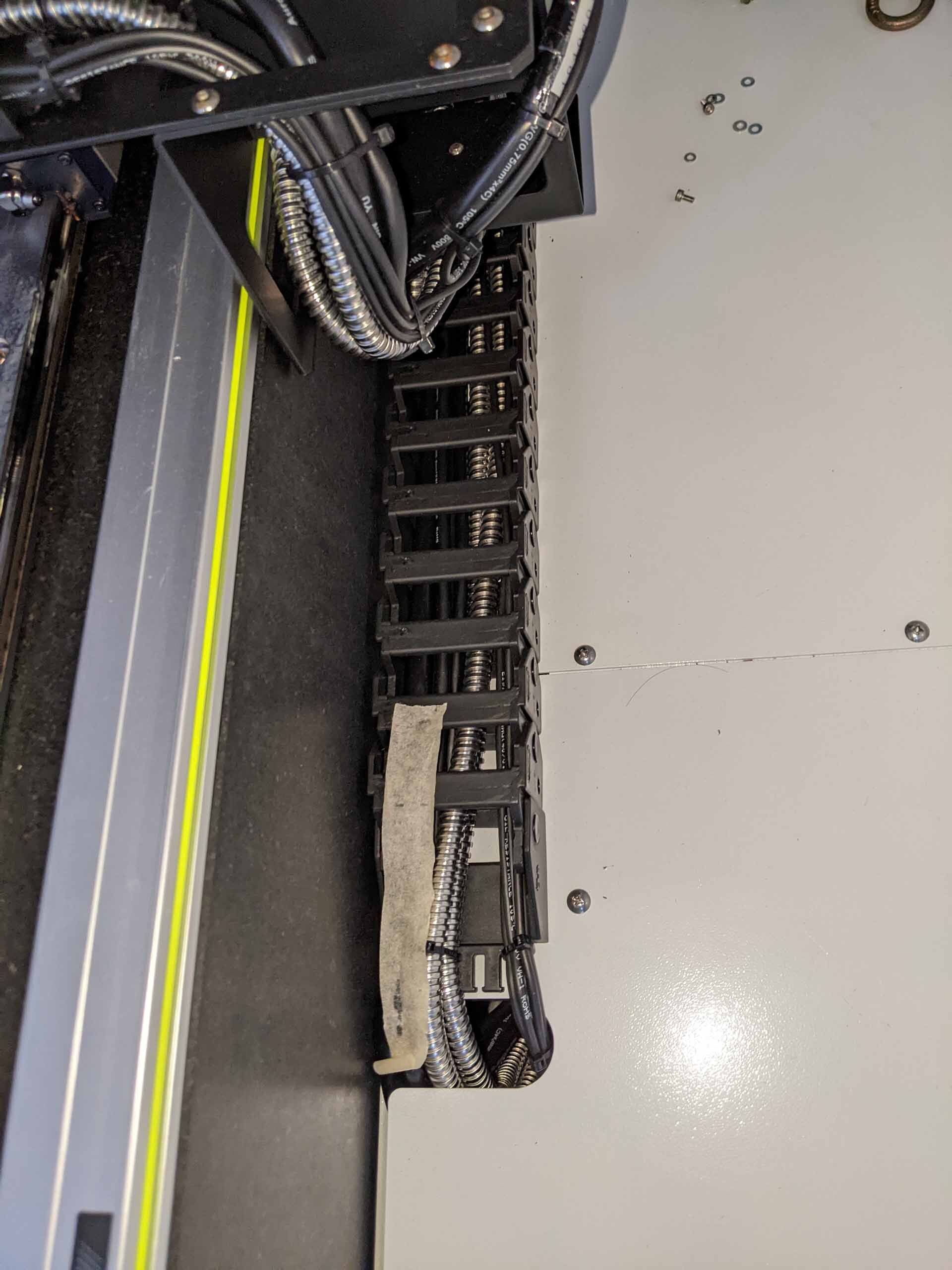

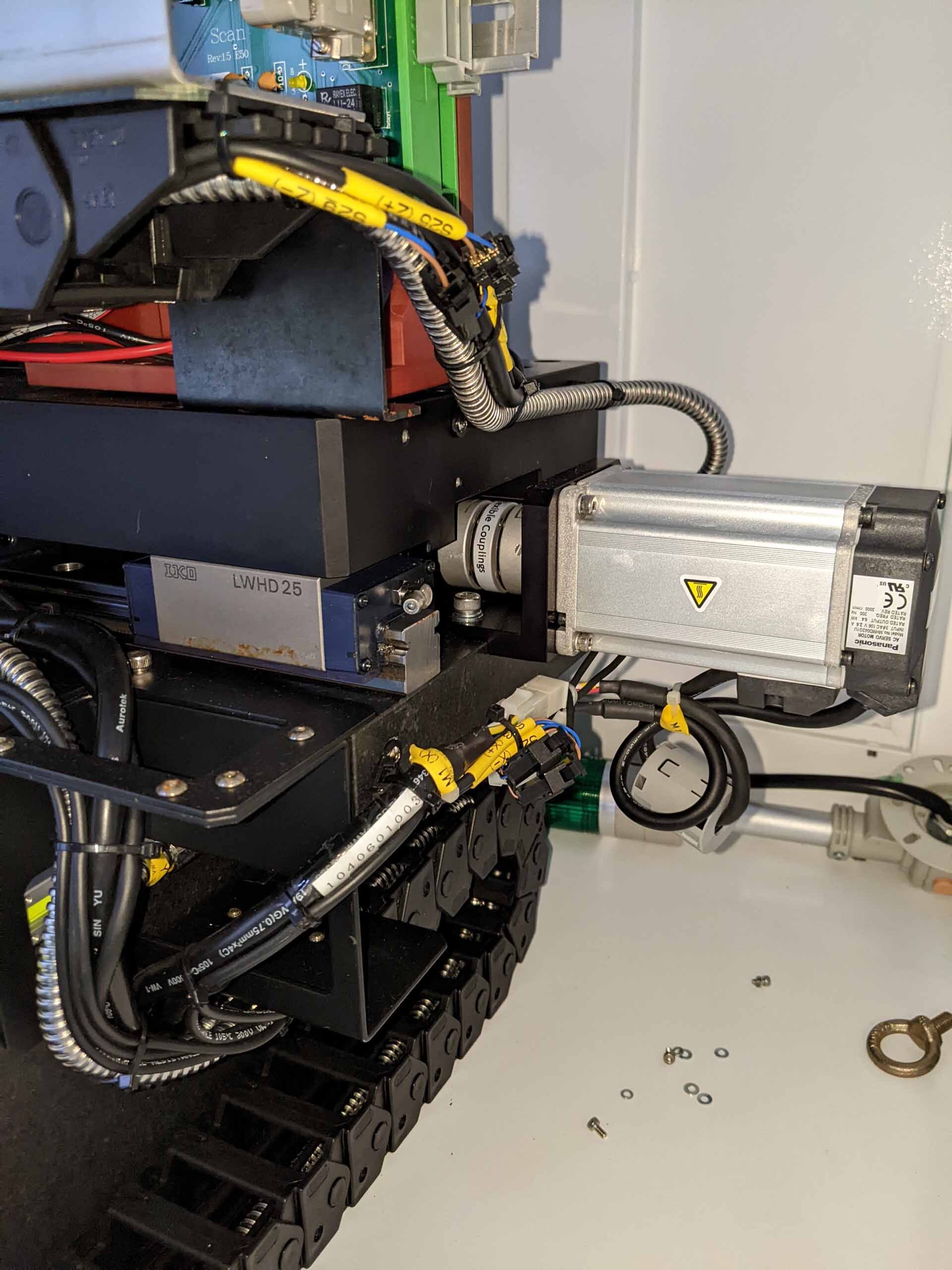

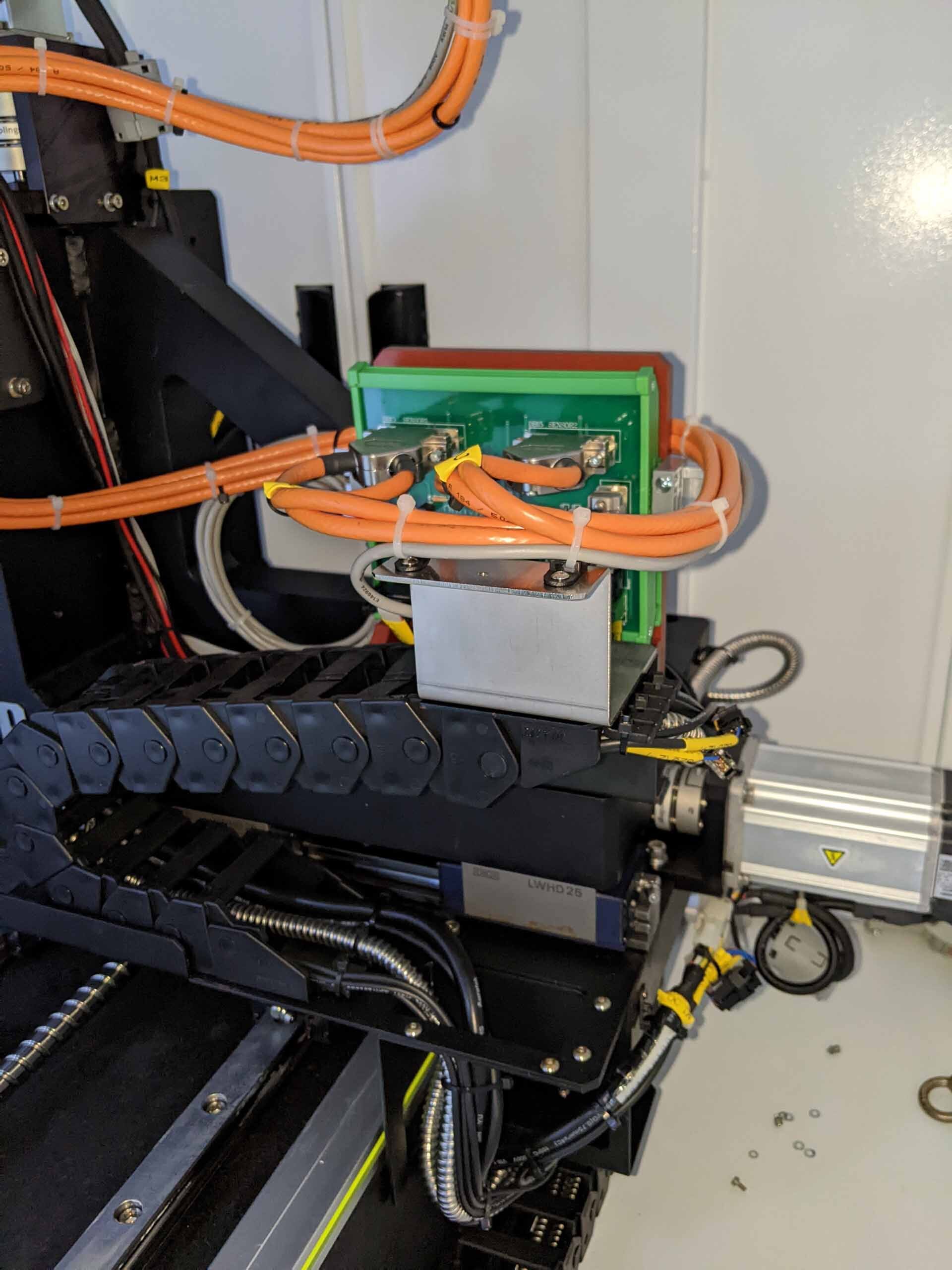

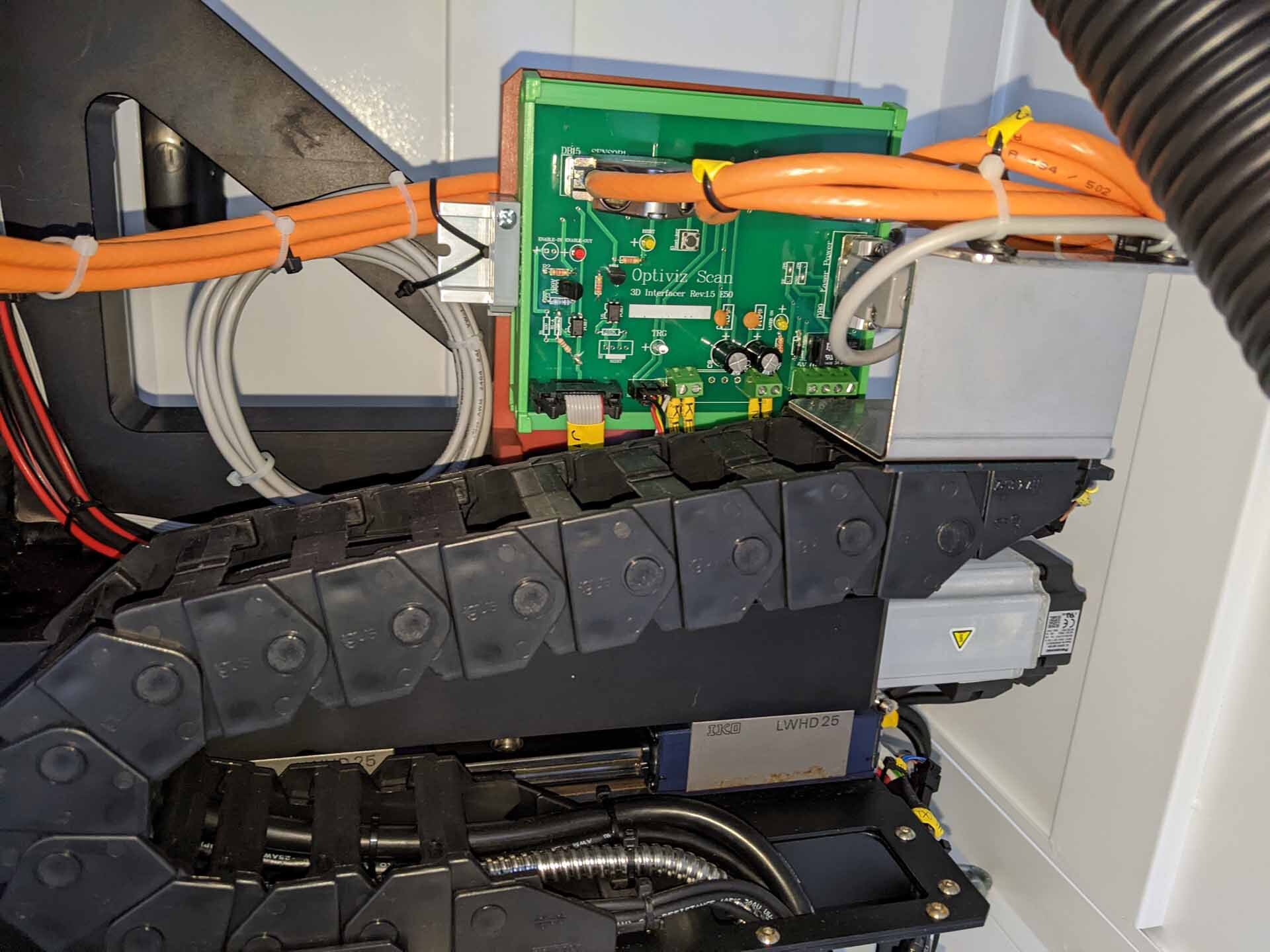

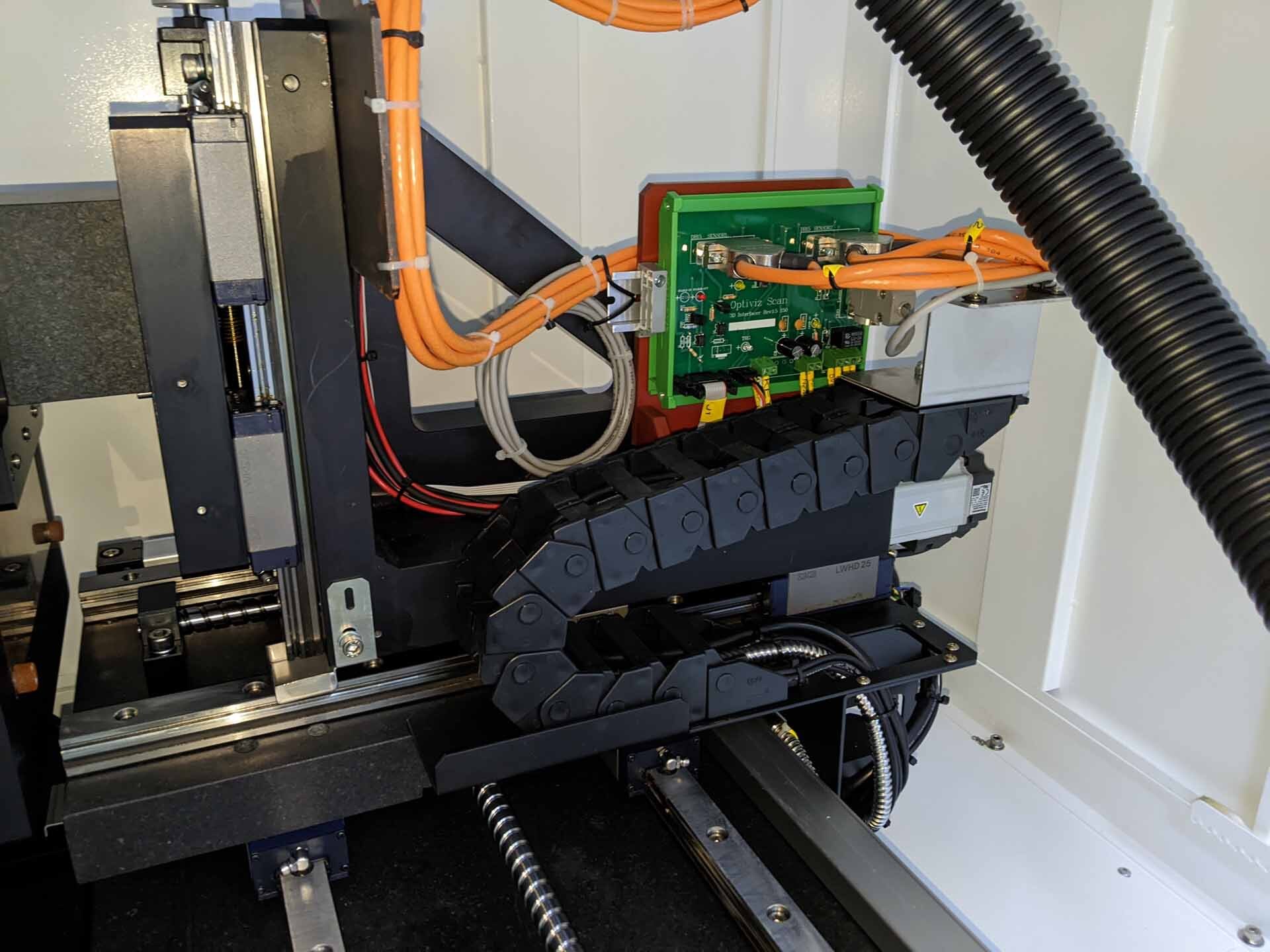

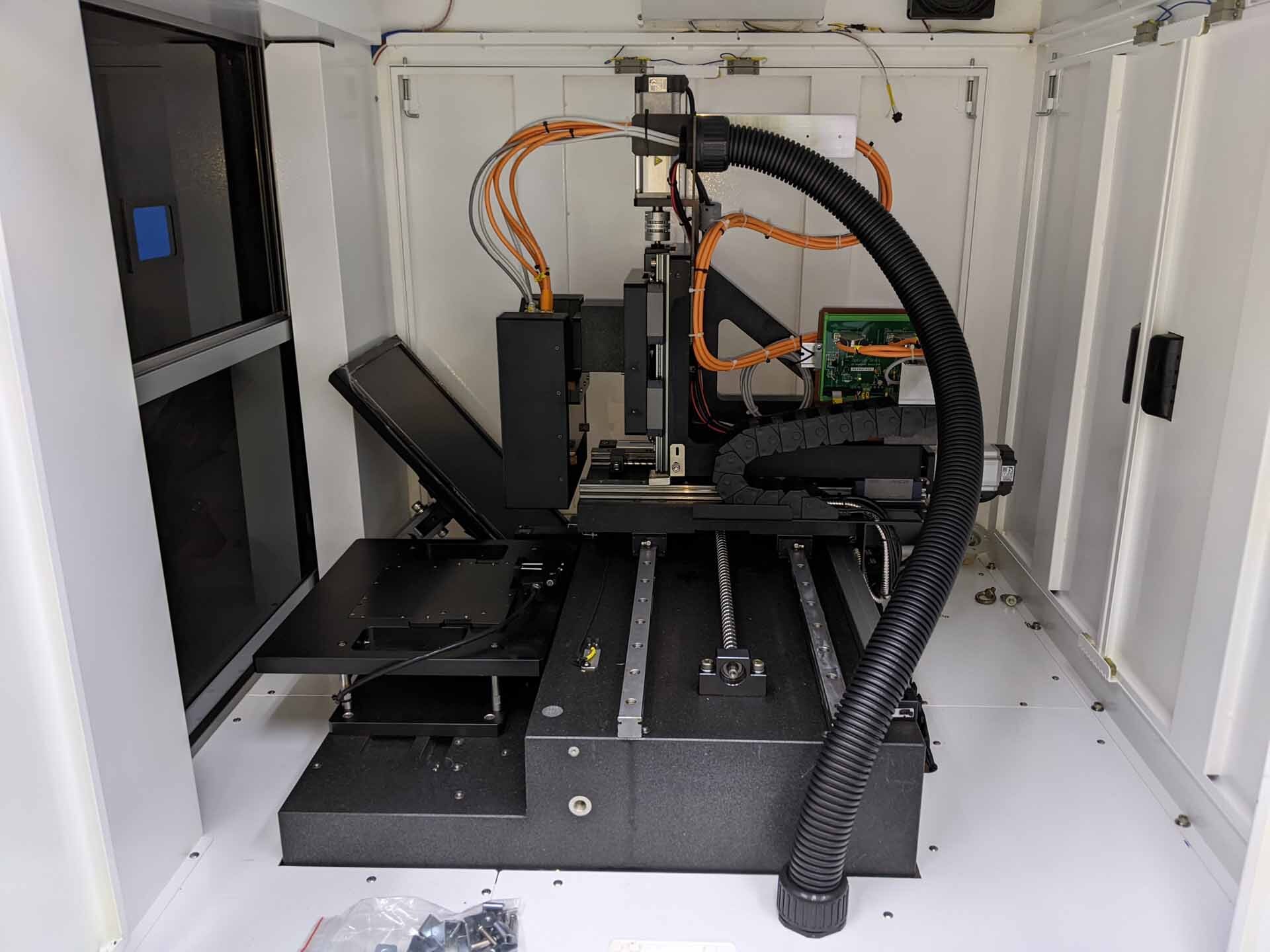

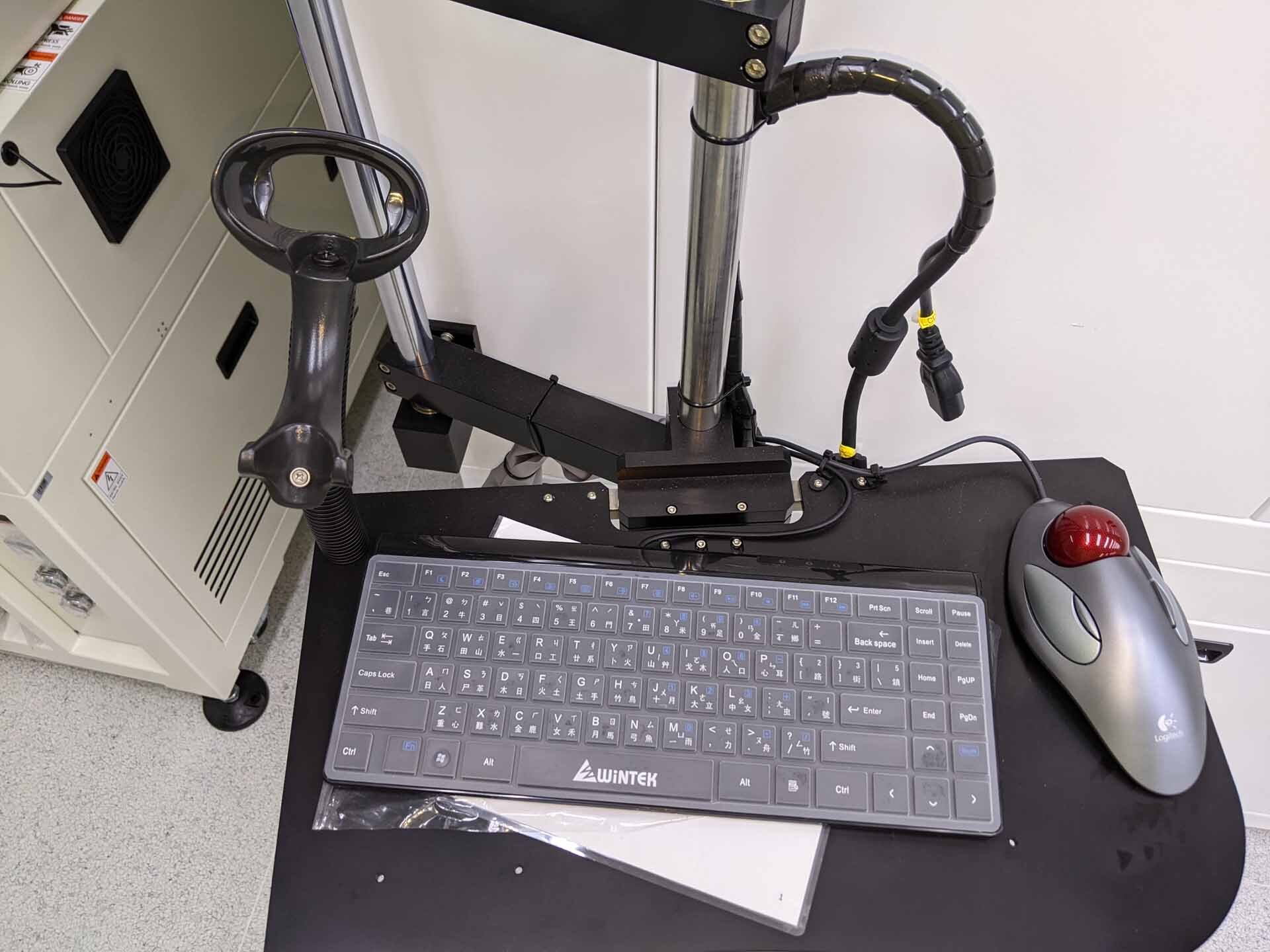

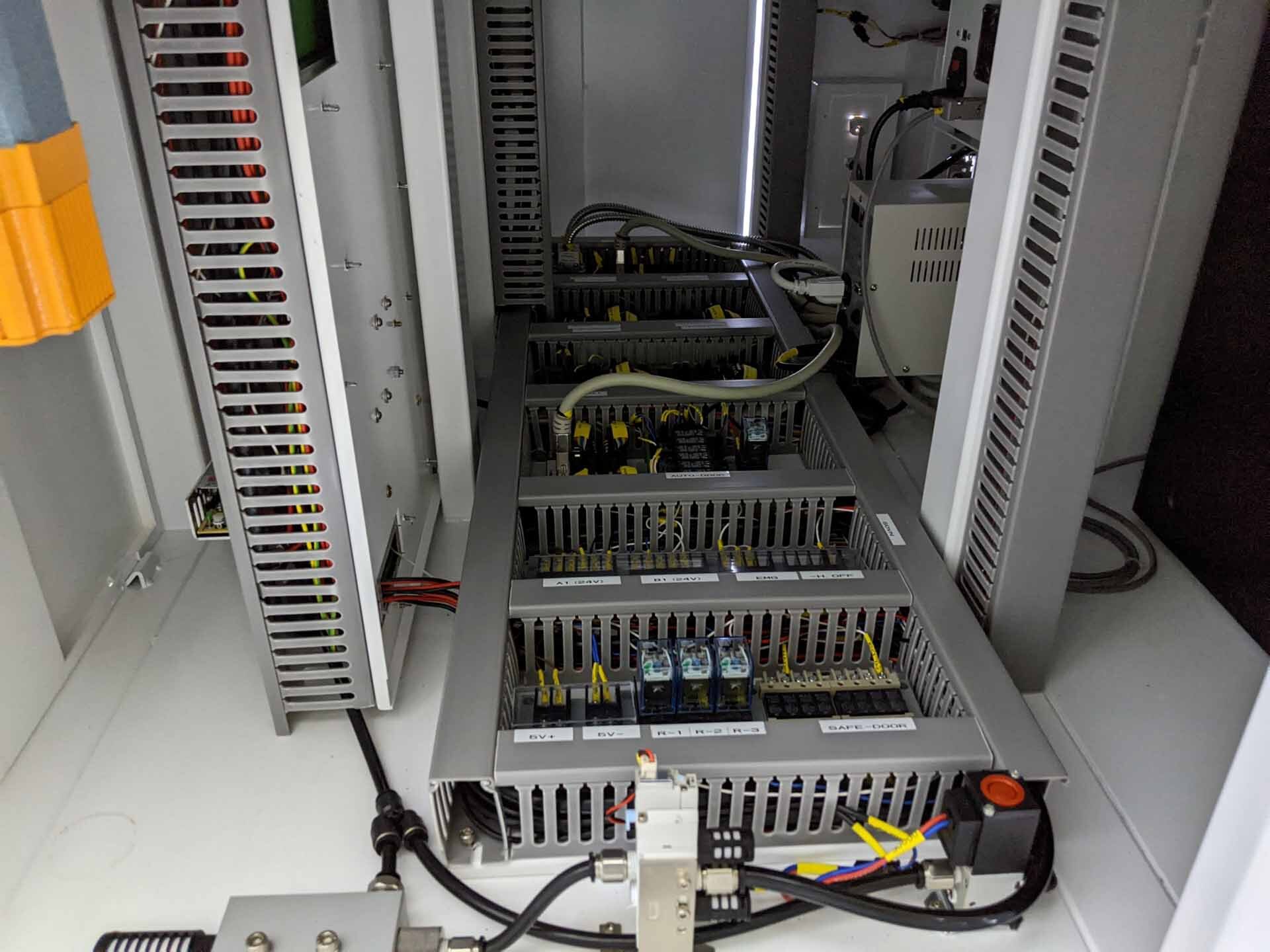

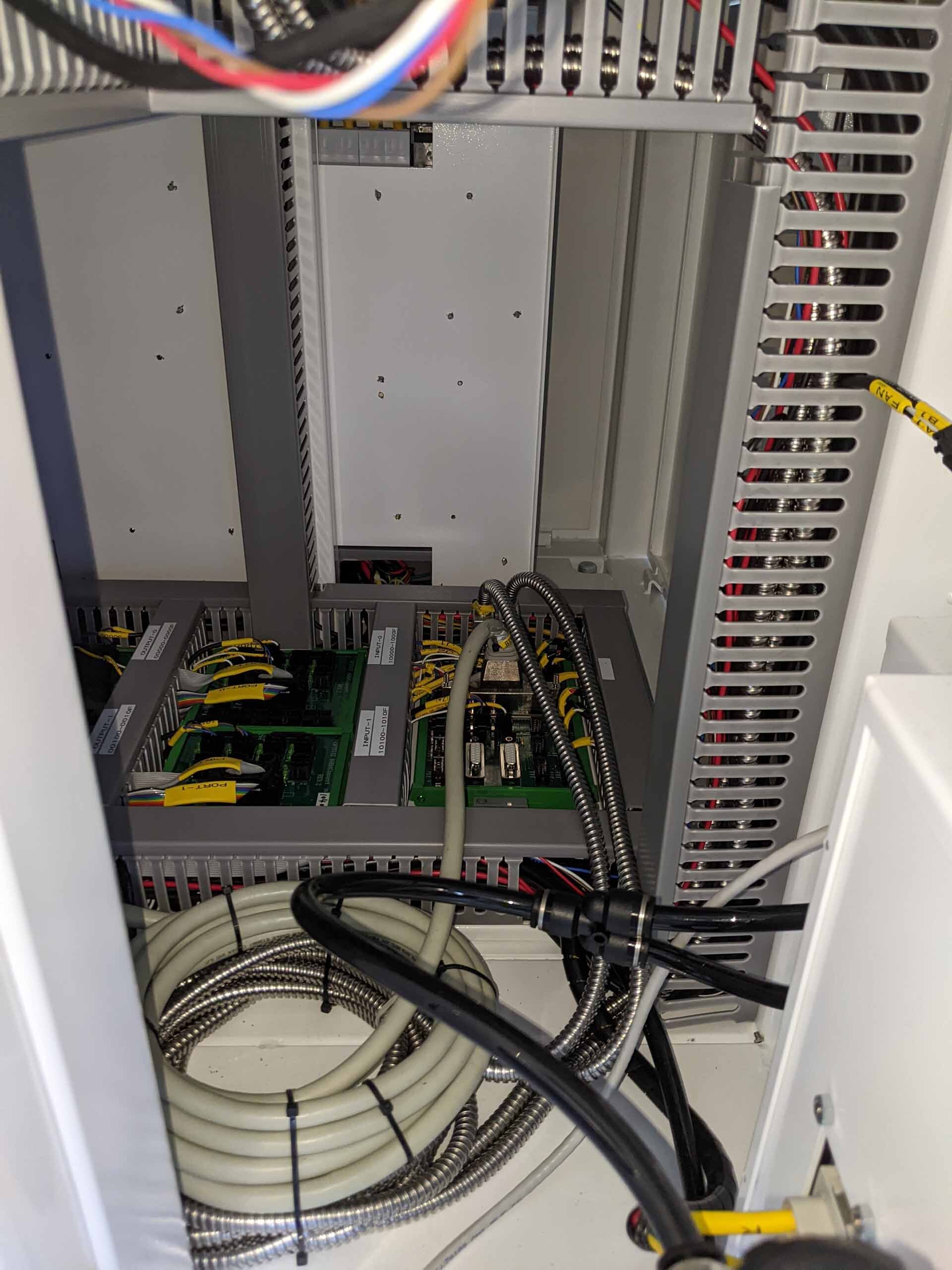

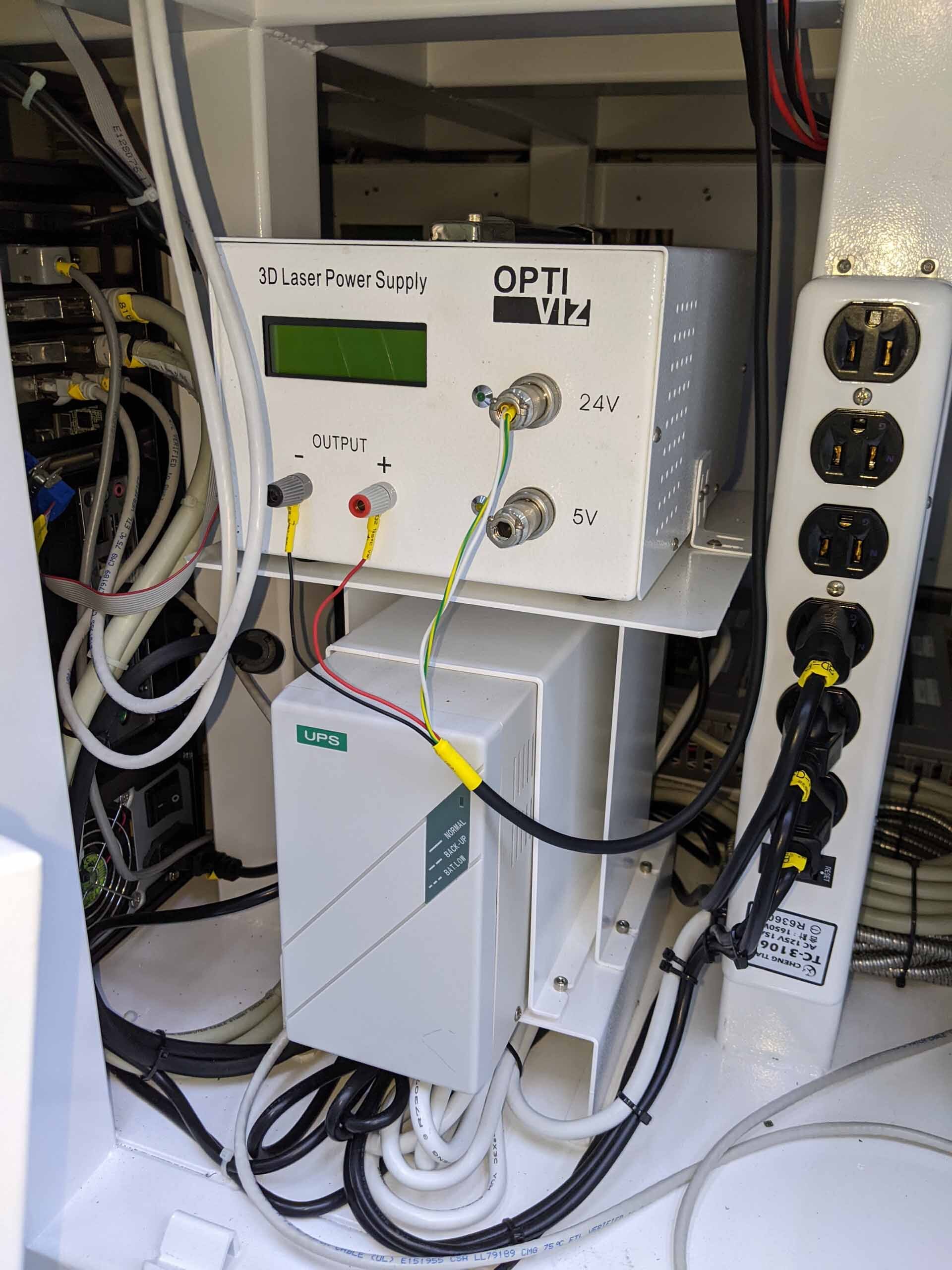

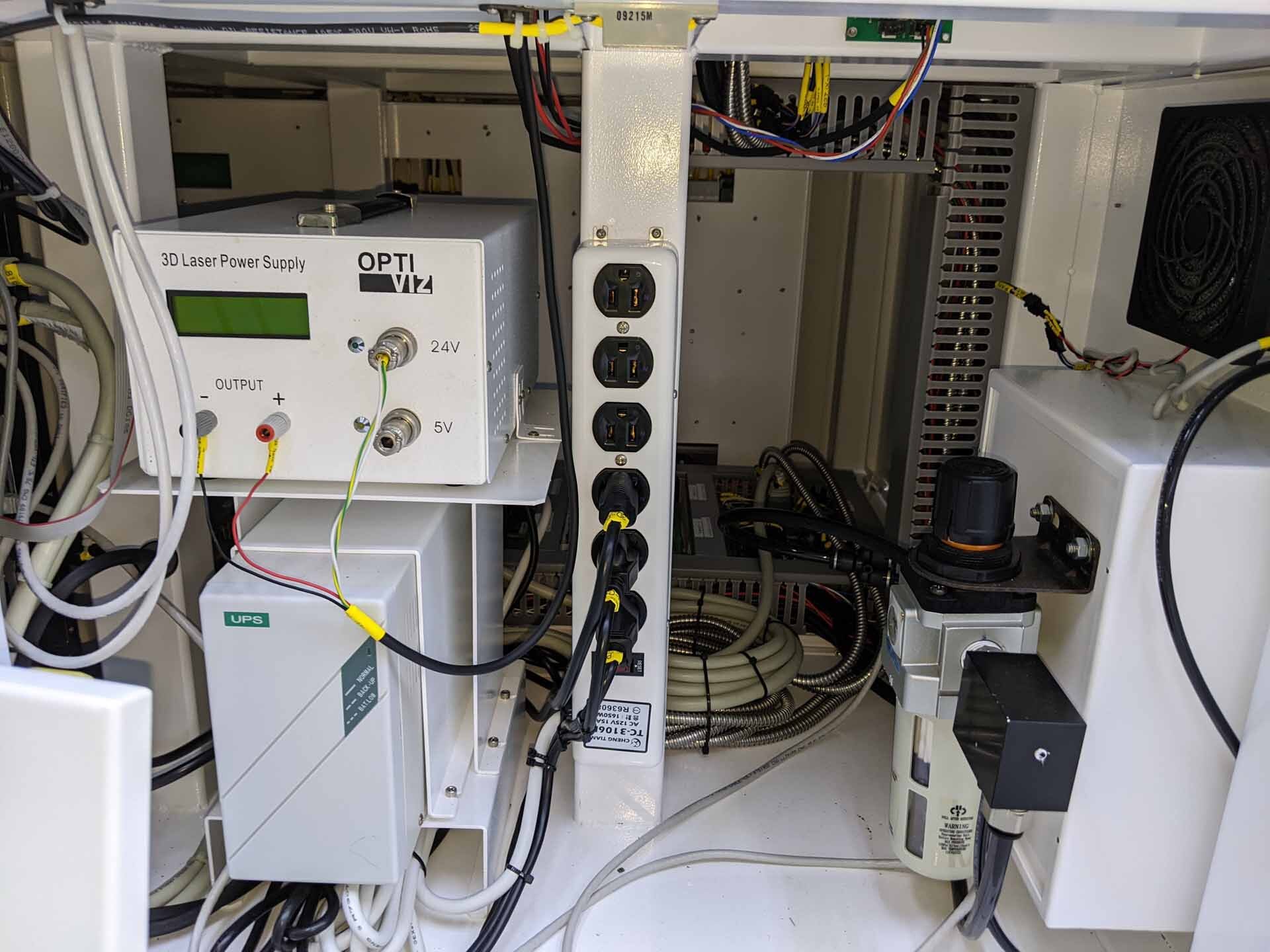

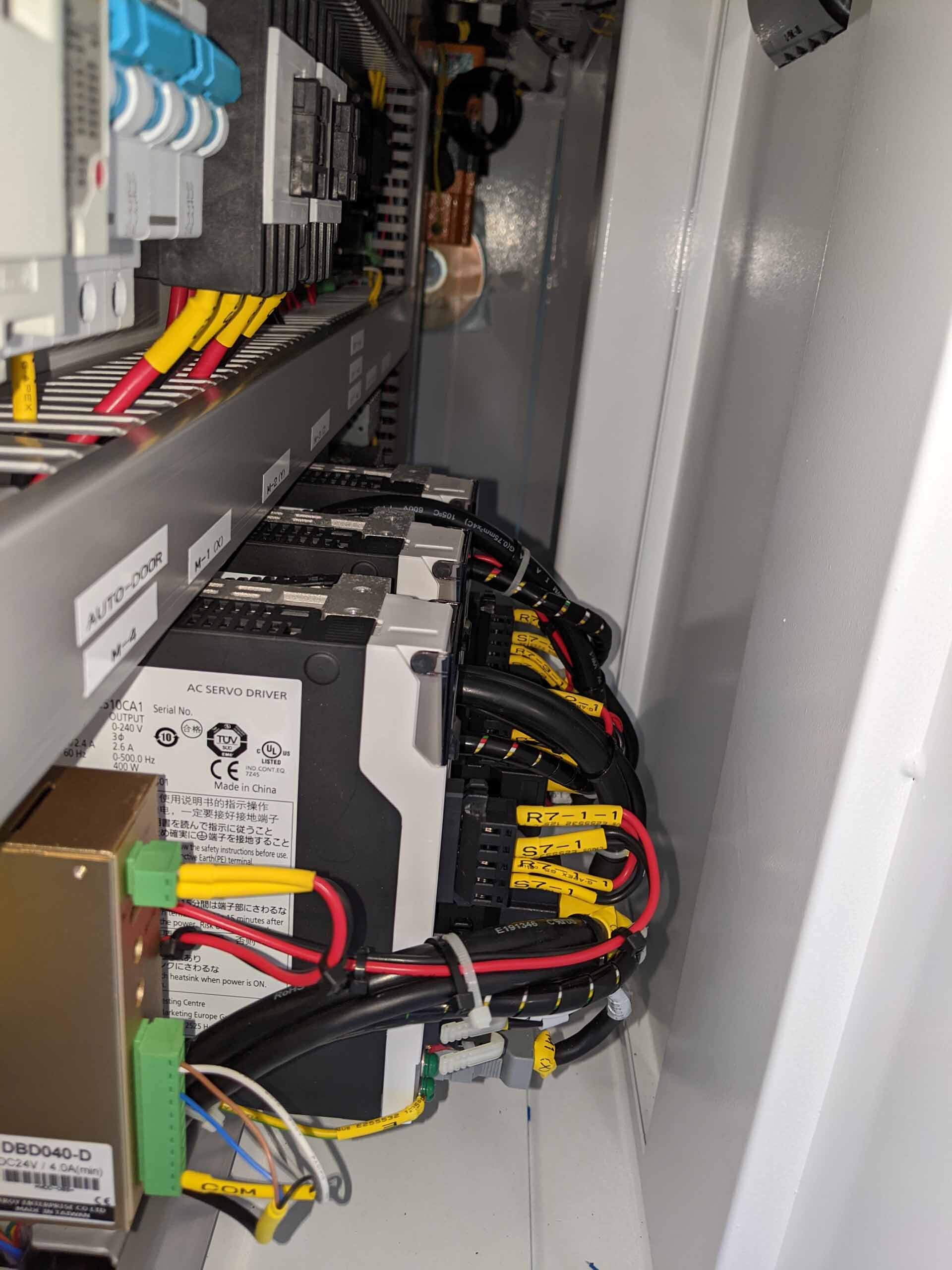

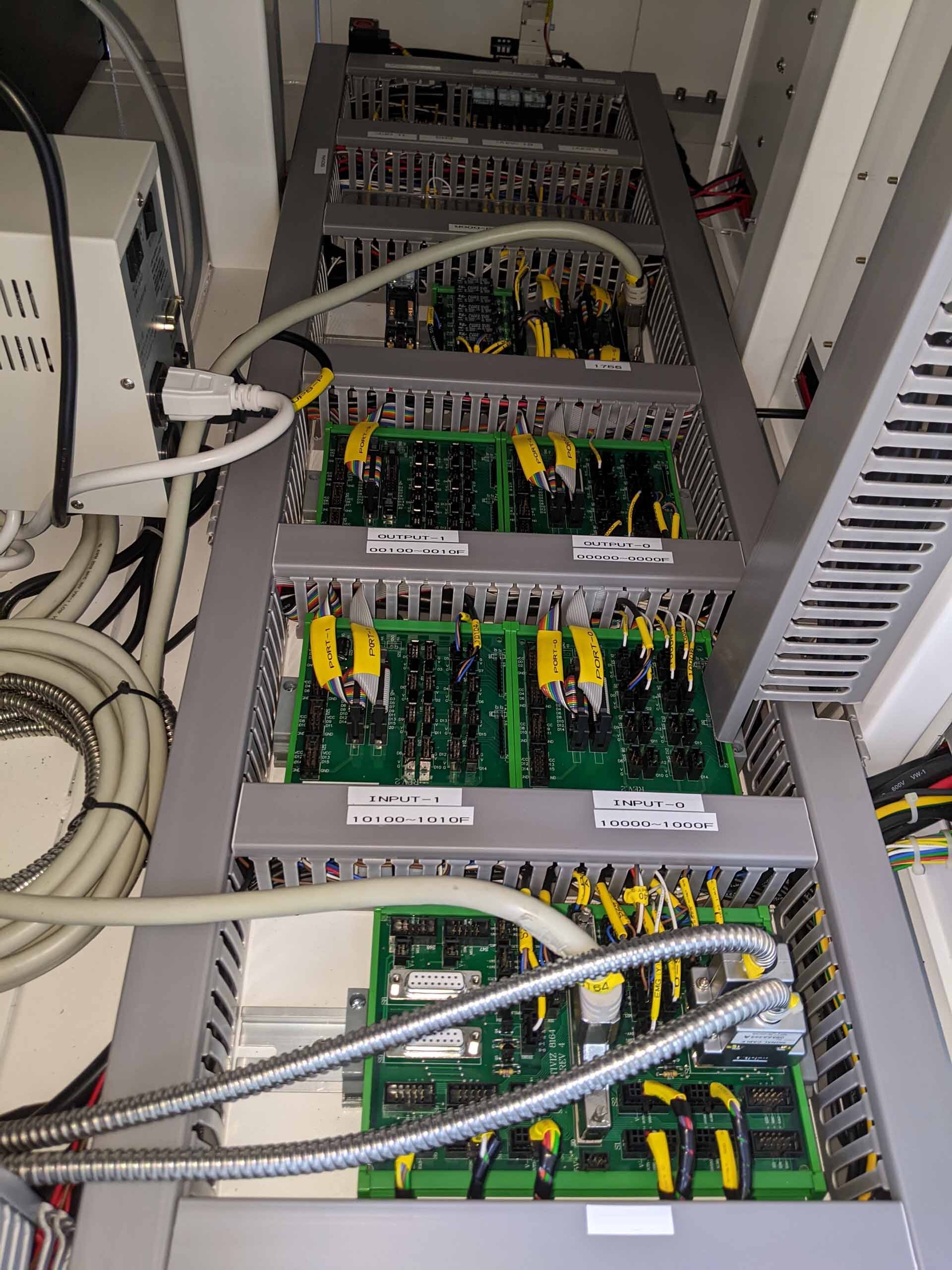

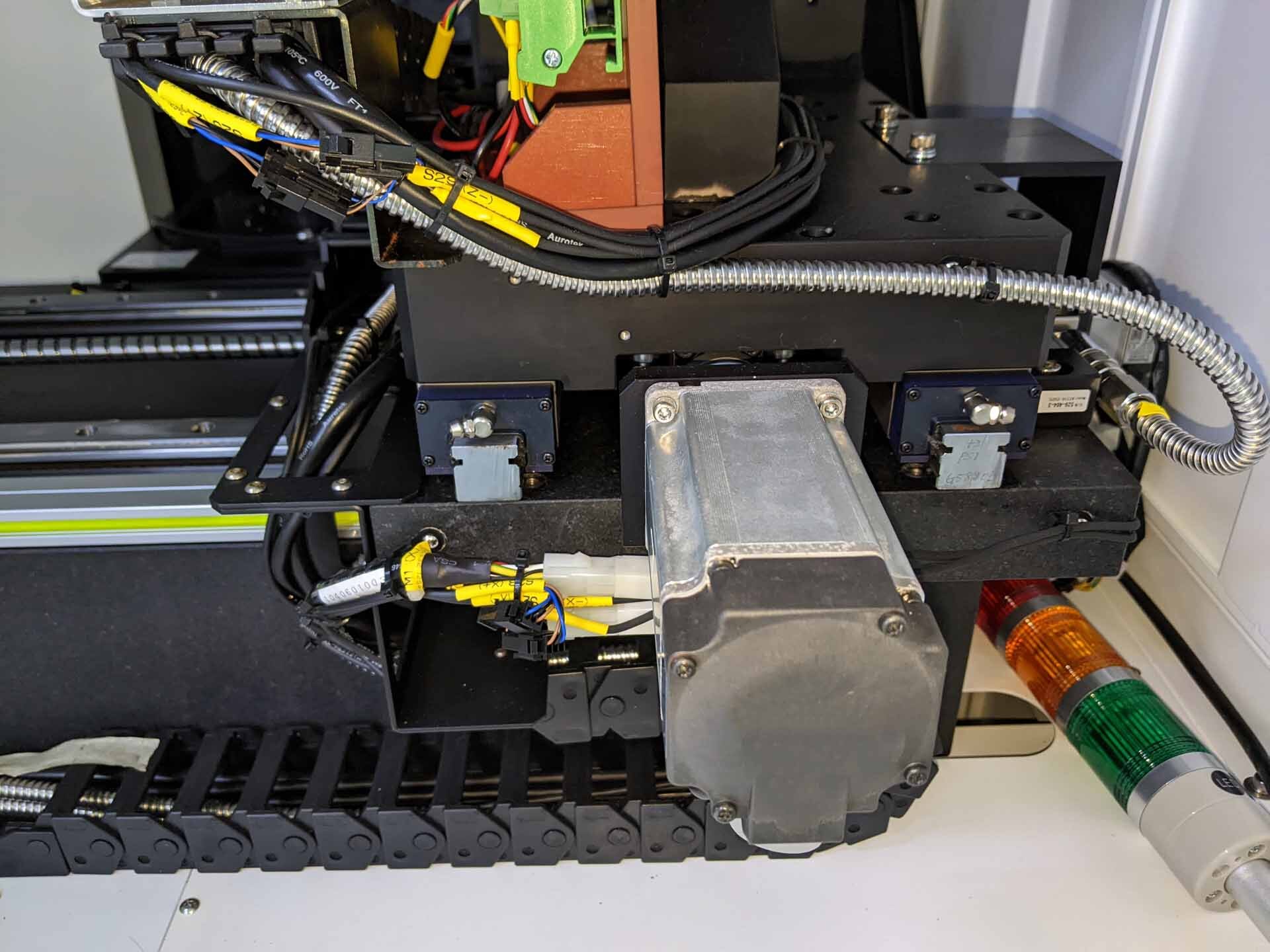

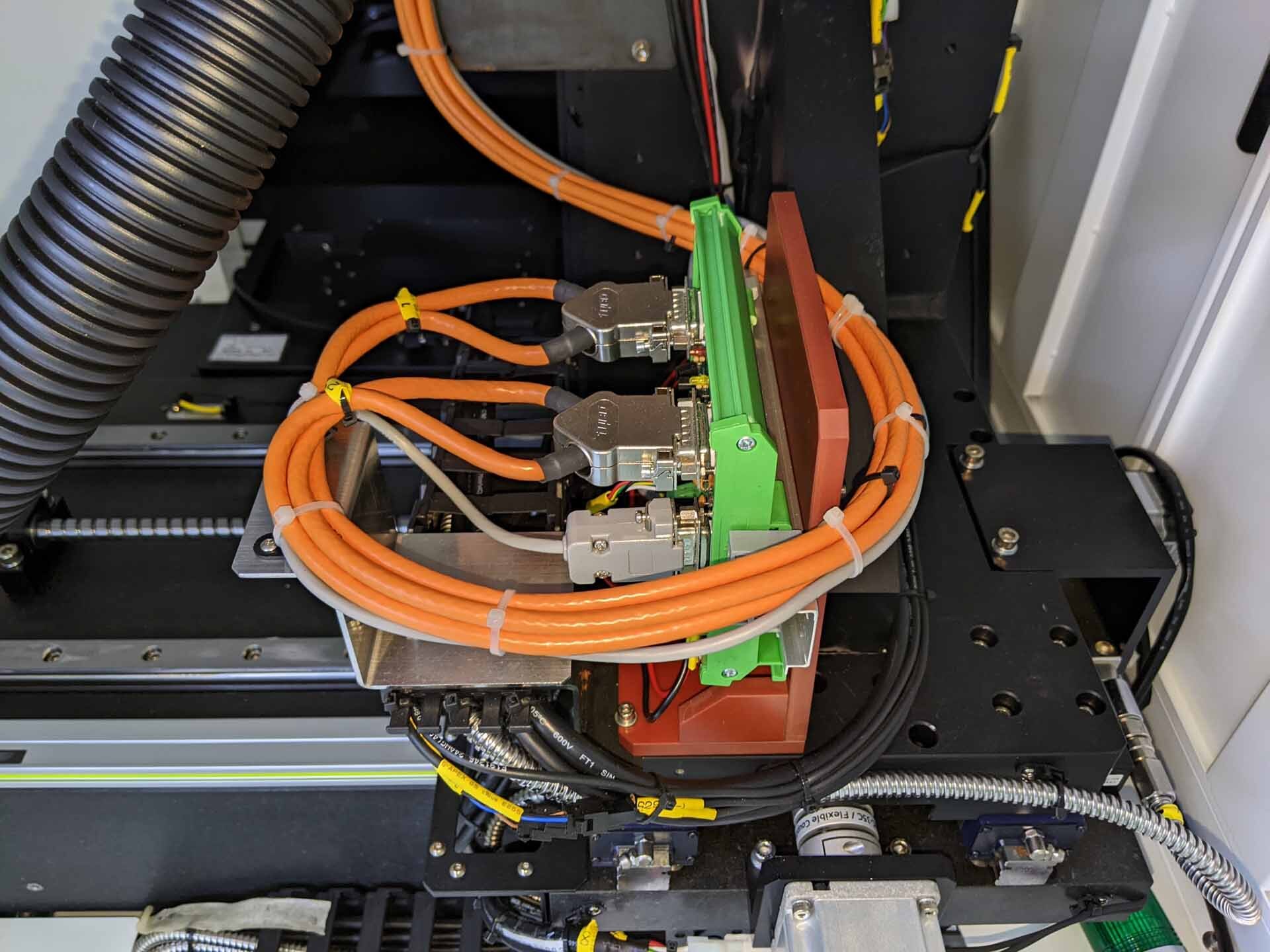

OPTIVIZ TECHNOLOGY OPTI-300M is a fully automated PC board assembly and manufacturing equipment designed for efficient assembly and testing of printed circuit boards (PCBs). OPTI-300M uses an advanced vision-based system to detect errors in the files during pick-and-place operations. It combines the use of high-speed vision and intelligent 3D imaging technology to make sure all components are placed in the right places at the right time. The unit is powered by a multi-step motion control algorithm, which optimizes PC board assembly by smoothing acceleration and deceleration, reducing process time, increasing accuracy, and improving energy efficiency. OPTIVIZ TECHNOLOGY OPTI-300M's advanced computer vision algorithms are able to read and detect components on the board, thus enabling complete accuracy even when components are misaligned. This helps optimize the placement process and reduce wasted placement time. The machine is also equipped with an advanced WIP control tool. This feature is used to track the progress of each stage of the assembly and manufacturing process, from feeders to final delivery. It also allows users to monitor real-time performance from each machine and set up automatic notifications for alerts. OPTI-300M is designed for maximum efficiency. It is equipped with optical vision systems and robotic arms for pick-and-place operations. The robot arms are able to pick components from trays and insert them into the correct positions on the board. This eliminates the need for manual intervention, providing a faster and more efficient assembly process. OPTIVIZ TECHNOLOGY OPTI-300M also comes with the latest version of automatic optical inspection (AOI) software. This feature is capable of identifying defects, broken leads, misalignments, and missing components. AOI can also detect variations in board layer thickness, ensuring quality control. Overall, OPTI-300M is an advanced PC board assembly and manufacturing asset that optimizes the production process while reducing risk, errors, and downtime. It uses the latest advances in vision and robotic technology to streamline PC board assembly and manufacturing, enabling users to create high-quality PCBs with minimal manual intervention.

There are no reviews yet