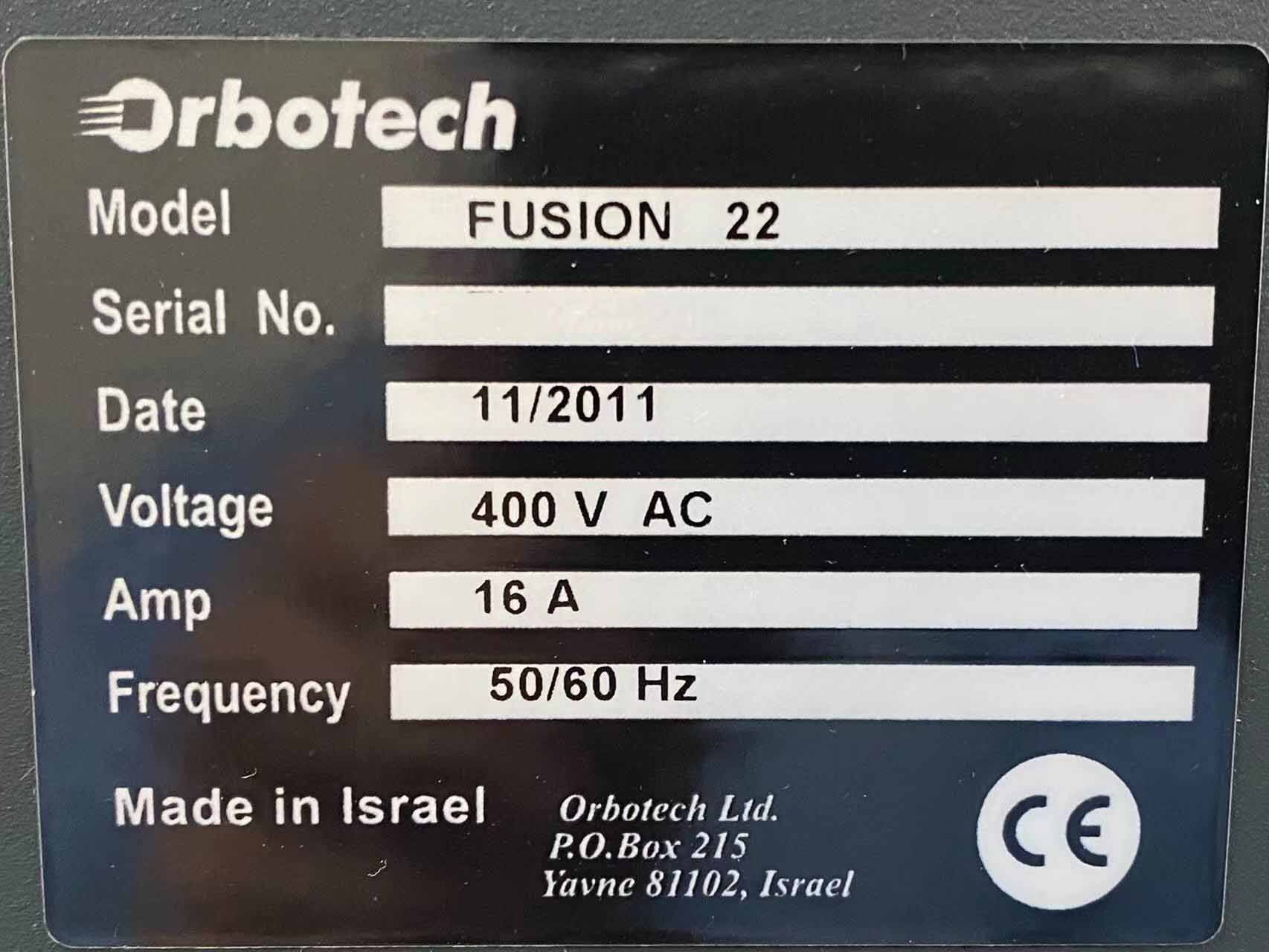

Used ORBOTECH Fusion 22 #293615645 for sale

URL successfully copied!

Tap to zoom

ORBOTECH Fusion 22 PC board assembly and manufacturing equipment is a powerful tool for assembling, printing and assembling printed circuit boards (PCB). It is an efficient and cost-effective 3-in-1 production system. Fusion 22 is made up of three individual systems - an automated optical inspection (AOI) machine, a printer and an assembler. The AOI machine is capable of detecting manufacturing defects such as missing components, misaligned components, and solder defects. It also ensures that there is adequate ink coverage across the printed circuit board. The AOI machine uses the latest in optical imaging technology and has been developed to inspect parts with the highest accuracy levels. The printer that is included in ORBOTECH Fusion 22 allows for precise application of a range of solders, printing colors and fluids. The printing process is automated, meaning it can be monitored quickly and closely. The printer also uses the latest laser imaging technology to ensure precise application and quality standards. The third unit found in Fusion 22 is an assembler. This assembler has a high-speed robotic arm to accurately place each piece of the printed circuit board in the correct location. It can also be used to connect components that require fine placement. Both the printer and assembler work in tandem with the AOI machine, so a complete production cycle of the PCB can be completed in the shortest possible time. ORBOTECH Fusion 22 is a comprehensive yet highly efficient tool for PCB assembly and manufacturing. Its AOI machine allows for precise detection and detection of manufacturing defects and its printer and assembler allow for precise application of solders and colors and fine placement of components. All of these systems come together to provide a powerful and cost-effective solution for producing high-quality PCBs.

There are no reviews yet