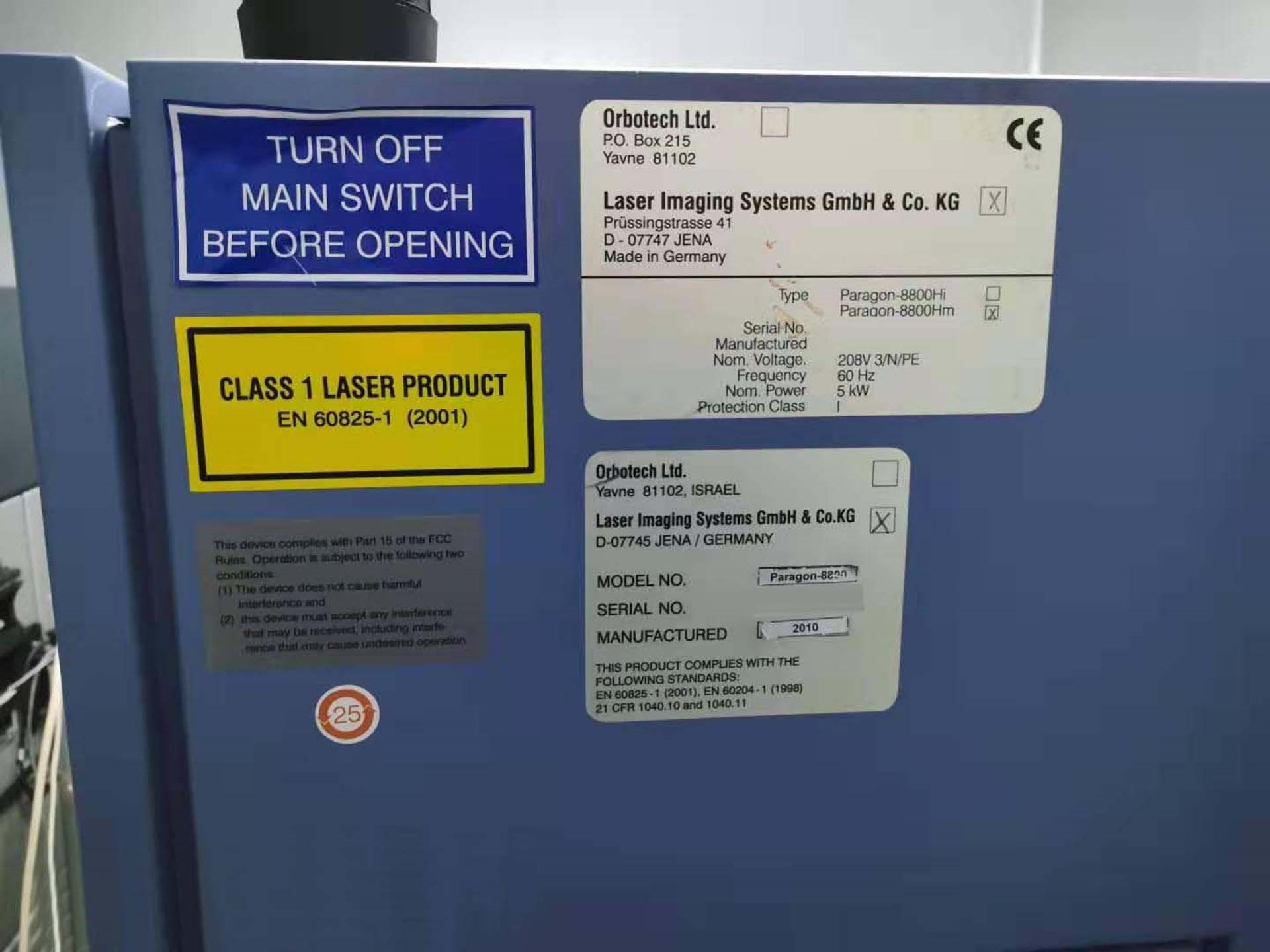

Used ORBOTECH Paragon 8800 #9265503 for sale

URL successfully copied!

Tap to zoom

ORBOTECH Paragon 8800 is a modern, high-performance, precision machine for the automated assembly and manufacturing of printed circuit boards (PCBs). It is designed to handle a wide range of complex substrate components, and offers sophisticated quality control features such as advanced vision systems and high-accuracy fiducial alignment. The machine is capable of providing production rates of up to 8800 Printed Circuit Boards per hour (PCB/h), with the ability to handle up to 80 feeders for the fastest throughput. The ORBO Paragon 8800 is no ordinary pick-and-place machine. Its powerful feeder capabilities leverage a unique dual-tool head, which allows two out of the four available heads to be utilized simultaneously. This patented feature helps to ensure rapid board throughput. Additionally, the machine is equipped with a wide array of tools for the accurate placement of components, including high-accuracy vision systems for component placement accuracy, as well as flexible gantry systems to accommodate a variety of PCB sizes and shapes. Together, these advanced features provide users with unprecedented levels of accuracy and throughput. ORBOTECH Paragon 8800 also offers comprehensive quality control, offering recordable, inspectable and traceable statistics for all of its activities. High-resolution cameras are used to detect and record any component misalignment along with a unique fiducial/vision pattern recognition system that minimizes time and improves production accuracy. Additionally, the machine's ability to produce detailed defect data allows users to quickly analyze any unexpected board behavior and improve yields. With its high-precision micro-mechanism, Paragon 8800 is a superior system for efficient PCB manufacturing. It is designed to handle a wide variety of complex components, and its advanced control systems provide users with uncompromising accuracy and throughput. By incorporating sophisticated feeder capabilities, integrated vision systems, and comprehensive quality control, the machine simplifies PCB production and ensures quality results in industry-leading time.

There are no reviews yet