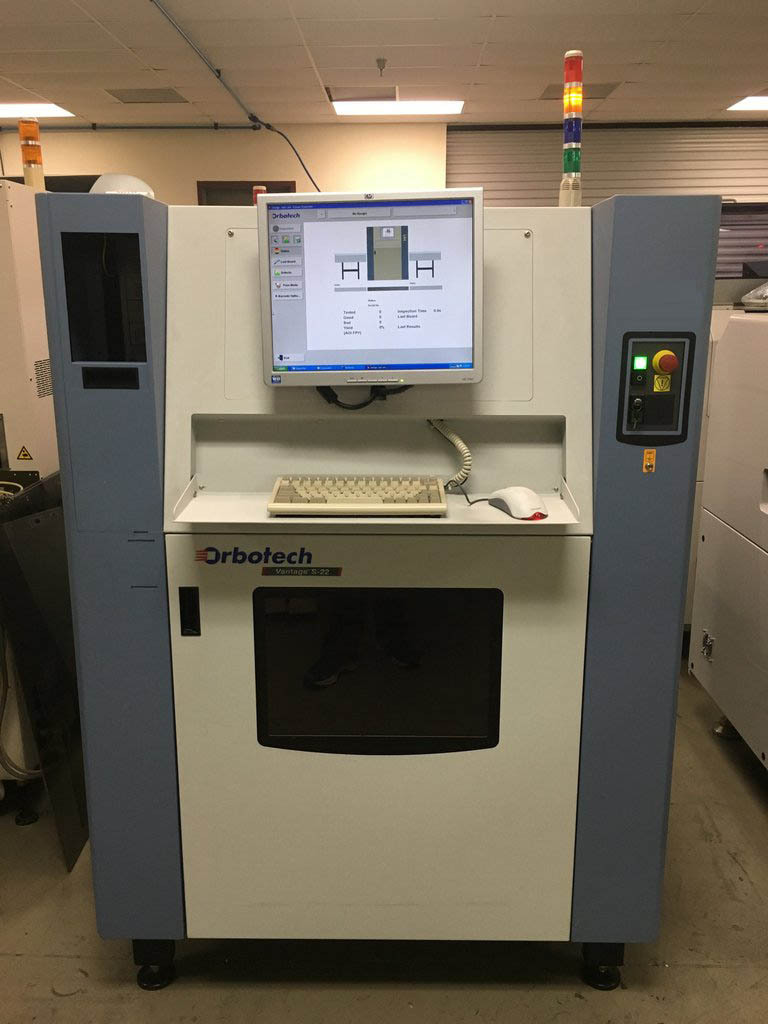

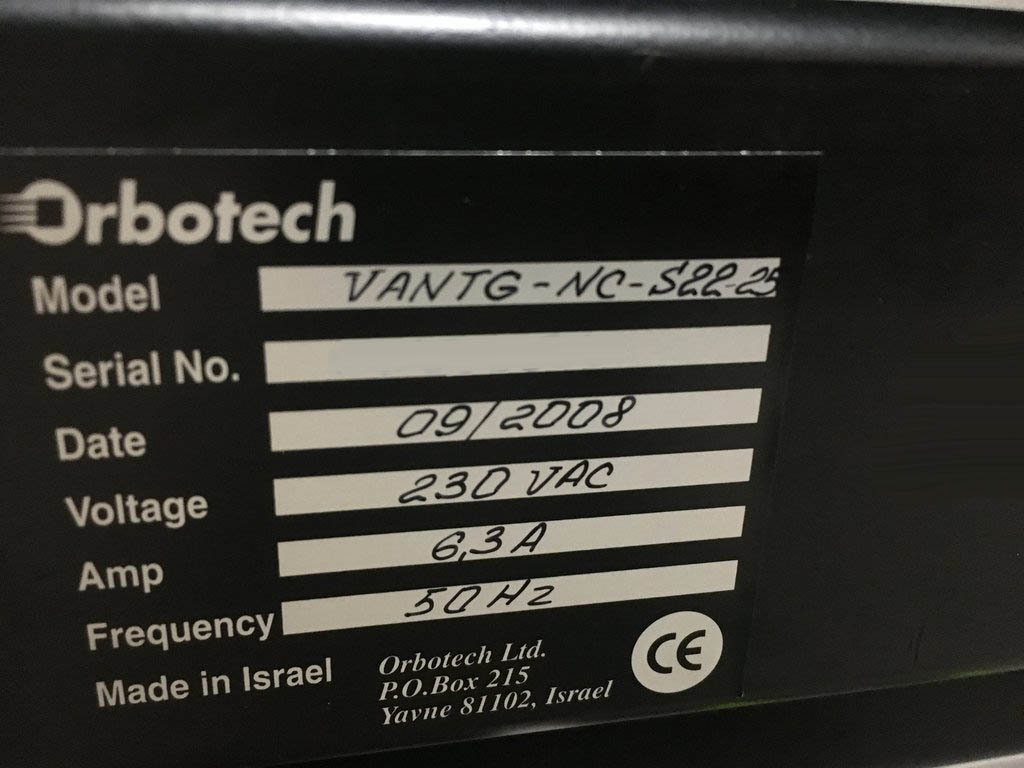

Used ORBOTECH Vantage-NC-S22-25 #9160807 for sale

URL successfully copied!

Tap to zoom

ID: 9160807

Vintage: 2008

Automated optical inspection system (AOI)

Components:

Optical character recognition (OCR)

Solder:

Insufficient / excess solder

Tombstone

Billboard

Coplanarity

Lifted leads

Shorts

Components packages:

All standard passive and active components down to 0201 and 0.3 mm pitch

Odd-form components and connectors

Inspection Speed: Up to 20 cm2/sec*

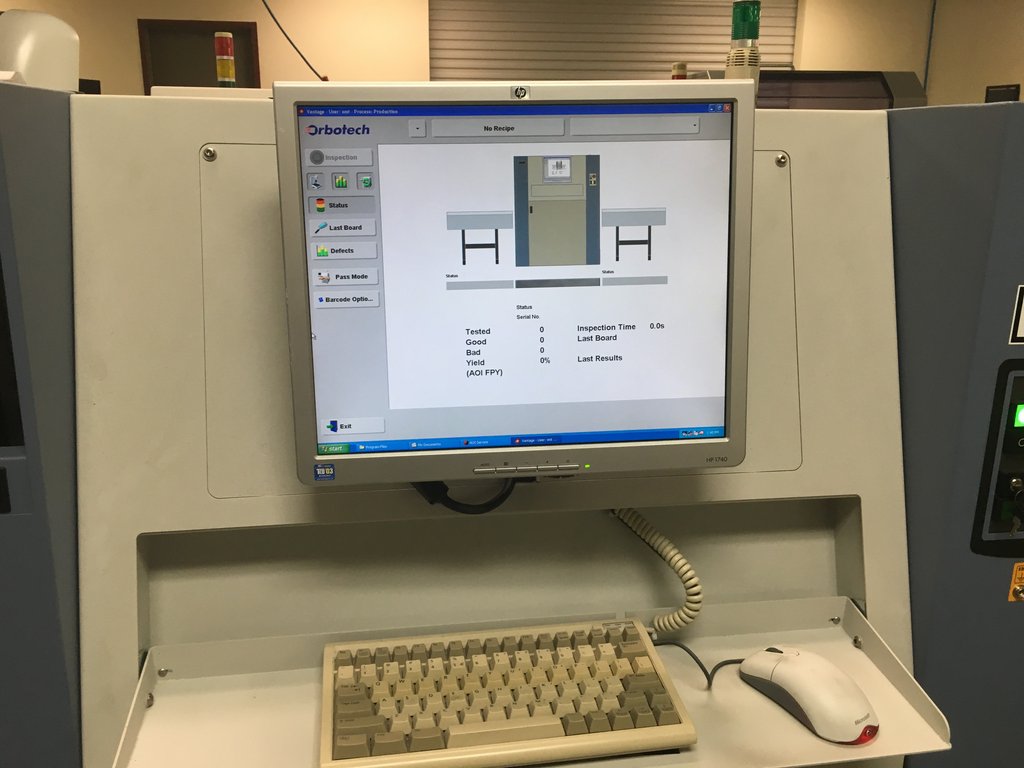

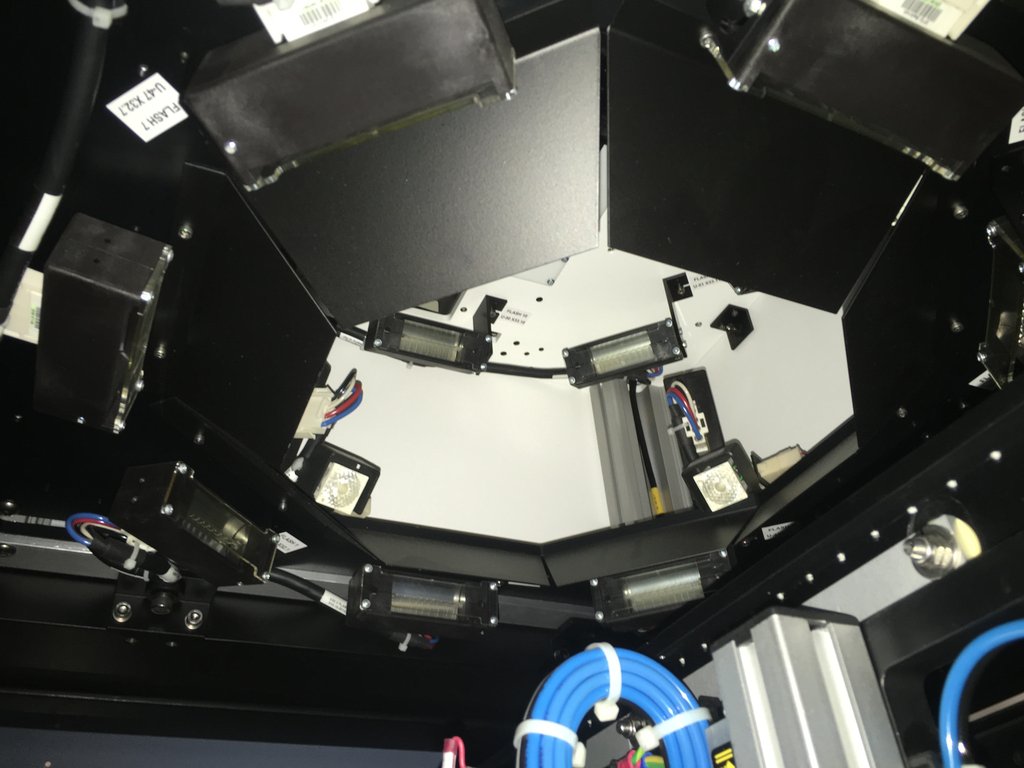

Vision system:

Type : Real 3-D imaging

Multiple cameras with multi-angle direct illumination

Camera:

(1) High resolution on top

(4) Side cameras

Pixel Size: 35μm

Effective optical resolution 1/4 pixel

Lighting:

Axial

Direct and diffuse white lighting

2008 vintage.

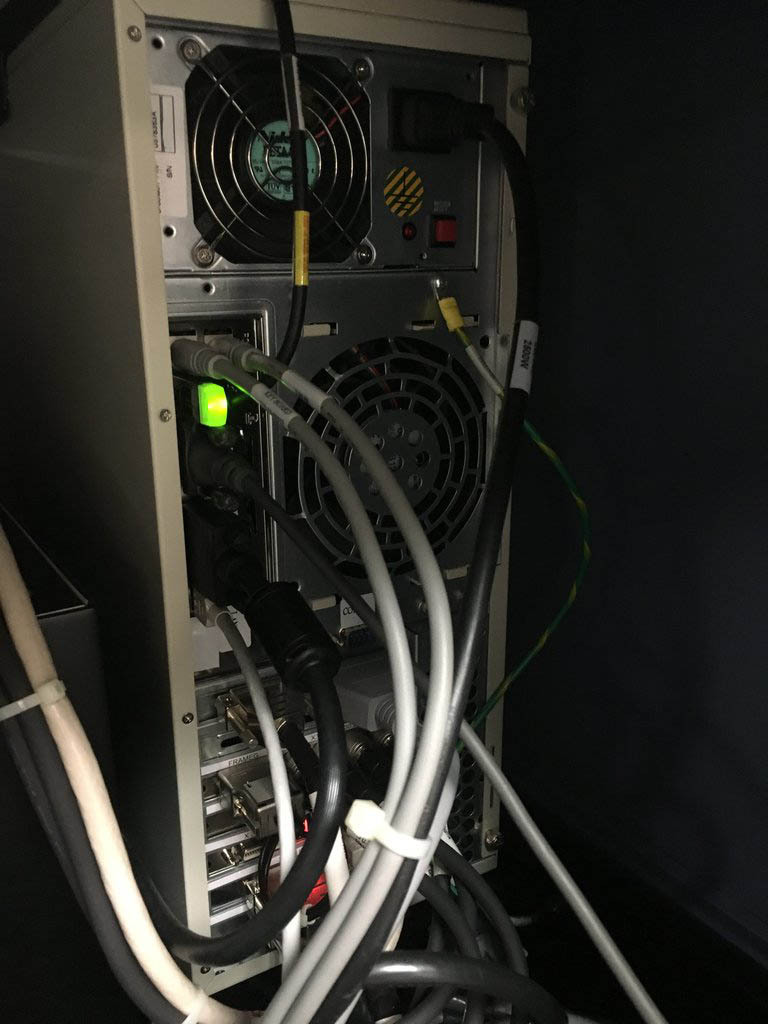

ORBOTECH Vantage-NC-S22-25 is an advanced pc board assembly and manufacturing equipment. It incorporates a full line of technologies including: multi-source feeders, printed circuit board handling robots, laser precision alignment, and solder jetting and printing. The system also offers the capability of manufacturing and assembling complex pc boards with multiple component types, sizes, and configurations. The core of the unit is the patented multi-source feeders that precisely align and feed components into the placement machine. This highly automated machine allows for both automatic and manual inspection, as well as dual-sided component placement. The laser precision alignment software allows for accurate component placement with complex geometries, including corrective or replacement vision recognition. The platform also offers advanced solder jetting and printing capabilities for a wide variety of printed circuit board configurations. This includes the preparation of plated thru-hole boards as well as mixed technology boards. This feature also allows for fast solder jetting of bottom-side components, allowing for immediate top-side placement. The integrated printed circuit board handling robot advances the tool in terms of speed, accuracy, and efficiency. This robot transports boards in and out of the placement machines, while handling components placement in the x-ray inspection zone and seaming sub-assemblies. The asset's user friendly interface allows for easy setup and efficient production management, and can be customized, and is user-programmable. Programs and settings for components, feeder, and paste printers are stored in non-volatile memory, meaning users can quickly transfer from one manufacturing line to another. The controller also interfaces with an integrated smart cabinet which stores the feeders and components for quick access and maximum utilization. Overall, the automated Vantage-NC-S22-25 pc board assembly and manufacturing model offers unparalleled component placement and soldering accuracy, allowing for the manufacturing of complex pc boards with precise configurations and with minimal rework. The equipment helps to reduce costs and increase production efficiency, ensuring that your projects run on-schedule and on-budget.

There are no reviews yet