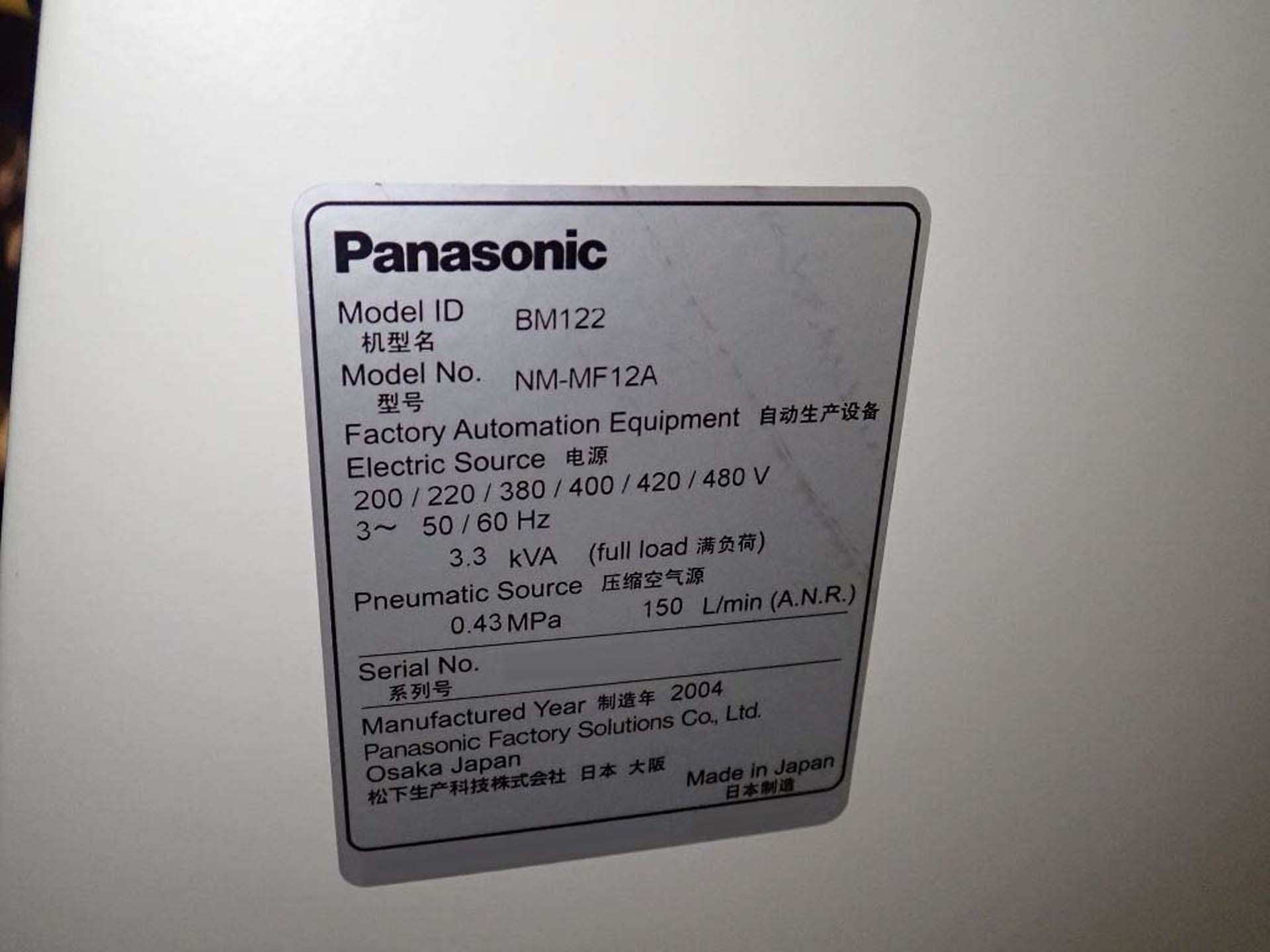

Used PANASONIC BM122 #9244800 for sale

URL successfully copied!

Tap to zoom

PANASONIC BM122 PC Board Assembly and Manufacturing Equipment is an advanced complete production solution for circuit card assembly and manufacturing, specifically designed to address the needs of small and medium-sized electronic manufacturers. This system is well suited for high volume throughput and production requirements, allowing manufacturers to meet production goals and reduce costs. BM122 features a high-speed integrated mounter that provides a flexible and highly automated assembly line for production. This unit is designed to be highly reliable and with advanced features such as the Direct Derivative Part Number (DDPN) recognition machine that helps reduce cycle times and improve accuracy and quality. The mounter is configured with multiple head types and can be programmed to place any kind of component via machine vision or a manual pick-and-place tool. The asset is connected to a PC with Windows operating model and integrated PANASONIC software that provides real-time monitoring and control of the entire equipment. PANASONIC BM122 also has an advanced front end that provides automated handling and inspection of incoming components, helping to ensure quality assurance by validating all parts before being sent to the mounter. The system also includes a multi-functional printer providing component identification, barcode printing, MAC+ printing, and Laser point marking. In addition, the unit comes with automated Laser Depanel, allowing for high-speed depaneling of large numbers of circuit boards without slowing down the assembly process. BM122 also includes several features to protect operators and workers from potential hazards and minimize fatigue. It has an automated material handling machine with integrated dust collectors that remove dust and debris from the operator's work area, as well as a large number of safety sensors built into the tool. The asset also comes with a power outage warning that alerts the operator in the event of a power failure. Finally, PANASONIC BM122 offers easy maintenance through the Remote Maintenance and Diagnosis tool that helps to reduce downtime and increase productivity. In summary, BM122 PC Board Assembly and Manufacturing Model provides a reliable, production-ready solution for high volume circuit card assembly and manufacturing. It is designed with advanced features to increase accuracy, quality, and throughput, while minimizing costs. The equipment offers multiple automated functions, including front-end material handling and inspection, printing, and Laser Depaneling, as well as advanced safety features to protect operators and workers. This system has been designed for long-term reliability and easy maintenance ideal for small and medium-sized electronic manufacturers.

There are no reviews yet