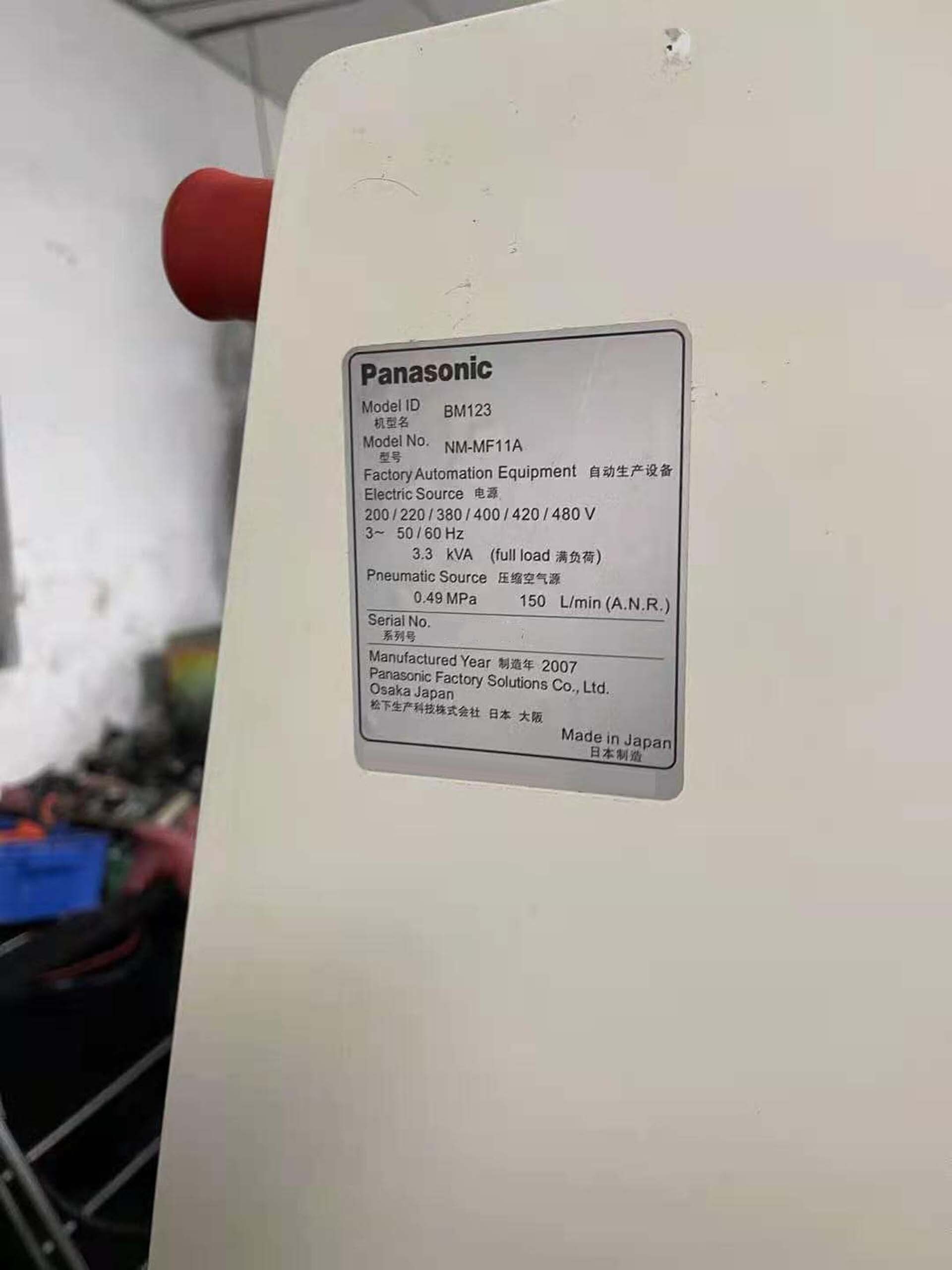

Used PANASONIC BM123 #9385644 for sale

URL successfully copied!

Tap to zoom

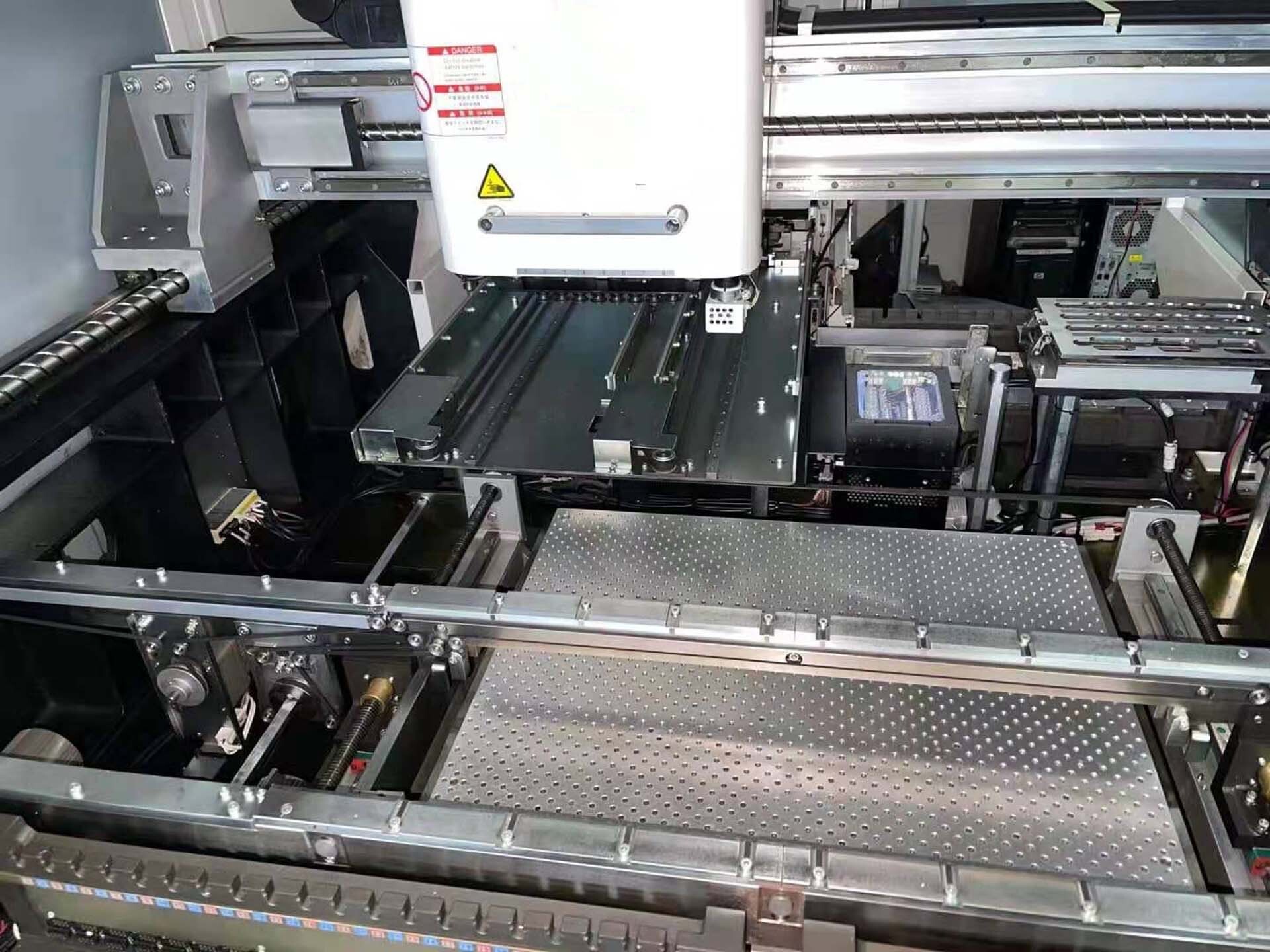

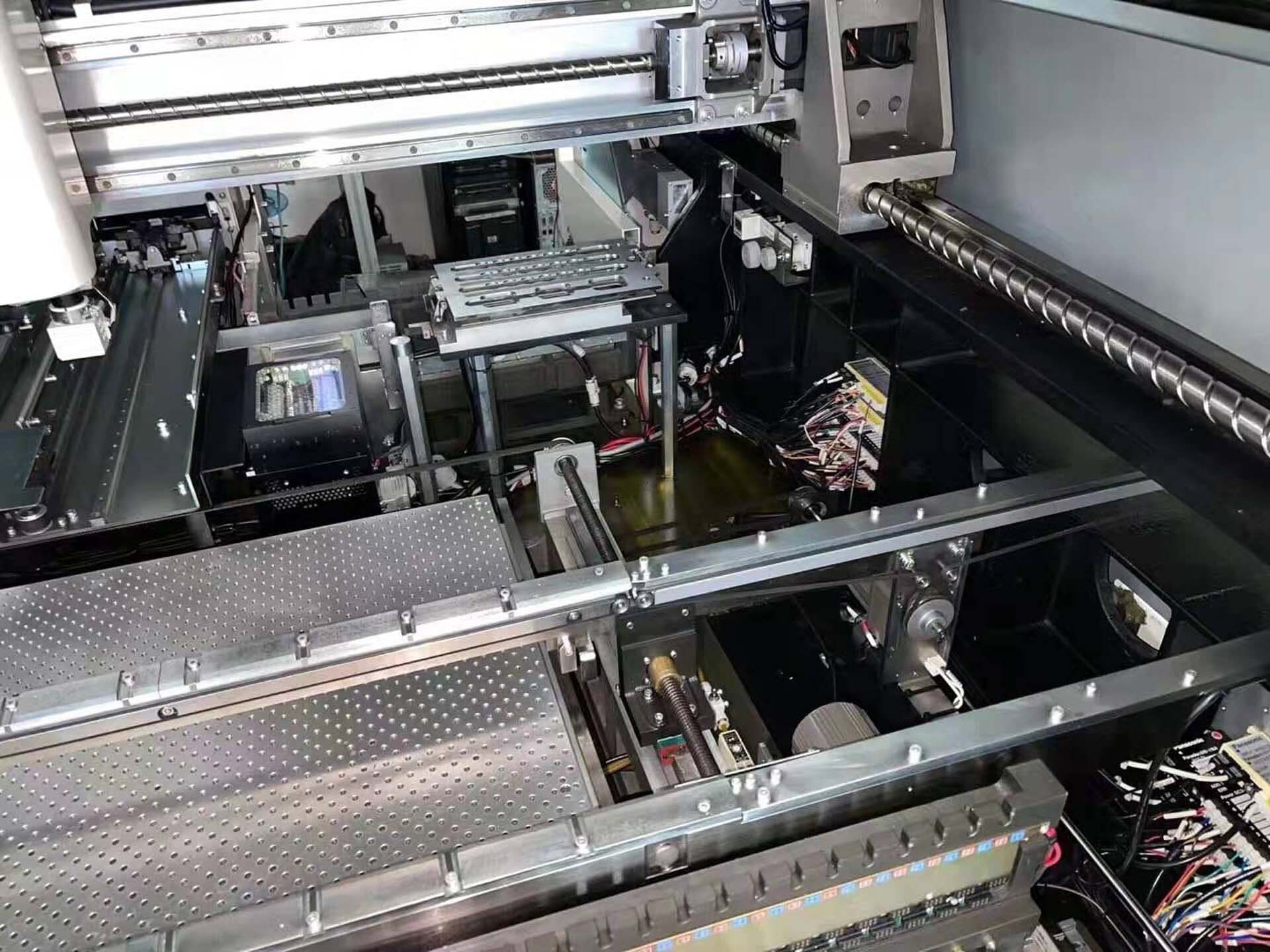

PANASONIC BM123 is a high performance PC board assembly and manufacturing equipment designed for the high speed automated production of printed circuit board assemblies. The system has been developed for high-volume, high-mix production of medium-to-large sized PC boards with a wide variety of component types. The unit can handle up to 400 components for the simultaneous assembly of complex and fine-pitch components onto printed circuit boards. BM123 is made up of several key components including a feeder unit, an indexing machine, an intelligent vision tool, a laser measuring asset and an intelligent table controller. The feeder unit can feed both components and circuit boards. It has a 90-bin memory for high-mix requirements and can feed components up to 25 x 40mm. The indexing model drives to multiple feeders to move the parts to the pick-up position. This helps streamline the feeding process and reduces the cycle time. The intelligent vision equipment is used for the precise placement of components. It uses an image processing system to analyze the parts and identify their exact placement points. The laser measuring unit is used to determine the exact height of the components for placement. The intelligent table controller provides automated machine vision based variable offset and variable die stack parameters. This ensures that the machine performs at its highest accuracy and speeds during production. PANASONIC BM123 also features an automated operation machine for the resetting of components and board positions. This ensures proper and consistent placement of components onto circuit boards. Other features include a special PC detection tool for detecting open shorts and other defects in boards, and a high speed vision asset to inspect the parts before and after they are attached. BM123 is a reliable and efficient model for the manufacturing of printed circuit board assemblies. Its features make it well-suited for high-volume and high-mix applications. It is easy to operate and maintain, with its automated operations and vision systems. The equipment can handle up to 400 components with accuracy and speed, and its components are easy to replace if needed. With its smart technology and user-friendly interface, PANASONIC BM123 is an ideal solution for PC board assembly.

There are no reviews yet