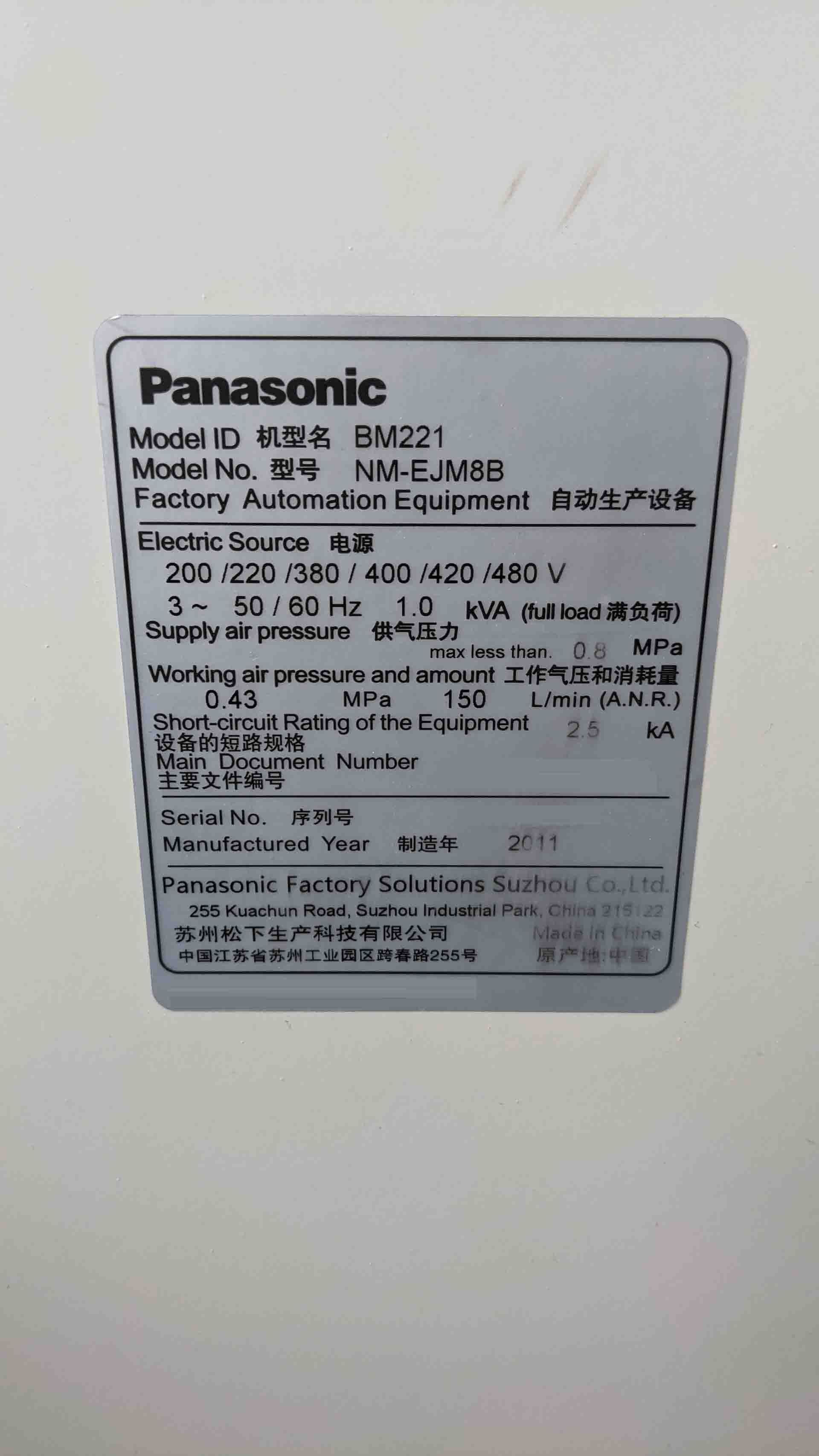

Used PANASONIC BM221 #293603086 for sale

URL successfully copied!

Tap to zoom

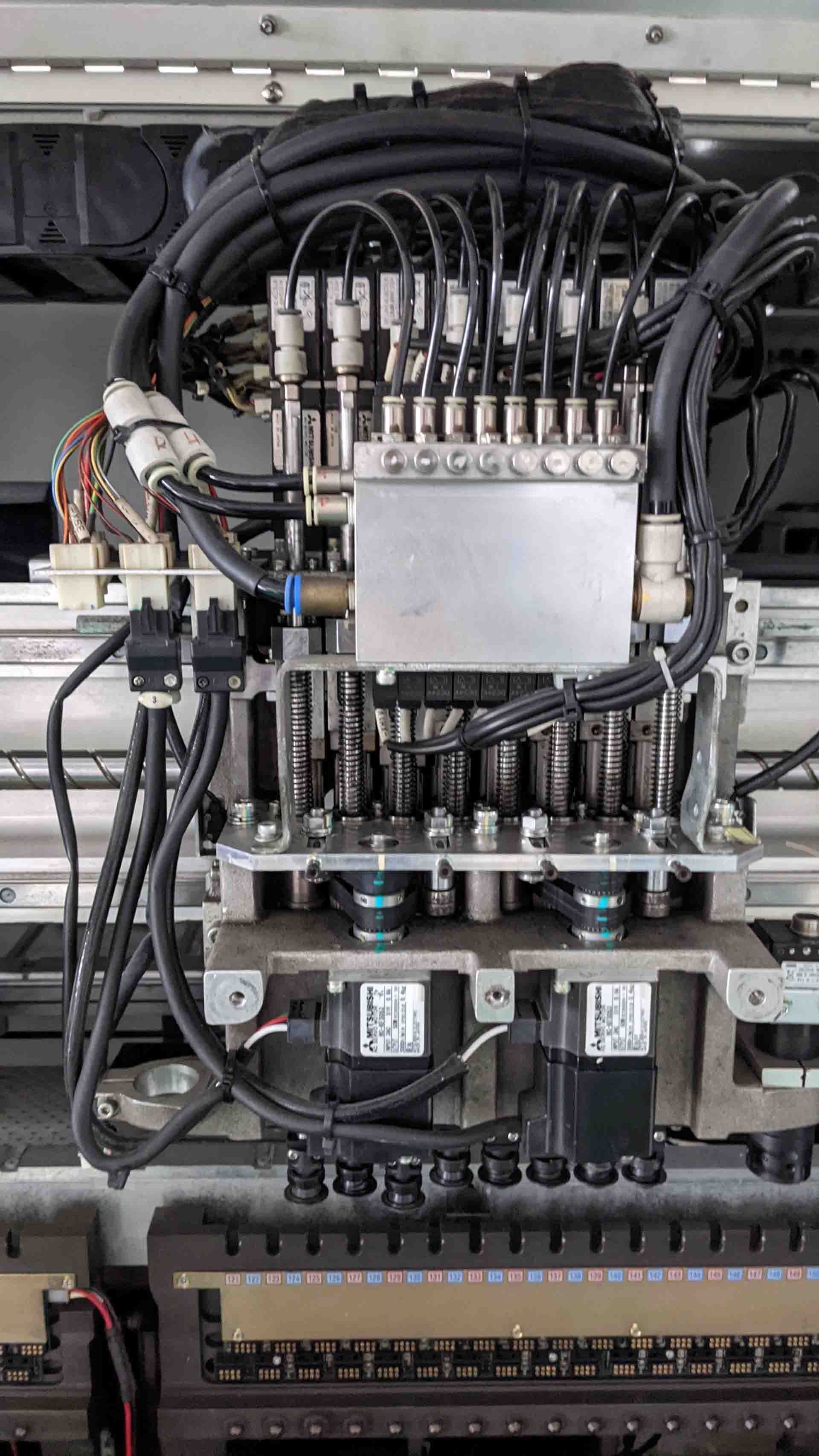

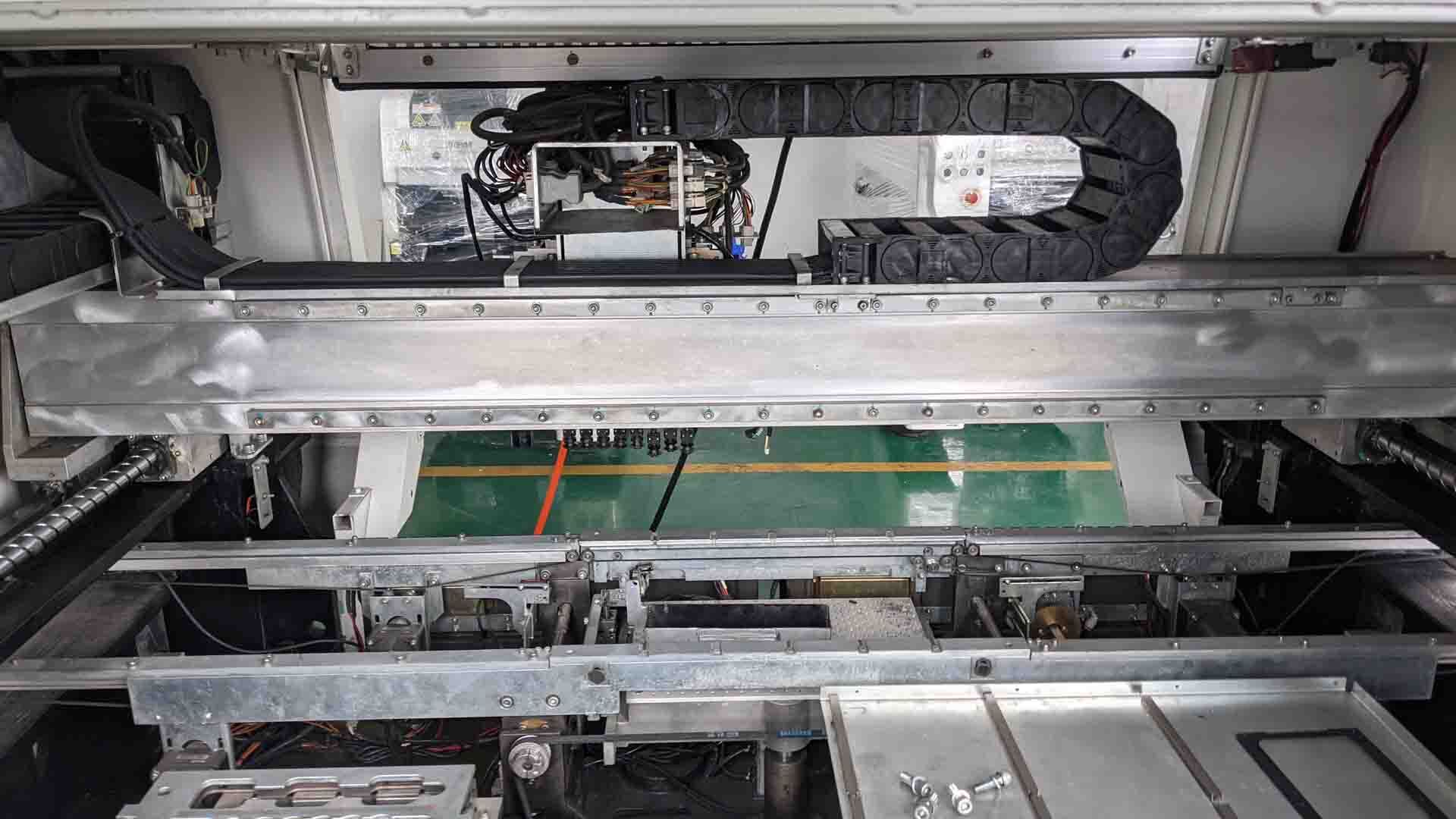

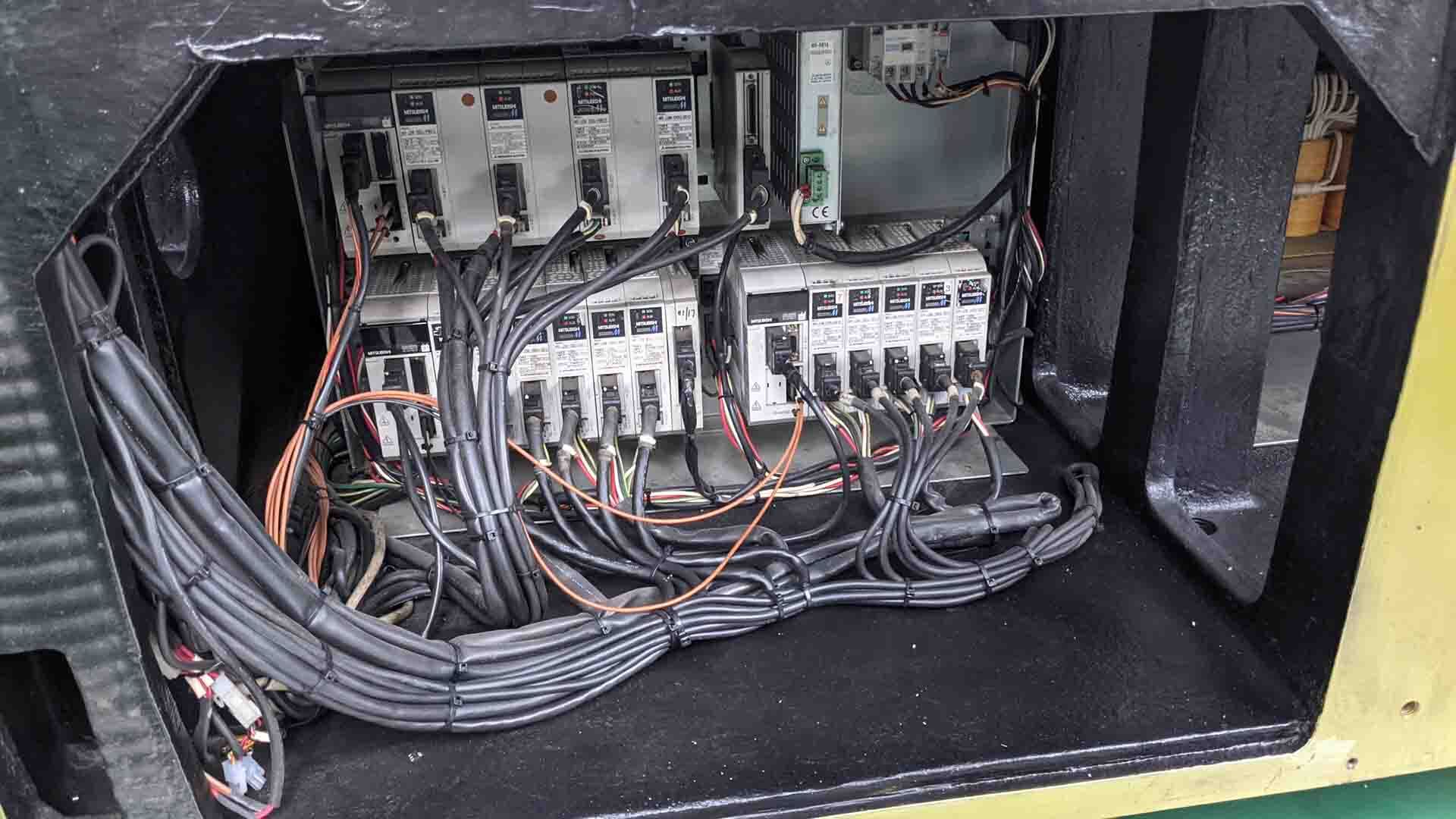

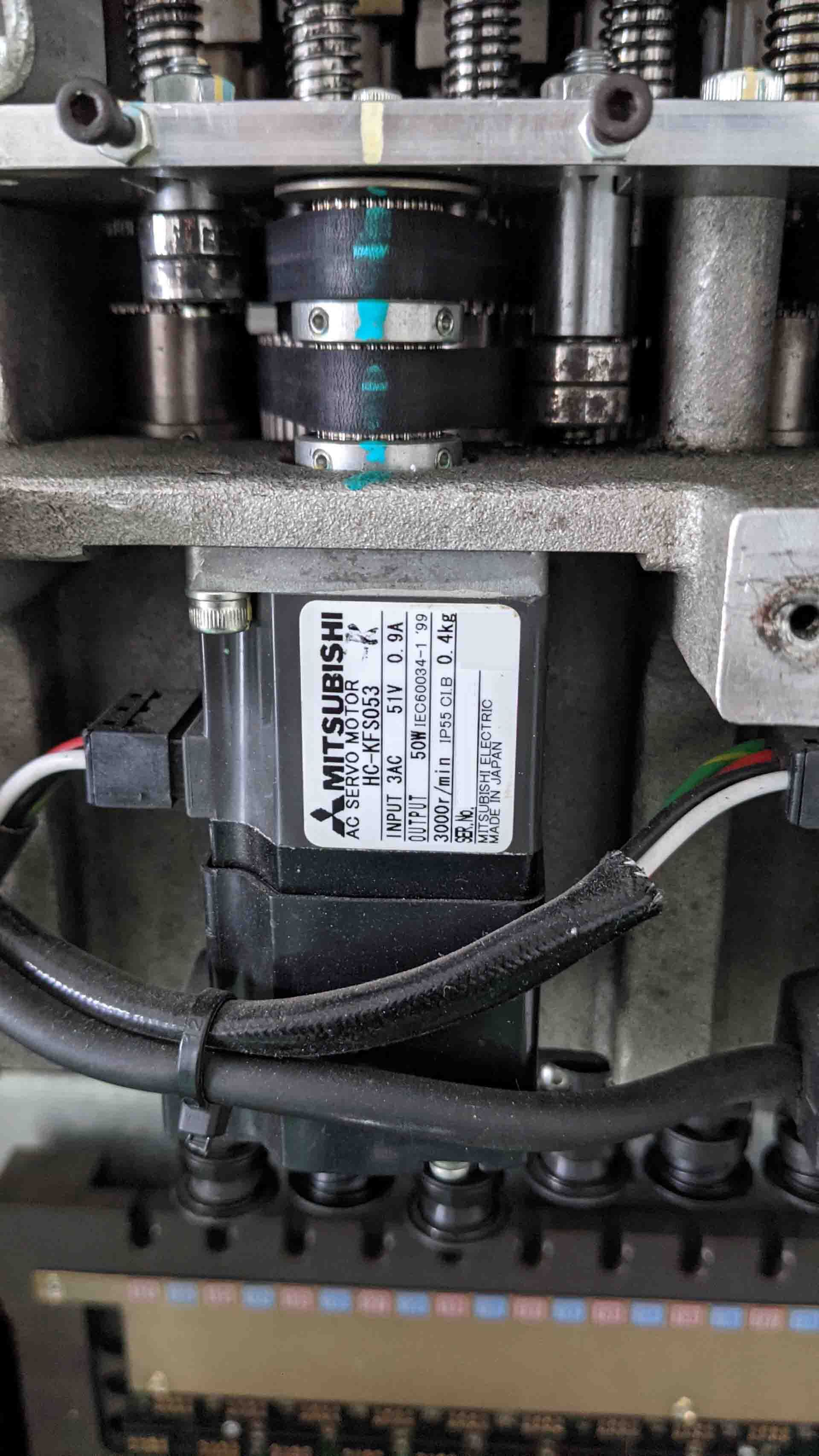

PANASONIC BM221 is an automated cost-effective PC Board assembly and manufacturing equipment that is both lightweight and highly efficient. It is specifically designed for the high-volume production of PC boards with a maximum size of 22 inches. The system is designed for both high and low-volume production of boards and is capable of throughputs of up to 40 boards per hour. PANASONIC BM 221 is equipped with a board handler that supports simultaneous feeding of up to five boards. This is used to feed boards in multiple layers at the same time and is especially useful during high-volume production runs. The board handler supports the multiple layers and is designed to be incredibly accurate and fast, thereby eliminating wasted time and material. BM221 is equipped with two high-speed nozzles which use a high-pressure vacuum paddle to accurately deposit solder paste on both sides of each board. The nozzles are mounted on a cantilever arm and are easily adjustable depending on the board being assembled. Additionally, the unit is equipped with a wide range of nozzle options which enable it to accurately handle a variety of complex components. BM 221 also has excellent component placement accuracy thanks to its precision placement head. The head is designed to ensure that all components on the board are accurately placed and is capable of picking up components with dual side adhesive tape. With the increased accuracy provided by this placement head, the machine is able to manufacture very complex components without the need for extra reworking or manual intervention. PANASONIC BM221 is also highly energy efficient. It is powered by a sophisticated PLC control tool that is capable of efficiently controlling all of the components on the board. This energy efficiency not only helps to keep production costs low, it also helps to reduce the environmental impacts of PCB production. PANASONIC BM 221 also offers a range of additional features, such as a SPI (solder paste inspection) asset which is able to quickly and accurately detect small volumes of solder paste. The model also offers additional customisation options, such as the ability to program multiple boards at once for maximum efficiency. Overall, BM221 is an efficient and cost-effective PC Board assembly and manufacturing equipment. It is designed for high-volume production runs and is equipped with a number of features that ensure accuracy and efficiency. With its wide range of additional customisation options, the system is a great choice for both commercial and hobbyist use.

There are no reviews yet