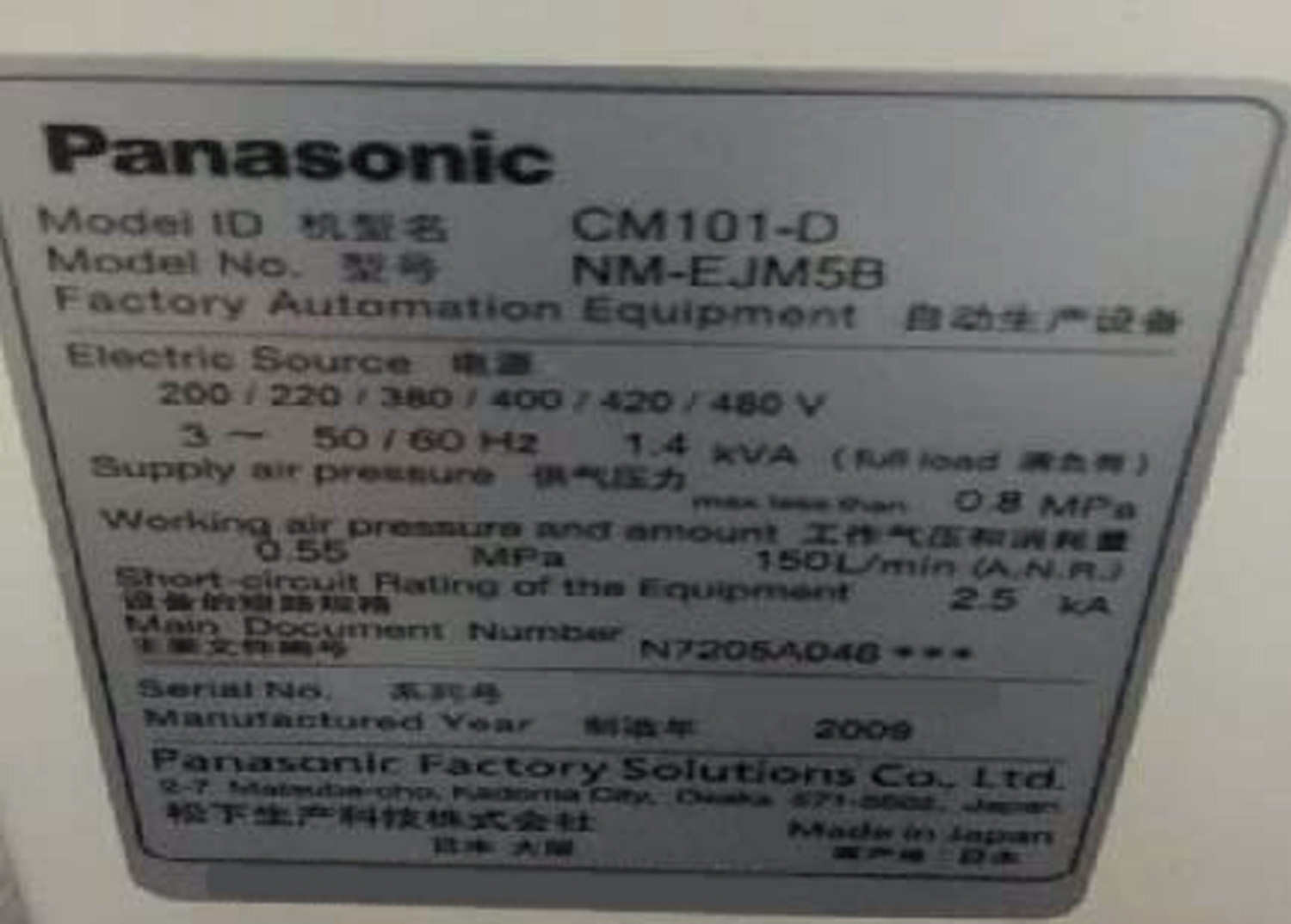

Used PANASONIC CM101-D #9246993 for sale

URL successfully copied!

Tap to zoom

ID: 9246993

Vintage: 2009

Chip mounter

(8) Heads

DT50S-20 Auto tray unit

Component dimensions 0603 Chip: 100 x 90 mm

Component thickness: Maximum 25 mm

PCB Size:

Minimum: 50 x 50 mm

Maximum: 460 x 360 mm

2009 vintage.

PANASONIC CM101-D is an advanced PC Board Assembly and Manufacturing equipment. It is designed to streamline the entire manufacturing process of printed circuit boards. It is a stand-alone system that is capable of producing a variety of advanced, complex circuit boards with high precision and efficiency. The PC Board Assembly and Manufacturing unit consists of several components that work together to achieve desired functionality. The machine includes a solder paste dispenser, solder placer, pick-and-place assembly, reflow oven, hot air reflow tool, and inspection asset. The solder paste dispenser deposits precise amounts of solder paste into individual board traces. The solder placer places and secures components onto the circuit boards with precision. The pick-and-place model moves components from storage tubes and accurately positions them onto the board. The hot air reflow equipment quickly and evenly heats the boards for a secure connection. The reflow oven is used to heat and cure the solder paste for better soldering. Finally, the inspection system tests each board for correct component placement and reliability. PANASONIC CM 101D is a very accurate and reliable PC Board Assembly and Manufacturing unit. It has the capacity to manufacture up to 8 different product types, with a cycle time of up to 4 minutes. The machine has its own built-in operator panel, PLC controller, and software controller to allow for efficient programming and tool operation. The software controller also allows for remote monitoring, as well as remote maintenance and upgrades. CM101-D offers many useful features such as auto dispense, auto board transport, and auto board pick-up, as well as three fully configurable heads to allow for flexible assembly. It is also capable of highly precise operation when placing components and is effective in producing high-quality circuit boards. The asset also has several safety features, such as a light curtain and crash protection for the moving parts. Overall, CM 101D is an extremely efficient and accurate PC Board Assembly and Manufacturing model. It is highly reliable and can be used to produce a wide variety of complex circuit boards with precision, speed, and accuracy. It offers many useful features, such as auto dispense and pick-up, that make the process even more efficient and versatile. With its reliable components, advanced software, and safety features, PANASONIC CM101-D provides a comprehensive solution for PC Board Assembly and Manufacturing.

There are no reviews yet