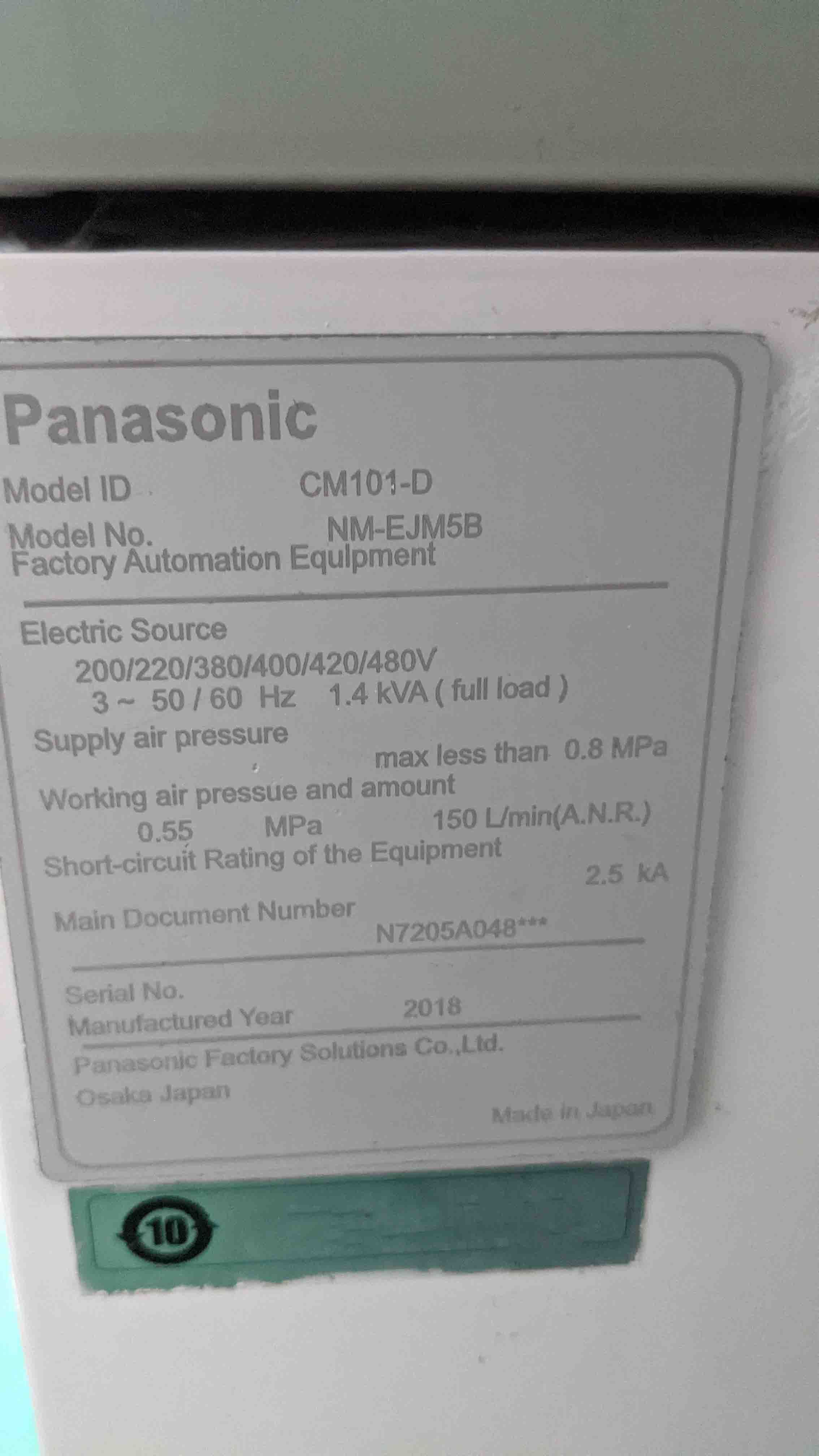

Used PANASONIC CM101-D #9386768 for sale

URL successfully copied!

Tap to zoom

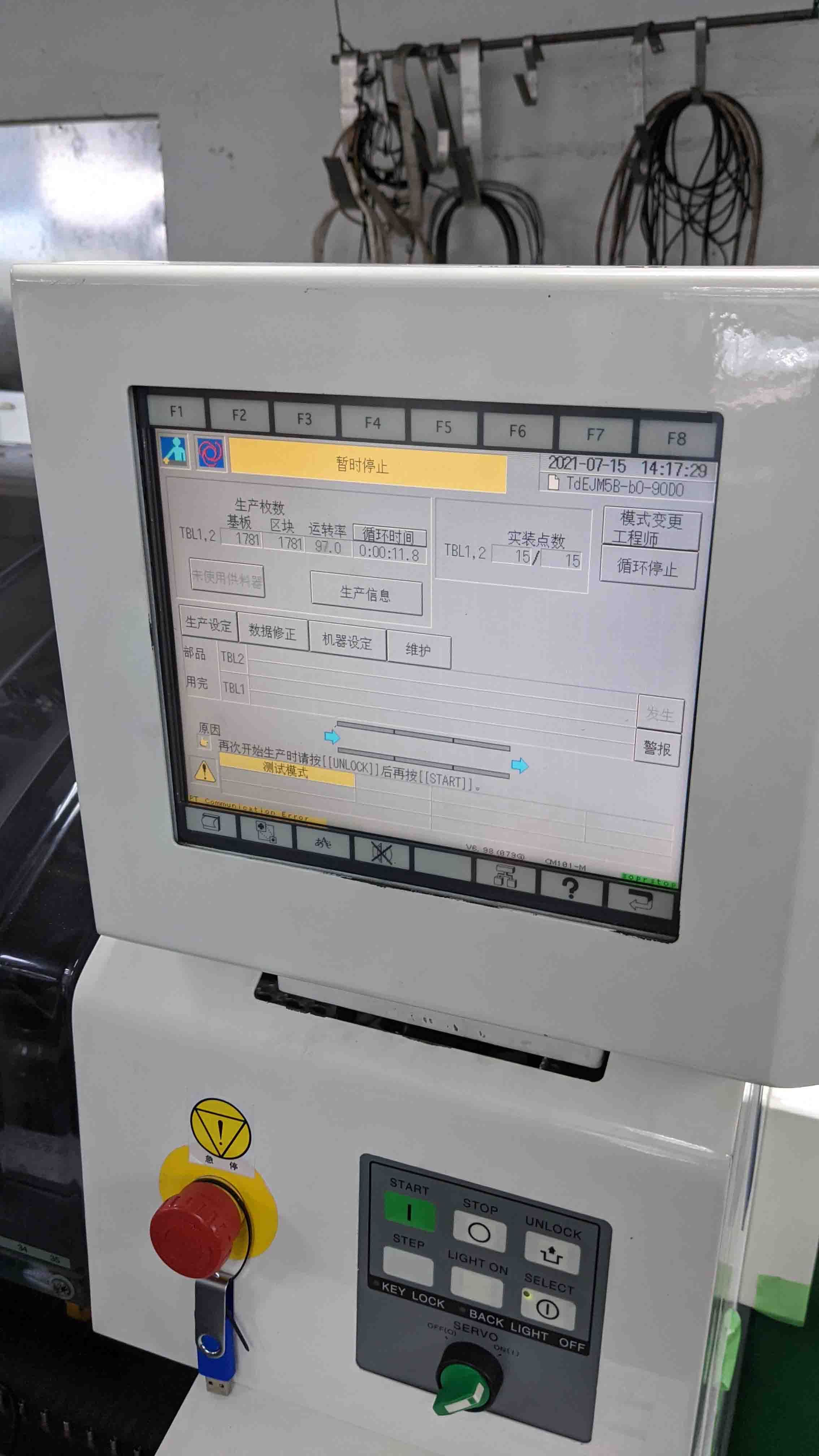

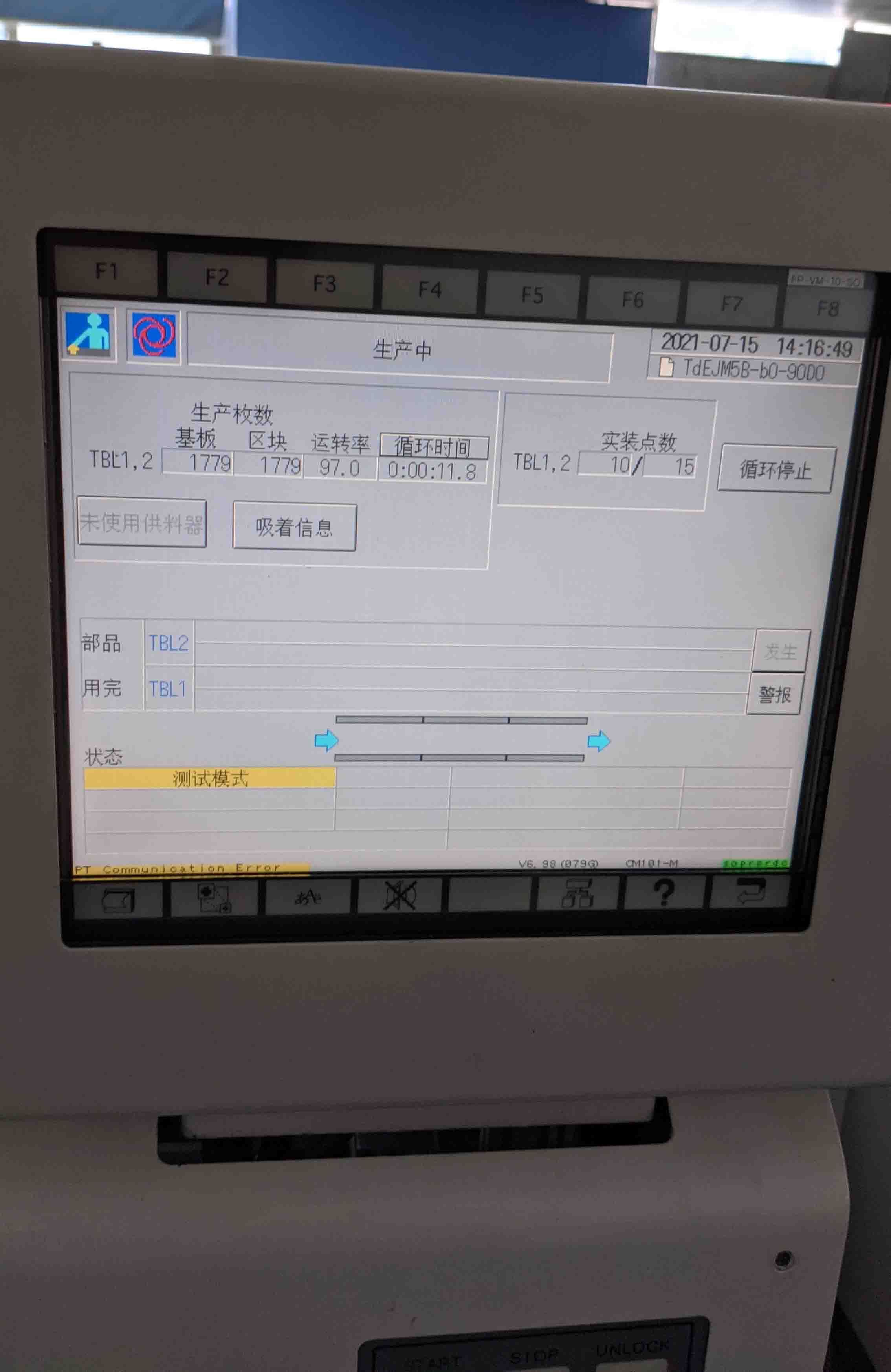

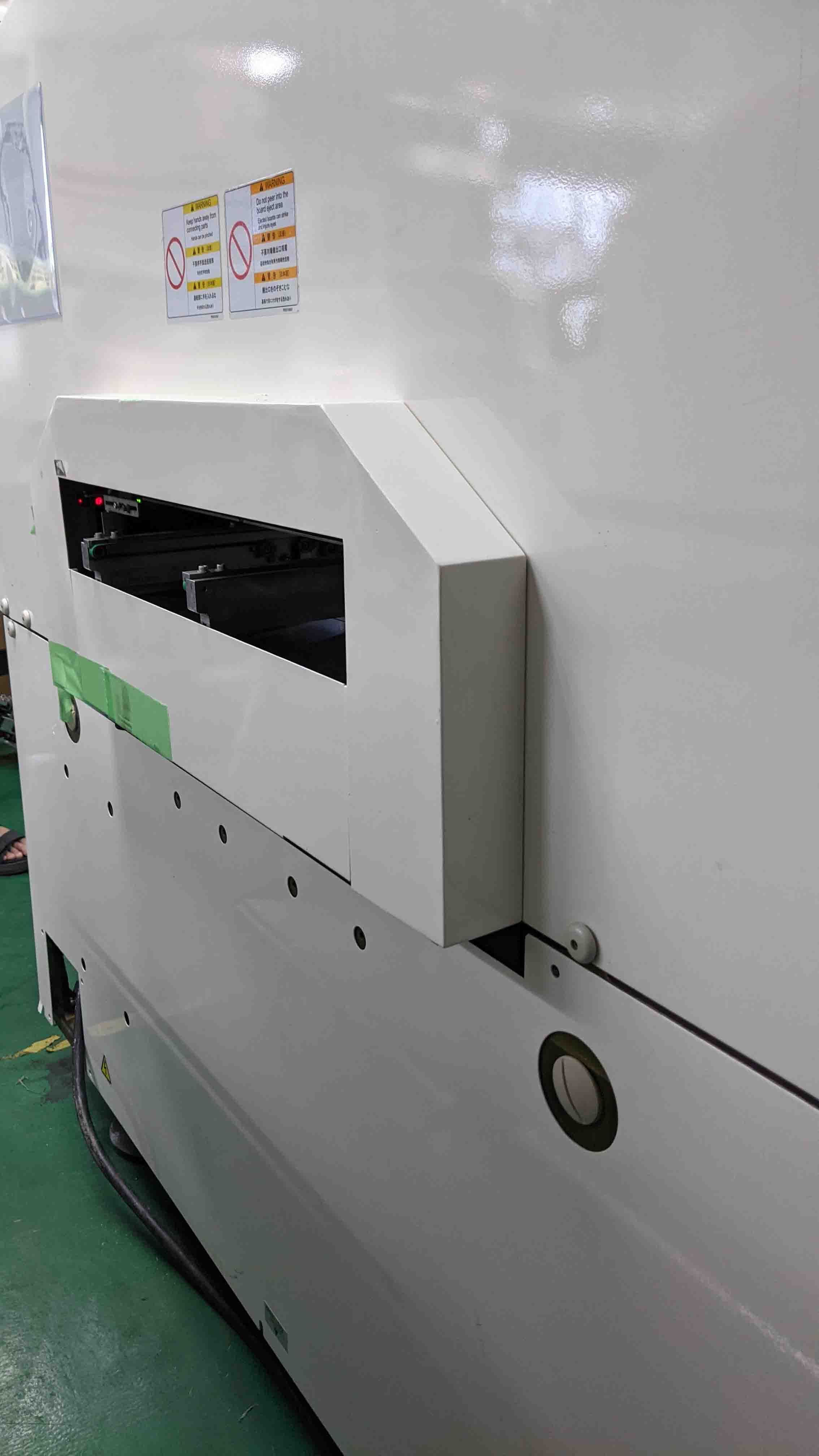

PANASONIC CM101-D is a PC board assembly and manufacturing equipment that is ideal for the production of medium to large-scale products. It utilizes advanced automation technologies and number-tracking systems to allow for total system control. The unit contains a fully automated component placement stage with a built-in vision machine for quality inspection. This feature allows for consistently high-quality results and helps to maximize efficiency. PANASONIC CM 101D includes a Dual-Gantry Pick & Place conveyor tool with a Magazine Loader. This allows the efficient placement of components by the automatic placement head. It can also accommodate a wide range of components including chip resistors, capacitors, LED, and connectors. It also features an optimized nozzle asset to improve placement accuracy, reduce operational errors, and minimize production downtime. The model is designed with flexibility in mind. It is equipped with a user-friendly graphical interface that allows for efficient parameter setting and program transfer. The touch-screen monitor displays critical information in real-time and enables integrated automation control for the entire production process. CM101-D also includes an adhesive dispensing equipment that has a precise injection technology for a variety of different components. This increases the efficiency of the production process, while also reducing the waste of raw materials. Additionally, it is designed with a powerful Vector control CPU that ensures precise control of the motor for high-speed production. For thermal assembly, the system utilizes an automated Reflow Oven that enables efficient processing of PCBs. The oven has a built-in unit for air pressuring and temperature control that allows for easy and accurate operation. It also features upgraded nozzles to optimize air pressure, air flow, and soldering time. Finally, CM 101D has an integrated off-line production machine, which eliminates the need for costly on-site installation or maintenance. The tool is also capable of collecting data via RFID tags and stores it in the database for later use. This allows users to easily trace production information and eliminate time-consuming paperwork. All in all, PANASONIC CM101-D is an ideal choice for automated production of medium to large-scale products. Its advanced automation systems and intuitive user interface enable efficient and optimized board assembly and manufacturing.

There are no reviews yet