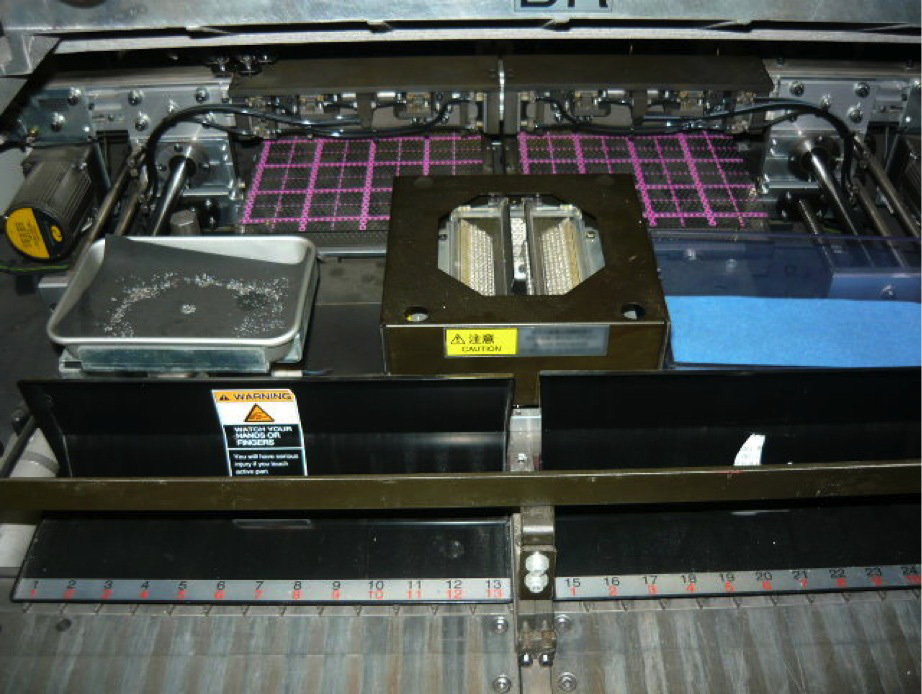

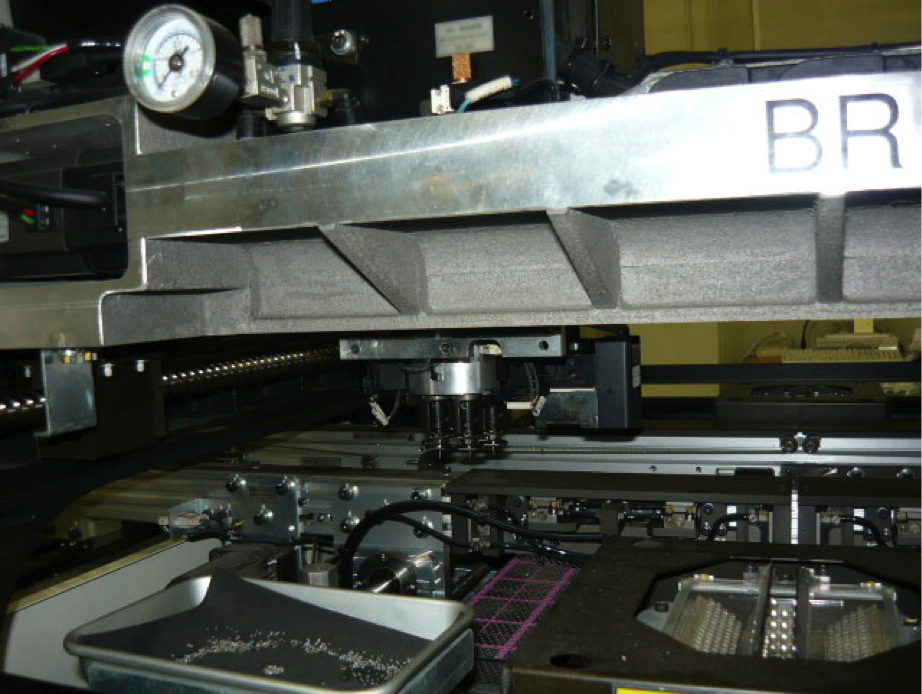

Used PANASONIC CM202-D #9016340 for sale

URL successfully copied!

Tap to zoom

ID: 9016340

Vintage: 2000

Chip mounter

Right to left (front rail fixed)

Modular type

Tact: 0.13 sec/pc

Board size (max): 460 (L) x 360 (W)

Chip 1005: 24 × 24 QFP

Feeder carry (max): 104 pcs (single)

Feeder: separate table type

Conveyor width auto-adjust

Bad mark detection

Transmissive, reflective recognition

Board recognition

Grey-scale

Nozzle Z digital

Rotation

Alternate

Auto-recovery

Touch panel

Cutting unit

Applicable for double feeder

Feeder changing cart: 800 (W) x 700 (D) x 1,400 (H)

Feeder setting table

Operation manual

System disk

(24) Nozzles:

110 Nozzle (Qty 18)

115 Nozzle (Qty 5)

130 Nozzle (Qty 1)

(70) Feeders:

8×2 W (Qty 15)

8×4 W (Qty 30)

8×4 S(P) (Qty 5)

8×4 S(E) (Qty10)

12×4 (Qty 2)

12×8 (Qty 4)

12×12 (Qty 2)

12×12 (Qty 2)

16×12 (Qty 2)

2000 vintage.

PANASONIC CM202-D is a PC Board Assembly and Manufacturing Equipment designed for medium to high-volume production operations. This system enables users to produce quality products quickly and accurately, with consistently low cycle times. It is designed to provide high flexibility and scalability for printed circuit board (PCB) assembly operations. The unit features a robust yet simple software design that ensures operator ease and flexibility, as well as robust tool components for efficient production processes. The machine is capable of semi-automated assembly of electronic components (SMT and Through Hole) with quick programmable changeover, coupled with the manufacturing of connectors, stiffeners, shielding covers, and much more. It is fully capable of programming, auto-adjustment, and automatic inspection processes, all done with minimal manual intervention. It has a vision inspection tool that performs accuracy judgment with pattern recognition for real-time inspection. The asset has strong communication capabilities and secured access, with integrated PLC, HMI, database, and communication functions. CM202-D model features an intuitive user interface with adjustable grids for working and programming PCBs. It is equipped with an eight-axis robotic arm for managing automatic components insertion and placement. There are also several programming options available, including pre-programmed models and parameter-based programming. It can store up to 250,000 products in memory. The equipment ensures high efficiency with serial and simultaneous loading and offloading of PCBs. The Pick and Place machines provide maximum efficiency and accuracy in assembly, while the miniaturization work station ensures high precision in soldering miniaturized components. Additionally, the system has the capacity to adjust pick-up velocities and track time measurements, enabling added accuracy in operations. The unit comes with a powerful and user-friendly software, R-Maker. This software offers a wide range of features for advanced management solutions including production data analysis, material control, traceability, data collection, and quality control. It also provides XML import and export of program data, thus ensuring compatibility with existing products/assembly processes. It has an Ethernet connection for communication with remote systems. PANASONIC CM202-D has been extensively tested for delivering best performance under various operating conditions, providing cost as well as time-savings to assembly jobs. The machine delivers extremely reliable results within current cycle times. It complies with the safety standards of global electronic manufacturing markets such as EU, CE, and UL/CSA, and provides an effective solution for quality-driven PCB assembly processes.

There are no reviews yet