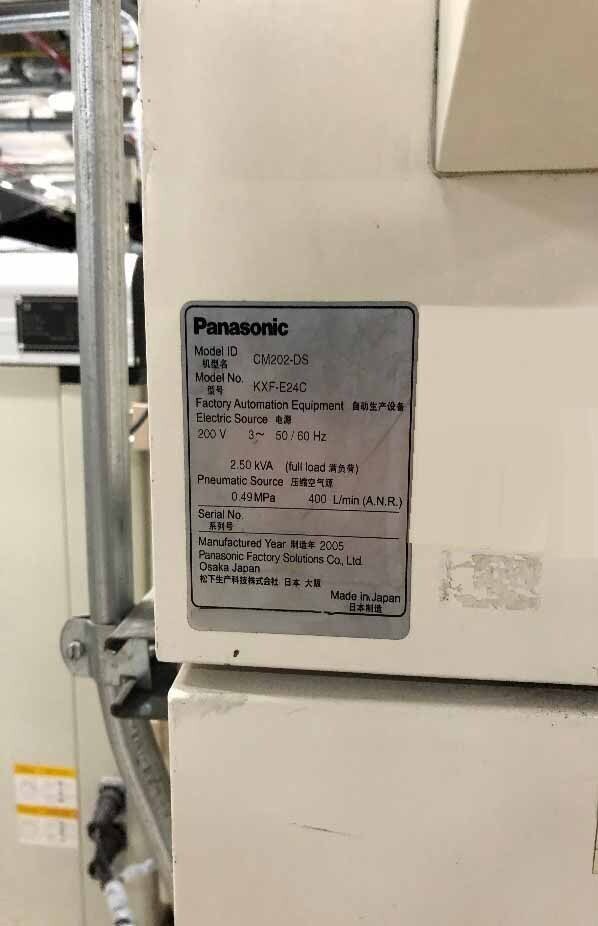

Used PANASONIC CM202-DS #9353042 for sale

URL successfully copied!

Tap to zoom

ID: 9353042

Vintage: 2005

Chip mounter

(4) Tables

(6) Nozzles per table

(4) Heads

2005 vintage.

PANASONIC CM202-DS is a board assembly and manufacturing equipment for efficient and high quality production of printed circuit boards (PCBs). It is designed to provide a complete manufacturing line with high precision and flexible production needs. The system increases productivity and decreases manufacturing costs while striving to reduce environmental impact. PANASONIC CM202DS is composed of a component placement unit, a reflow oven, a single lane router (for routing holes on PCBs) and an inspection unit. It has an also an energy efficient design that optimizes the power and energy saving benefits. The component placement unit of CM 202DS utilizes optical recognition and a pick-and-place operation for precise placement of the components. The maximum board size is 680 mm x 450 mm. The placement speed is up to 0.060 m/s. The alignment accuracy is ±50 μm and the positional accuracy is ±50 μm. The reflow oven is a single chamber, six zone oven with a programmable running direction and temperature control for homogeneous heating and cooling of the PCBs. The capacity is up to 900 W (maximum power output) and the maximum temperature is 450°C. The reflow oven has a dampening machine to reduce noise and ensure safety during operation. The single lane router is mainly used for routing holes on the PCBs. It can accommodate a maximum routing width of 4 mm and has a length of 48 mm. The router handles drill bits made with carbide and diamond and is capable of drilling up to 10,000 holes/hr. PANASONIC CM 202DS also features an inspection tool to detect any deformation on the PCBs after the components have been placed. The inspection asset is equipped with a vision model and a CCD camera. It inspects the position and pads of the components, as well as solder defects. CM202DS is a highly advanced board assembly and manufacturing equipment for efficient production of PCBs. The system utilizes optical recognition and pick-and-place operation for precise placement of the components with a maximum board size of 680 mm x 450 mm. It also features a single chamber, six zone reflow oven, a single lane router for routing holes on PCBs, and an inspection unit with a vision machine and a CCD camera. This combination of advanced equipment enables efficient and high quality PCB production.

There are no reviews yet