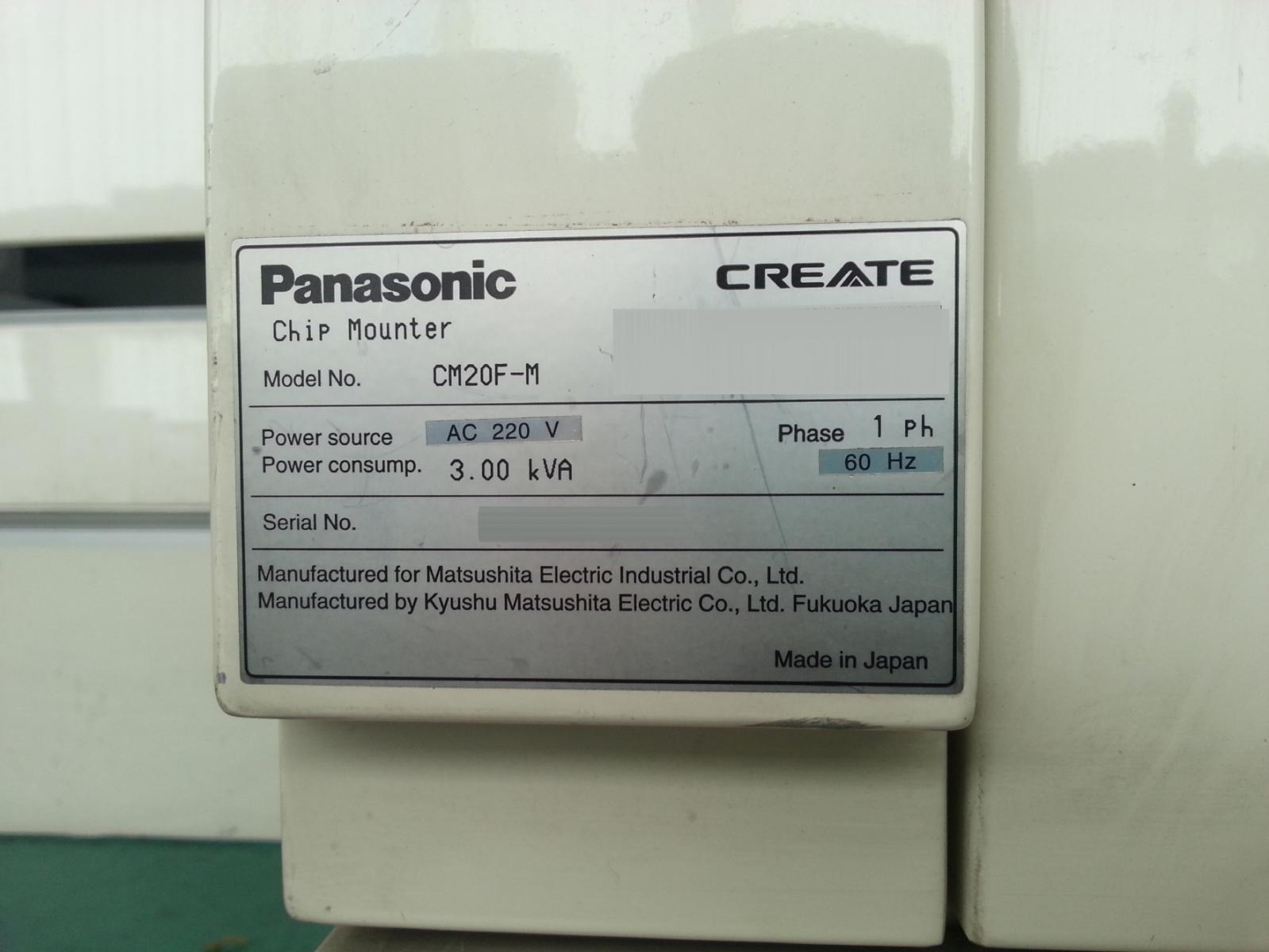

Used PANASONIC CM20F-M #9117143 for sale

URL successfully copied!

Tap to zoom

ID: 9117143

Chip mounter

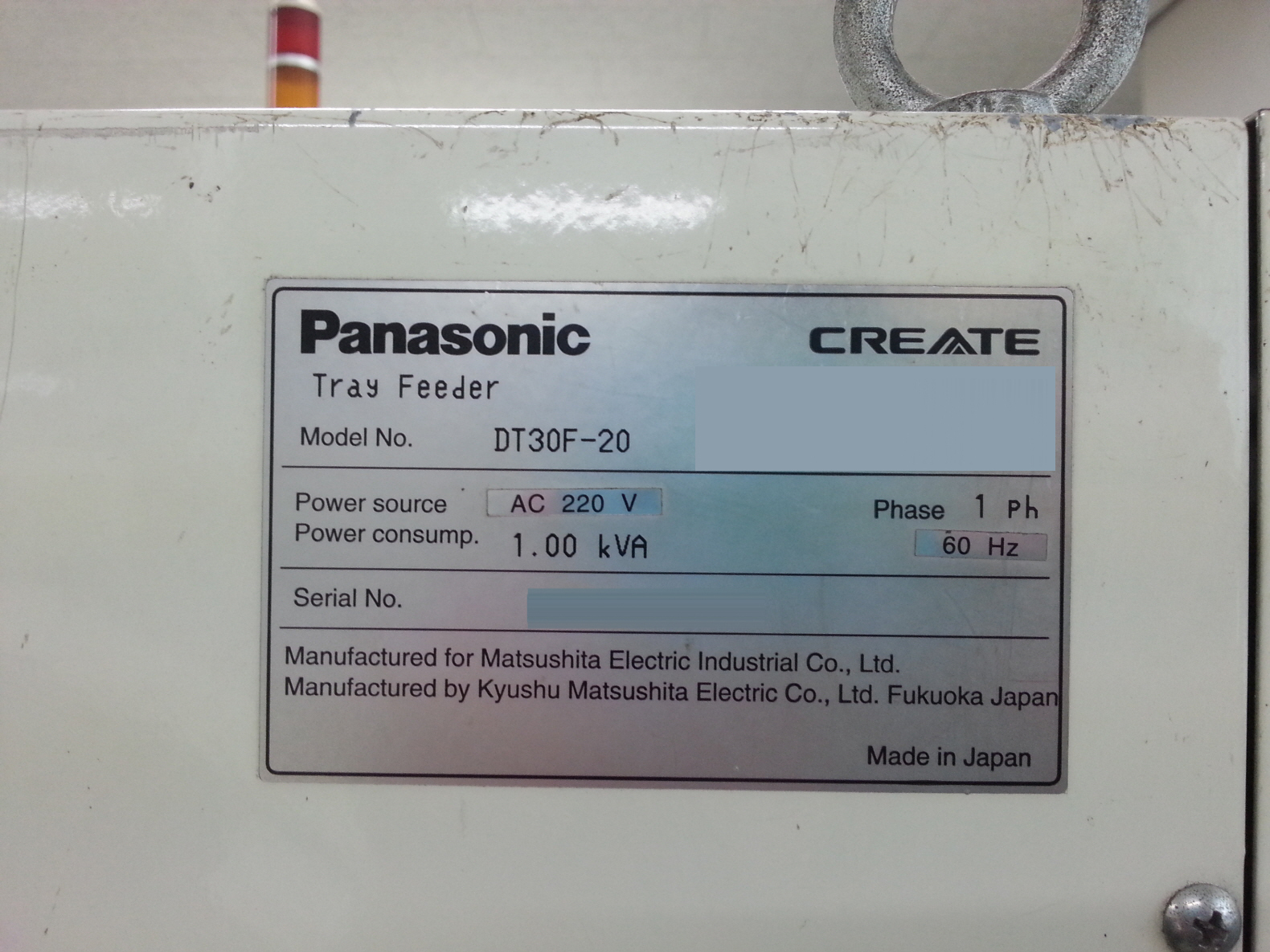

Auto Tray: Model DT30F-20

Feeders:

(5) 8 x 4 paper large

(4) 8 x 4 emboss large

(3) 12 x 4 large

(6) 12 x 8 large

(1) 12 x 12 large

(5) 16 x 4 large

(2) 16 x 8 large

(10) 16 x 12 large

(2) 24 x 12 large

(2) 24 x 16 large

(2) 32 x 16 large

(2) 44 x 12 large

(2) 44 x 16 large

(2) 44 x 24 large.

PANASONIC CM20F-M, model number CM20F-M, is a pc board assembly and manufacturing equipment. It is based on the Snap-step II platform and incorporates a range of features to make the production of pc boards faster, safer, and more reliable. The system is equipped with two connective molds, a full-sized press fixture, and a robot that is powered by a servo motor. The robot enables the automated assembly of the pc boards. It can be programmed to retrieve components from the racks and feed them into the press fixture. It can also be used to stack multiple pc boards. The robot is designed to assure precision accuracy and reliable placement of components at any speed. PANASONIC CM20F-M is also equipped with a full-length conveyer belt. This allows for efficient use of resources, as the boards are able to be automatically transported to their destination as soon as assembly and testing has been completed. The unit also has robust EMI/EMC protection, active grease scraper, and video monitoring capability to ensure the consistency of the assembly process. In addition, the machine has an integrated CCD camera which is used to inspect the assembled pc boards. The camera ensures that no components have been missed, or installed in the wrong place. Furthermore, the tool is also equipped with an inspection light for further verification and analysis. CM20F-M is further equipped with a Modular Design asset, which enables the users to customize the model to meet their specific requirements. PANASONIC CM20F-M is an advanced pc board assembly and manufacturing equipment that is designed to help users increase their productivity while reducing costs.

There are no reviews yet