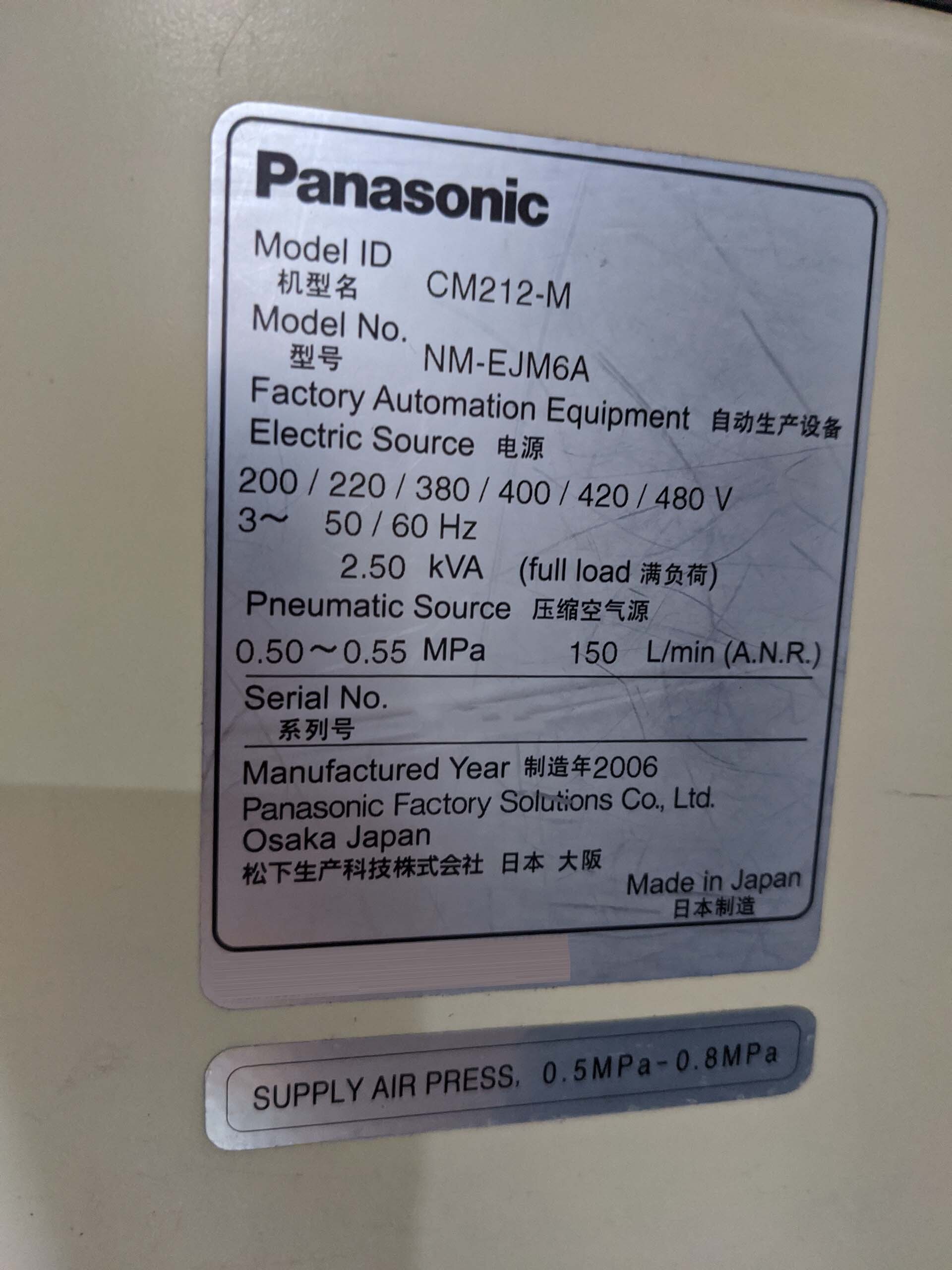

Used PANASONIC CM212-M #293659439 for sale

URL successfully copied!

Tap to zoom

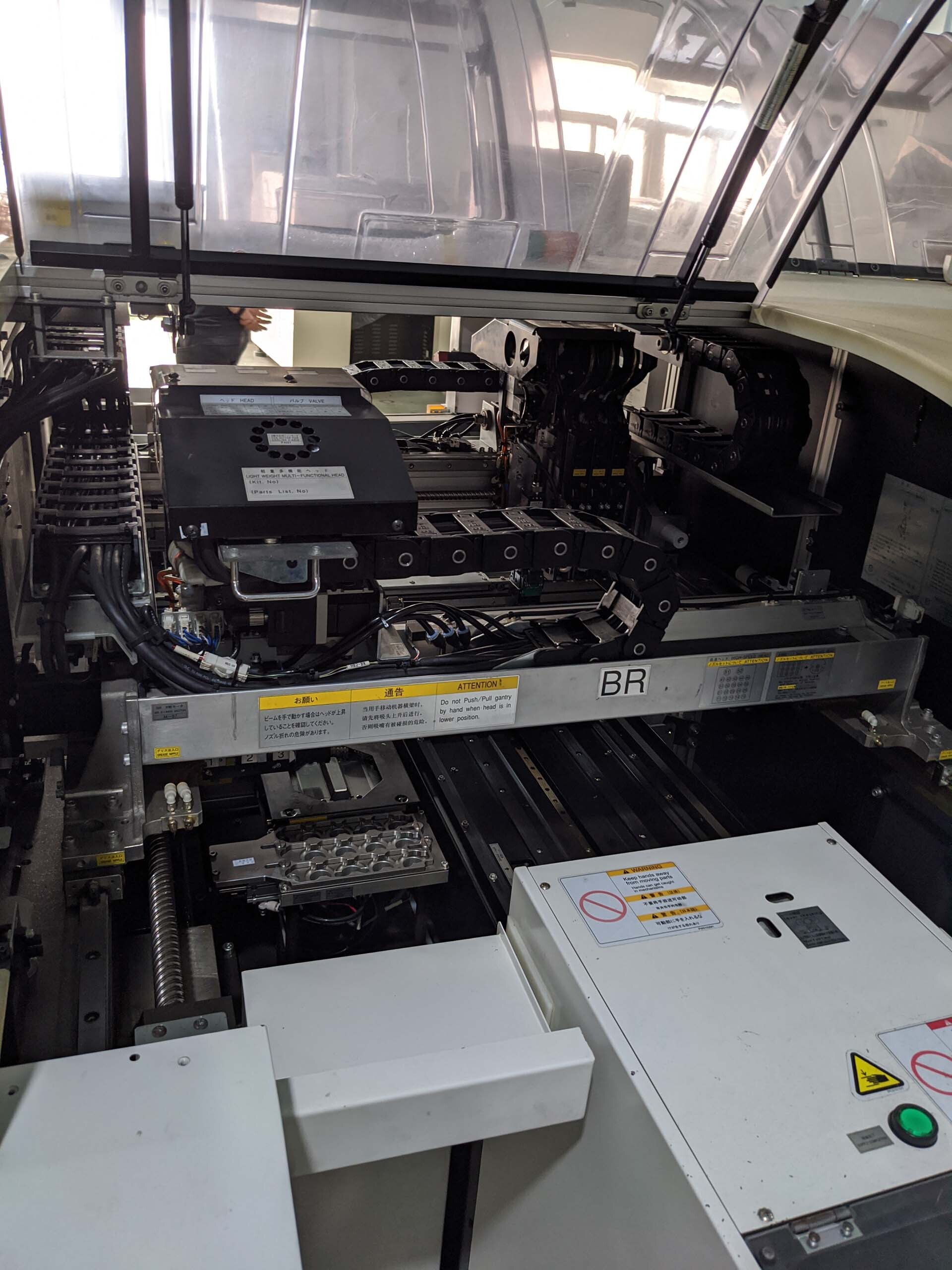

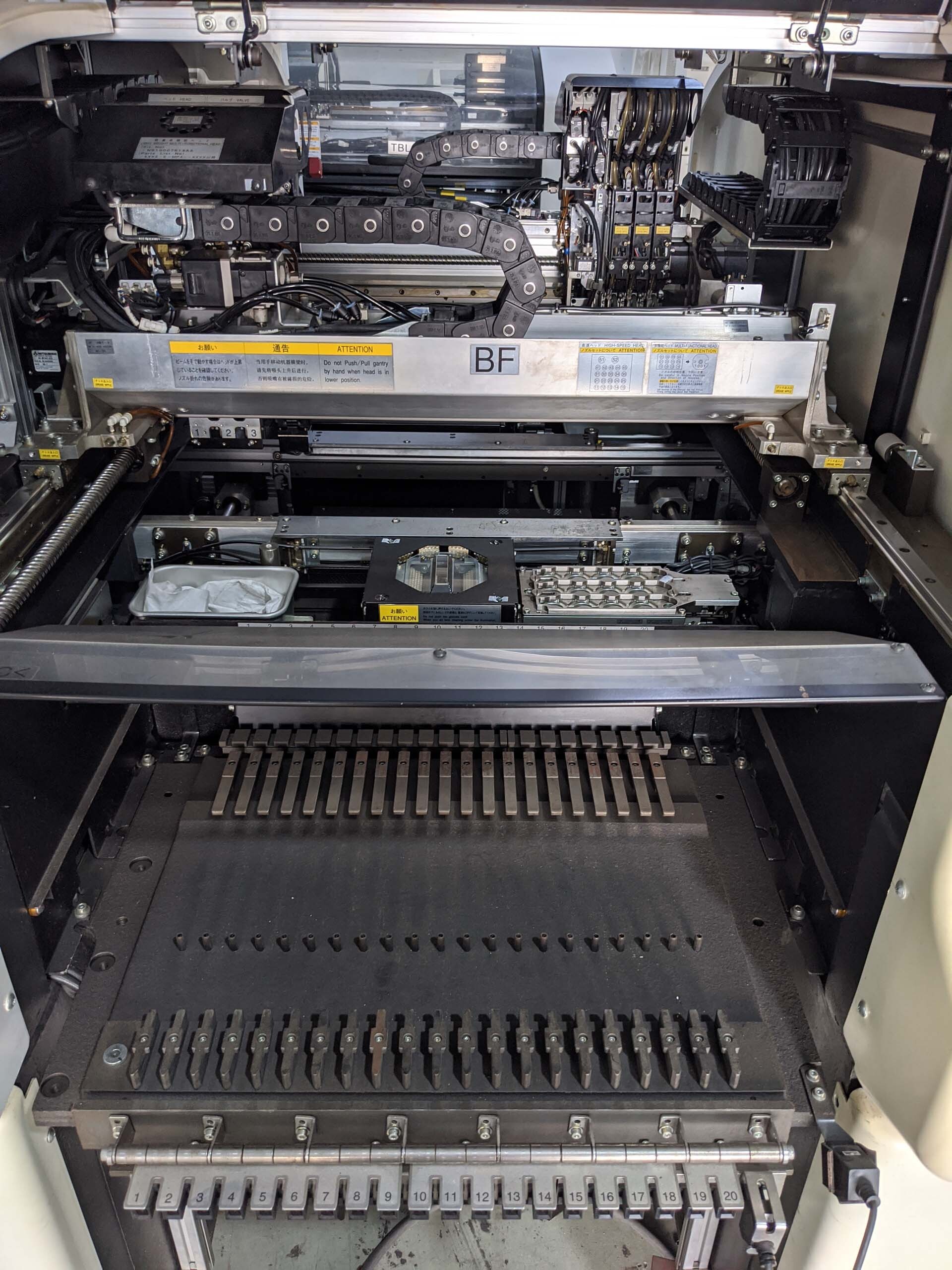

PANASONIC CM212-M is a comprehensive PC board assembly and manufacturing equipment from Kenmore. The system leverages advanced robotic pick modular placement technology to enable more efficient and reliable assembly of PC boards. The unit is equipped with storage for up to 5000 components, offering increased flexibility and efficiency in assembly processes. Multi-function placement heads are designed to provide high speed and precision in replacing electronic components, while providing highly accurate control during the assembly process. These advanced placement systems also have the capacity to detect conflicting component placement, as well as component follow-up functions to prevent overlaps between different layers of soldered joints. The machine is equipped with a multi-function transport tool consisting of multiple input and output conveyors, making it easy to achieve continuity of production from the input of parts to the outfeed of finished products. A double head component checker allows the placement data to be checked and verified for accuracy prior to placing components onto the PC board. Additionally, a component score mode is available for use during testing that results in more accurate and consistent diagnostics. PANASONIC CM212M offers a full range of high-speed production capabilities and highly precise production accuracy. Placement accuracy is provided at 0.08mm for standard components, while chip components can be placed with an accuracy of 0.05mm or better. With a placement speed of up to 6,000 CPH, the asset can accommodate production demands from low- to mid-volume applications. The model is also designed for maximum production efficiency, with built-in function for automatic startup, Automatic Feeding, Automatic Component Checker, Automatic Placement, and Automatic Oscillation Unload. The Visual Teach mode can also be used to ensure materials are placed consistently and correctly. In addition to its efficient production, CM212-M also offers a comprehensive set of post-processing capabilities, such as the Off-Axis Compatibility Mode for picking up misprinted components, Off-Axis Bias Adjustment for providing bias during placement, and Anti-Stiction Correction which ensures that components with thin pins do not stick to the head during placement. A built-in lead inspection equipment allows you to accurately detect component position deviations, while Unload Vibration helps release the components from their feeders accurately and quickly. Overall, CM212M is an advanced assembly and manufacturing system that offers precise production accuracy, maximum efficiency, and comprehensive post-processing for improved reliability and quality control. Whether you're looking for requirements in low- to mid-volume applications or for faster time to market with a quality product, PANASONIC CM212-M is the right choice.

There are no reviews yet