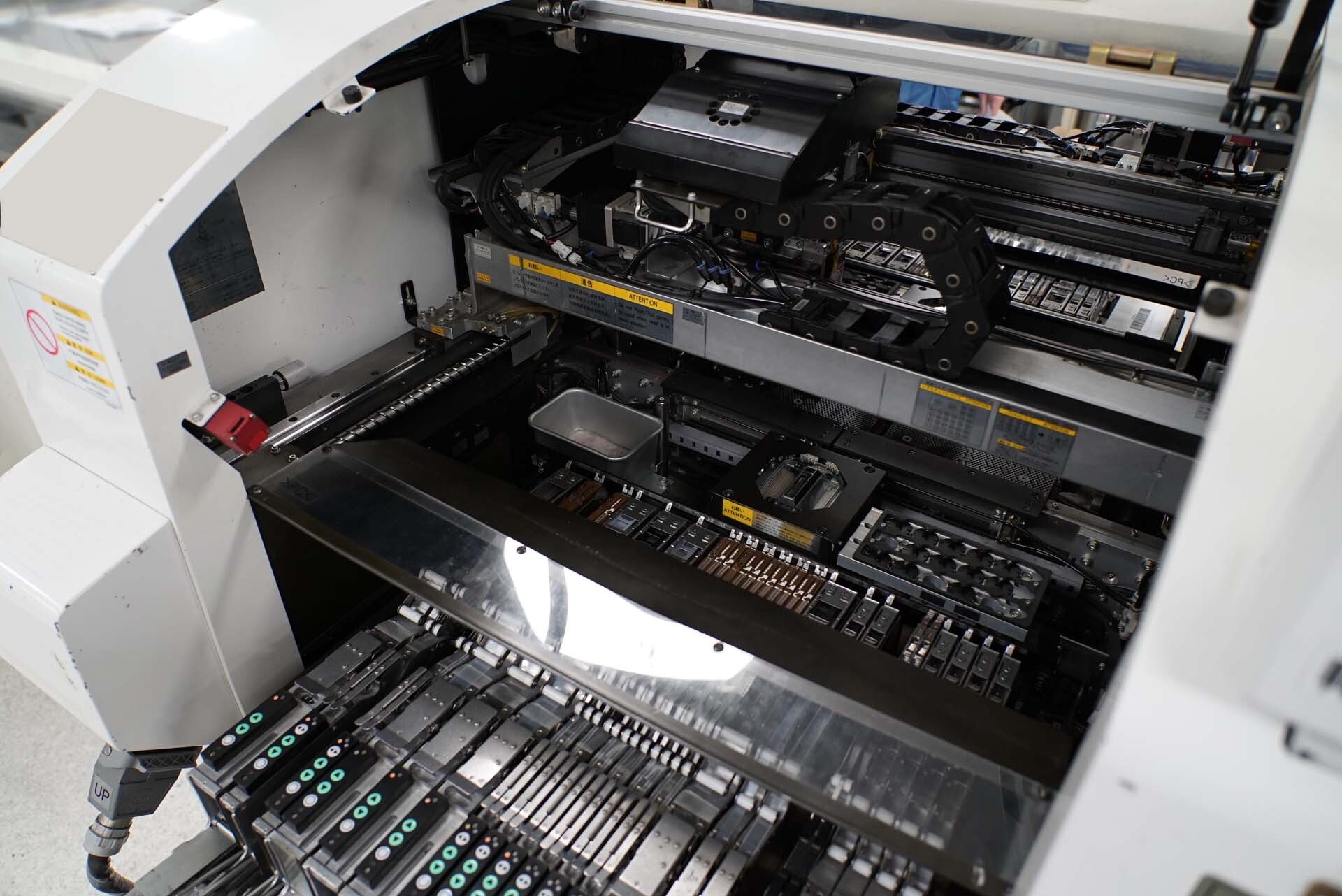

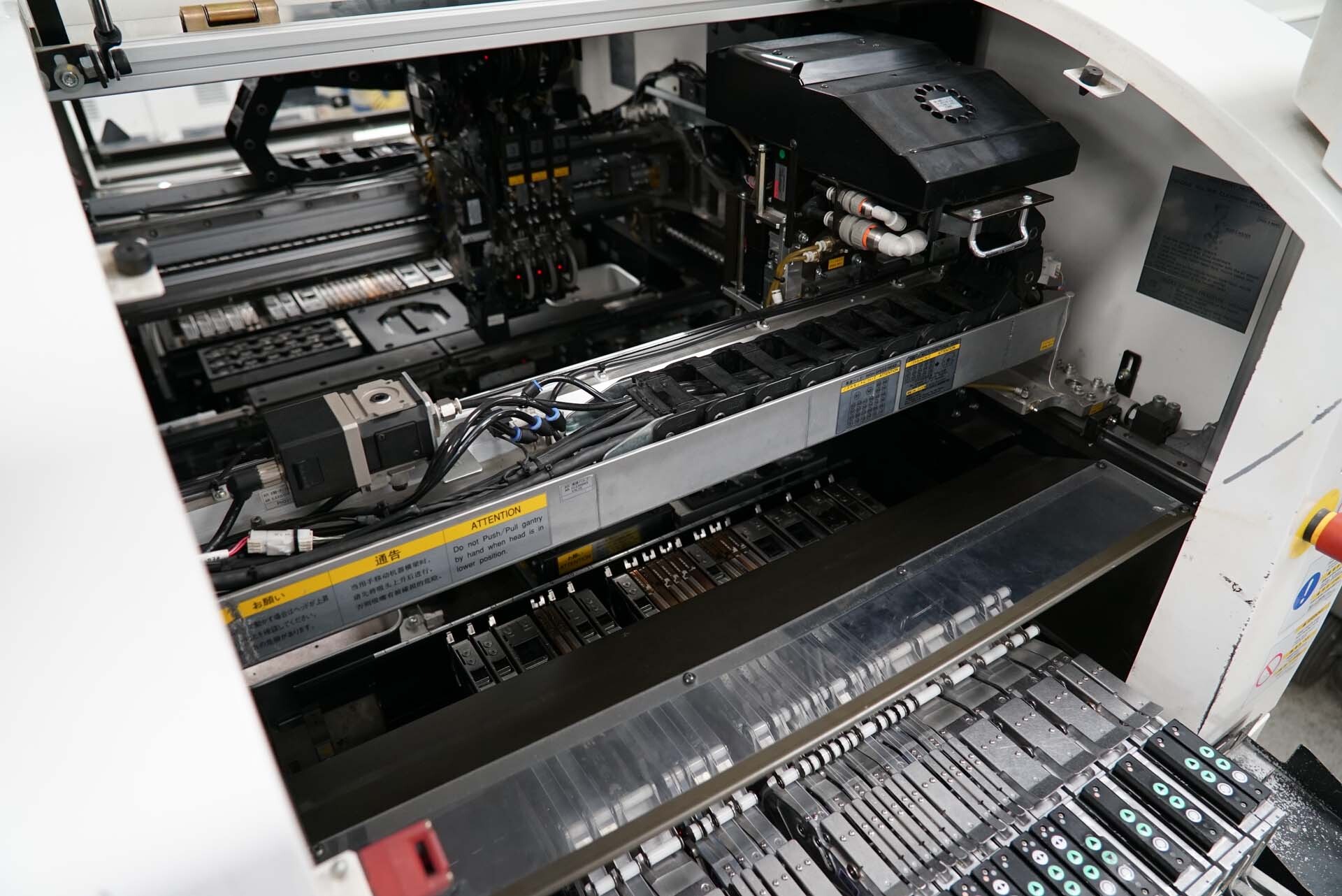

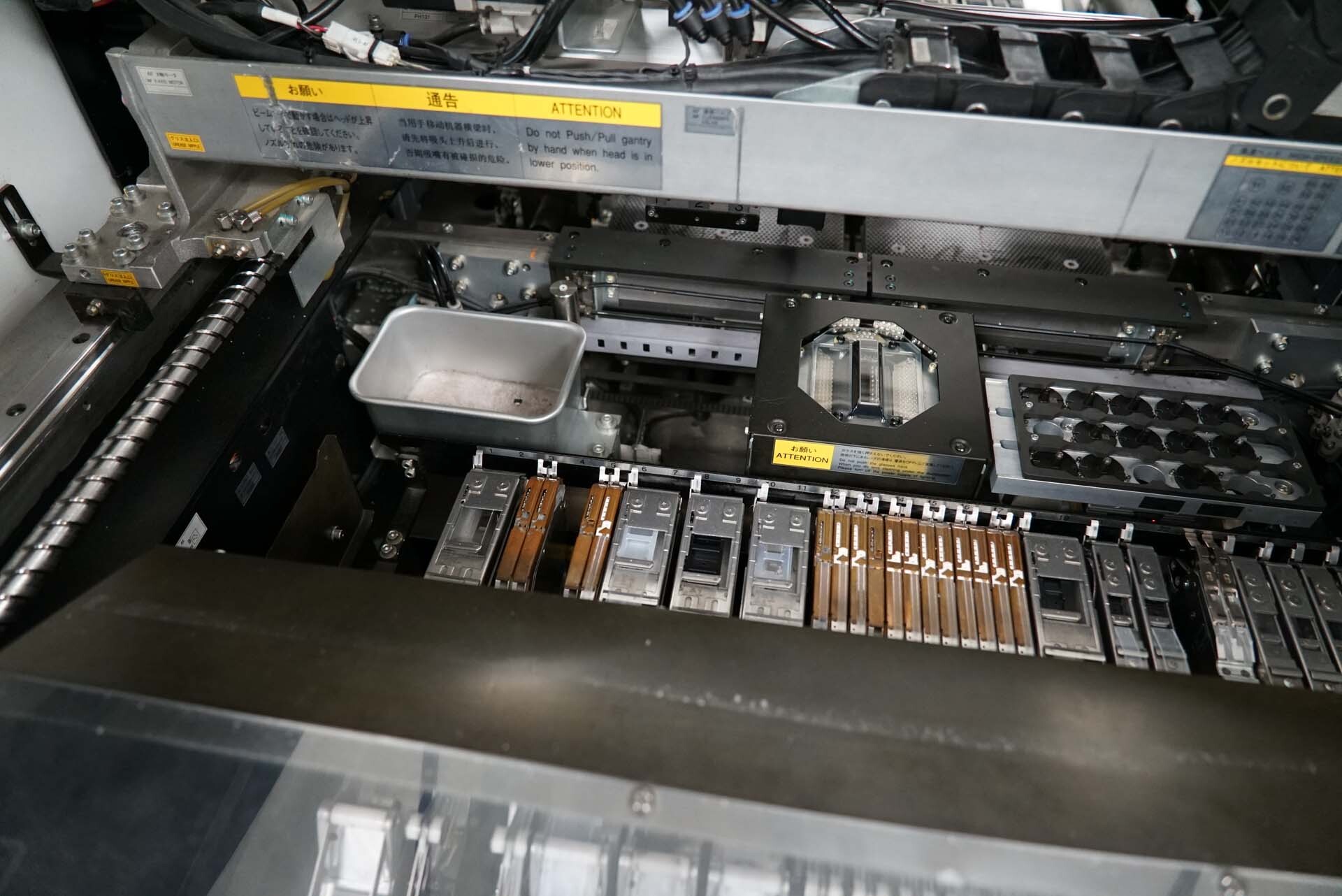

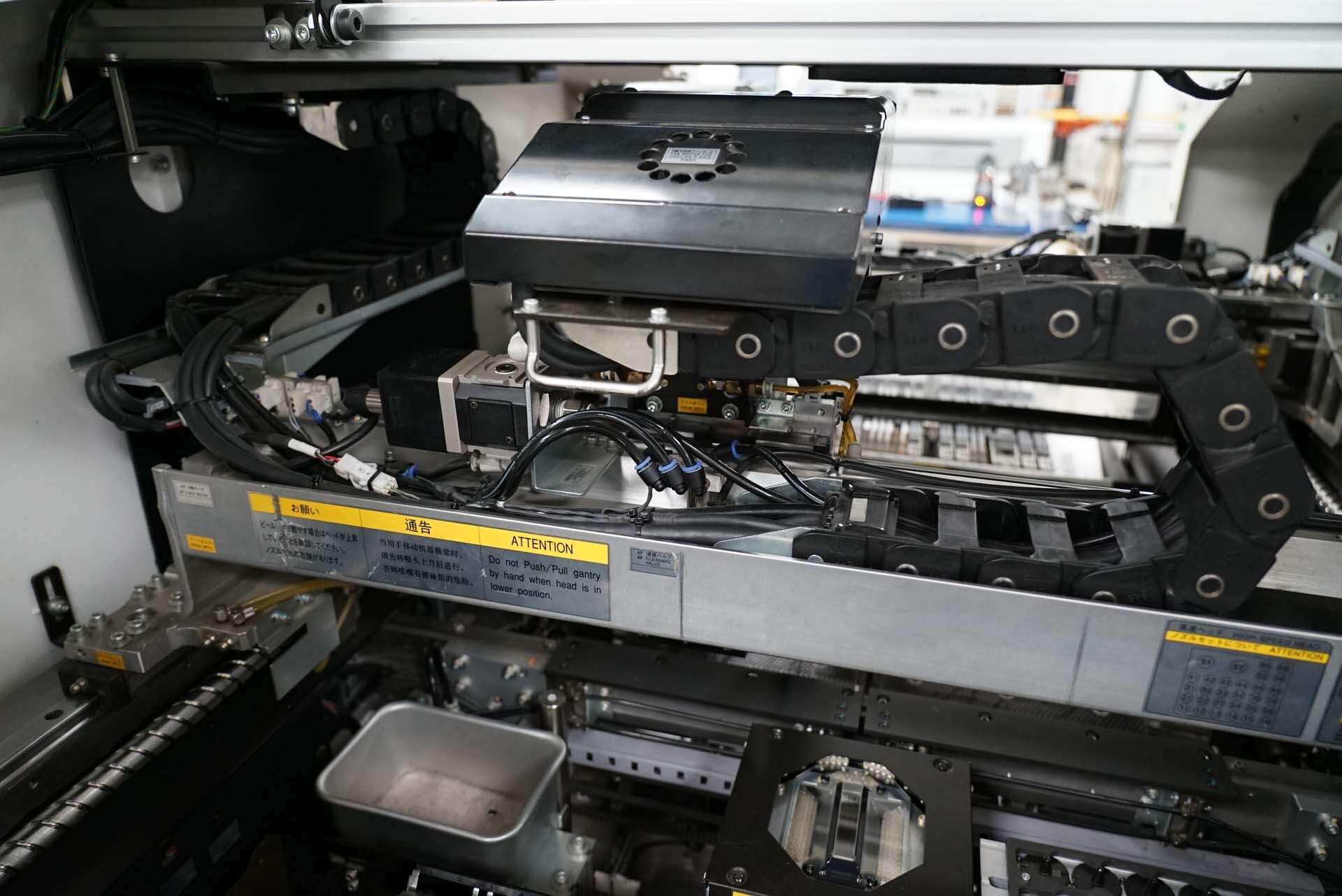

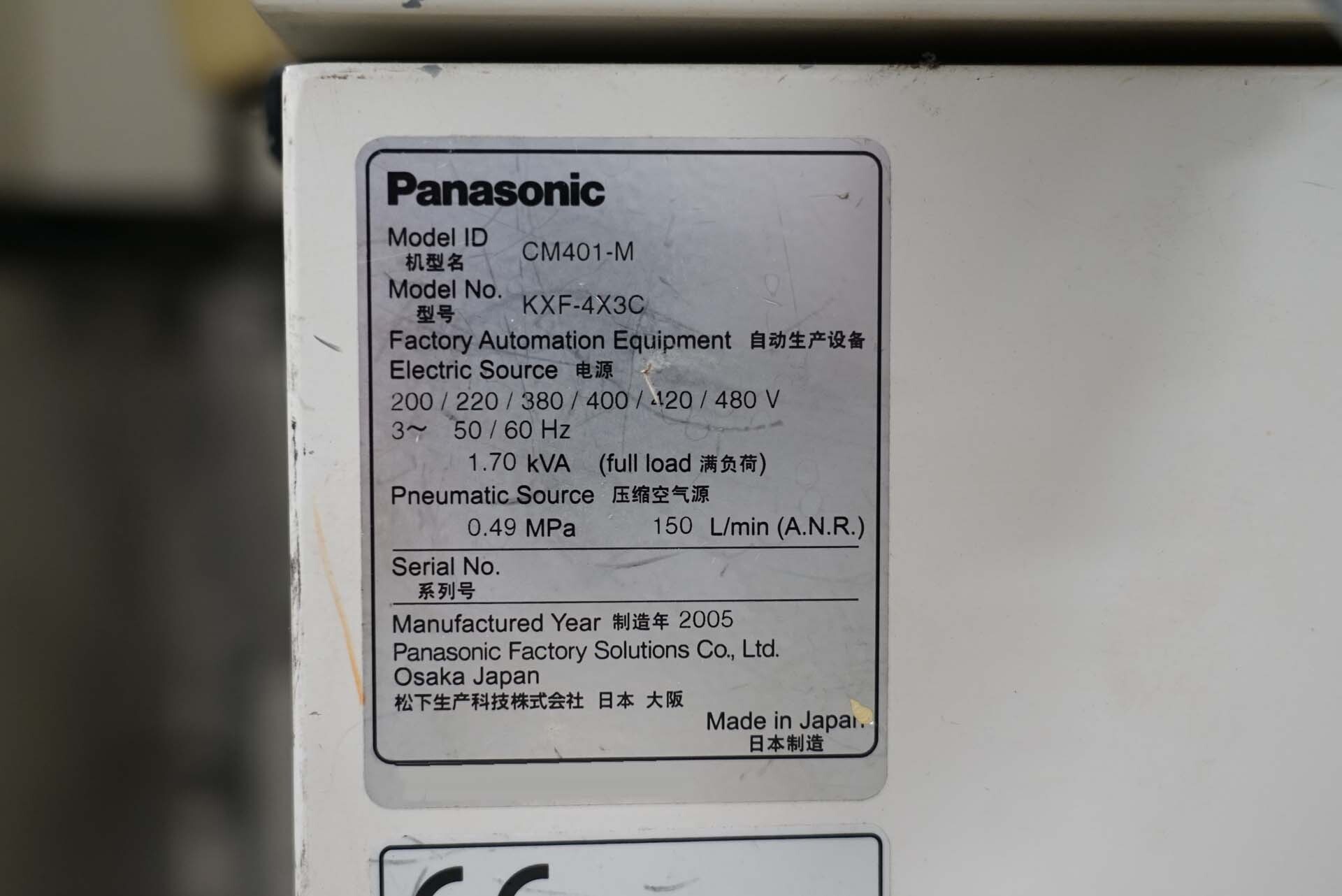

Used PANASONIC CM401M #9390011 for sale

URL successfully copied!

Tap to zoom

ID: 9390011

Vintage: 2005

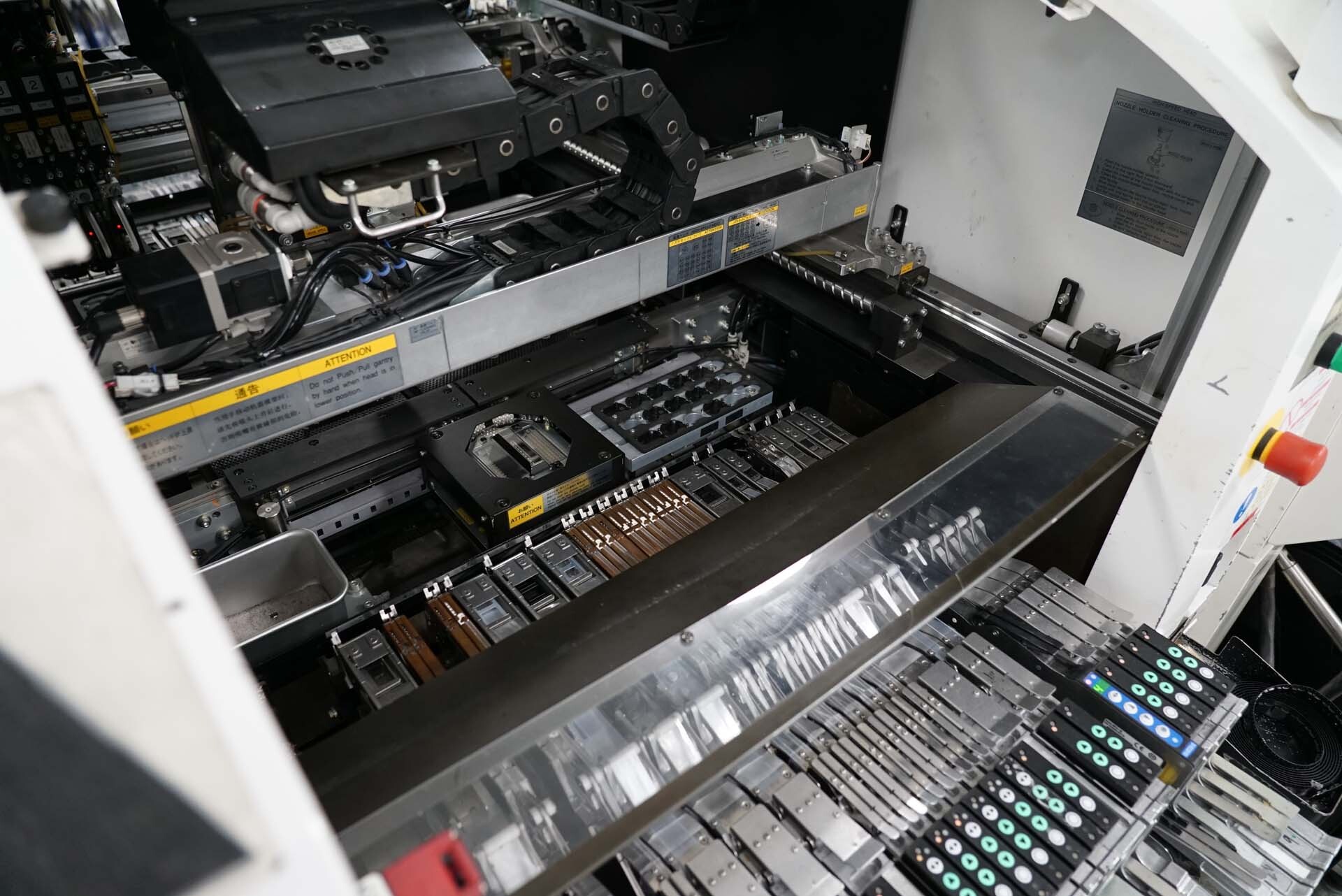

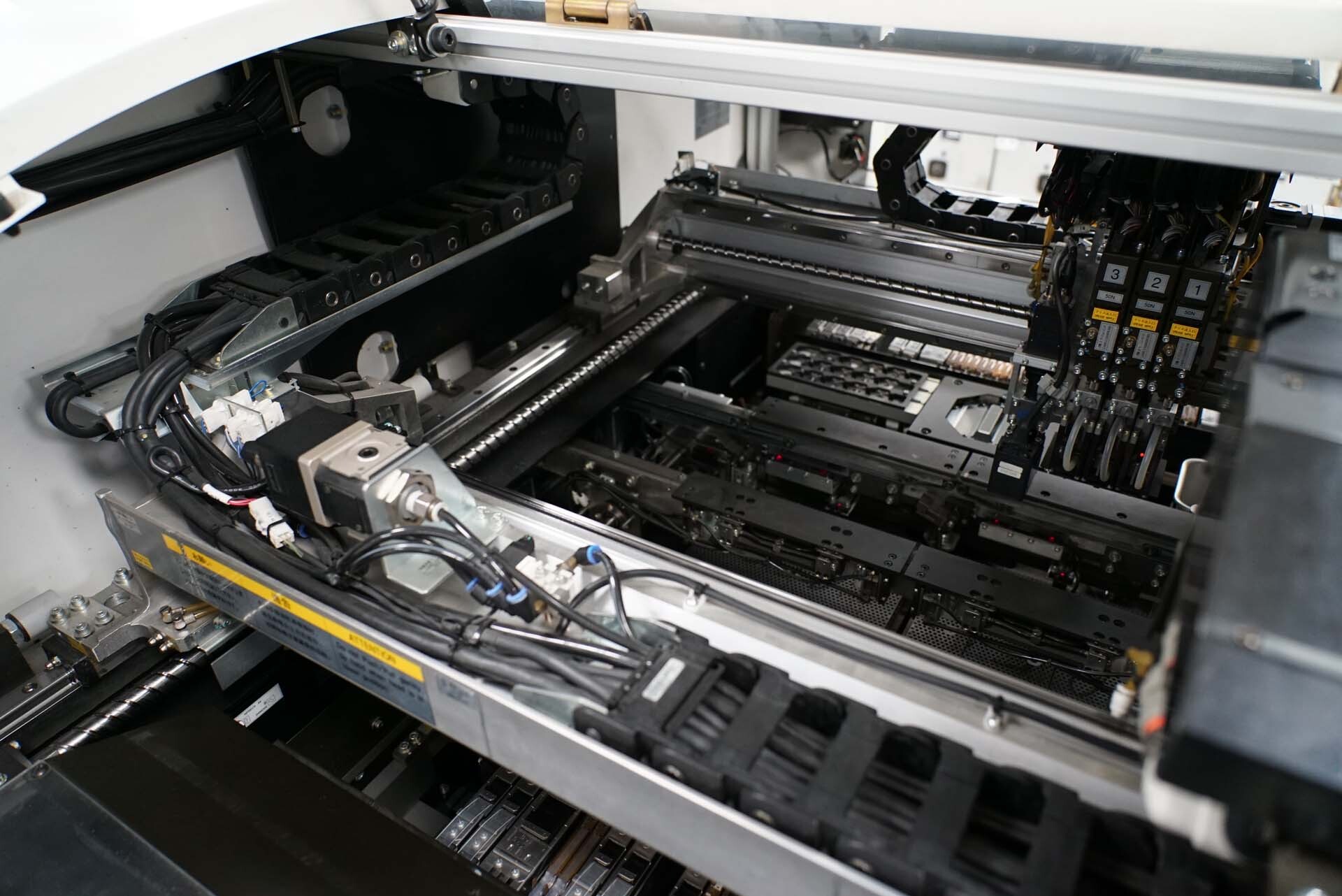

Pick and place machine

Model no: KXF-4X3C

Stage A: 3" x 3"

2005 vintage.

PANASONIC CM401M is an advanced pc board assembly and manufacturing equipment designed for ease of use while providing advanced technology and faultless accuracy. It features industry-leading manufacturing speed of 15,000 cph (components per hour) and supports a wide variety of components from 01005 to 12mm x 12mm. It is equipped with intelligent vision systems that can easily identify and analyze shapes and features of components. This advanced system is capable of high-density flip chip placement and high-precision flexible cable placement, eliminating the need for manual handling. PANASONIC CM401-M is equipped with a dual head soldering process which allows for dual simultaneous assembly, increasing assembly speed and accuracy. It also features a high-precision vision unit that is capable of detecting small components and identifying their exact position. This machine allows for higher quality and greater accuracy when soldering components in place. The tool also features a high-precision automatic alignment asset which optimizes productivity and ensures accurate placement of components. The model is equipped with a 100% component placement accuracy guarantee, which ensures that every component is placed in its designated position. The highest placement accuracy that can be achieved is 98.7% and this is done by using the linear guide equipment which is precise enough to measure and analyze the space between components. The system is also equipped with an intelligent feeder unit that increases testing and maintenance operations efficiency. This intelligent feeder machine uses SWIR (SMA Wave Indicated Receiver) and FWH (Ferrule Wave Hole) technologies to identify components on the workpiece and select the appropriate component precision. It can be used for both in-line and stand-alone operations, providing flexibility and convenience for handling various components. The innovative design also allows for compatibility with diverse PCs, reducing the need for manual re-configurations. It is also compatible with a range of software programs and protocols such as Gerber, ODB++, RS232/BCD, TCP/IP, and AUTO-CU. Furthermore, this tool supports both barcode reading and tool identification making it even easier to identify parts. This advanced asset is capable of handling a variety of processes such as conventional soldering, hot bar soldering, video recognition, ICT (In Circuit Test) and complex reflow processes. With its rugged construction, high-precision optics and cutting-edge vision sensors, CM401M model is capable of handling a variety of electronic and manufacturing processes. This versatile equipment is the perfect choice for high-volume manufacturers who require a reliable and efficient system.

There are no reviews yet