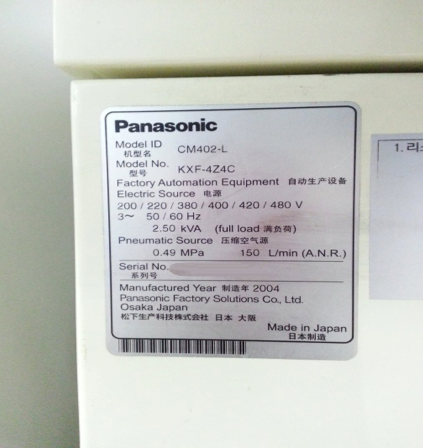

Used PANASONIC CM402-L KXF-4Z4C #9038035 for sale

URL successfully copied!

Tap to zoom

ID: 9038035

Chip mounter

Tact time: 0.06 sec/chip (head), 0.21 sec/QFP (head)

Centering: upward vision

B'd change time: 0.9 sec

Size: max 510 x 460 mm, min 50 x 50 mm

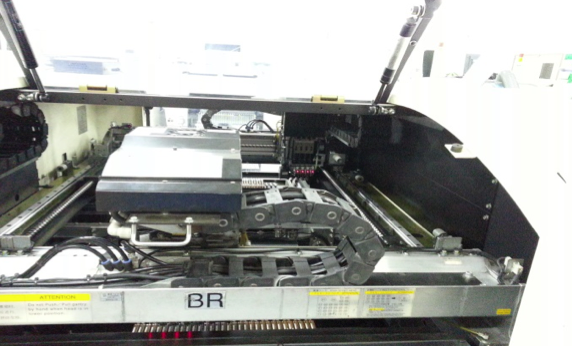

Feeder station: 48 stations (double feeder 96 station)

Feeder: 8~72mm tape, bulk, vibration feeder, tray feeder

Conv. transfer: right to left (left to right: op). Front fix (read fix: op)

Power: AC200V, 3 Phase, 50/60 Hz, 2.5 kVA

Air: 0.5MPa 150L/min

2004 vintage.

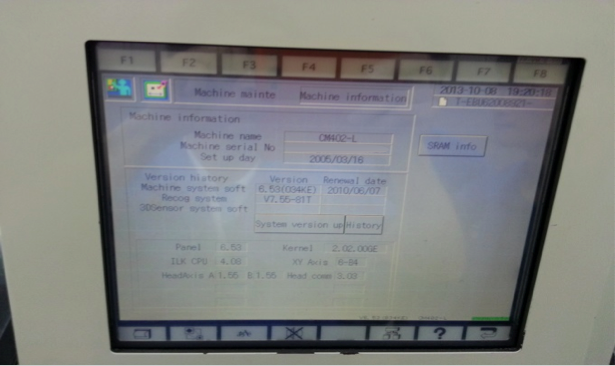

PANASONIC CM402-L KXF-4Z4C is a highly advanced PC board assembly and manufacturing equipment built with the highest levels of precision and accuracy. The system is comprised of several sub-systems, the most important being its placement head, which is equipped with 8 independent heads and capable of placing up to 8000 components per hour with a positioning accuracy of +/- 0.02mm. Additionally, the unit is outfitted with an intelligent placement head machine that offers a high level of flexibility, enabling each multi-tasking head to autonomously select components from the machine's 28 external and 4 internal feeders. This is further augmented by a board recognition tool, allowing the asset to accurately identify and position components on the PC board. In addition to its placement head, the model includes an ingenious optical recognition-based options, which allow it to read component codes using either laser or CCD cameras. This feature allows the CM402-L to verify components and detect misplacement scenarios, ensuring that only correctly placed components are integrated into the PC board. Furthermore, the equipment includes a built-in buffer system that offers the flexibility to manage up to 22 different frames with up to 8 different components on each frame. This ensures that even the most complex designs can be accommodated without compromising the unit's precision. Moreover, the machine includes an intuitive and highly-engineered software package that enables users to easily operate the machine without advanced training. This software package allows users to input recipes, manage frames with differing components, and check and validate the tool's production data. This software is further supplemented with a comprehensive Library function that automatically records the data from each PC board assembly. Finally, the asset is built with a host of safety features, including safety mats, door locks, and a dedicated soft grip work surface. This ensures that users are kept safe at all times when operating the machinery and that the model itself remains protected from any potential damage. The equipment is further certified by various international bodies for radiated and conducted emission standards. In conclusion, PANASONIC CM402L KXF-4Z4C is a highly advanced PC board assembly and manufacturing system that offers maximal precision, accuracy, efficiency, and safety. Its combination of advanced components and an intuitive software package grant it the ability to meet any and all of its user's requirements while ensuring that components are placed correctly and safety is always maintained.

There are no reviews yet