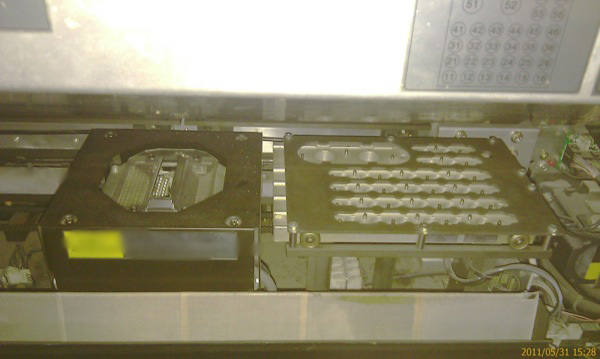

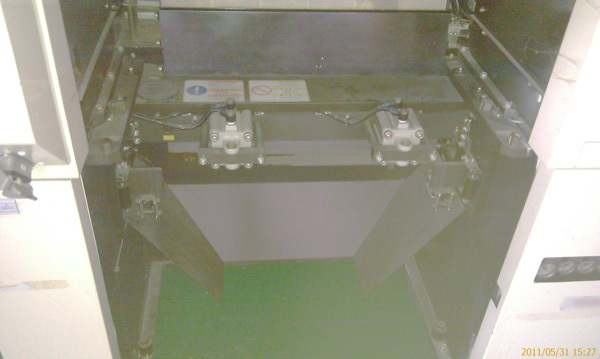

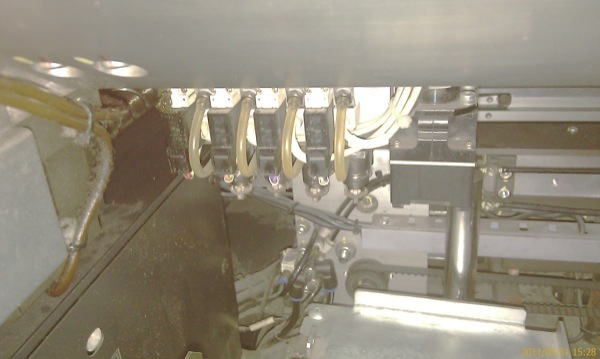

Used PANASONIC CM402 #154408 for sale

URL successfully copied!

Tap to zoom

PANASONIC CM402 is a leading-edge 'pc board assembly and manufacturing' equipment designed for high volume and high accuracy production. It provides exceptional repeatability and cut-through speeds allowing for greater yields and throughput. The system is capable of handling a variety of board sizes and thicknesses, and utilizes several interchangeable, fine pitch heads and an externally driven conveyor unit. The machine boasts a wide choice of different equipment types, enabling it to automate common printed circuit board assembly processes, such as placement and soldering of surface mount components, conformal coating, testing, inspection, and labeling. PANASONIC CM 402 boasts a dual gantry design, featuring two 6-axis robotic arms. This allows it to perform multiple tasks simultaneously and independently, significantly increasing throughput and yields. It is also equipped with a quick-change head machine, allowing the user to quickly and easily switch the equipment used for different production stages, such as SMT, AOI, and Soldering. This versatility greatly reduces down time for maintenance and refitting, further increasing productivity. In addition, CM402 is designed with an advanced Vision Tool for accurate vision-guided placement and inspection. The Vision Asset accurately detects and identifies components in order to accurately place them with near zero errors. It is also able to detect faults, short circuits, and mis-placements, significantly reducing the rate of rejects and therefore increasing yields. Furthermore, CM 402 is designed with integrated safety protocols, providing operators and employees with peace of mind when working with the machine. The safety protocols include the ability to detect abnormalities, sensors to detect unintentional opening or closing of the door, and lockout features that disable problem areas. Overall, PANASONIC CM402 is a reliable, high-precision pc board assembly machine that provides a simple and efficient way for manufacturers to quickly and accurately produce high-quality printed circuit boards. With its dual gantry design, quick-change head model, vision equipment, integrated safety measures and high repeatability, this machine is ideal for high volume, high accuracy production.

There are no reviews yet