Used PANASONIC CM402L #9156367 for sale

URL successfully copied!

Tap to zoom

ID: 9156367

Vintage: 2003

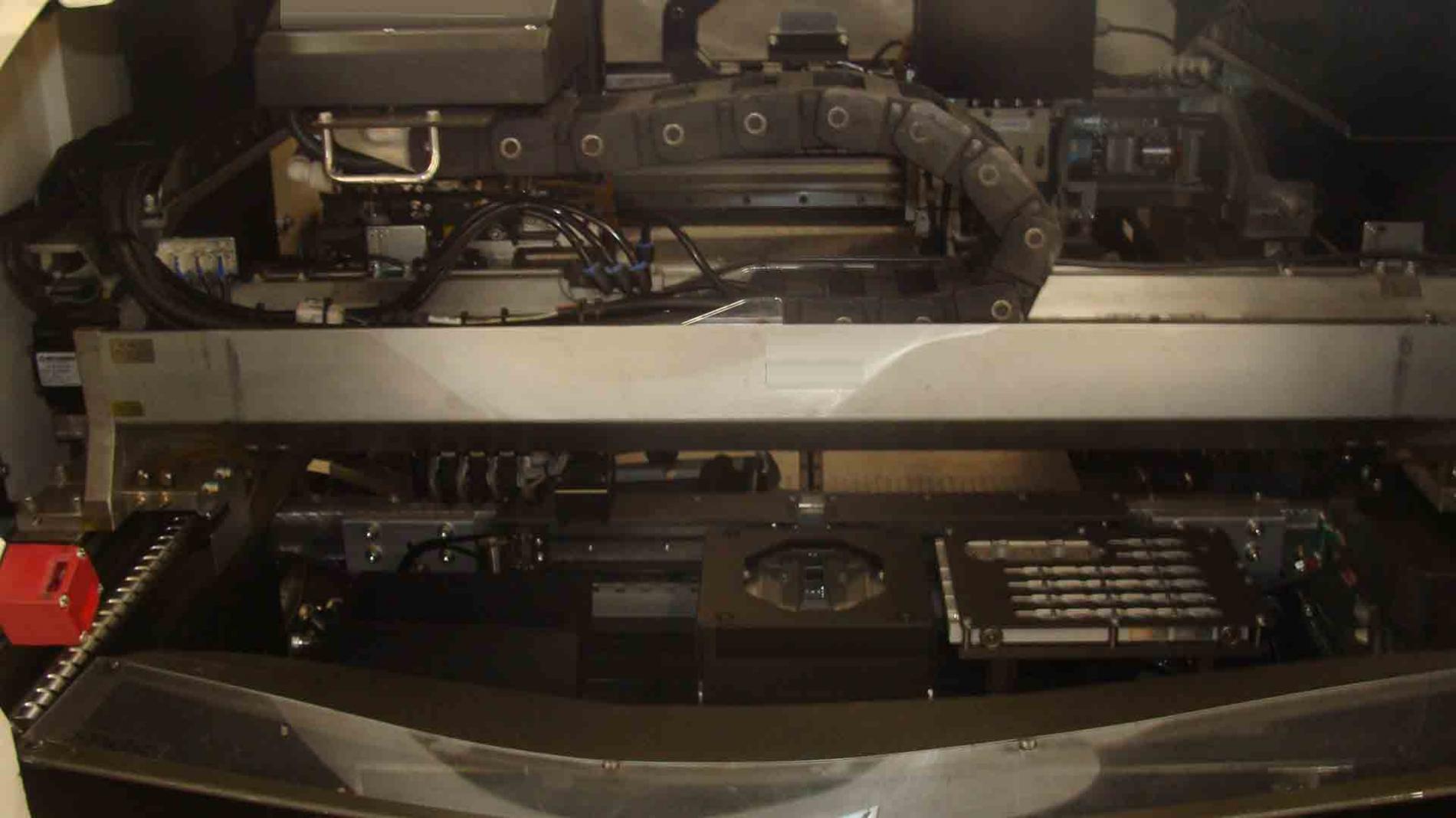

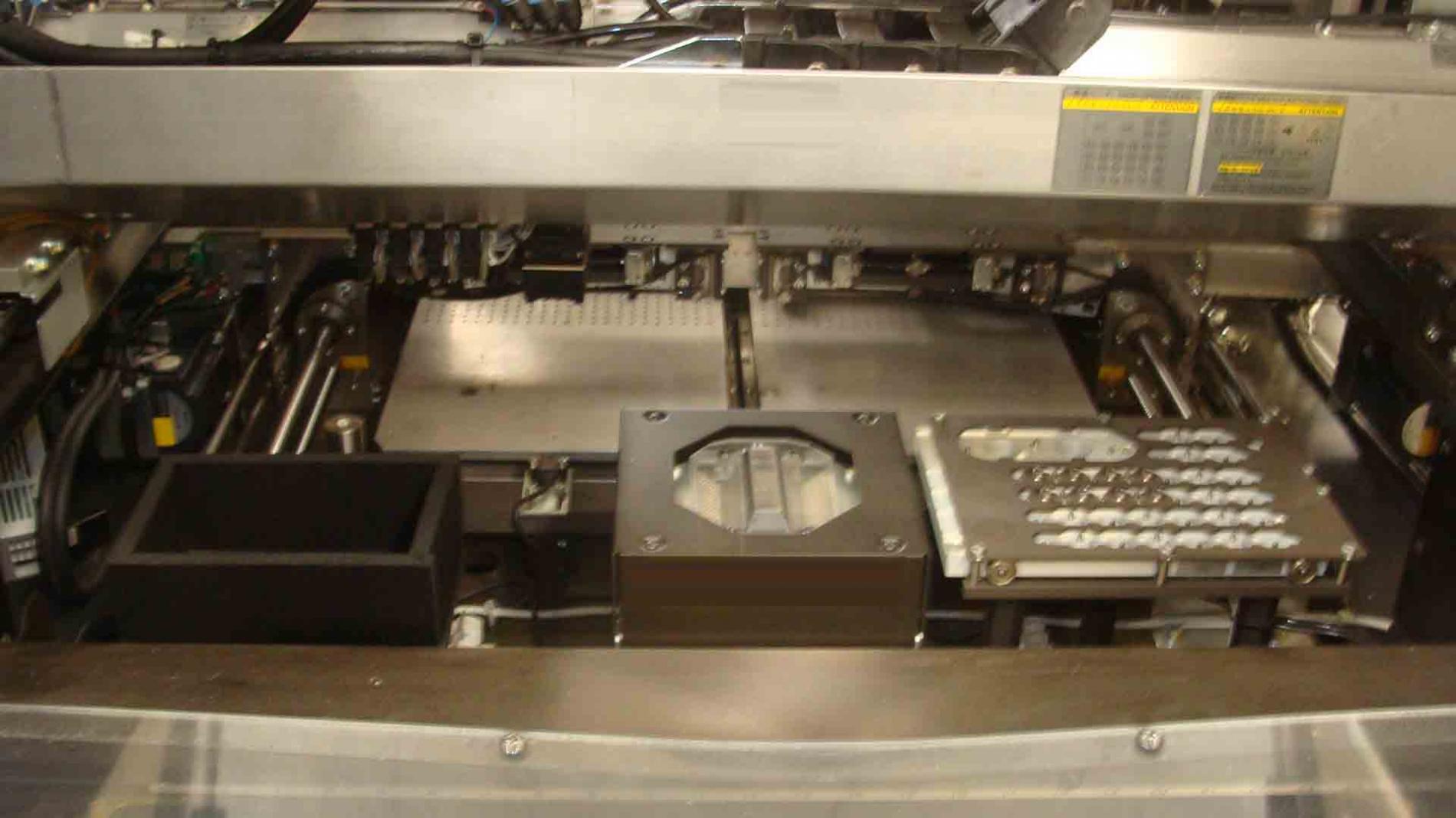

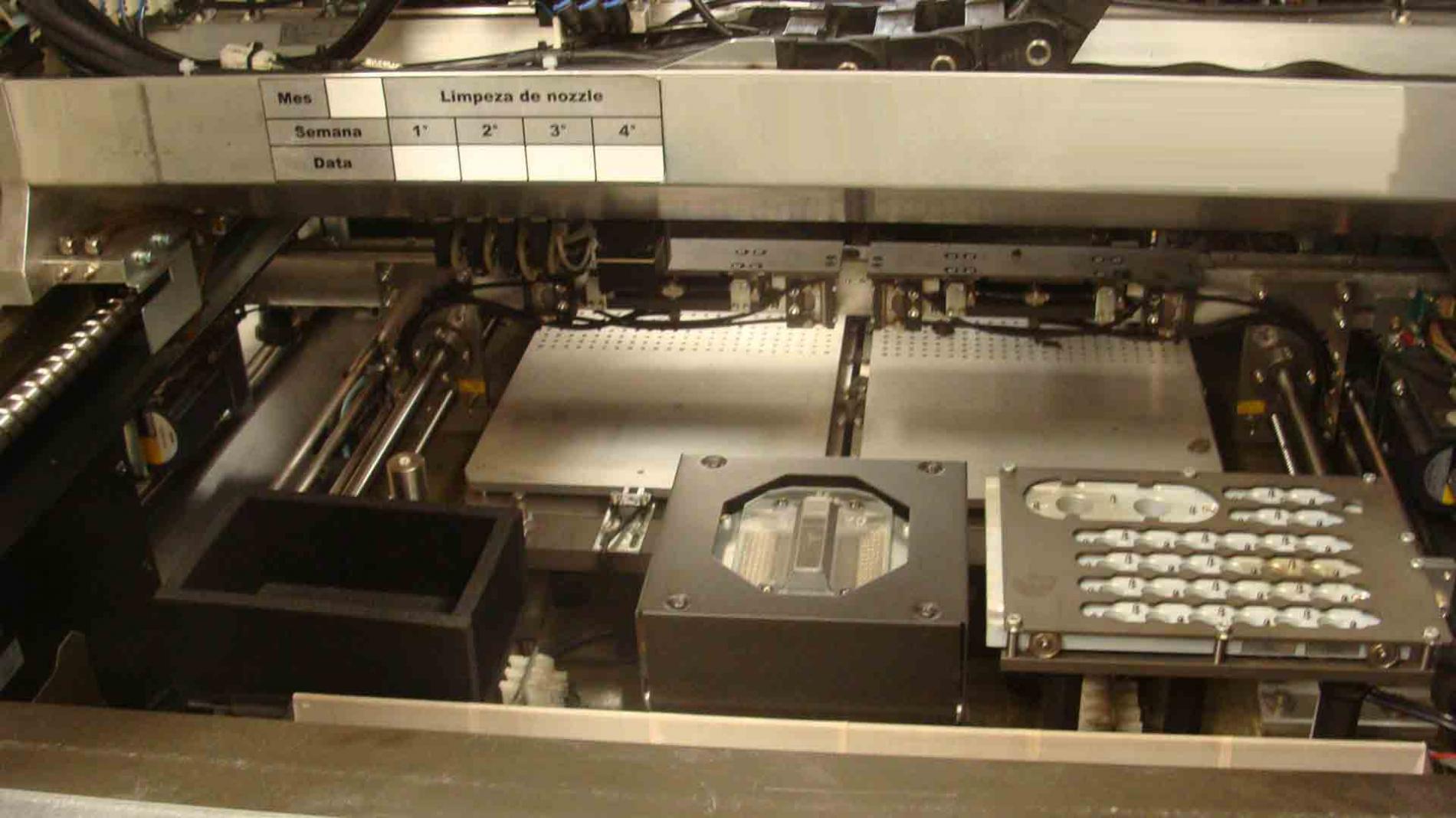

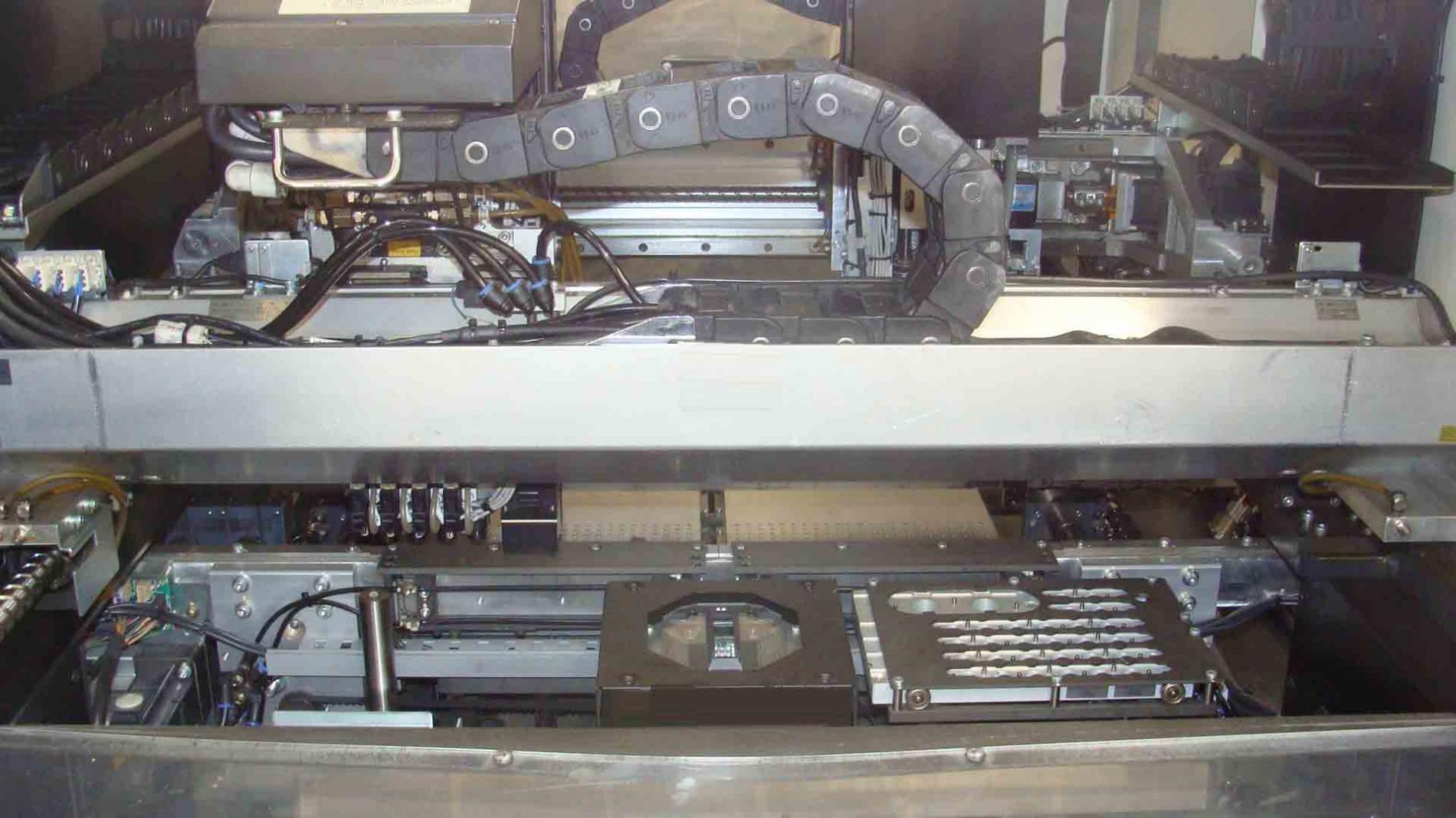

Pick & place machine

(4) Feeder carts

Nozzle and nozzle holders: No

2003 vintage.

PANASONIC CM402L is a high-precision, PC board assembly and manufacturing equipment designed to increase productivity and reduce scrap rates. This PC board assembly and manufacturing system has a range of advanced features including Integrated Intelligent Component Placement (ICP) heads, a high-speed axis conveyor, PCB camera inspection unit, and Real-time Component Imaging Machine (RCIS). The ICP heads on PANASONIC CM 402L allow for placement of components at speeds up to 50,000 components per hour. The heads come with a variety of interchangeable nozzles and feeder systems to meet the requirements of a wide variety of board configurations, including both matte and glossy finishes. The high-speed axis conveyor of the tool increases throughput by increasing the number of components that can be placed onto a handful of boards simultaneously. This also helps to reduce the chances of any asset downtime due to high board throughput rates. The camera inspection model of CM402-L comes with a range of camera stilts and an improved vision lens to provide continuous monitoring of the workpiece during all stages of assembly. The Real-time Component Imaging Equipment (RCIS) also enables the operator to detect any component misalignment, which can then be corrected quickly. This helps to improve product quality and decrease overall scrap. PANASONIC CM 402-L also provides automatic PCB tracking, which eliminates the possibility of incorrect circuit board placement. This system also provides automatic component polarity recognition, which ensures that any negative and positive components are placed in the correct orientation. Finally, CM 402-L is equipped with a built-in expert unit which provides real-time feedback on component performance and operator progress in order to ensure maximum efficiency. To sum up, CM402L is a highly advanced, high-precision, PC board assembly and manufacturing machine designed to increase production and reduce the chances of scrap. It has a range of features such as integrated intelligent component placement heads, a high-speed axis conveyor, PCB camera inspection tool, and Real-time Component Imaging Asset (RCIS) which make it one of the most advanced systems on the market. All these features combine to make PANASONIC CM402-L one of the most efficient and reliable PC board assembly and manufacturing systems available today.

There are no reviews yet