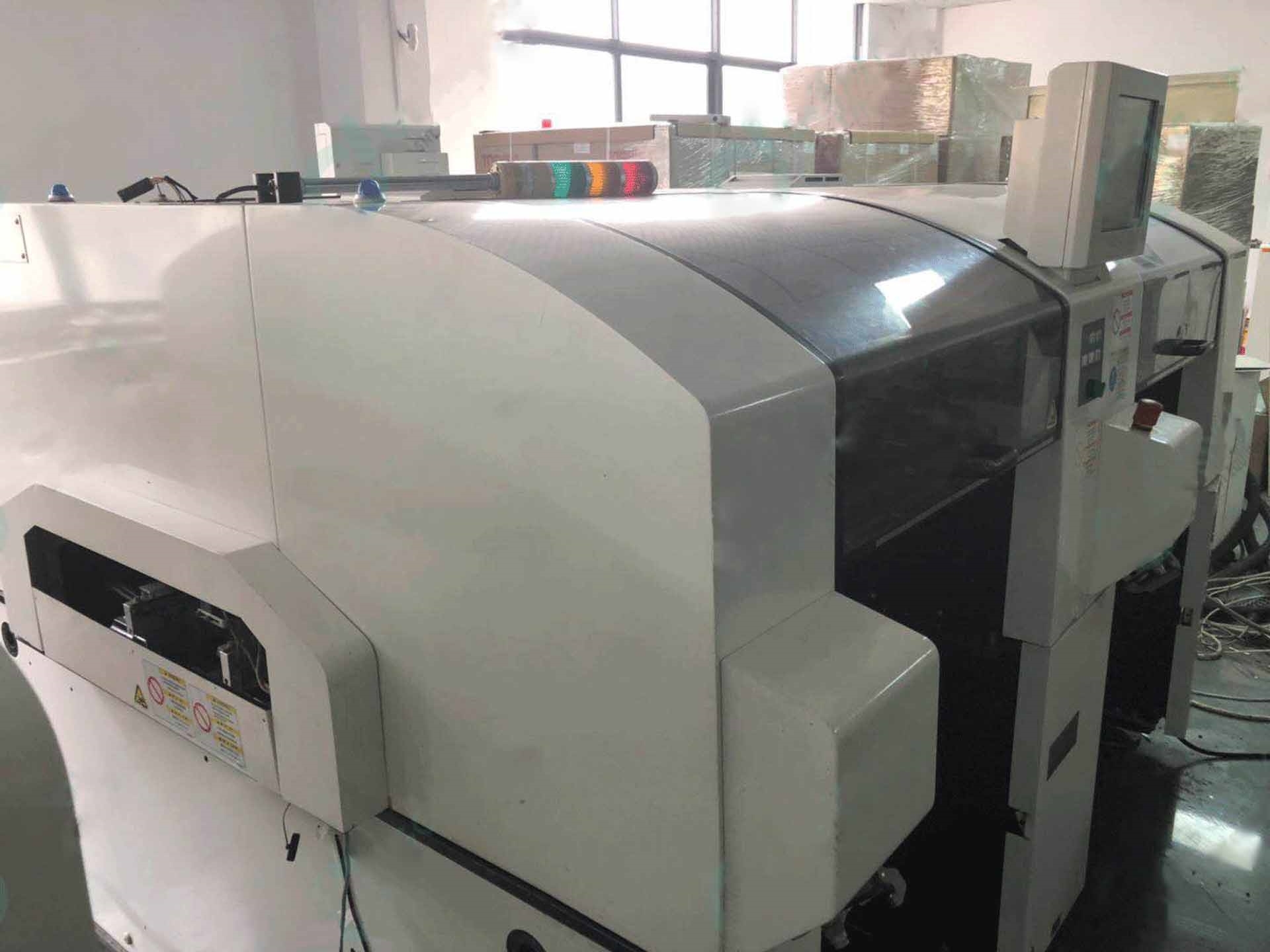

Used PANASONIC CM402L #9231036 for sale

URL successfully copied!

Tap to zoom

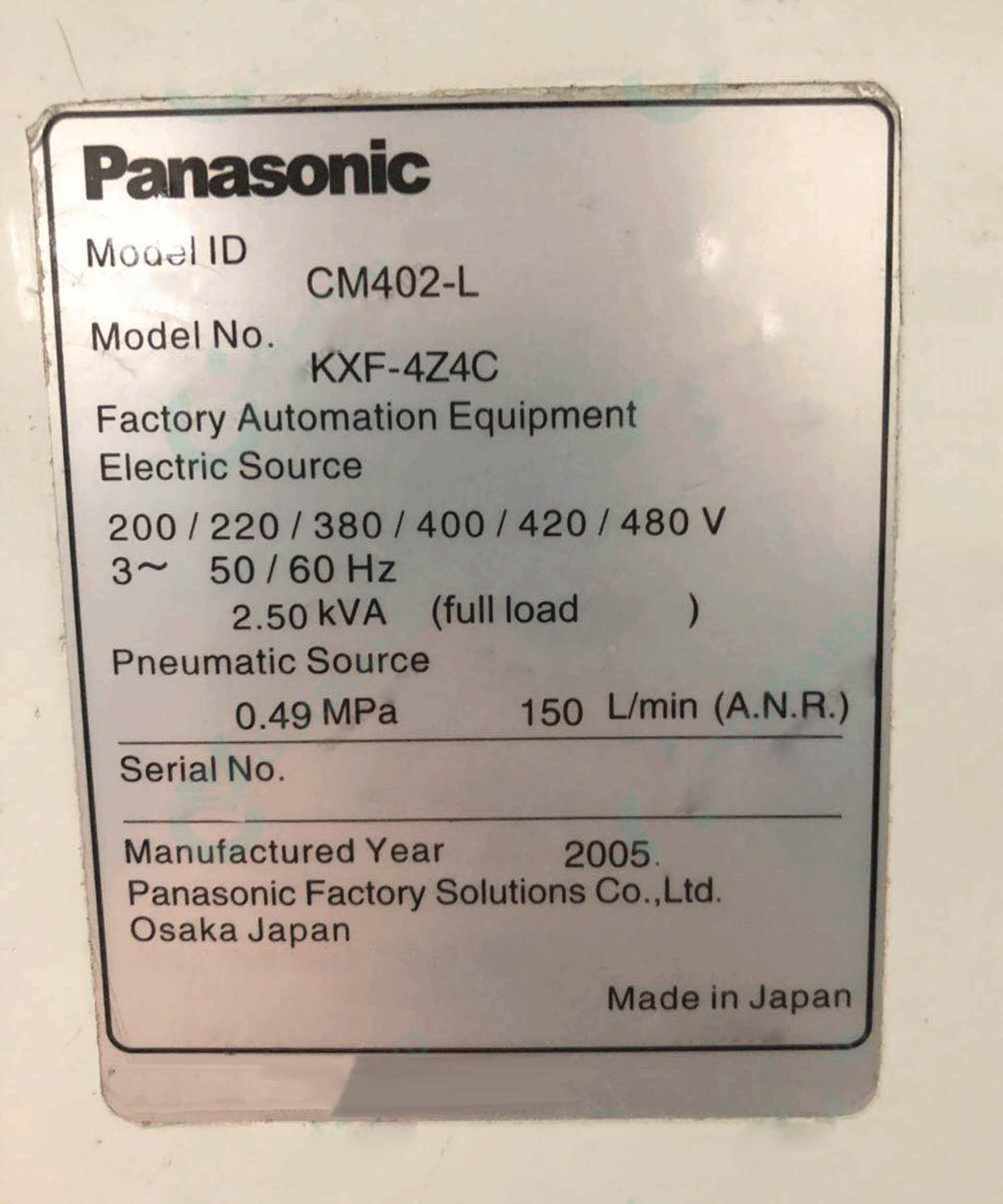

ID: 9231036

Vintage: 2005

Pick and place machines

Model number: KXF-4Z4C

Head type: A-2 (12/12 Nozzles high speed)

Number of nozzles: (12) Nozzles / head

Maximum speed: 0.052 s / chip (69,500 cph)

Placement accuracy: ±40 um / chip

Head type: 8+3 Multi function

Number of nozzles: (3) Nozzles / head

Maximum speed: 0.21 s / QFP (17,140 cph)

Placement accuracy: ±0.035 mm / QFP

Head type: 8+8 High speed

Number of nozzles: (8) Nozzles / head

Maximum speed: 0.06 s / chip (60,000 cph)

Placement accuracy: ±50 um / chip

PCB Exchange time: 0.9s (Board length: up to 240 mm)

Pneumatic source: 490 kPa, 150 L/min (Standard, machine body only)

Power requirement: 3 Phase AC 200 V ±10 V / AC 400 V ±10 V, 2.5 kVA

2005 vintage.

PANASONIC CM402L is a PC board assembly and manufacturing equipment that provides superior throughput and unmatched flexibility with its intuitive and expandable design. It integrates advanced manufacturing techniques, automating the entire production process to streamline production cycles and eliminate potential human errors. This system is capable of producing large volumes of high quality PC boards quickly and efficiently, while also providing users with the greatest degree of customization available. The main components of PANASONIC CM 402L include a powerful dual-axis placement head, a high-speed laser cutting unit, and an integrated adjustment module. The dual-axis placement head allows precise placement of components on the board with micro-step positioning and a programmable chip tray. The laser cutting machine delivers precise and fast cutting of PC board contours, while the integrated adjustment module automatically adjusts component pitch. The tool is also modular in design, meaning it can be easily configured for different production runs. It offers a wide range of production configurations, with the ability to be linearly or rotationally oriented, minimize short loops, or make space for extra components. Furthermore, it utilizes a powerful placement algorithm to make optimal component layout, reducing component placement time and increasing throughput. CM402-L also offers quality control and automated testing. Throughout the process, defect detection technology and real-time monitoring can detect anomalies in each product and ensure that only the highest quality-control standards are met. In addition, it is equipped with a powerful PC-controlled machine programming language, providing the ability to quickly customize operations, with the ability to save programs and improve production cycles. The asset also features a user-friendly 10.4-inch touchscreen interface allowing operators to easily monitor the performance of the equipment and make adjustments in real time. Overall, CM 402L PC board assembly and manufacturing model provides incredible speed and accuracy, while maximizing flexibility for complete customization of PC board designs. It ensures high quality results, reduced production cycles, and fewer production defects, all of which lead to improved production speeds and greater throughput. This equipment is a must-have for any company looking for a reliable and efficient way to manufacture high-quality PC boards.

There are no reviews yet