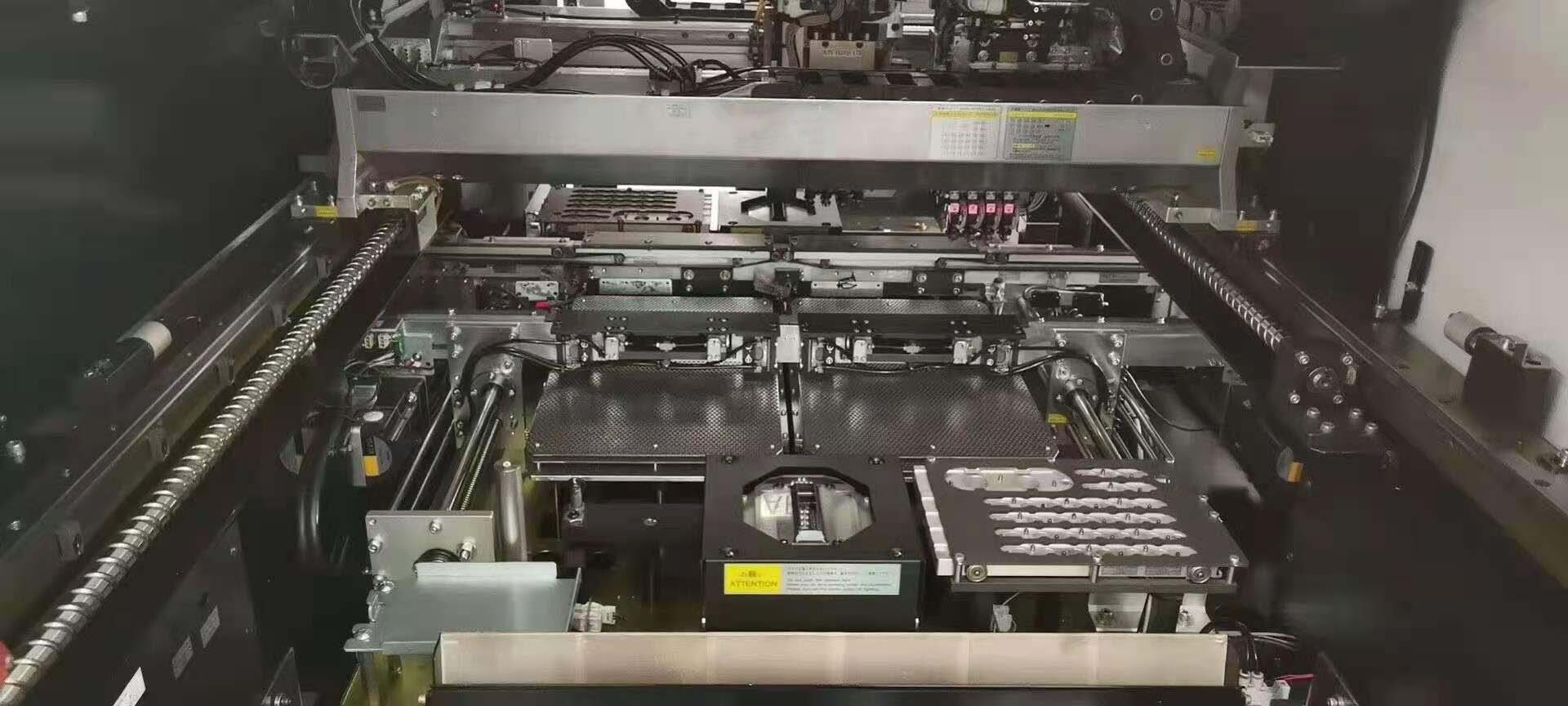

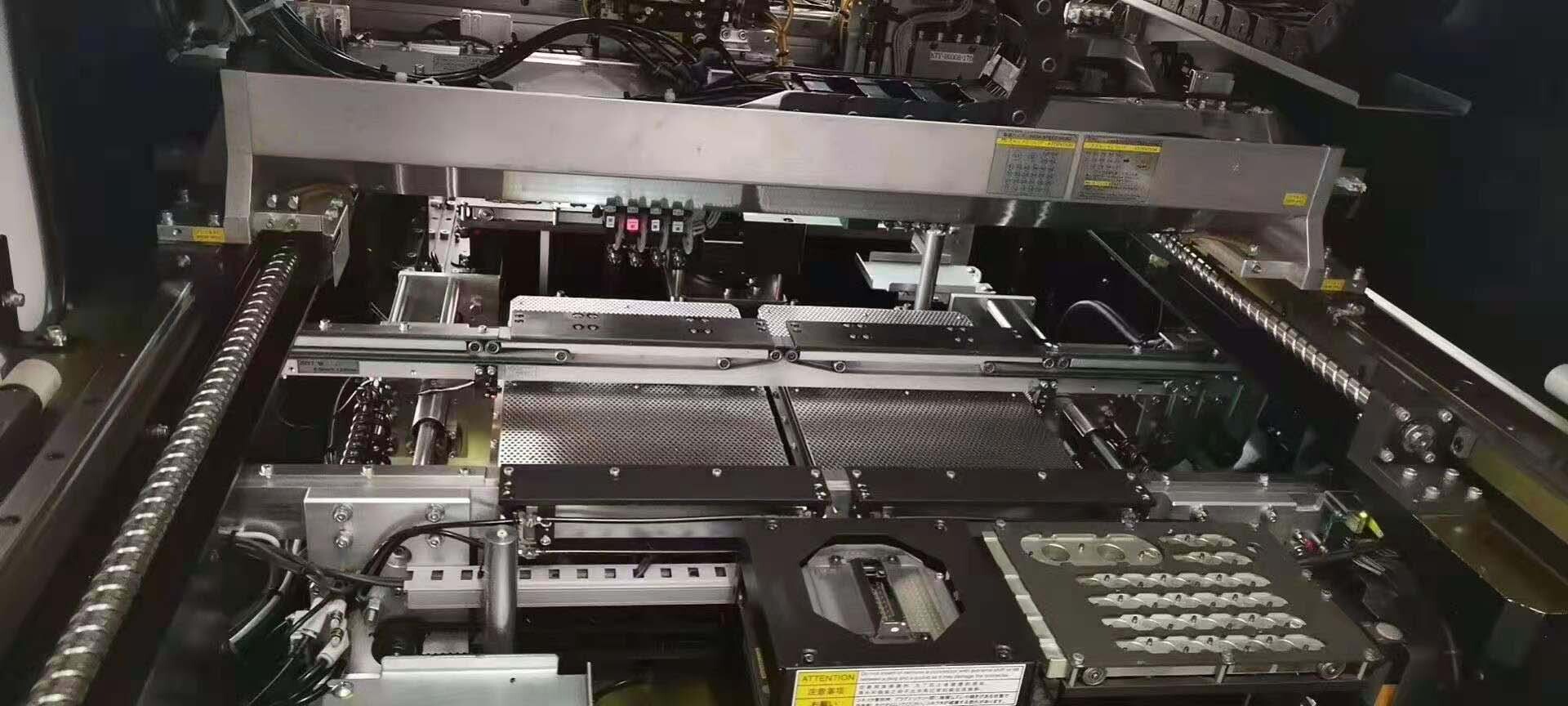

Used PANASONIC CM402L #9361104 for sale

URL successfully copied!

Tap to zoom

PANASONIC CM402L is an advanced PC Board Assembly and Manufacturing equipment. It is a multi-purpose device ideal for high-volume printed circuit board (PCB) production. It is a highly efficient, cost-effective production system for surface mount tech (SMT) processes. PANASONIC CM 402L uses an advanced self-correction unit to ensure accuracy and reliability. It features an innovative vision machine for defect recognition and removal, and incorporates a barcode-based data management tool. Its advanced 9-zone conveyor belt design allows for quick and efficient assembly of larger PCBs. CM402-L has an extensive array of features that make it a leader in PC board assembly and manufacturing. It includes a high-performance board loader, substrate Magazine, sub-package Magazine, Pre-reflow Magazine, Reflow Magazine, component placement head, wave solder, solder paste inspection, and selective solder. The board loader of CM 402-L allows for quick and easy loading of substrates. It is able to handle a wide range of substrates including multi-layer, multi-type, surface mount devices, and component populated substrates. It is also capable of loading up to 24 substrates at a time and has a programmed feed rate of 40mm/s. The substrate Magazine of PANASONIC CM402-L is designed to increase throughput. It is capable of handling a wide range of substrates and has a capacity of up to 200 substrates per magazine. It is constructed from stainless steel and is equipped with an easy-loading mechanism. The component placement head of PANASONIC CM 402-L is a high-speed head designed to quickly and accurately place components. It can handle components as small as 0201 chips and is capable of mounting up to 12,000 components per hour. The head is adjustable and can be adjusted to accommodate a variety of boards, including small palm-top boards. The wave solder of CM 402L is designed to provide perfect soldering results with minimal waste. The solder wave features precise temperature control, a 400mm wide conveyor belt, and an infrared camera to ensure perfect results. The solder paste inspection asset is used to inspect the entire surface of the board. The selective solder of CM402L is designed for quick and accurate soldering of small components. It utilizes a self-learning model to ensure fast and accurate soldering. The head can handle components as small as 0201 chips and is adjustable to accommodate a variety of boards. PANASONIC CM402L is a powerful and reliable PC Board Assembly and Manufacturing Equipment. It is designed for easy use and quick setup. It features an extensive array of features and is ideal for high-volume PCB production. When combined with proper training and support, PANASONIC CM 402L will provide exceptional results and unsurpassed quality.

There are no reviews yet