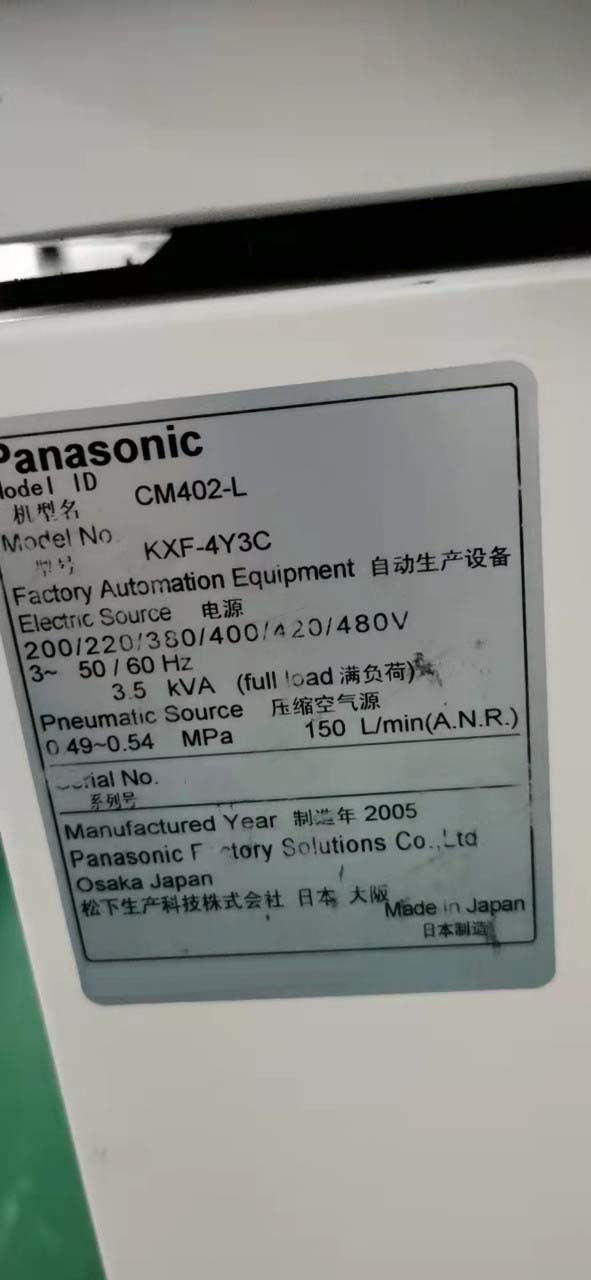

Used PANASONIC CM402L #9408152 for sale

URL successfully copied!

Tap to zoom

PANASONIC CM402L is a fully automated PC Board Assembly and Manufacturing Equipment designed to provide efficient and reliable automated production of printed circuit boards. It is equipped with the latest technologies to offer efficient and accurate production of high quality printed circuit boards. The system is equipped with dual-lane placement of parts along with 10mm wide lines for higher space constraint operations. It has an advanced flexible part feeding construction that offers an extensive range of options for discrete components, such as Nozzle Change Parts, Dual Nozzle Side Feeder, Dual Lane Tape Feeder, Small Parts Pick & Place Nozzle and High Speed TCN Nozzle. PANASONIC CM 402L is further equipped with a laser head for the applying non-contact measurements of exceptionally tiny components. CM402-L is designed for high-speed SMT production of printed circuit boards and features a maximum placement speed of 76,800CPH. It is also capable of handling a wide range of components, including 0201 andQFN/QFP components. The unit supports flexible printed circuit boards as well as standard FR-4 boards up to 0.3mm thickness. The equipment also includes a double chucking machine to ensure a low vibration in high-speed motion operations. It is also integrated with a Splice Tape Recognition Tool to minimise tape waste. In addition, PANASONIC CM402-L is equipped with a panel camera asset to ensure accurate inspection of parts placement and in-line continuity etc. It also includes a fully compatible front-end data processing model which enables the equipment to operate with several desktop and PC software programs. CM402L is designed with a robust and rigid structure to ensure reliable and repeatable performance. The system is made from steel, aluminium and non-magnetic materials to ensure accuracy and stability in high-speed production operations. The unit is also designed with an advanced dust prevention machine to reduce the failure rate of components. The tool is further equipped with a gantry robotic arm to ensure accurate alignment of components on boards and maintain the highest quality standards in production. CM 402-L is an ideal choice for printed circuit board mass production and offers efficient, precision and process reliability. The full automation of the asset, combined with its advanced technology offers a cost-effective and total production solution for PCB assembly.

There are no reviews yet