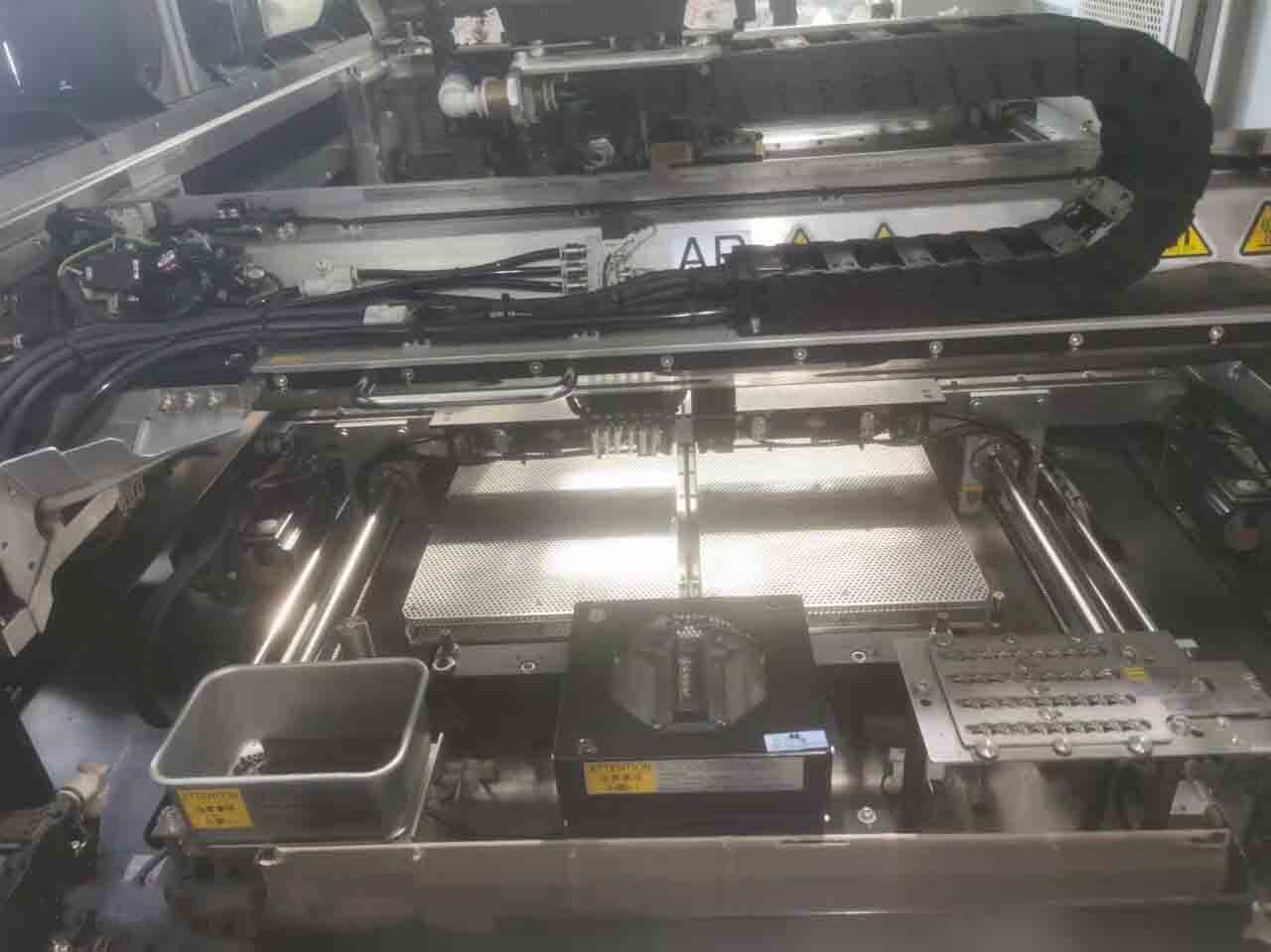

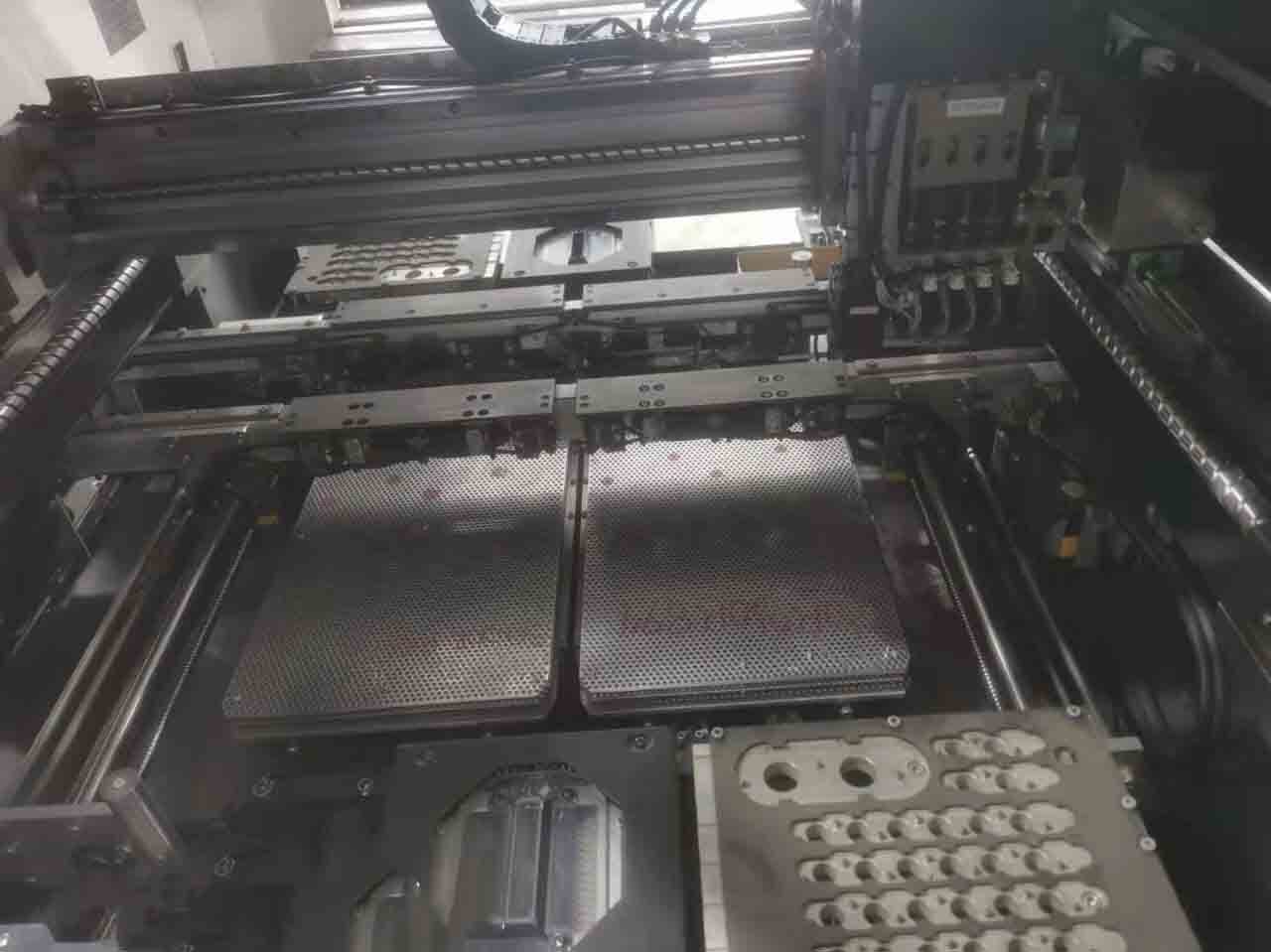

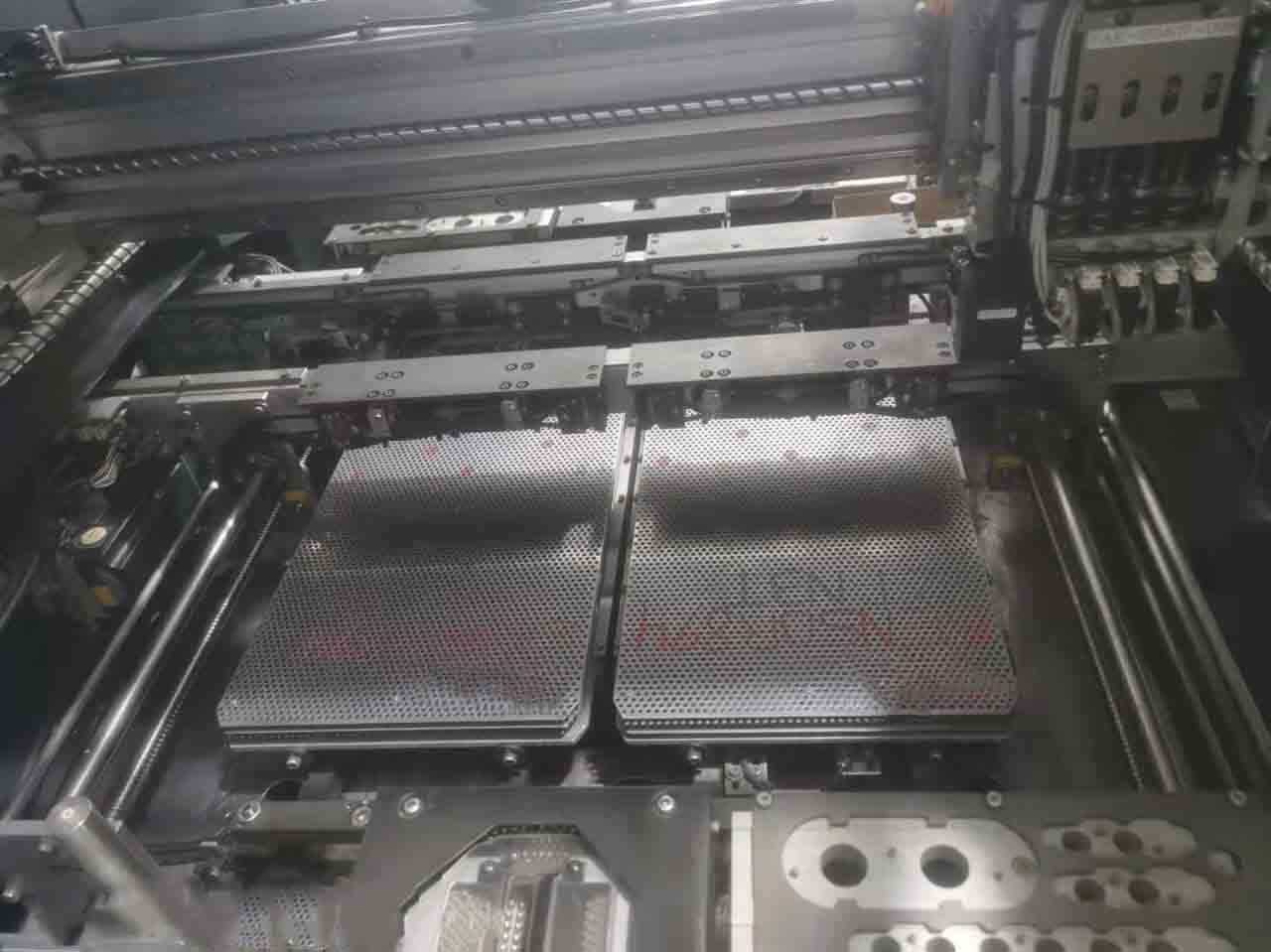

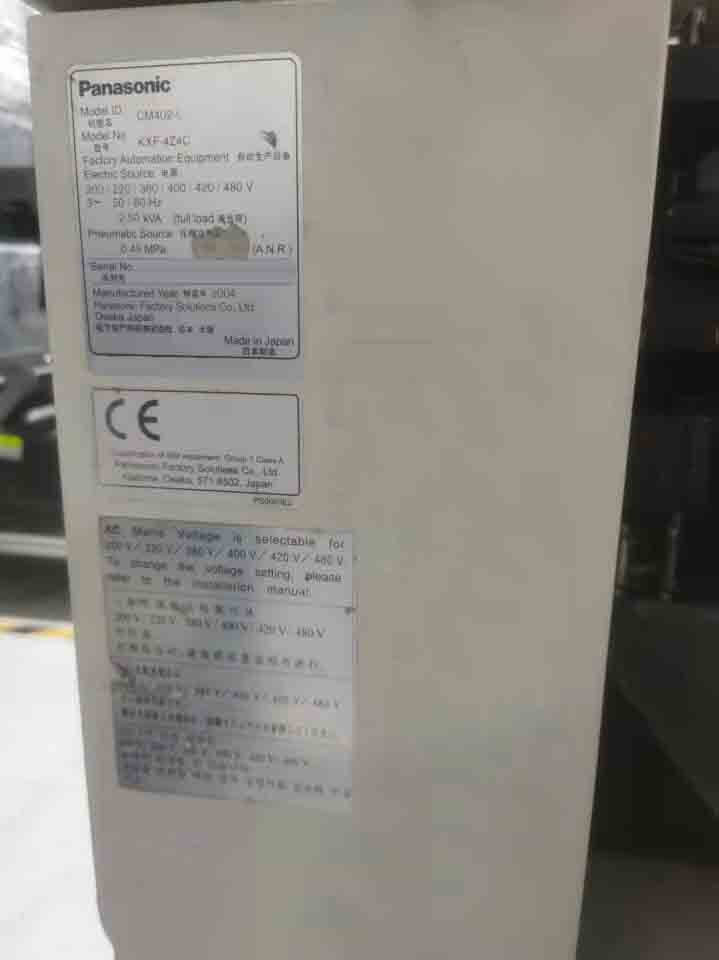

Used PANASONIC CM402L #9410056 for sale

URL successfully copied!

Tap to zoom

PANASONIC CM402L is a high-performance production platform designed for PC board assembly and manufacturing. It is a flexible Pick and Place machine that is the ultimate in high-speed precision. This machine has the capability to handle components from 0201 to large BGAs and fine pitch components. Additionally, the feeder equipment allows for a vast range of component sizes and shapes, such as small surface mount, fine pitch, and leaded components. PANASONIC CM 402L is an incredibly fast and reliable machine, with a cycle rate of up to 16,000 cph, which is about three times faster than other machines on the market. CM402-L can be moved around with ease, as the design includes casters on the base of the machine. This makes it possible to move the machine between production areas and store it in a range of locations. It has a maximum board size of 510 x 460mm, and has a full range of placement heads to suit the customer's requirements. CM 402L features dual-lane feeding and multiple heads with vision recognition that are designed to reduce material usage and minimize defect rates. The component libraries are easily upgradable and able to handle up to 2.5 million component types and sizes. In terms of its visual programming, CM 402-L features an easy-to-use IPC control system that allows users to edit and create programs with a simple drag and drop interface. Additionally, PANASONIC CM402-L uses a plus-level position recognition unit for greater accuracy, even on boards with holes, cutouts, and other irregularities. The built-in datalogger also provides comprehensive information on component feed accuracy and other important factors, making it easier to troubleshoot production problems. To ensure that your product is of the highest quality and reliability, PANASONIC CM 402-L includes multiple checks throughout the various production stages. This includes a built-in vision machine for component recognition and placement accuracy. Furthermore, the tool includes component inspection, placement verification, and fault detection. Finally, CM402L features a range of features that make it a highly efficient and hassle-free machine. This includes its production monitoring asset, which provides detailed reports on operational efficiency and traceability, as well as its advanced nozzle model and component cassette that is designed to reduce component damage and optimize feed rate. In summary, PANASONIC CM402L is an advanced PC board assembly and manufacturing equipment that offers high-speed precision and accuracy, efficient operation, and a range of innovative features. Its robust design, easy-to-use systems, and advanced programming capabilities make this a great choice for those who need a reliable and cost-effective machine.

There are no reviews yet