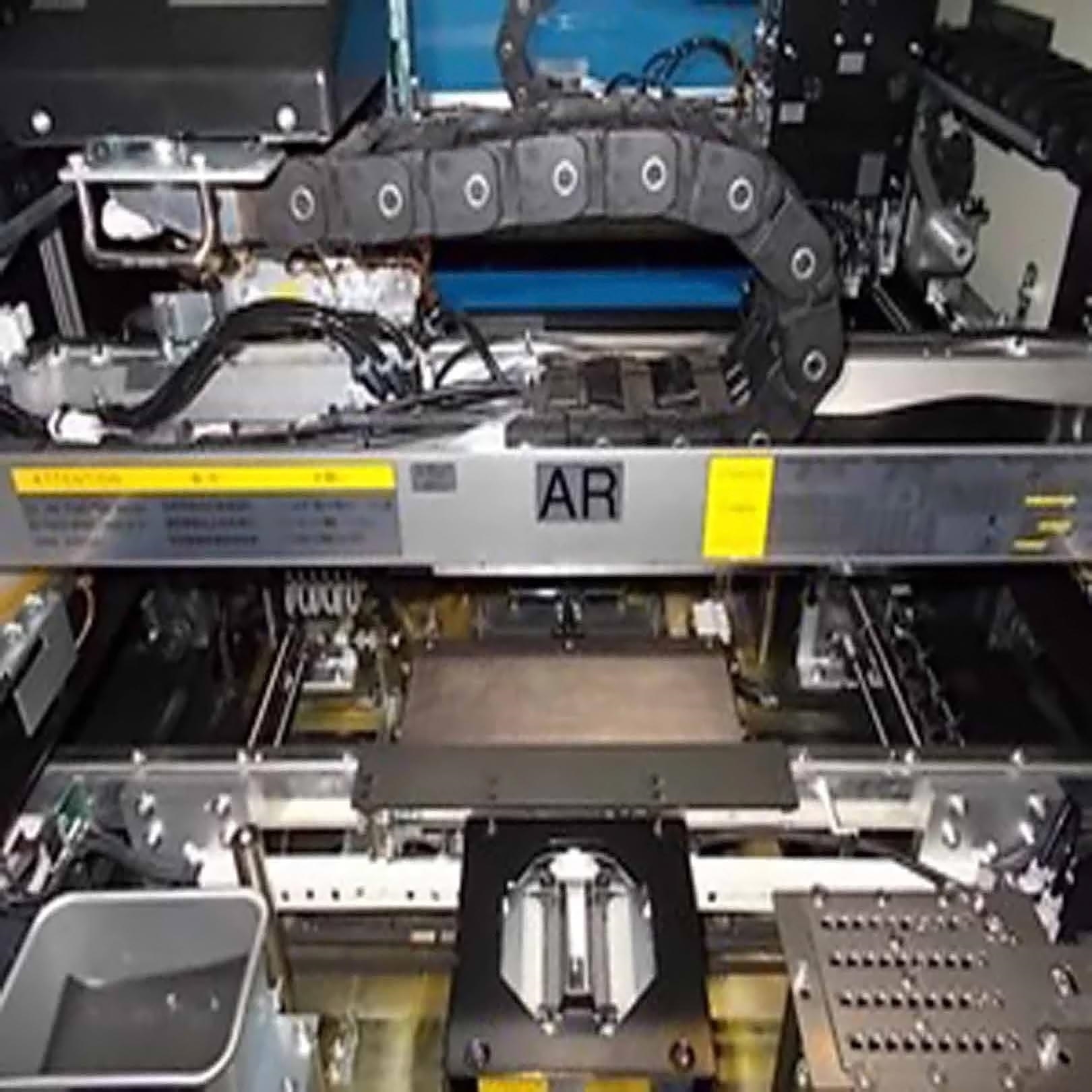

Used PANASONIC CM402M #9216340 for sale

URL successfully copied!

Tap to zoom

ID: 9216340

Vintage: 2008

A-Type chip mounter

(12) Nozzles

(4) Heads (A2 type)

(4) Feeder changing carts

PCB Size: Maximum 300 x 250 mm

Direction: Left to right (Rear fixed)

2008 vintage.

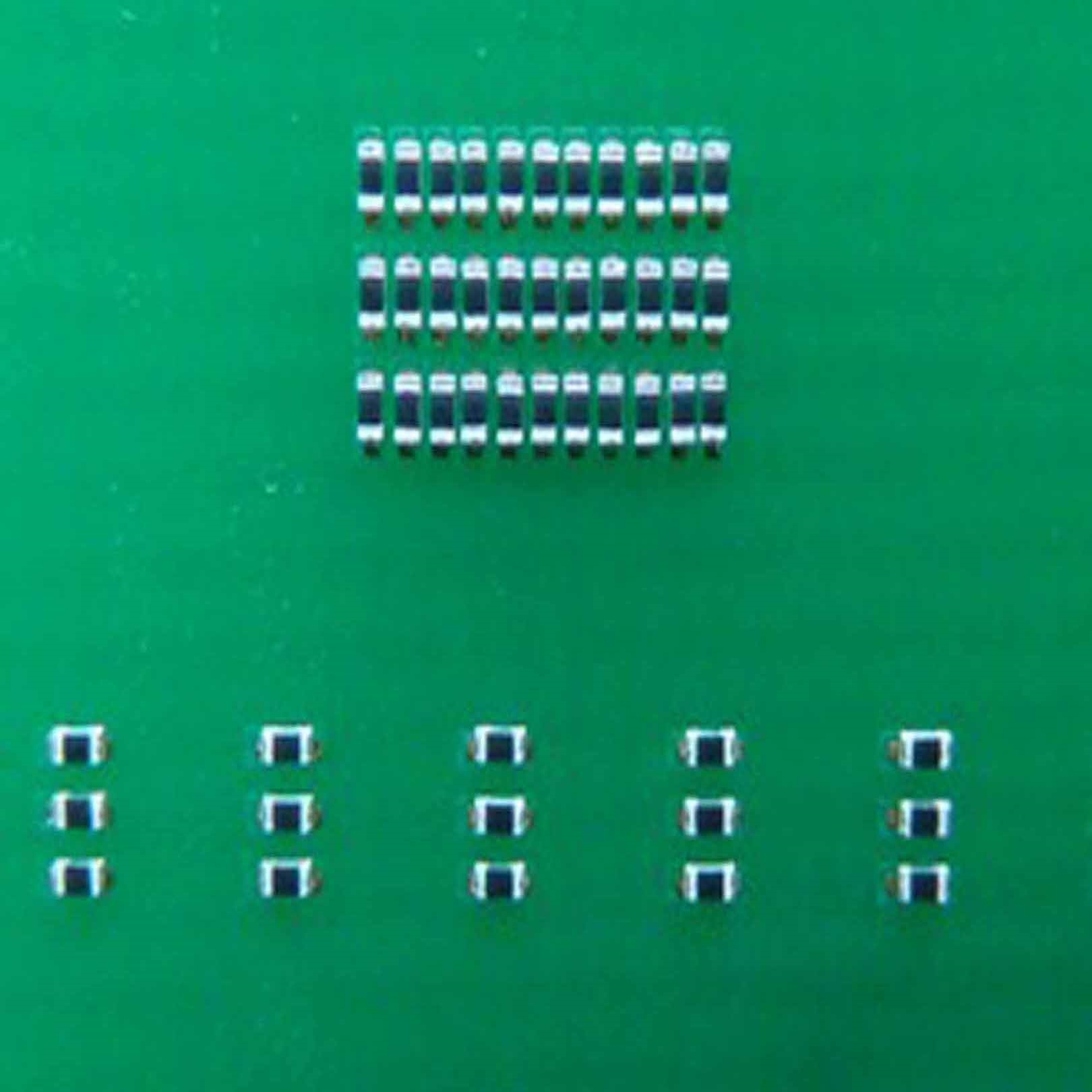

PANASONIC CM402M is a pc board assembly and manufacturing equipment that accesses and utilizes highly modular and intelligent components to maximize productivity and product quality. The system consists of several components, including an automated mounting head, an intelligent placement head, a vision inspection head, an oscillation head, an embedded computer, and a teach box. The automated mounting head, or "head", is an integral part of the unit. It is designed to reduce the workload for operators by automating the transfer of components and eliminating the need for manual fixtures. The head can mount components such as resistors, capacitors, connectors, and ICs on to the pc board in a faster, more efficient manner. The intelligent placement head is also an integral component of the machine. It enables the tool to accurately and reliably place components on the pc board. The head is equipped with an advanced vision-recognition asset that can detect a range of component properties, such as size and orientation, before placing them. This helps to increase accuracy and reduce potential errors. The vision inspection head allows the model to check the pc board assembly for any errors or faults. The head is equipped with a high-resolution imaging equipment that can detect any errors. The system can then recommend any corrective measures to the operator. The oscillation head provides the unit with precise control of oscillation movement. This optimization allows the head to move smoothly along the surface of the pc board to reduce damage and improve accuracy. In addition, the head can be used to test and validate components, which helps to increase the overall quality of the pc board assembly. The embedded computer is an essential component of the machine as it enables the tool to access all of the necessary information for the pc board assembly process. The teach box allows the operator to quickly and easily set up the asset and adjust parameters as needed. It also provides access to troubleshooting guidance if any issues arise. In conclusion, PANASONIC CM402-M is a pc board assembly and manufacturing model that combines a range of advanced features to maximize productivity and product quality. It utilizes intelligent components and a teach box to enable the operator to quickly and easily set up the equipment. Moreover, the system's embedded computer and vision inspection head can detect a range of errors and faults to help ensure a high-quality product.

There are no reviews yet