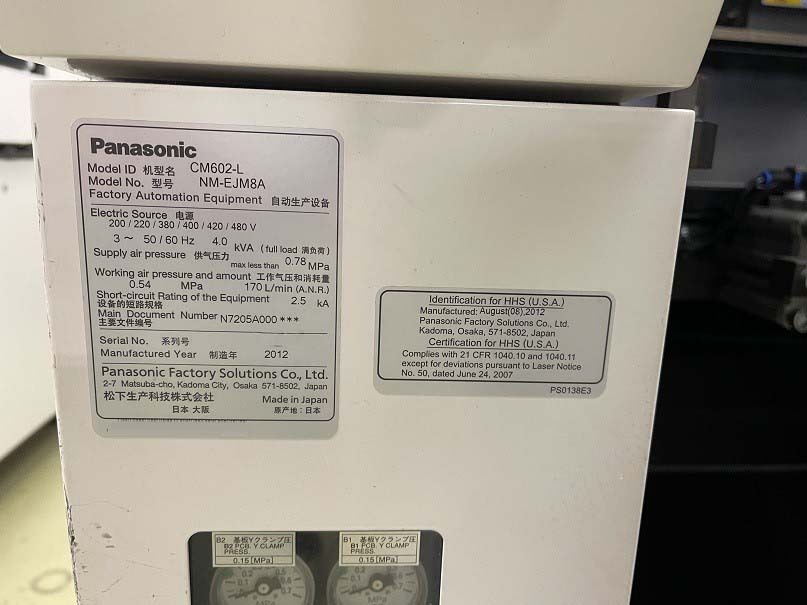

Used PANASONIC CM602-L #293591676 for sale

URL successfully copied!

Tap to zoom

ID: 293591676

Vintage: 2012

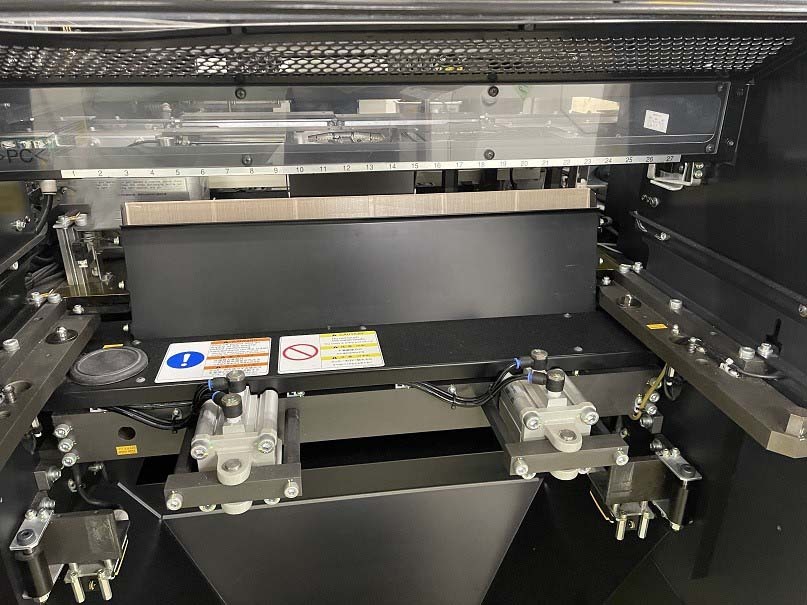

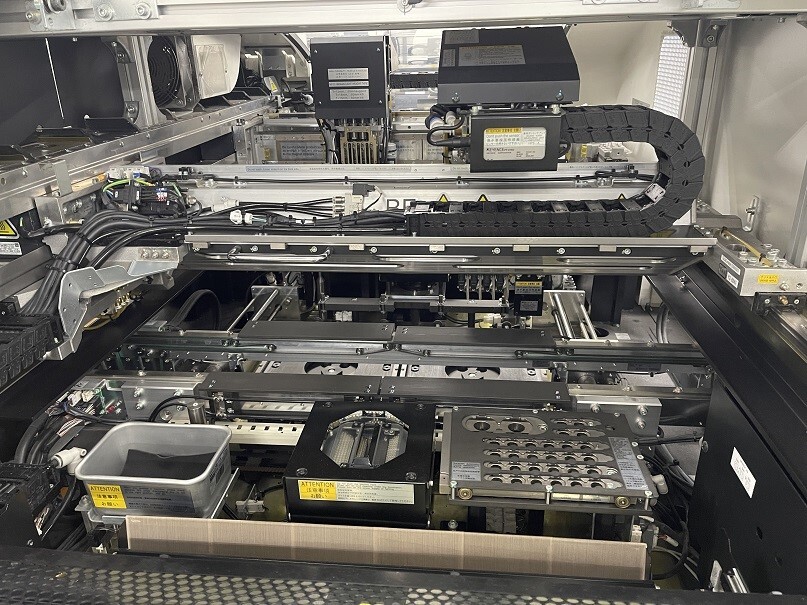

Pick and place machine

NM-EJM8A

Flow direction: Right to left

(2) Heads: 8 x 2 / 3

(3) Compact carts

Tray unit

2012 vintage.

PANASONIC CM602-L is a high-tech PC board assembly and manufacturing equipment designed with advanced features for increased efficiency and accuracy. It is ideal for use in automotive, consumer electronics, medical, aerospace and other industries. This machine provides maximum flexibility with its broad range of technology and expanded capabilities. PANASONIC CM602L is highly automated, allowing users to program all the production parameters at a single-piece level. It uses a 4D motion system to accurately and precisely position each component on the circuit board in a single operation. It can mount inserts, surface mount components, axial components and has a vision unit for component placement verification. The new CM 602L can handle board sizes of up to 510mm (width) x 460mm (length) with a maximum component height of 45mm and lead pitch of 0.3mm. In addition, the machine provides an innovative software based on advanced 3D simulation and analysis capabilities. This tool can simulate the entire production process and make necessary corrections if any component is inaccurately placed. The software also allows users to download programs to the robot controller, making for an easy and fast setup procedure. This software is designed to help manufacturers optimize processes, increase throughput and reduce costs. CM602-L also features a variety of advanced safety features. It is equipped with a light curtain asset that detects any movement in the robot's working area and halts the robot immediately. It also includes a three-point pressure model and a four-point support mechanism, ensuring that all modules are in contact with the board without distortion during the soldering process. PANASONIC CM 602 L is a must-have tool for any serious PC board assembly and manufacturing plant. This advanced equipment can significantly reduce cycle time, improve product quality and reduce costs. It provides users with the capability to closely monitor and control the entire production process, ensuring accuracy and precision every step of the way. It is the perfect choice for any complex manufacturing environment.

There are no reviews yet