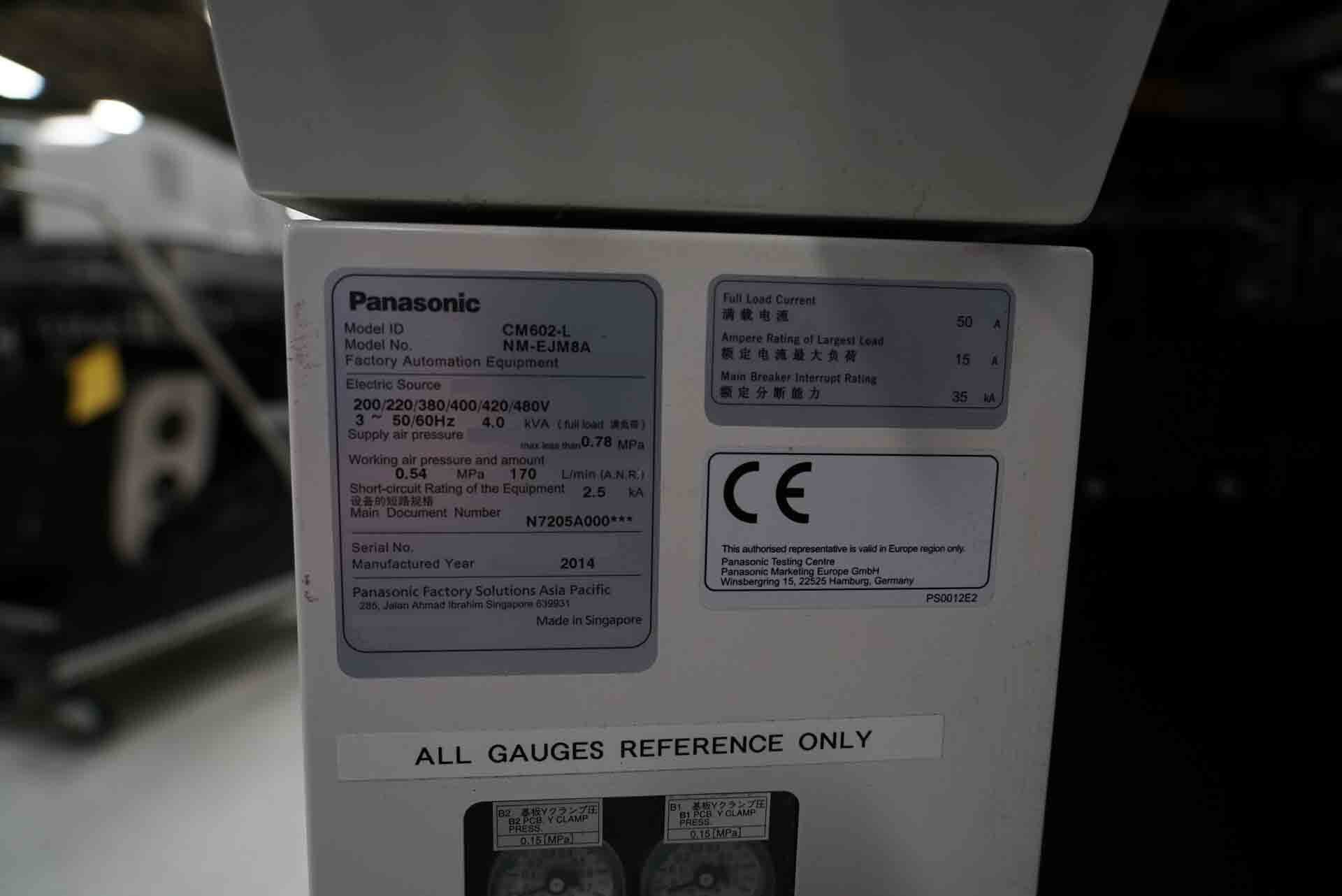

Used PANASONIC CM602-L #293592343 for sale

URL successfully copied!

Tap to zoom

ID: 293592343

Vintage: 2014

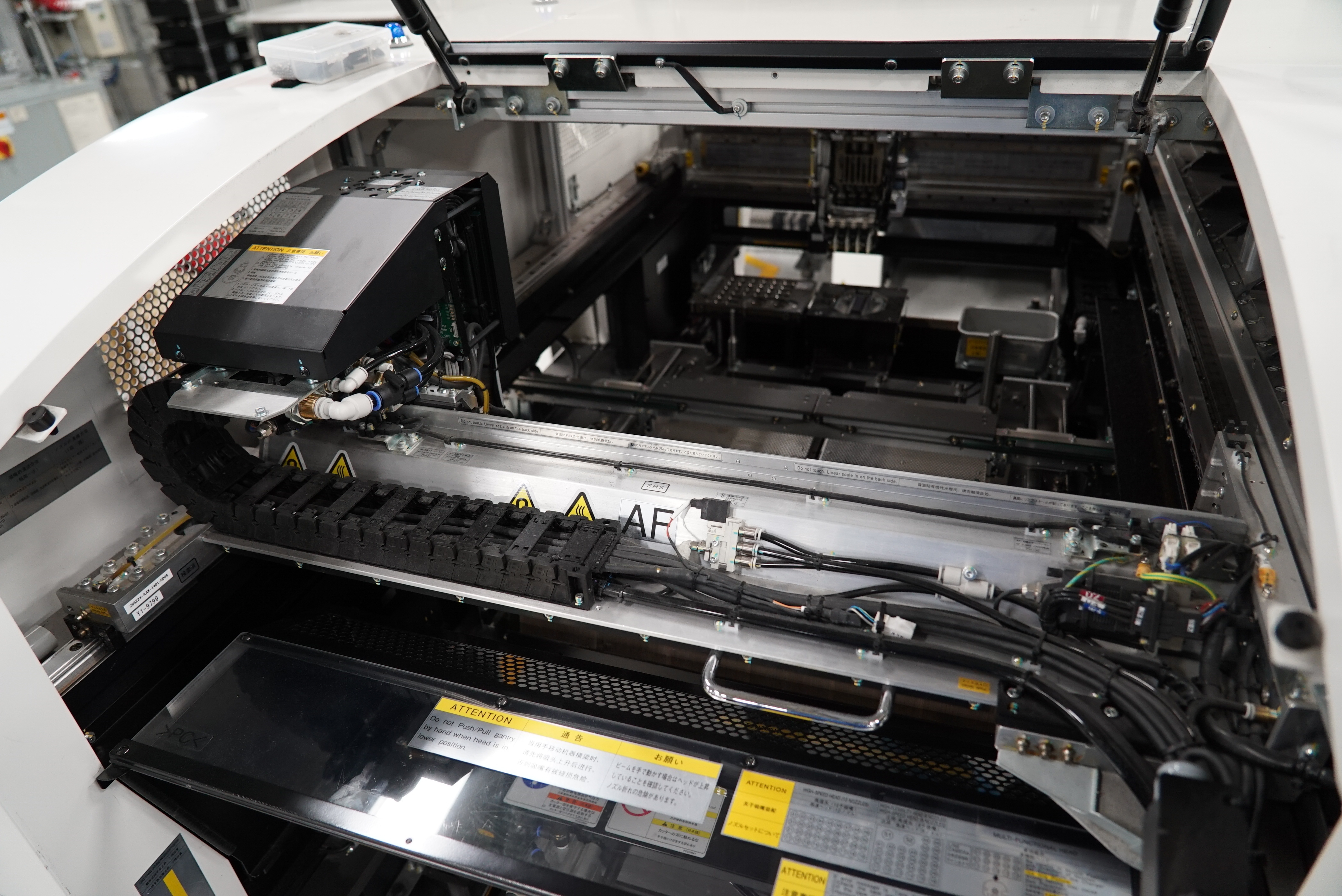

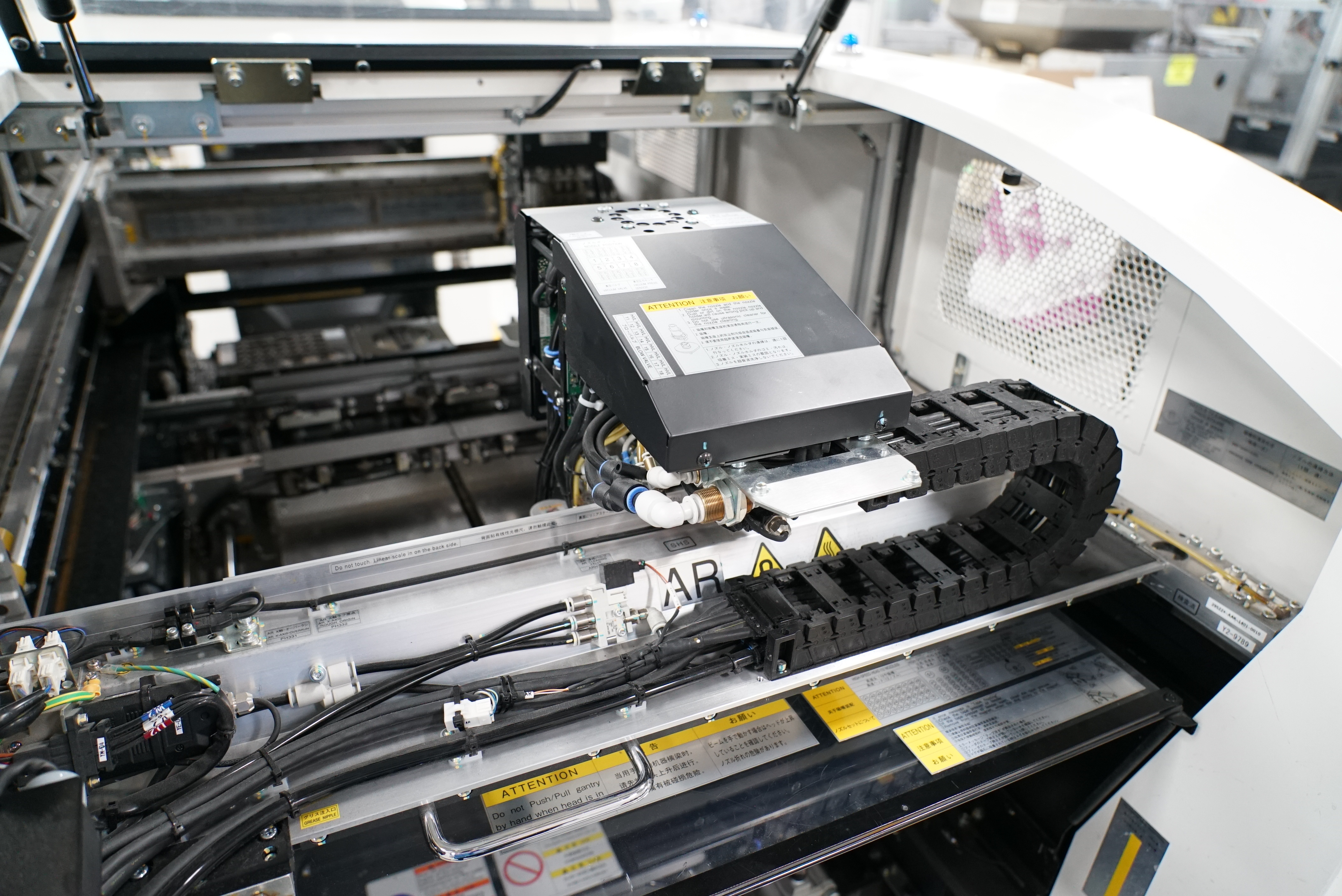

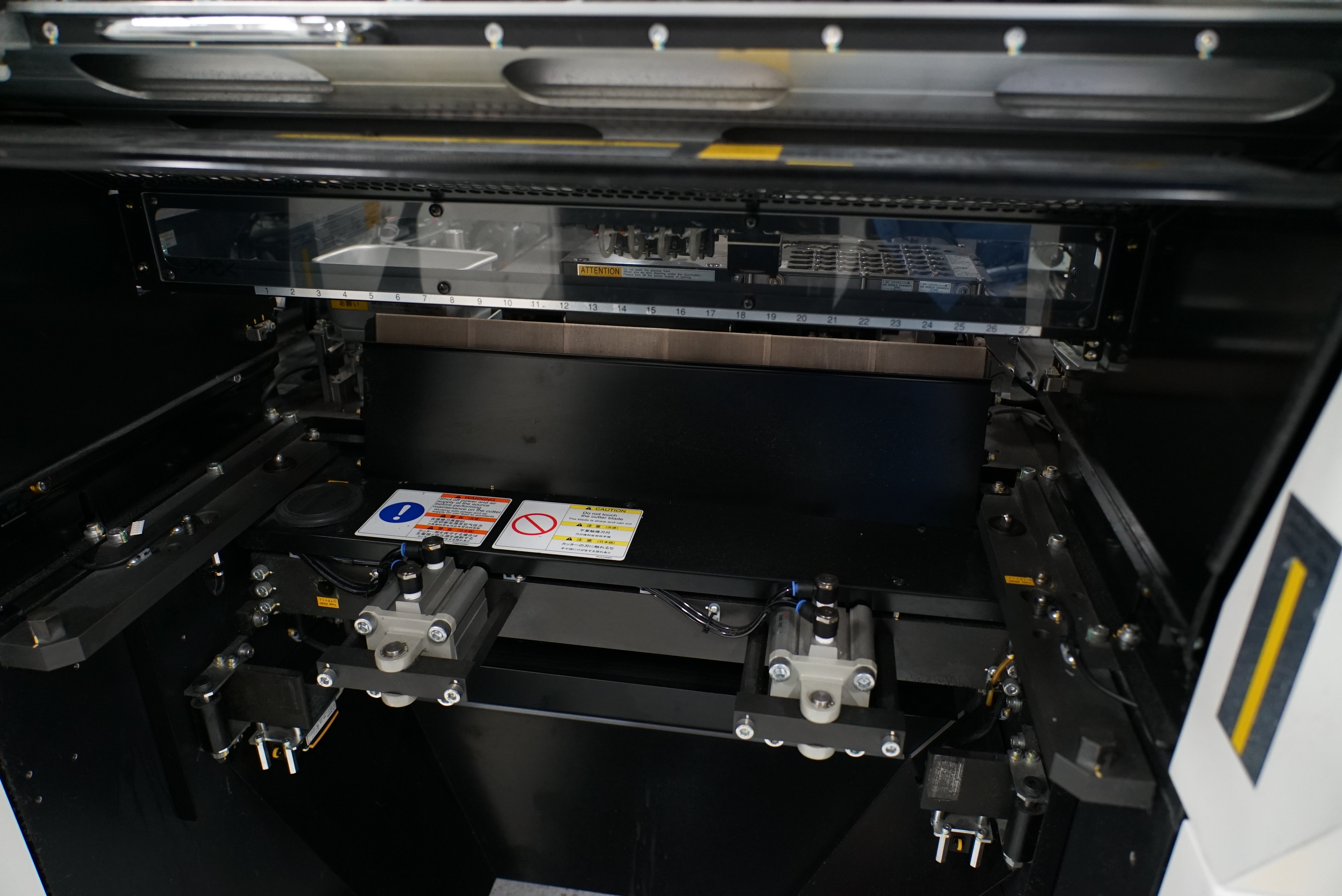

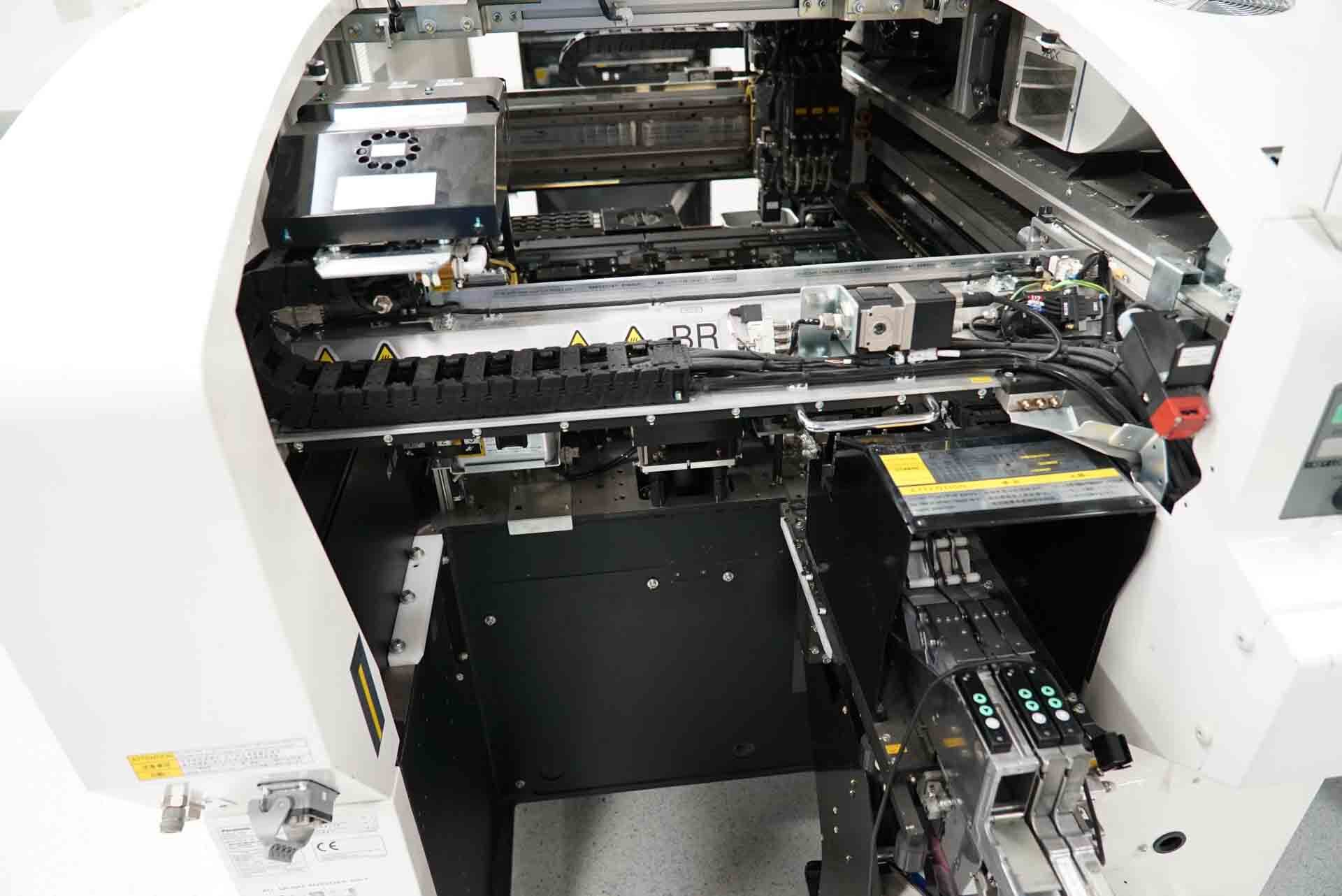

Pick and place machine

Model no: NM-EJM8A

(2) Tray feeders

Tray shuttle

Feeder cart

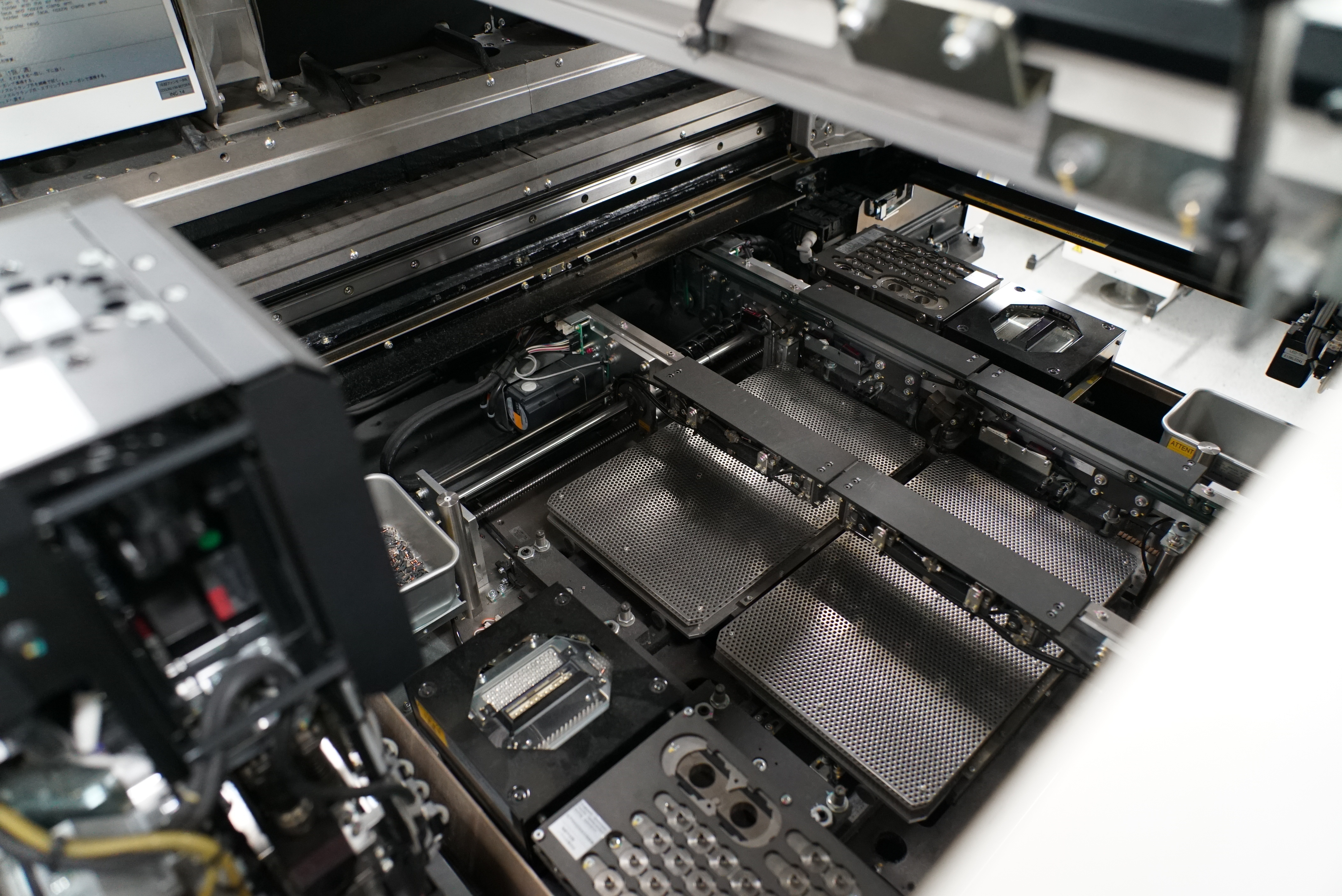

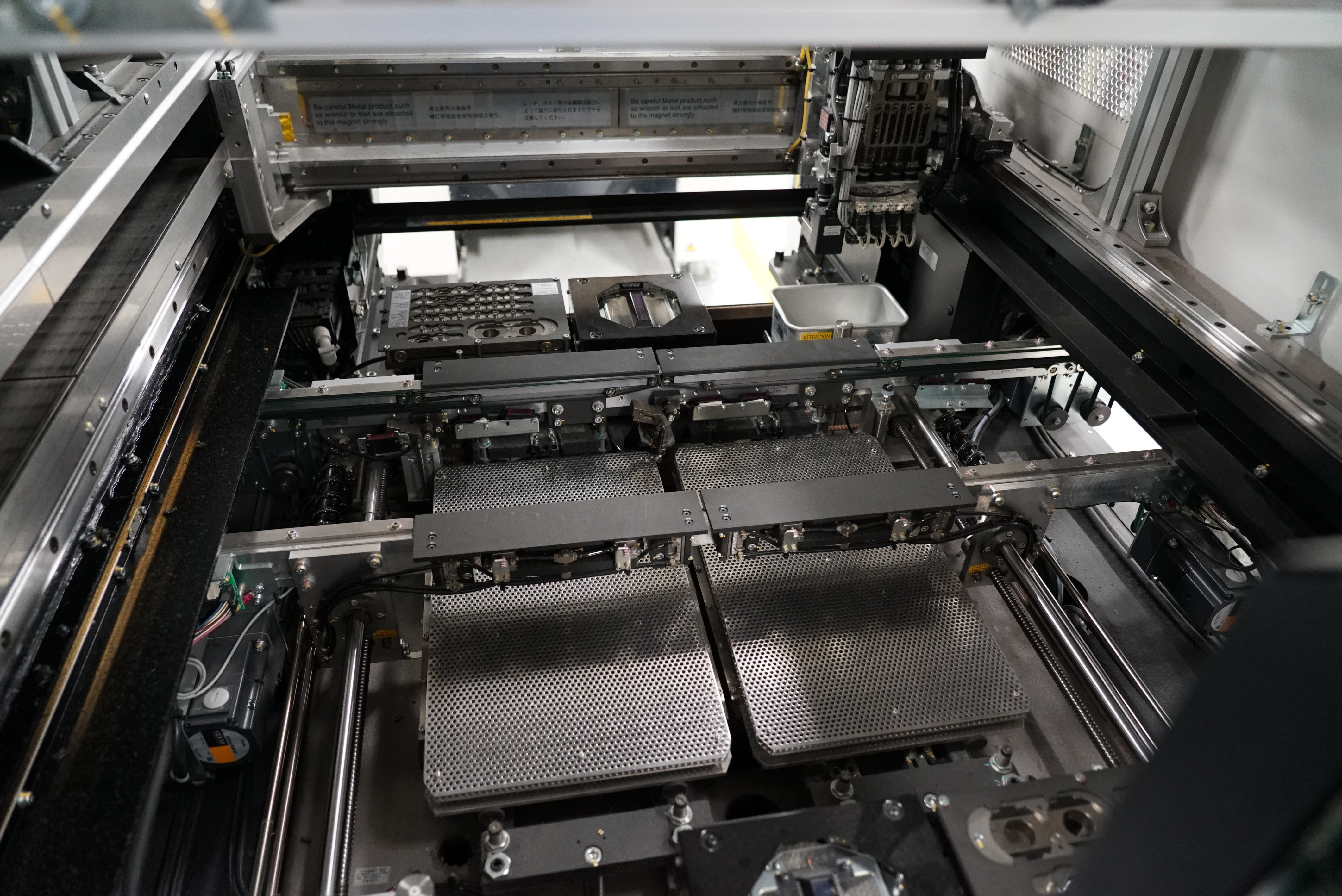

Stage A: 8" x 8"

Stage B: 8" x 3"

2014 vintage.

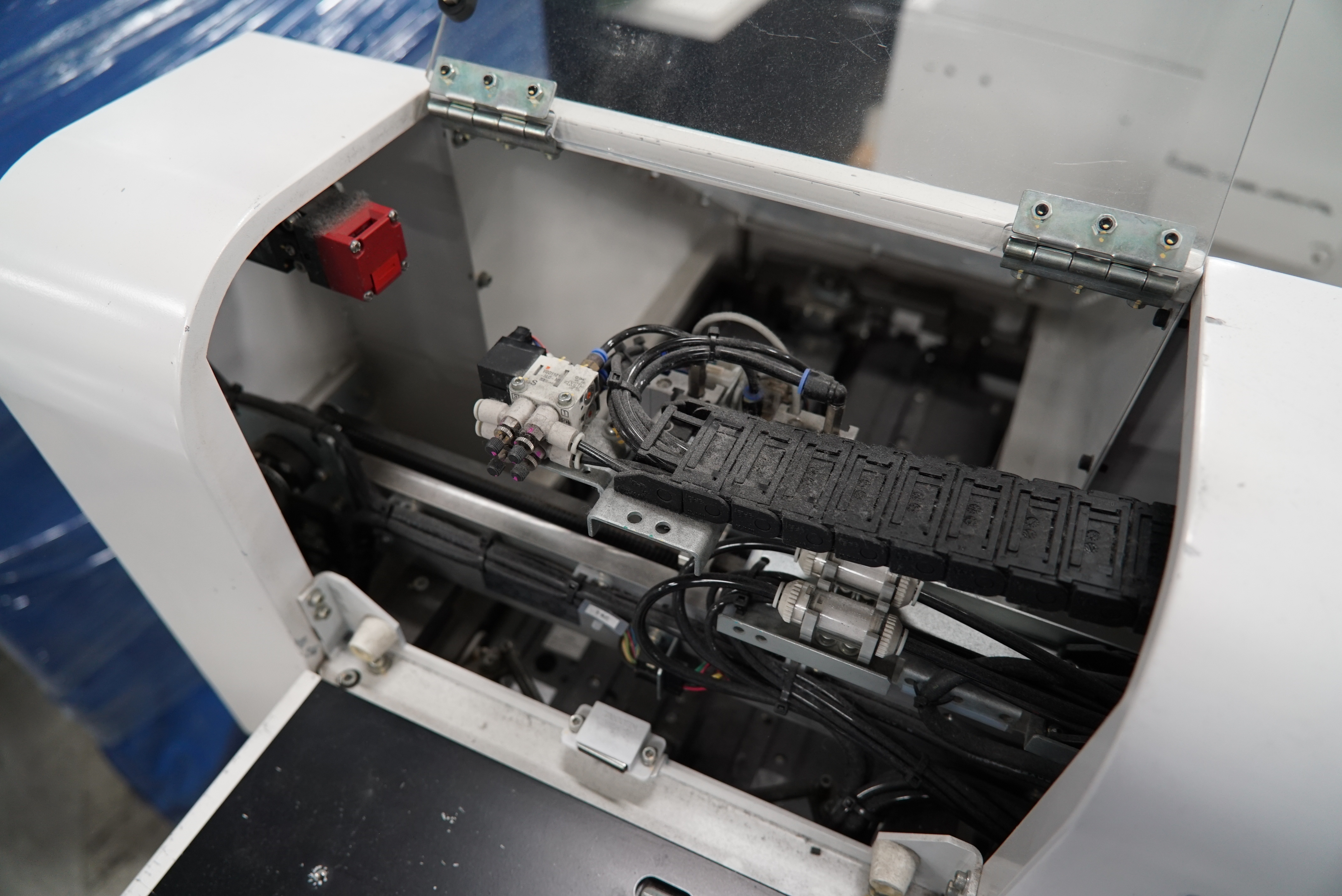

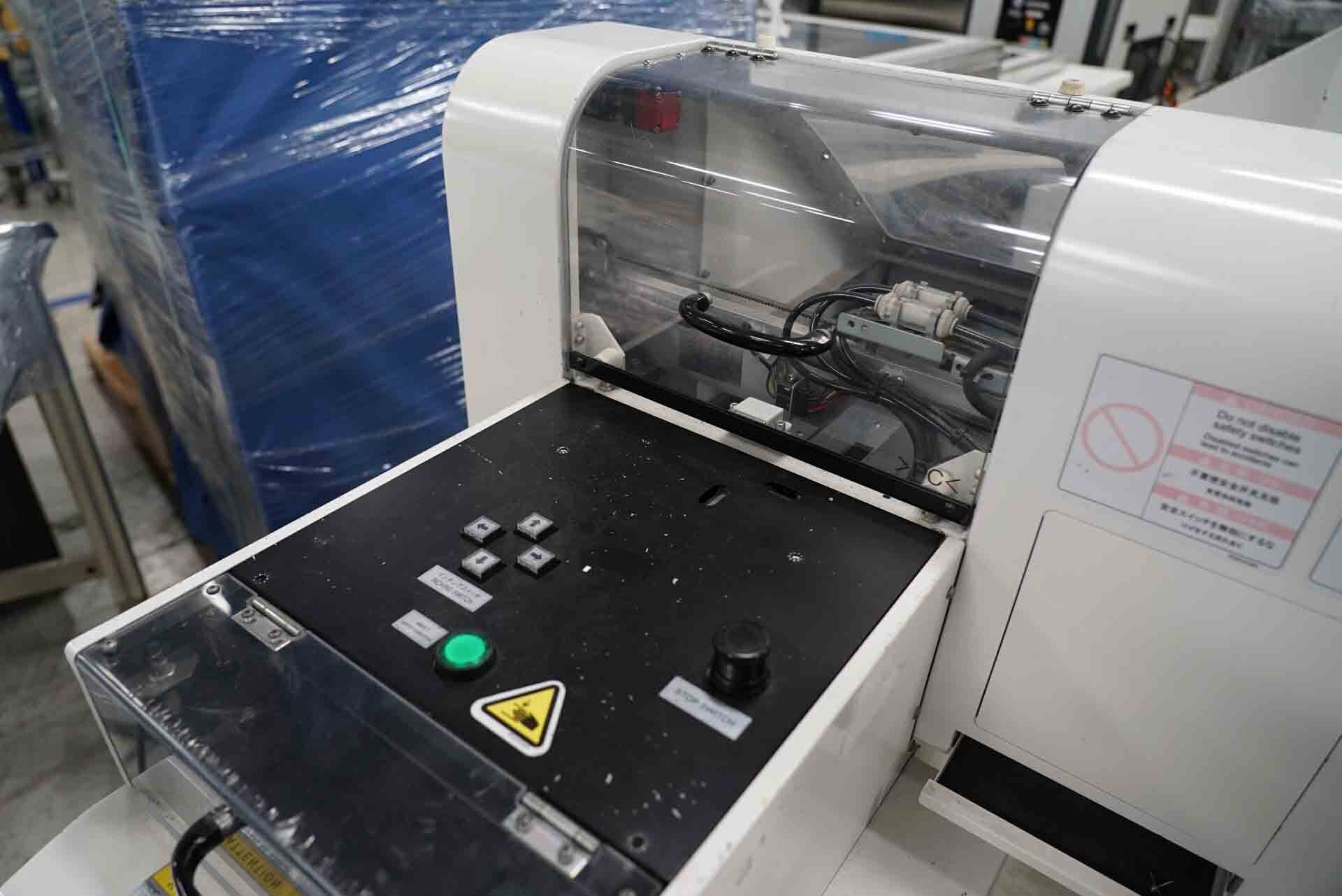

PANASONIC CM602-L is a PC board assembly and manufacturing equipment developed by PANASONIC Corporation. This system is a high-speed, high-accuracy, and highly flexible production line solution for medium to high volume production. The unit is designed to handle the challenges of the modern electronics industry by streamlining the PCB assembly and manufacturing process. PANASONIC CM602L runs on PANASONIC intelligent NPM control software, an integrated PC-based control machine designed specifically for automated production lines. This enables CM 602L to quickly and accurately transfer information between work centers in the PC board assembly and manufacturing process. The NPM control software also ensures that the tool is able to precisely calibrate part and substrate positioning and tolerances during machining, assembly, and inspection. CM 602-L uses multiple QFP, BGA, and LGA placement heads, as well as chip and fine pitch placement, to assemble a wide variety of surface mount components. This versatile asset can reliably place components as small as 0201s, as well as standard size components, at a rate of up to 2000 and 1100 cph (components per hour) respectively. For even greater throughput and accuracy, PANASONIC CM 602 L is also equipped with a Dual Placement Head and Dual Camera model, which allows for simultaneous placement and inspection for components on both sides of the board. PANASONIC CM 602L also features a high-precision cutting head for cutting, grooving, and routing PC boards. With a maximum cutting speed of 35m/min and accuracy of ±0.02mm, PANASONIC CM 602-L can process a wide range of materials, including FR-4, Flexible Board, and CCL. For safety, CM 602 L is designed to comply with the most stringent international safety standards, including OSHA, IEC, and CE. Additionally, the equipment is equipped with multiple built-in safety features, including a light curtain to detect operator entry and an E-Stop button to immediately stop operation in case of emergency. Manufactured for reliability, CM602-L utilizes state-of-the-art servo motors and sensors to ensure quiet, reliable operation. The system is also protected from electrical interference, which helps to minimize downtime. Overall, CM602L is an advanced PC board assembly and manufacturing unit that combines ease of use, flexibility, and precision to achieve reduced set-up time, higher yields, and ultimately lower machine costs.

There are no reviews yet