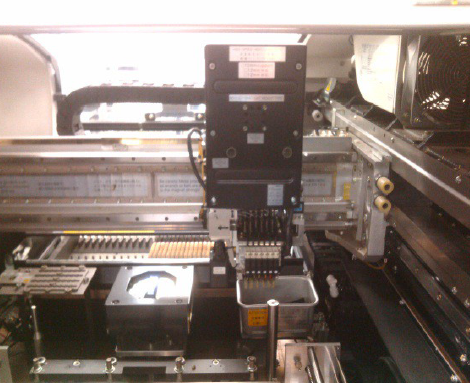

Used PANASONIC CM602-L #9117283 for sale

URL successfully copied!

Tap to zoom

ID: 9117283

Vintage: 2012

(2) Pick and place systems

Left to right

Front rail fixed

Machine 1:

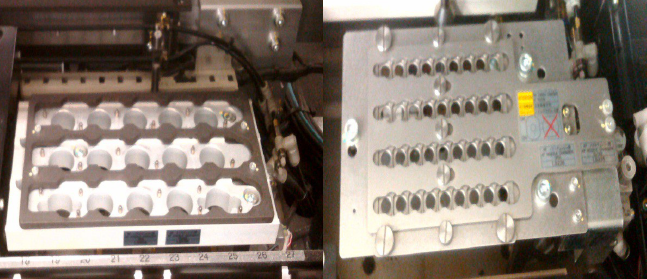

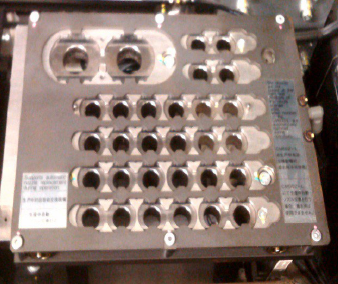

(2) 12-Nozzle heads

(2) 8-Nozzle heads

(4) Feeder trolleys

Hours: 10,368

Machine 2:

(2) 8-Nozzle heads

(2) 3-Nozzle heads

(3) Feeder trolleys

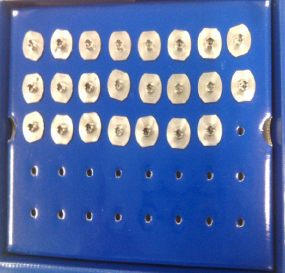

DT50S-20 Direct tray feeder unit

Hours: 10,612

Feeders:

(90) 8mm dual lane

(25) 12/16mm

(12) 24/32mm

(1) 44/56mm

(1) 88mm

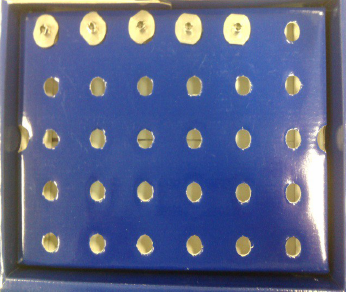

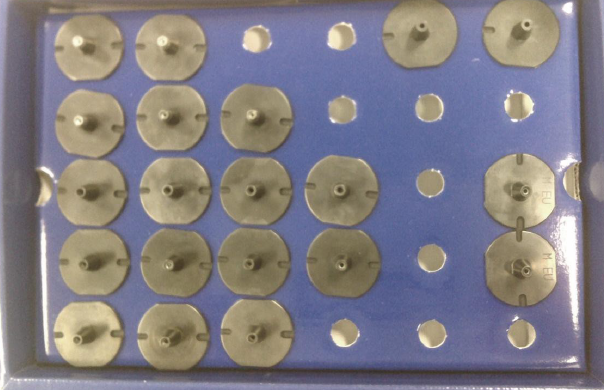

Nozzles:

(54) 110A

(23) 115A

(5) 120A

(5) 130A

(3) 185A

(3) 199G

(2) 1001

(3) 1002

(4) 1003

(4) 1004

(3) 1005

(2) 2421

(31) 110S

(12) 115S

(5) 120S

2012 vintage.

PANASONIC CM602-L is an advanced, precision pc board assembly and manufacturing equipment. It is a highly automated pick-and-place machine capable of working with a wide variety of components, including Through Hole, Surface Mount, BGA, CSP, and Flip Chip devices. This makes it an ideal solution for factories, particularly those working with highly complex pc board designs. The system works by placing component carriers or tubes on a conveyor which then feed them to the machine for pick-and-place operations. The unit can be configured with a variety of heads, such as a 2mm Double Head, 3mm Double Head, 4mm Double Head, 6mm Double Head, and 8mm Double Head. A built-in camera facilitates the accurate placement of components by taking a picture of the component before it is placed. PANASONIC CM602L offers a high-speed, high-accuracy placement process that can process up to 1,450 components per hour. It also offers a Vision Alignment machine which uses special vision functions like Area Scanning, Edge Detection, and Component Marking. This allows for reliable accuracy in the placement process. In addition, the tool features a wide range of tools and features that make it easier to use. These range from a Programmable Logic Controllers (PLCs) for controlling asset operations, to onboard scara and linear robots for precise and accurate deliveries. There is also a handy online help model, which offers advice and assistance on the use of the machine. Finally, the equipment is equipped with intuitive user-friendly programming and operating controls. The machine also comes with a variety of different software packages, such as AOI, Solder & Pitting, and Process Control software. These make it easier for operators to manage the system and to ensure the highest quality of finished pc boards. Overall, CM 602L is one of the most advanced pc board assembly and manufacturing systems on the market today. It offers excellent performance, precision, and reliability, and can handle a wide variety of components with ease. As a result, it is an ideal option for anyone in need of efficient, cost-effective production of precision pc boards.

There are no reviews yet