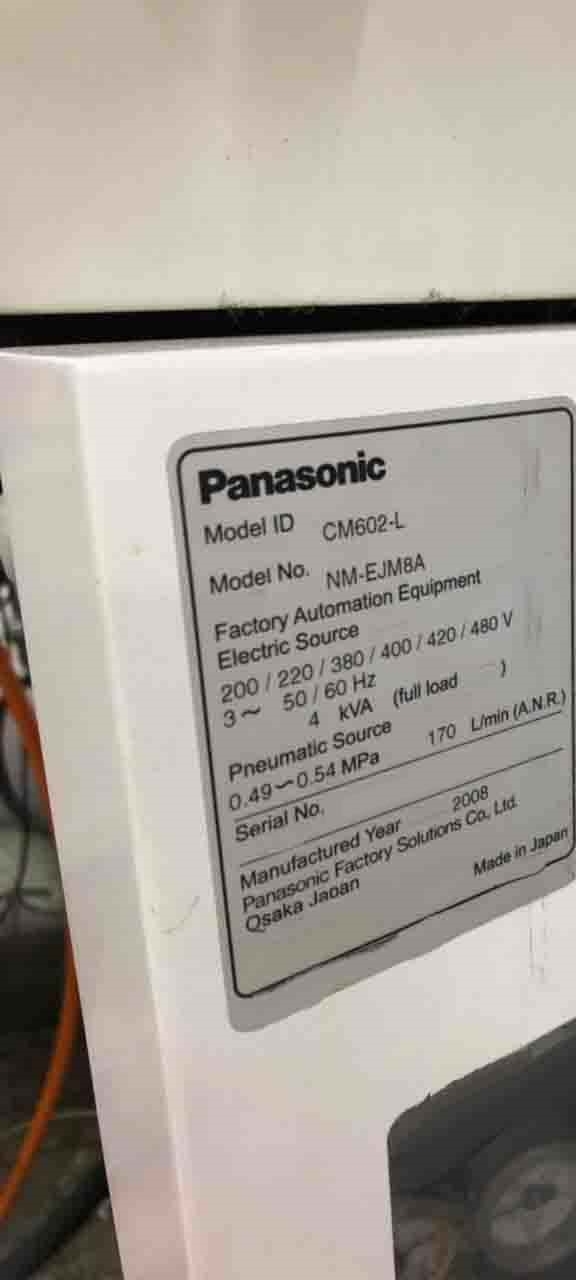

Used PANASONIC CM602-L #9203853 for sale

URL successfully copied!

Tap to zoom

ID: 9203853

Vintage: 2008

Pick and place machine

Head12 + Head3 with tray

2008 vintage.

PANASONIC CM602-L is a PC board assembly and manufacturing equipment that offers a unique and optimized solution when it comes to assembling and manufacturing printed circuit boards. It is a highly efficient system that makes use of efficient component placement and powerful data integration capabilities to get the job done quickly and effectively. The unit comes with six heads which can be used to place all components including through-hole components, BGAs, SMDs and chip components. The independent heads can move independently of each other to provide the best placement accuracy while ensuring high speed production. Each head is capable of handling up to 360 degrees of rotation, enabling it to place even small and difficult components accurately and quickly. The machine is also fitted with a sensitive vision tool that can detect fine details like fiducial marks, component marks and parts polarity. This helps the machine automatically verify component placement before the board proceeds to the next process. Datasheets and CAD designs can be used to program PANASONIC CM602L so that it can efficiently and accurately handle component placement, solder paste dispensing and other processes. The asset is also equipped with an intuitive user interface which makes it easy for operators to program and monitor the machine's actions. CM 602L also comes with an updated software algorithm which ensures proper board positioning on different sized boards and even on boards with difficult shapes. The model is also suited for inline board inspection, helping you discover any defects that the machine may have missed while placing components. Overall, PANASONIC CM 602-L is a powerful PC board assembly and manufacturing equipment that is designed to meet the demands of modern industrial processes. It provides efficient component placement and data integration capabilities and features an intuitive user interface for easy programming and monitoring. Additionally, it is equipped with an updated software algorithm that helps it ensure proper board positioning even on difficult sized boards and an inline inspection system to check for any defects.

There are no reviews yet