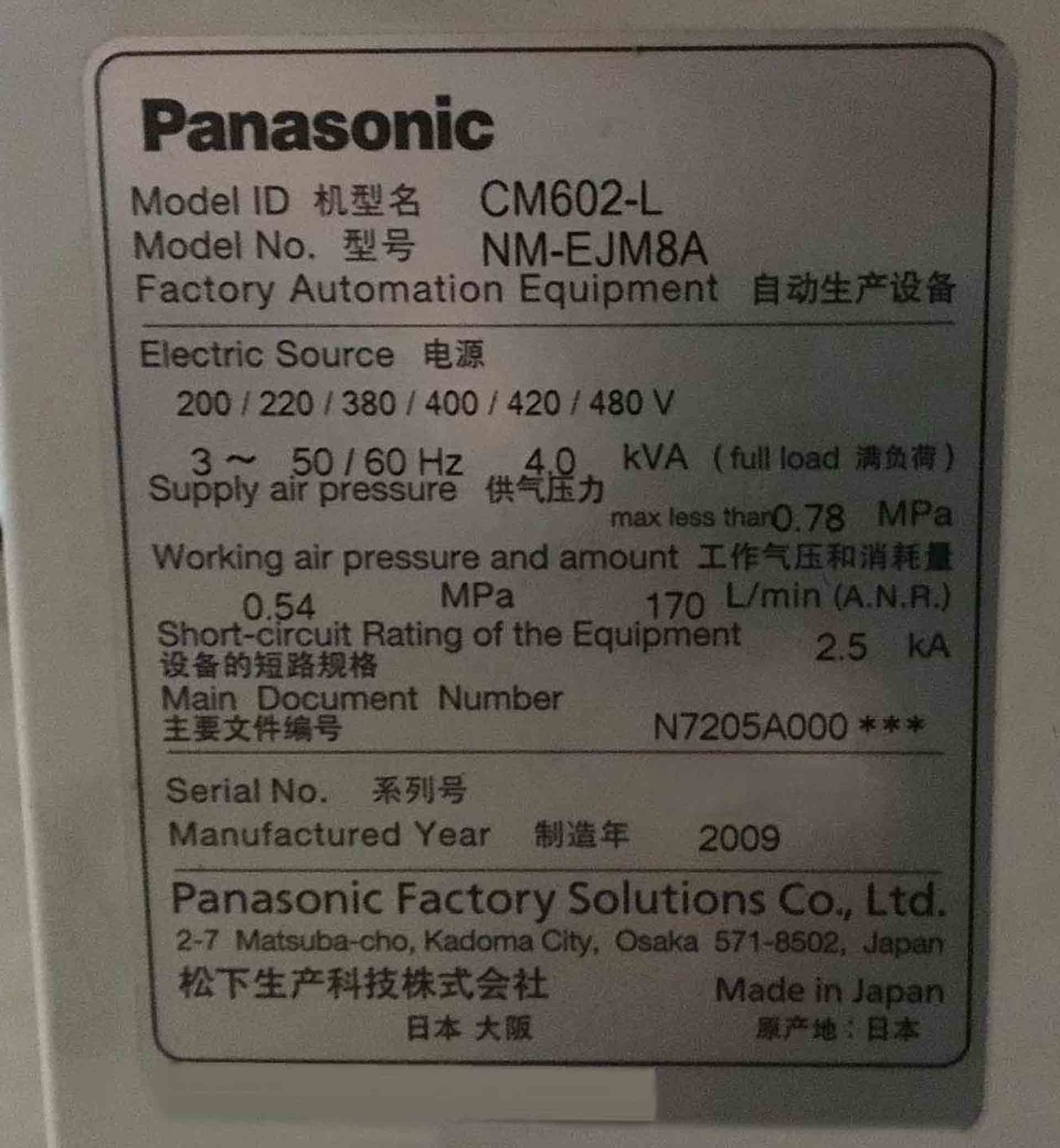

Used PANASONIC CM602-L #9244590 for sale

URL successfully copied!

Tap to zoom

ID: 9244590

Vintage: 2009

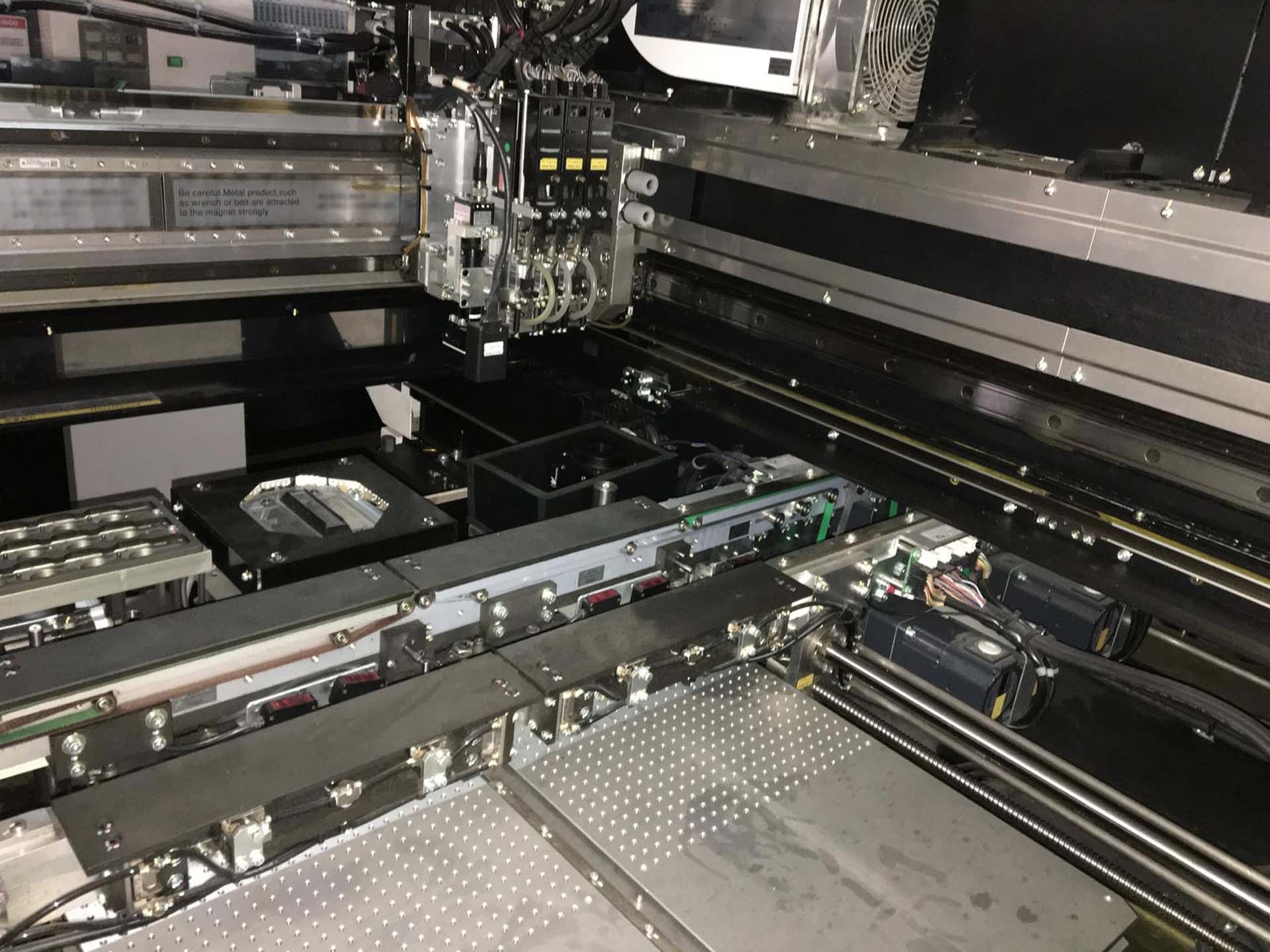

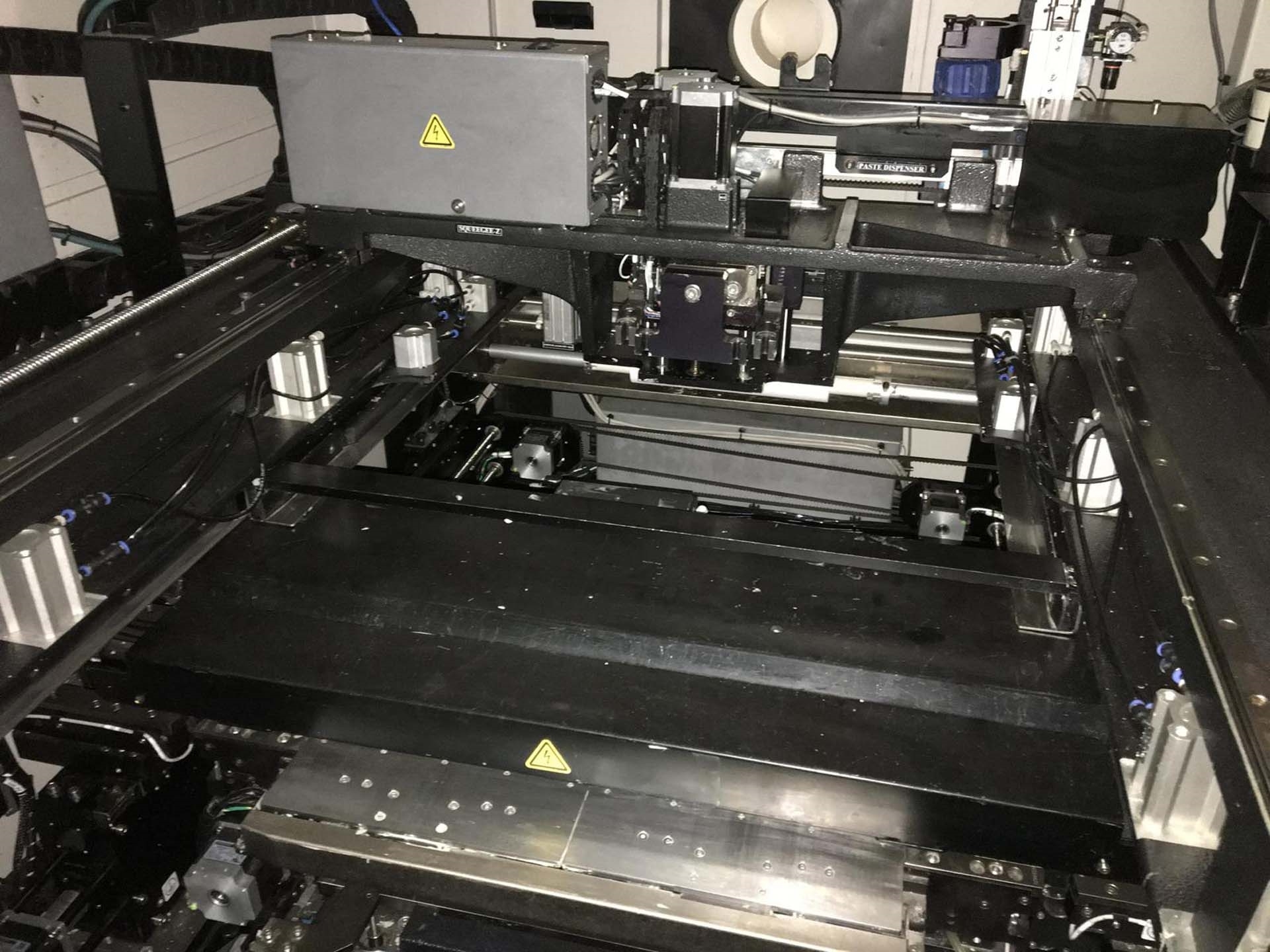

Pick and place machine

MTU

Running hours: 31,085

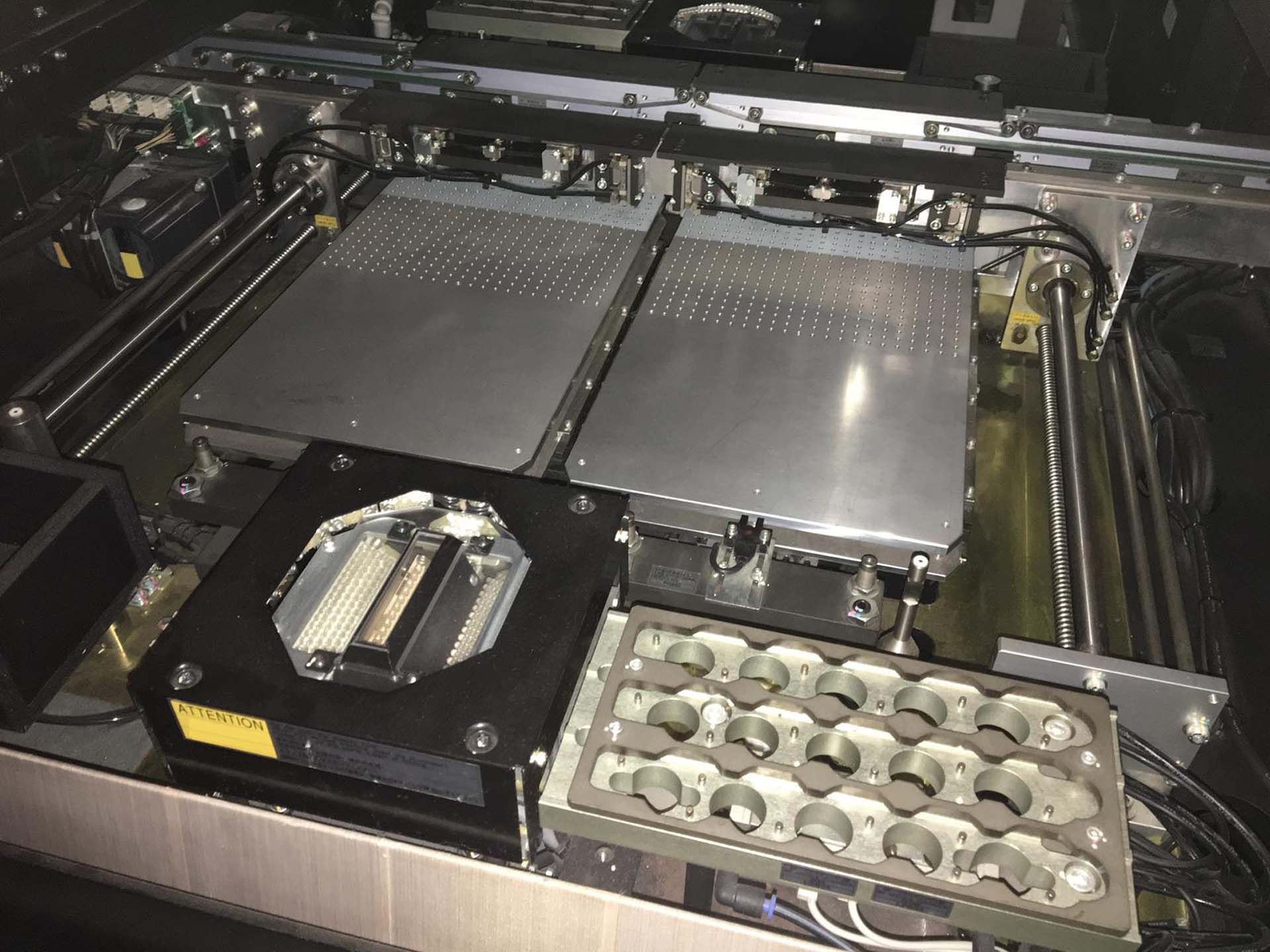

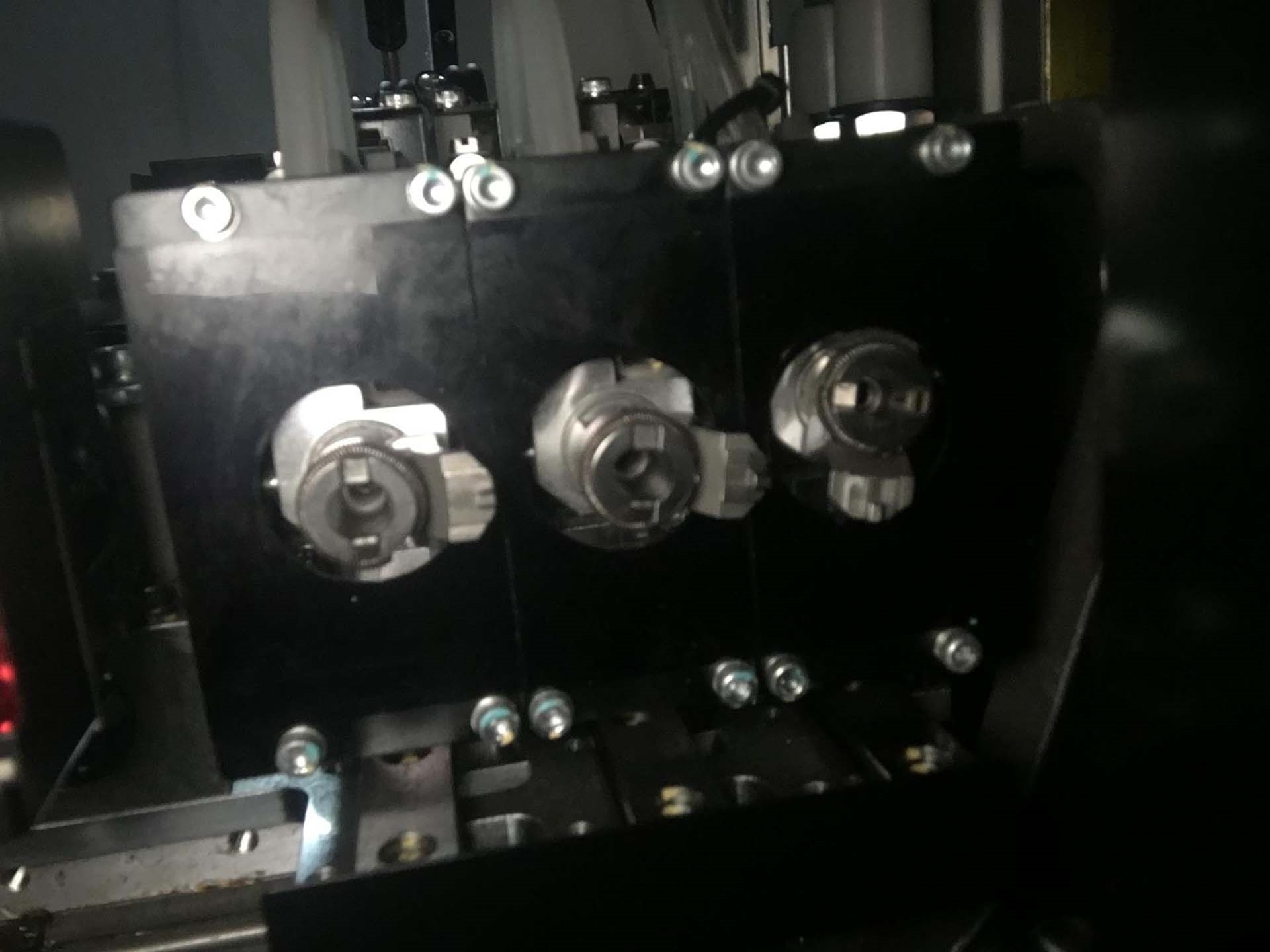

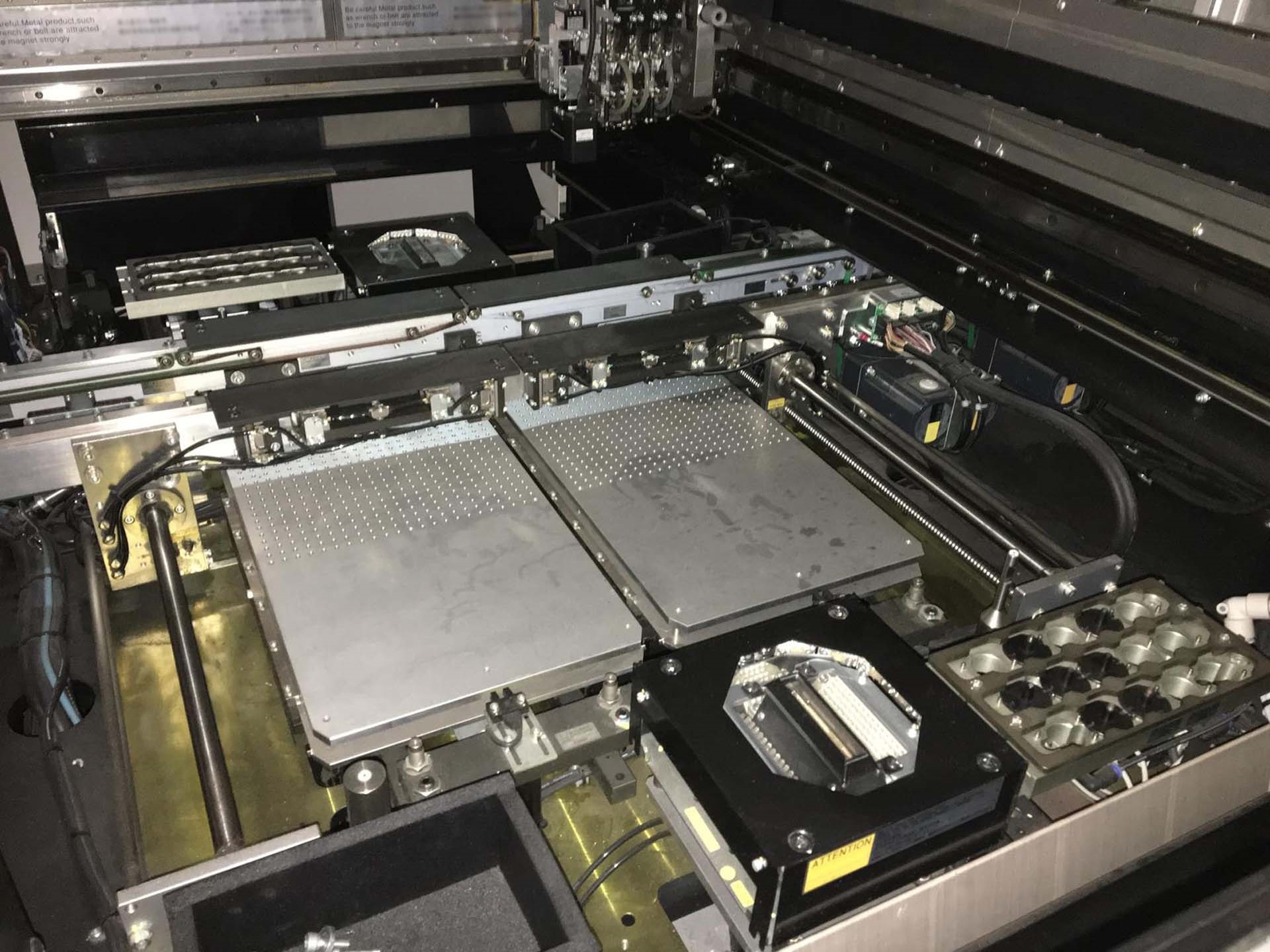

(3+3) Nozzle heads

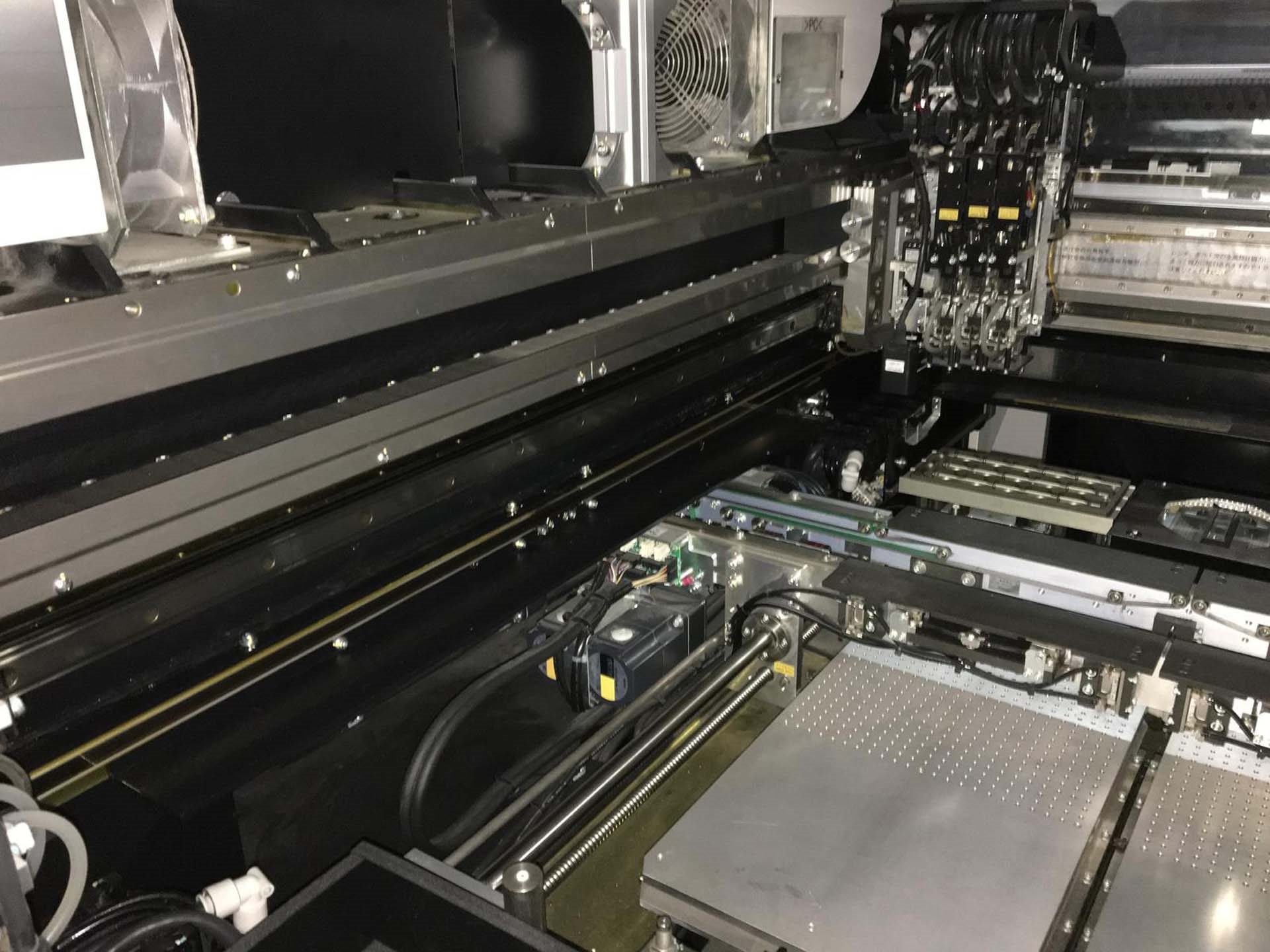

Rear rail fixed

Left to right

(3) 1002 Nozzles

(4) 1003 Nozzles

(12) Holder units

(4) Nozzle changers

(4) Camera units

No lead checker

(4) AF/BF Camera units with side light option

PCB Sensors

CPU Unit with cards

Missing parts:

(6) X/Y Servo drivers

(4) Scrap boxes

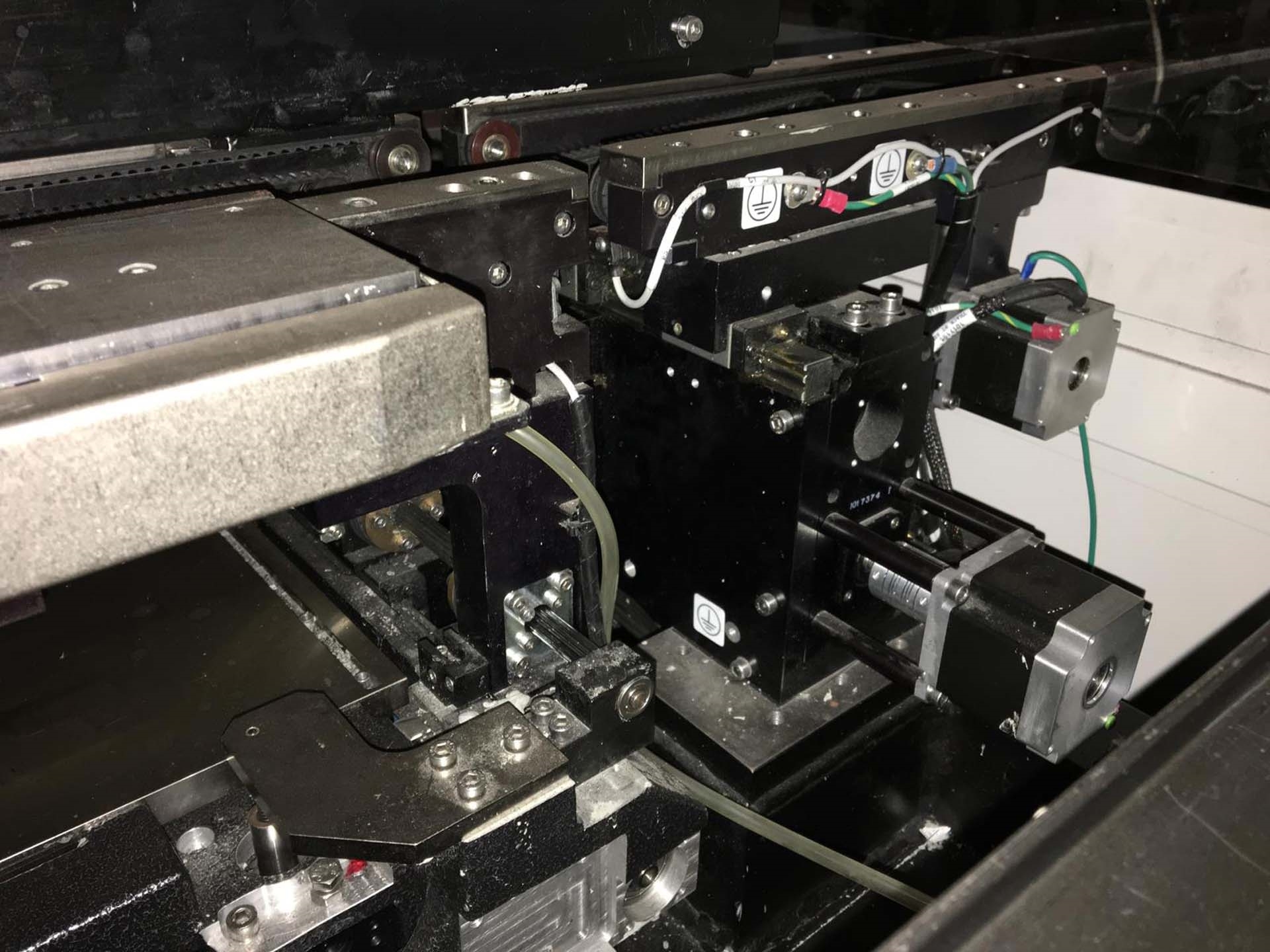

Plastic carrier of cables in axis AR

Right side feeder cover

PCB Stoppers in AF/AR & BF/BR

Conveyor exit cover

(4) Screws in feeder cover

(2) Power supplies

Head BF in nozzle holder

(3) Blue lamps for feeder

PCB Support pins

Damaged parts:

Front & rear control panel with damaged plastic cover

2009 vintage.

PANASONIC CM602-L is a PC board assembly and manufacturing equipment designed for high production throughput and efficient automated operation. It is a highly reliable system which features a precision multi-head feeder assembly, enabling quick and accurate loading of components onto PC boards. The machine is equipped with a vision unit, which is used to identify each component and the correct feeder path to load it onto the PCB. The loading head is capable of loading up to 10 components from a single feeder at once. The head features a high-torque, high-power motor that is designed to withstand high temperatures and to ensure accurate orientation and placement of the components. The two-stage nozzle assembly ensures precise positioning of components and a consistent feed rate. PANASONIC CM602L also features a component recognition machine that can detect and identify different types of components. This ensures precise and accurate placement of the components. It is also equipped with a circuit feeder tool that can feed components into their respective positions on the circuit board. This ensures that correct components are placed in the correct position and eliminates the need for manual component positioning. Components are then soldered to the board using a one-step soldering process. CM 602L also features an advanced material management asset which is used to monitor, track and manage the inventory of components. This model ensures that components are always available when needed and reduces the risk of running out of a particular component during production. The machine is also equipped with a built-in diagnostic equipment which can detect and diagnose any issues during operation. In addition to the automated assembly and material management systems, CM 602-L also features an ergonomically designed operator console which allows the operator to perform various tasks, such as programming, monitoring and debugging, in a comfortable and easy to use environment. The machine also includes a user-friendly software interface which assists the operator in the setup and operation of the machine. CM602-L is an essential system for production and manufacturing operations, providing high-speed assembly and efficient material management. It is reliable and offers excellent precision and accuracy to ensure top quality output. It is easy to operate and maintain, and its user-friendly design ensures that operators are able to quickly and accurately perform their tasks.

There are no reviews yet