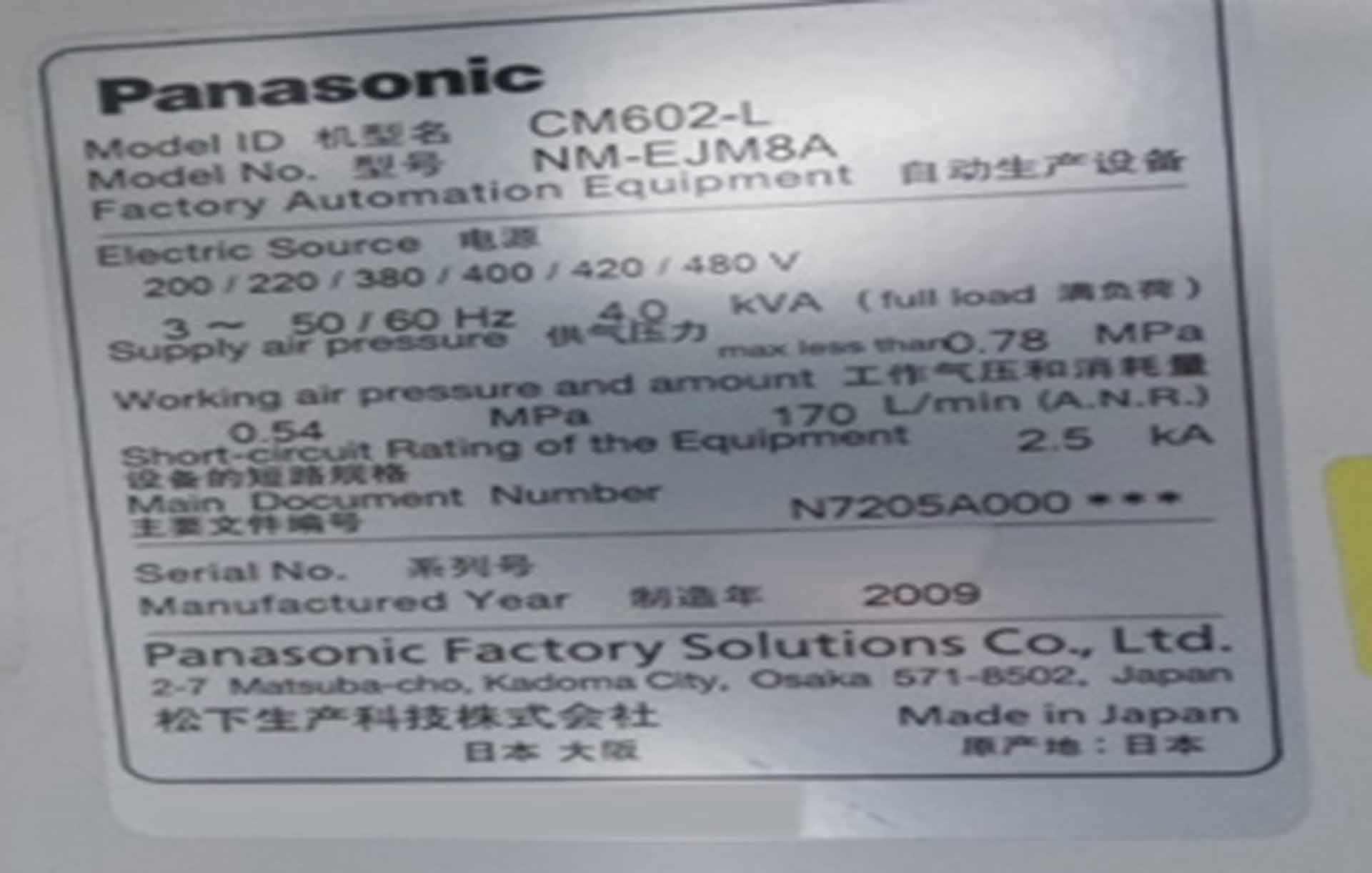

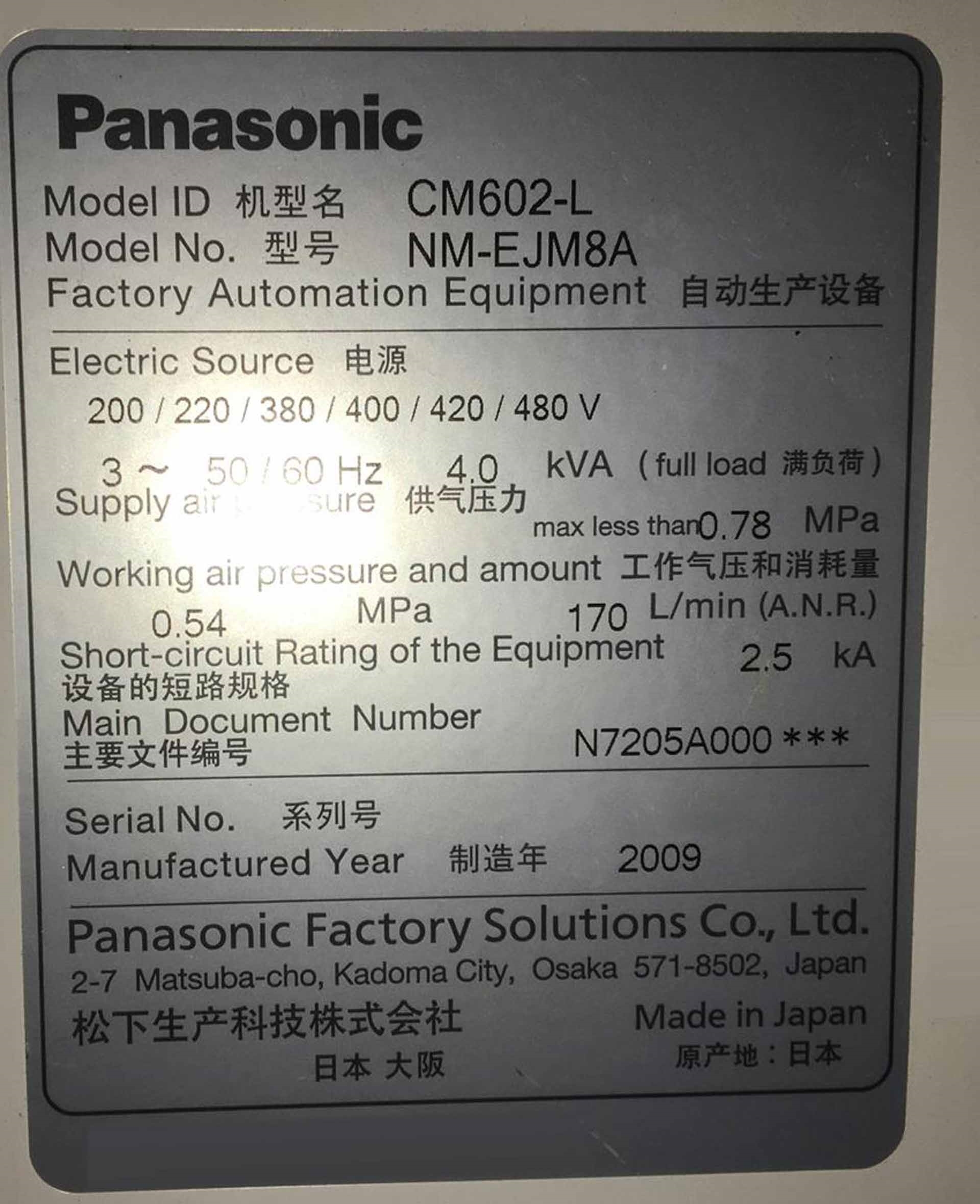

Used PANASONIC CM602-L #9244670 for sale

URL successfully copied!

Tap to zoom

ID: 9244670

Vintage: 2009

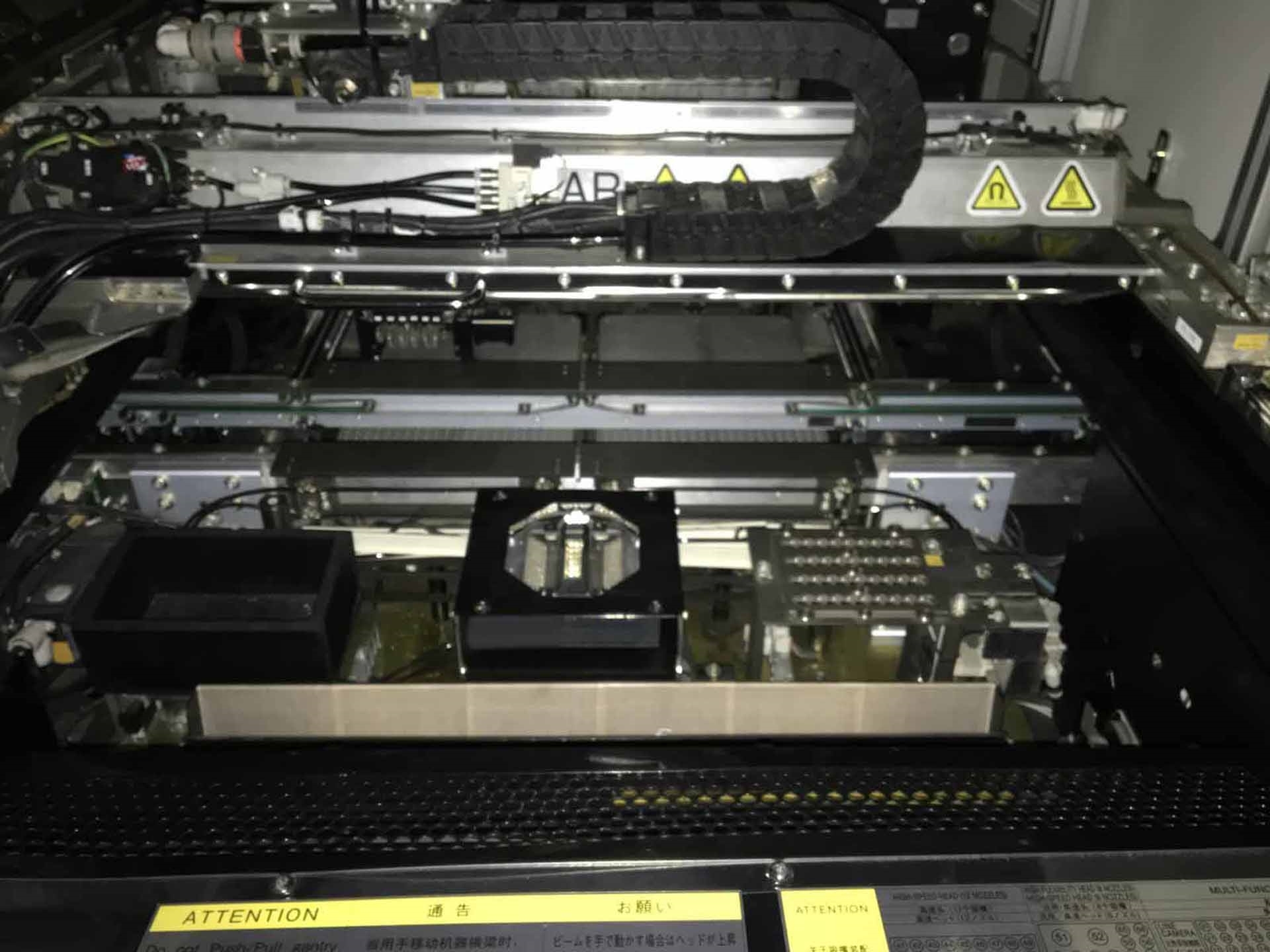

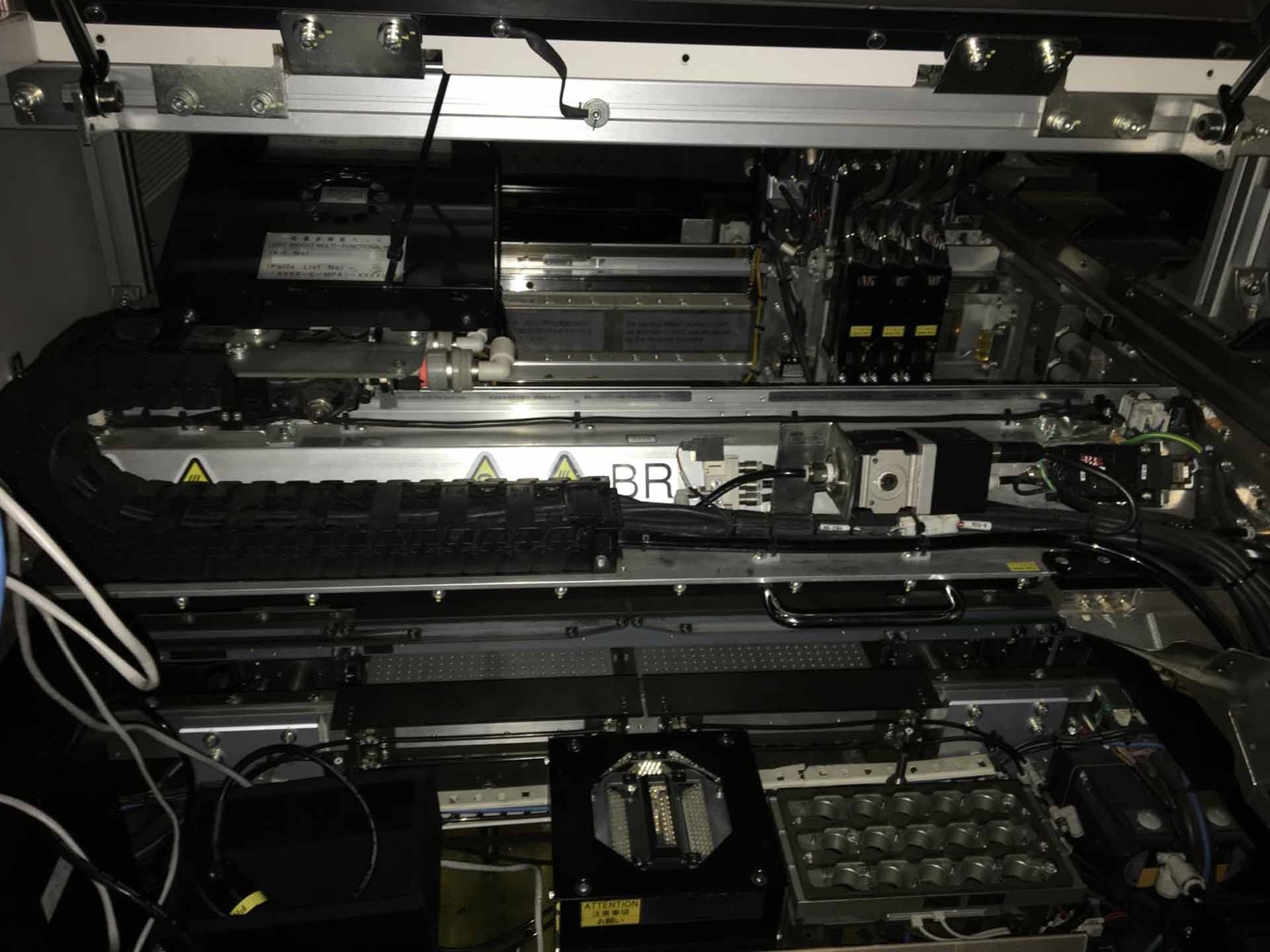

Pick and place machine

MTU

Running hours: 53,842

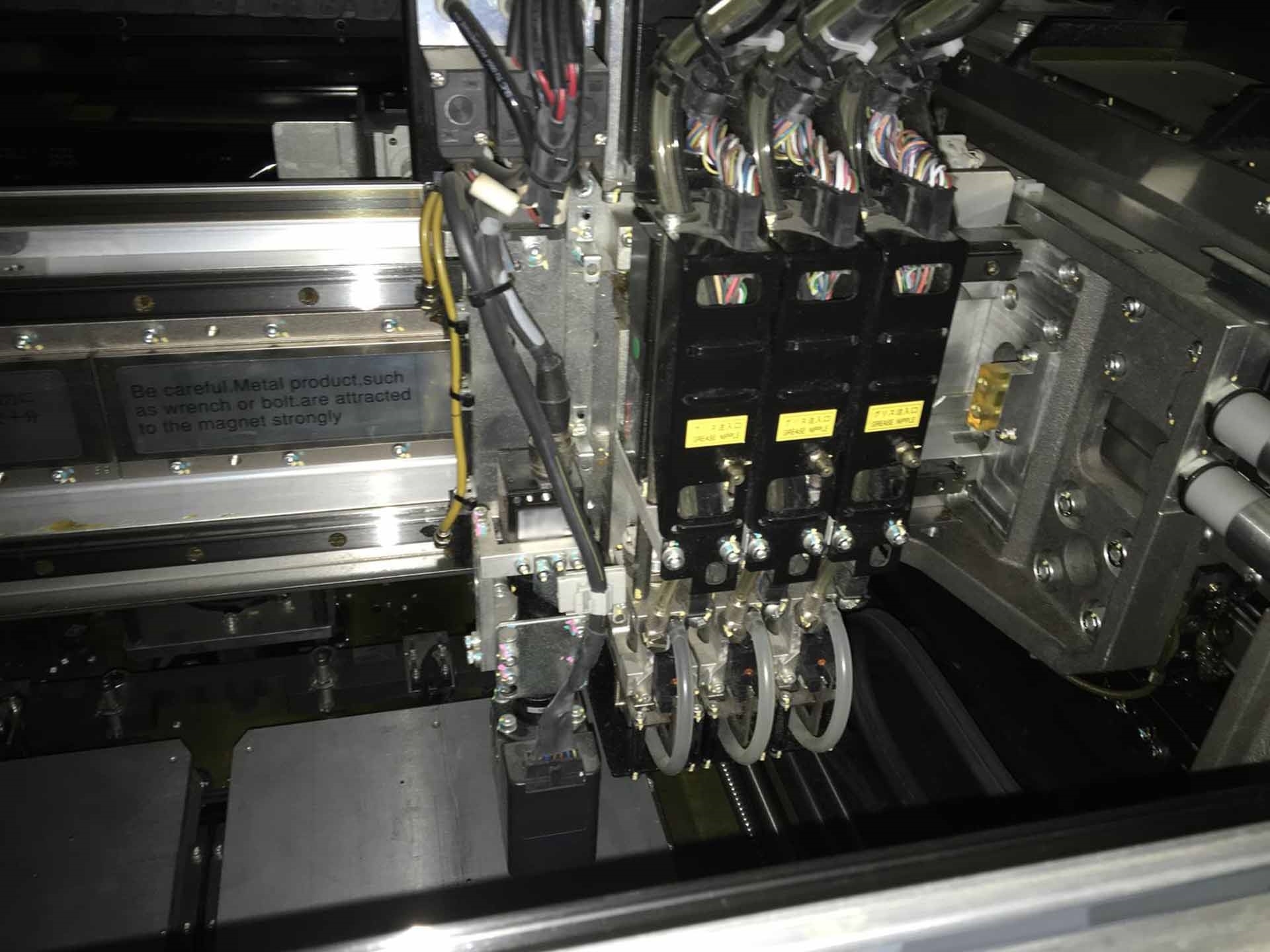

(12+3) Nozzle heads

Rear rail fixed

Left to right

No nozzles

(24) Holder units (AF/AR)

(6) Holder units (BF/BR)

X/Y Servo drivers

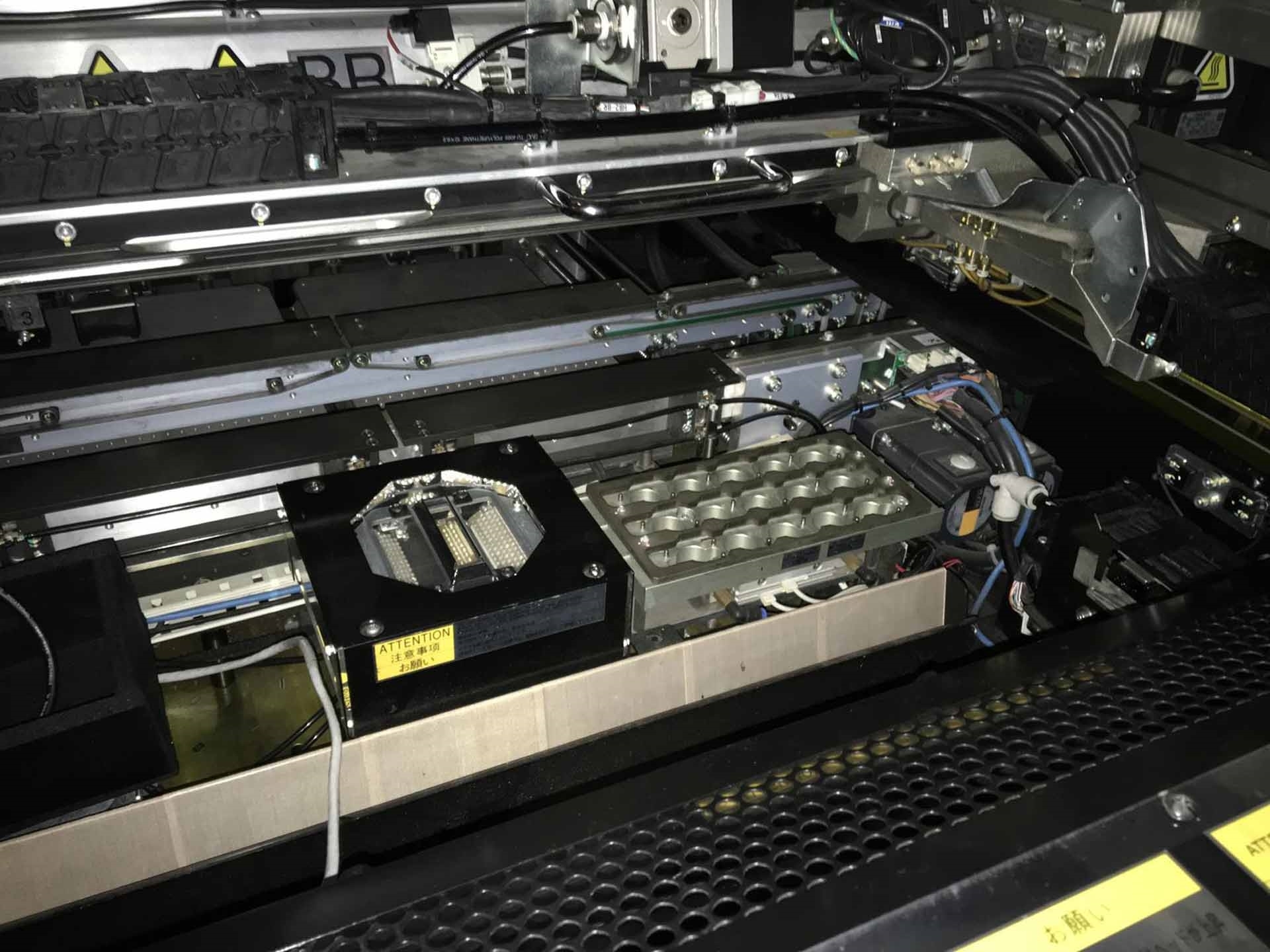

(2) Height component thickness sensors

(4) Nozzle changers

(4) Camera units

(4) Camera units with side light

PCB Sensors

PCB Stopper units

CPU Unit

Missing parts:

(4) Scrap boxes

PCB Support pins

(2) Screws from feeder cover

Bracket in head unit from nozzle holder

Damaged parts:

Front and rear control panel with damaged plastic cover

2009 vintage.

PANASONIC CM602-L is a highly reliable board assembly and manufacturing equipment, designed for high volume production of printed circuit boards. The system is capable of performing high precision surface mounting, solder paste printing, vision centering and alignment, selective soldering, and other processing. The unit comes with an intuitive, operator-friendly human machine interface, allowing operators to easily set up and run various board assembly processes. It is equipped with a motorized linear movement machine, which gives it the ability to quickly move from one workstation to the next. The placement accuracy of the tool is 0.04 mm, which provides outstanding performance for small components and closely spaced components. In addition, it has the flexibility to handle a variety of components, from 0402s up to large, wide-bodies. The asset is equipped with extensive vision options, allowing it to accurately recognize various components and edges for repeatable processes and consistent high-quality precision. Its 3-depth off-line programming assures rapid programming of jobs for high production volumes. The model is also equipped with a no-clean flux supplier option, which allows it to automatically start flux feeding as soon sheets are mounted on the rails. PANASONIC CM602L is equipped with an encoder-based servo positioning equipment, providing smooth, fast, and accurate movements. This helps improve throughput while maintaining high quality board assemblies. The system also has the capability to manage multiple boards at once, which increases efficiency by enabling multiple boards to be processed simultaneously. The unit is also designed for environmental reliability, and features an IP5X dustproof construction and anti-corrosive coating. CM 602L is designed to be energy efficient with a low-power consumption rate. The machine is also certified to the EMCEMC standard, ensuring compatibility with the latest electrical safety regulations. In summary, PANASONIC CM 602-L is a board assembly and manufacturing tool with a range of features, designed for high volumes of production with exceptional accuracy over a wide range of components. Its ease of operation and energy efficiency make it an attractive choice for board assembly and manufacturing.

There are no reviews yet