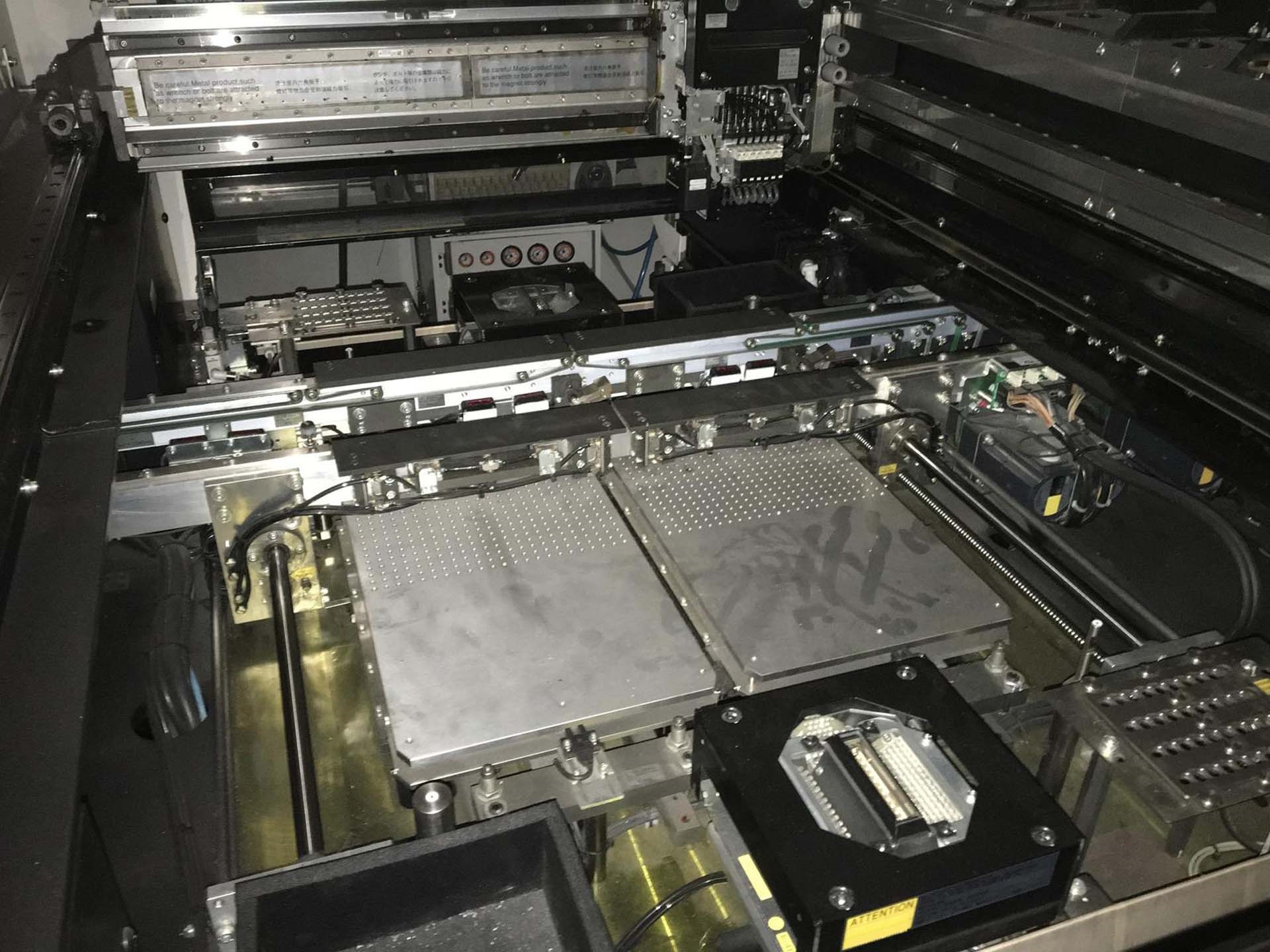

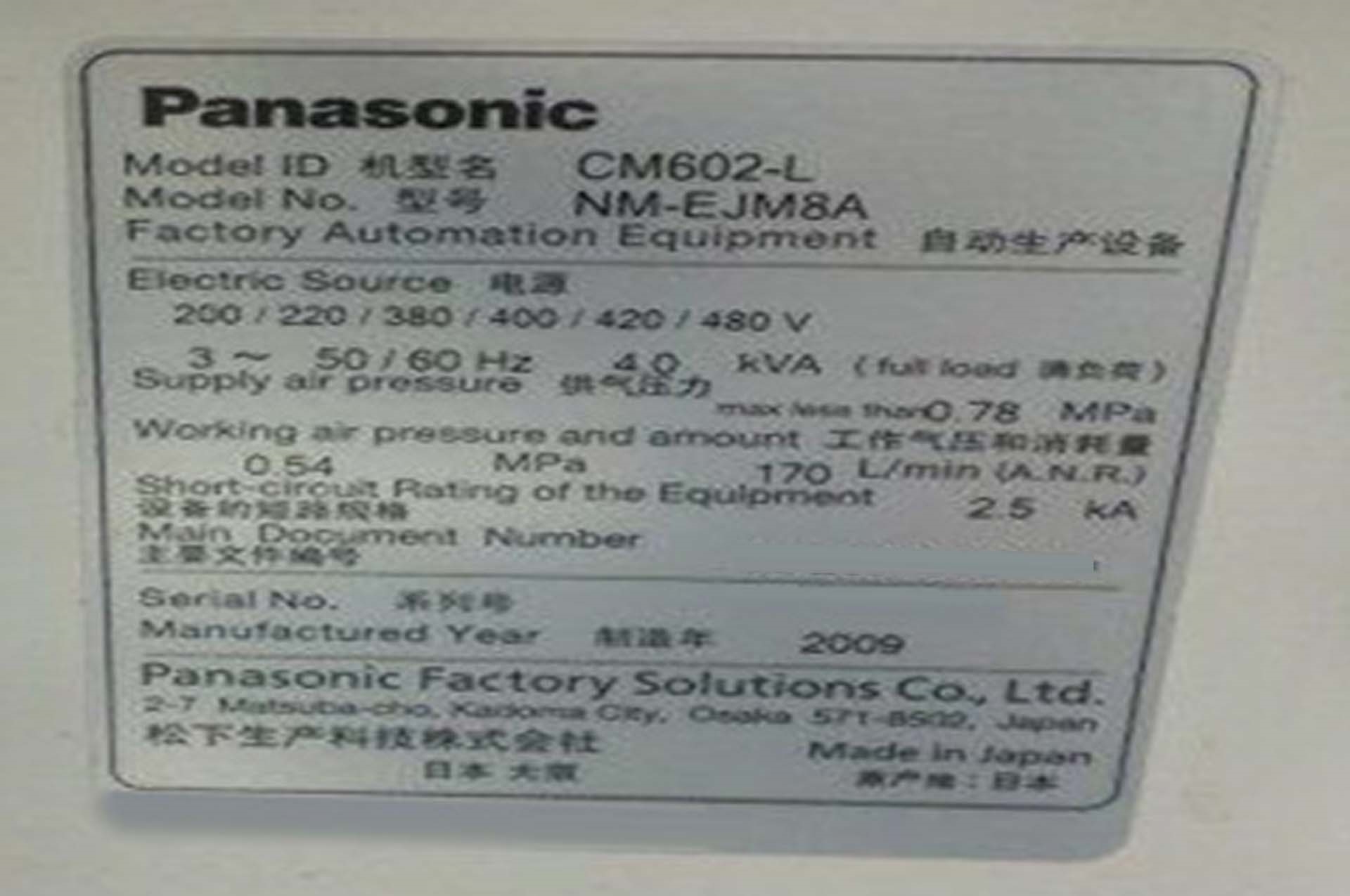

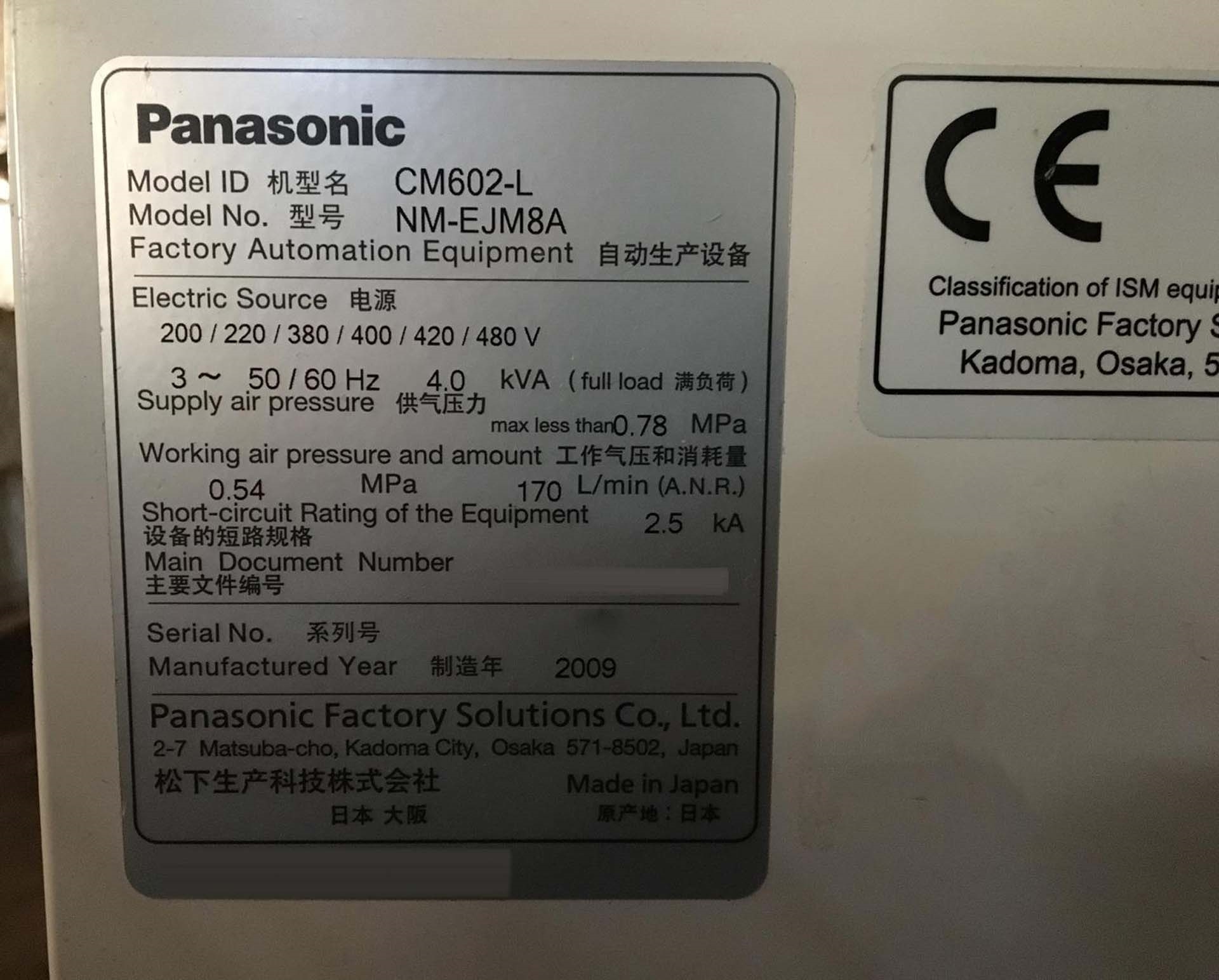

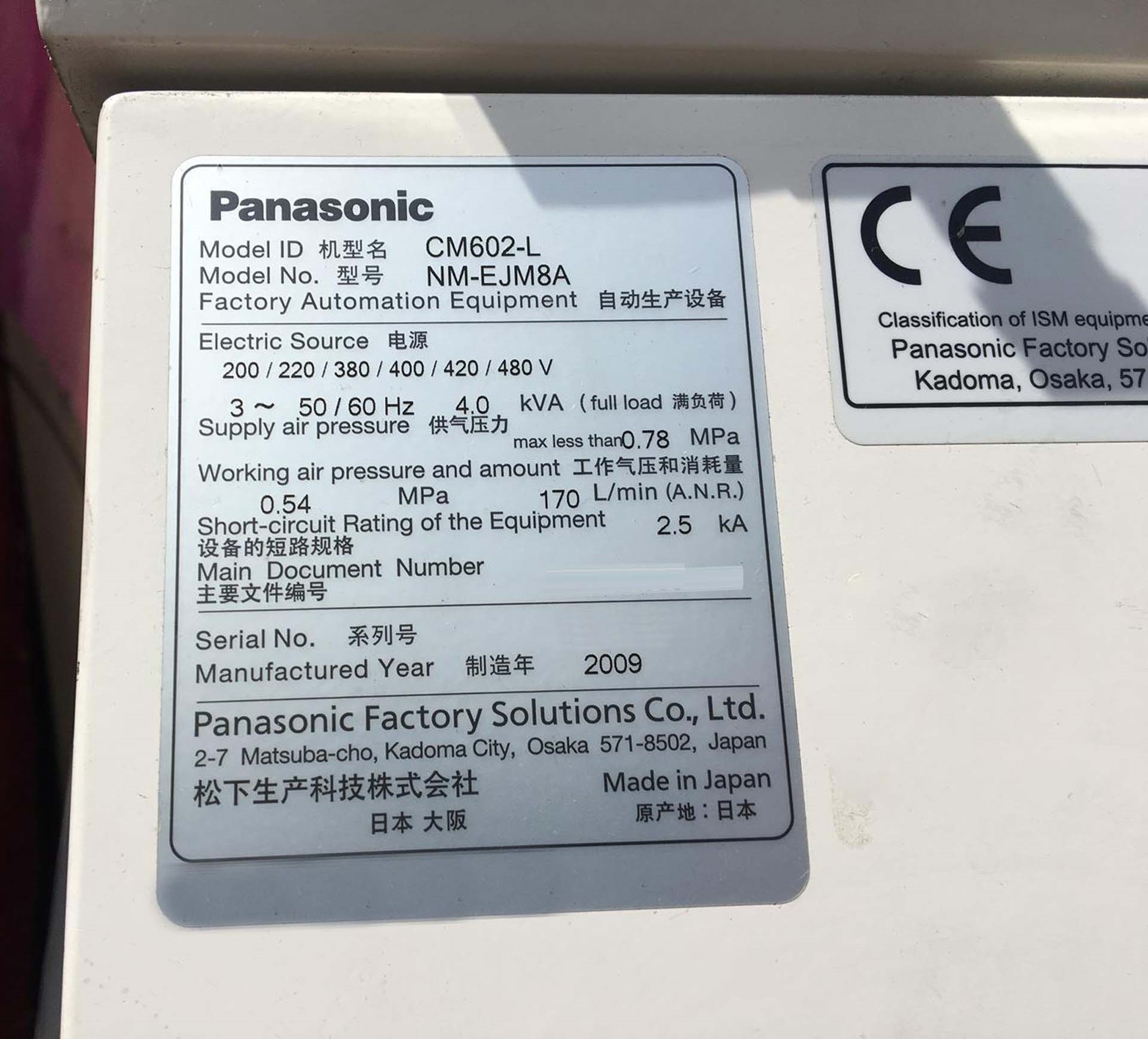

Used PANASONIC CM602-L #9244673 for sale

URL successfully copied!

Tap to zoom

ID: 9244673

Vintage: 2009

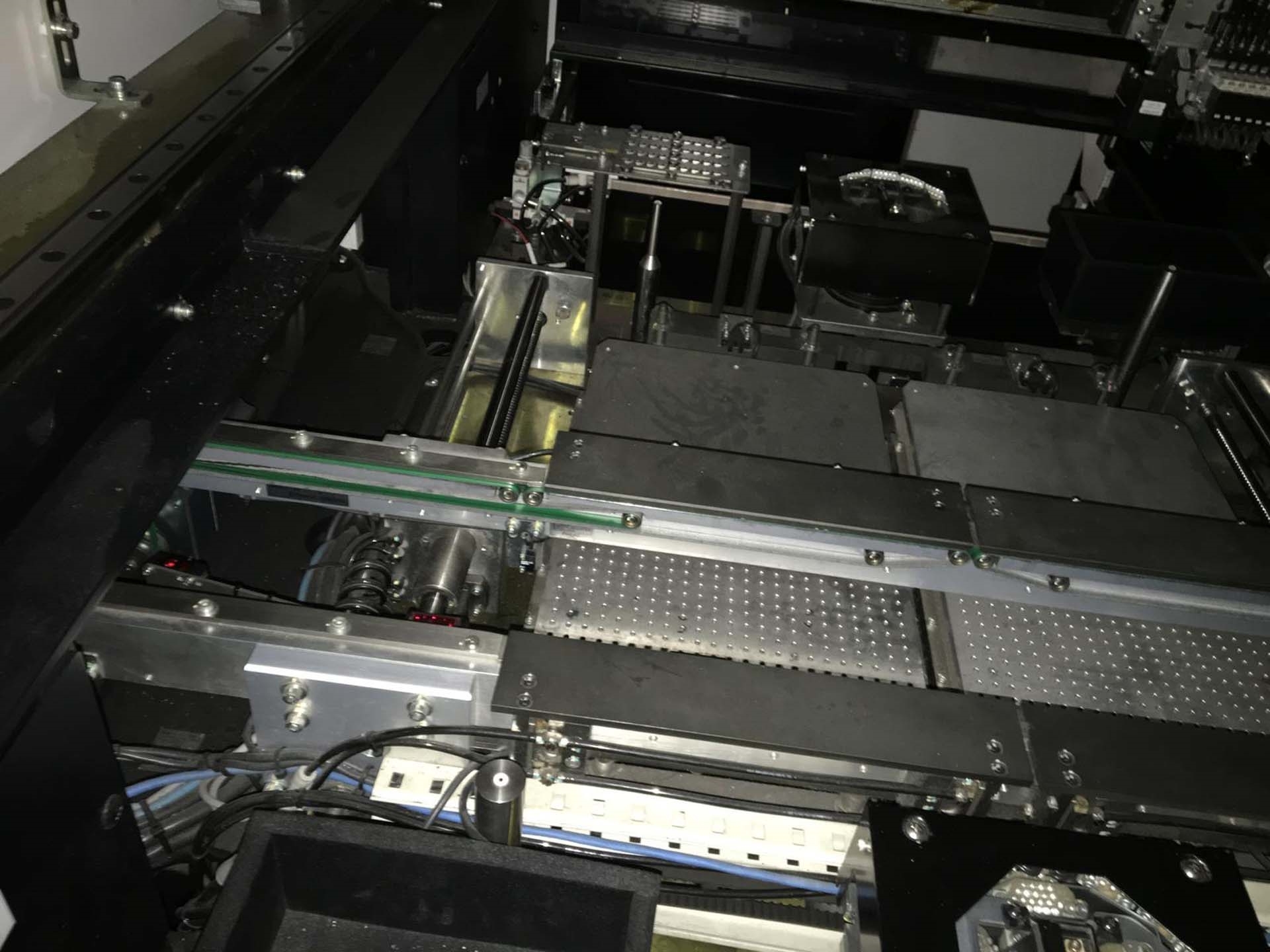

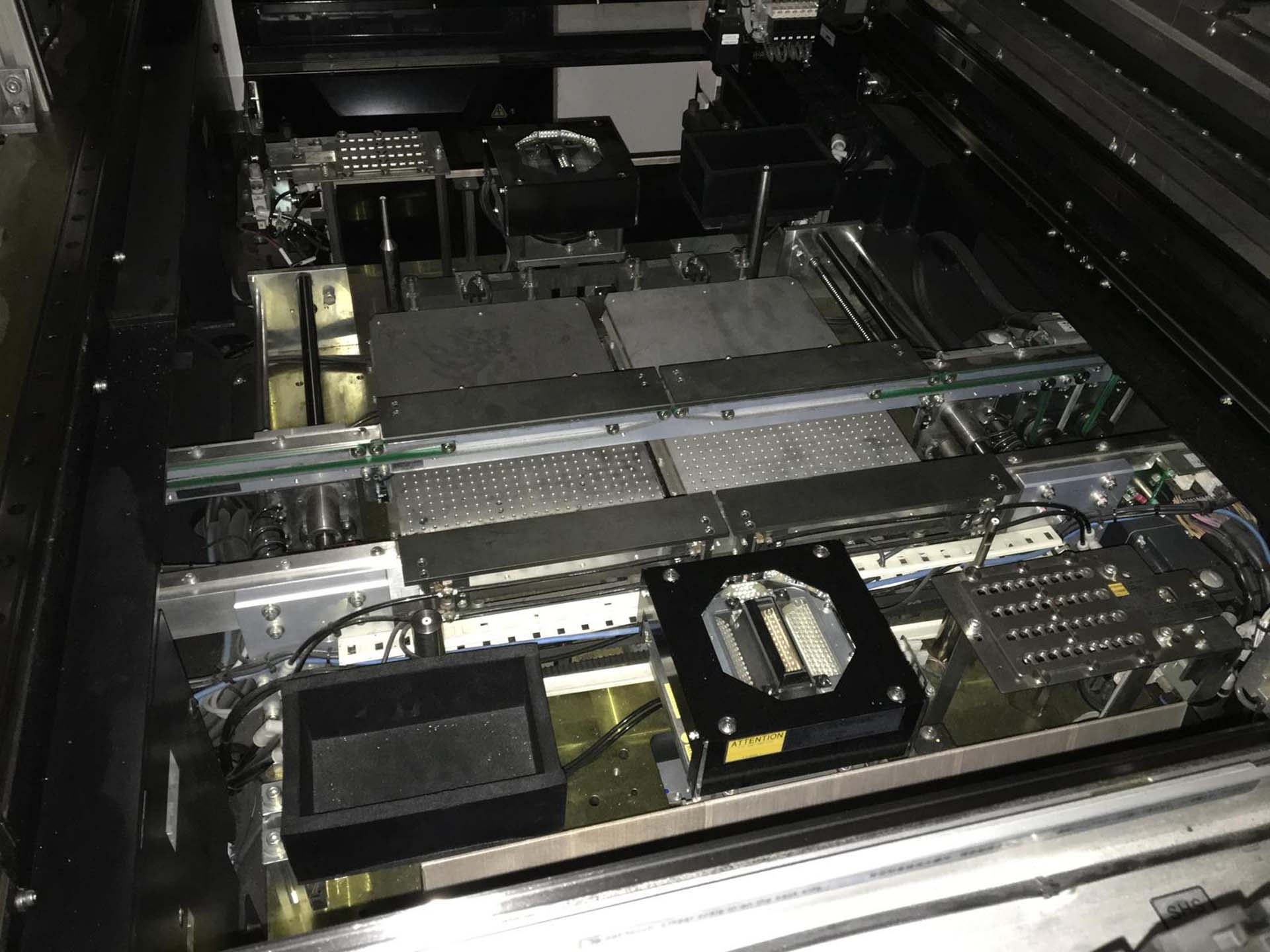

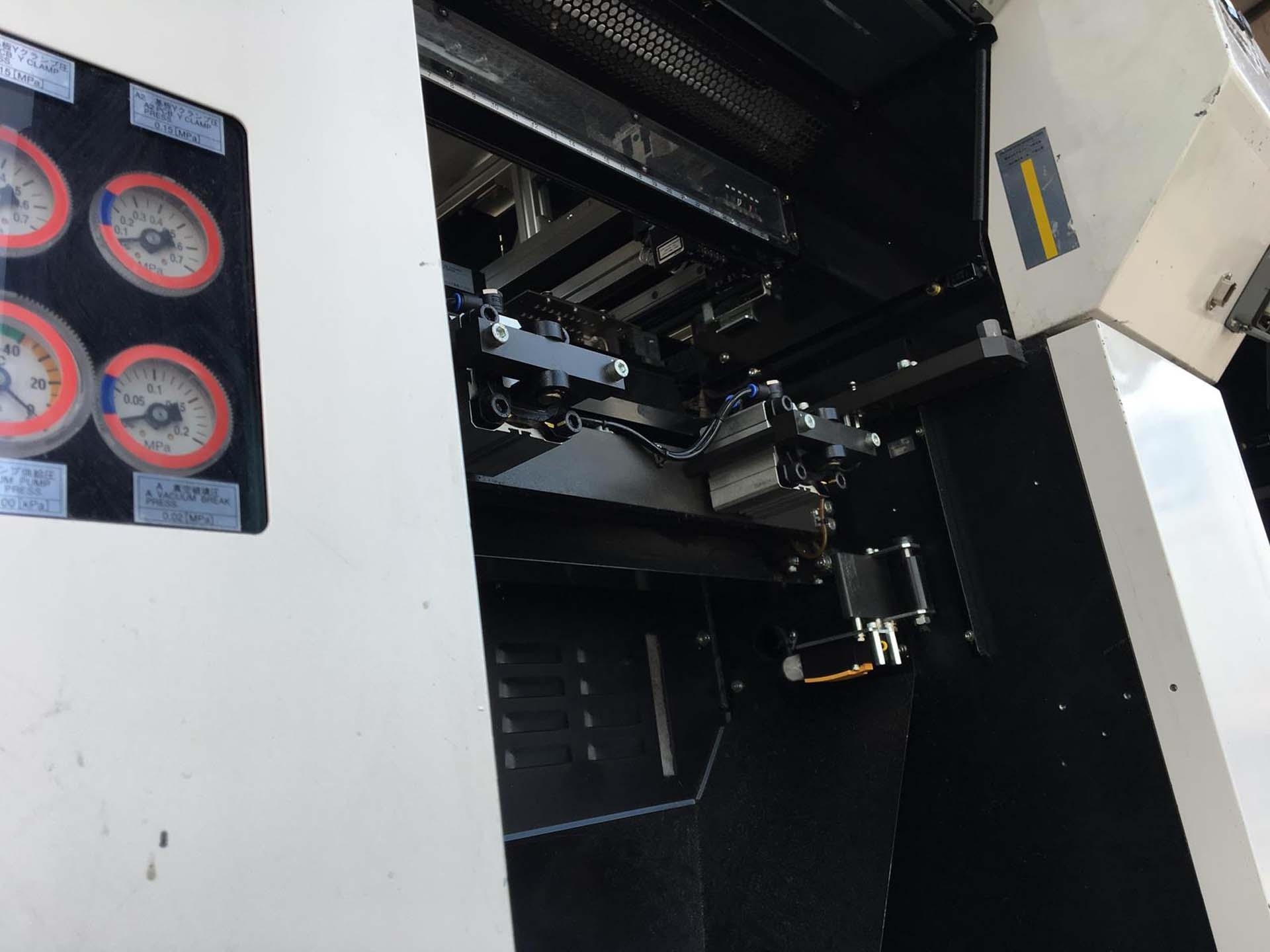

Pick and place machine

Running hours: 64,455

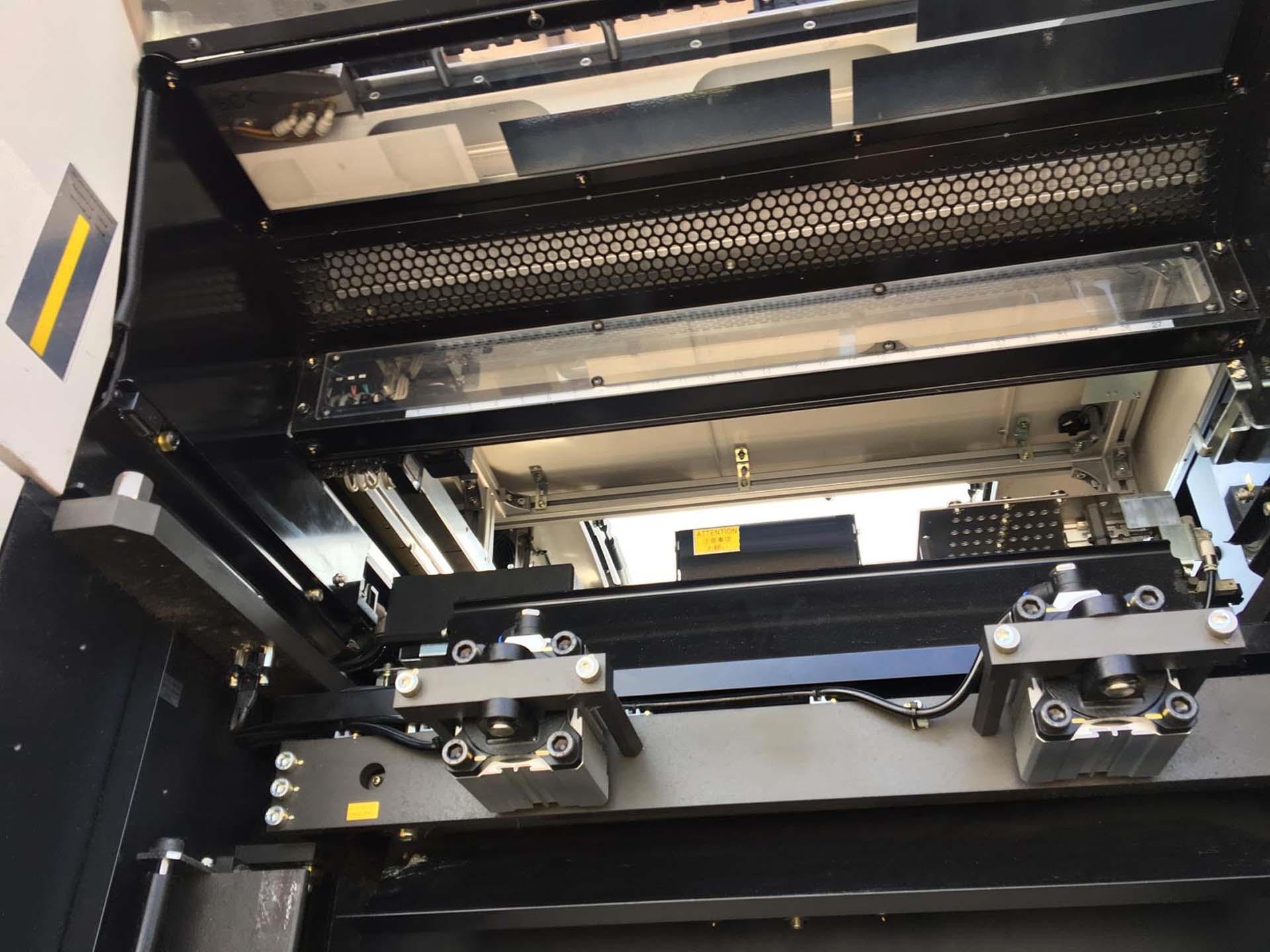

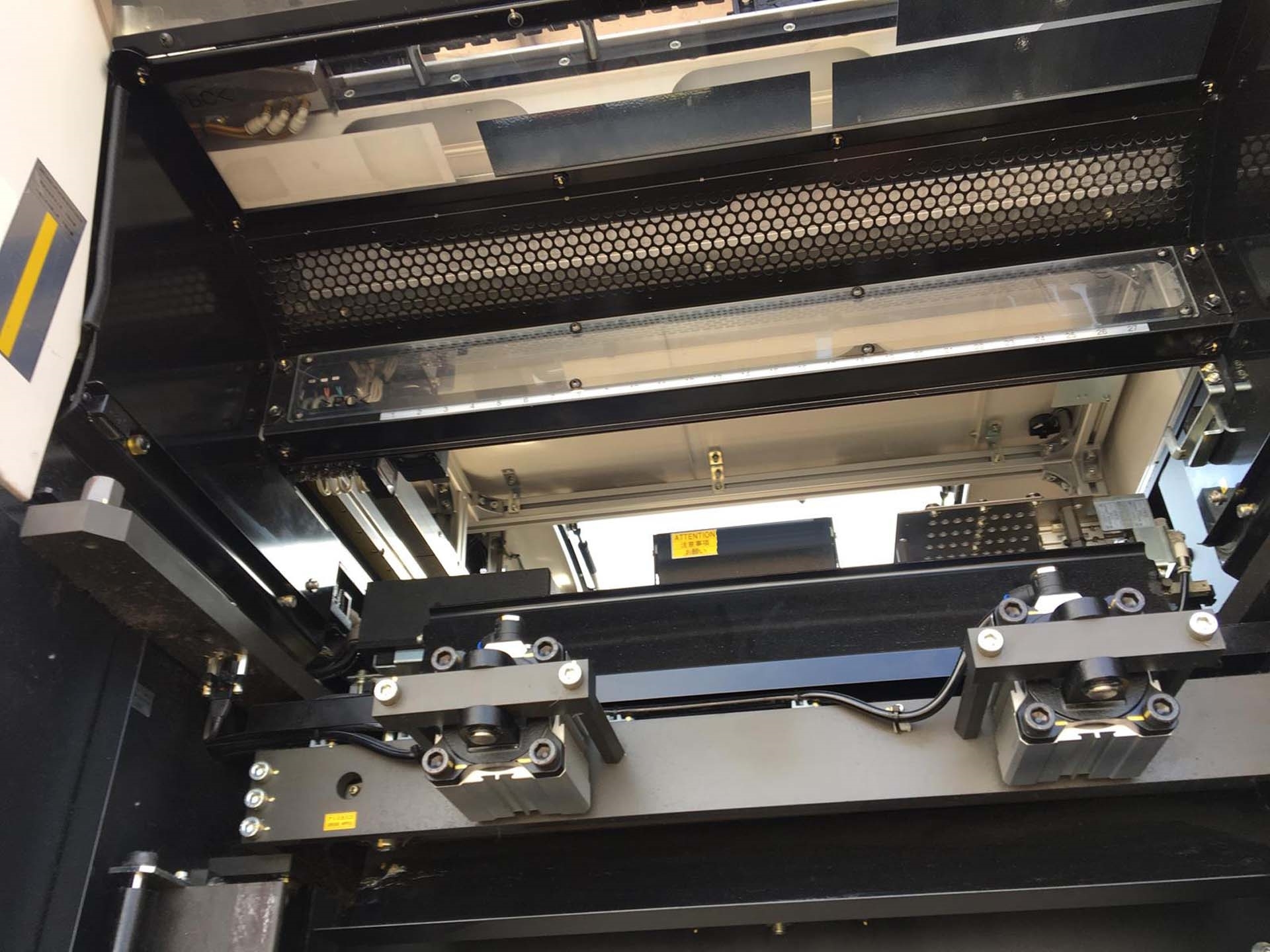

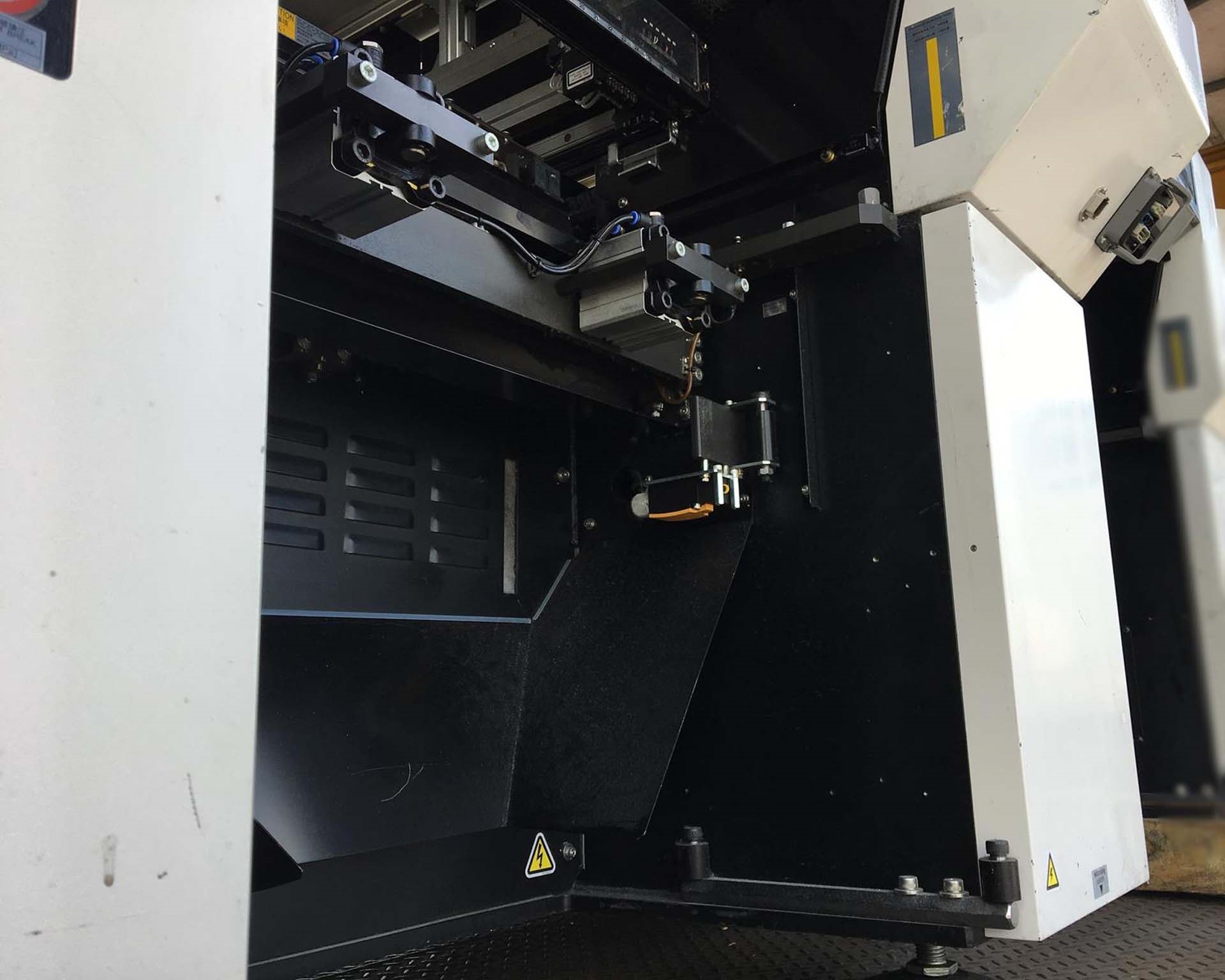

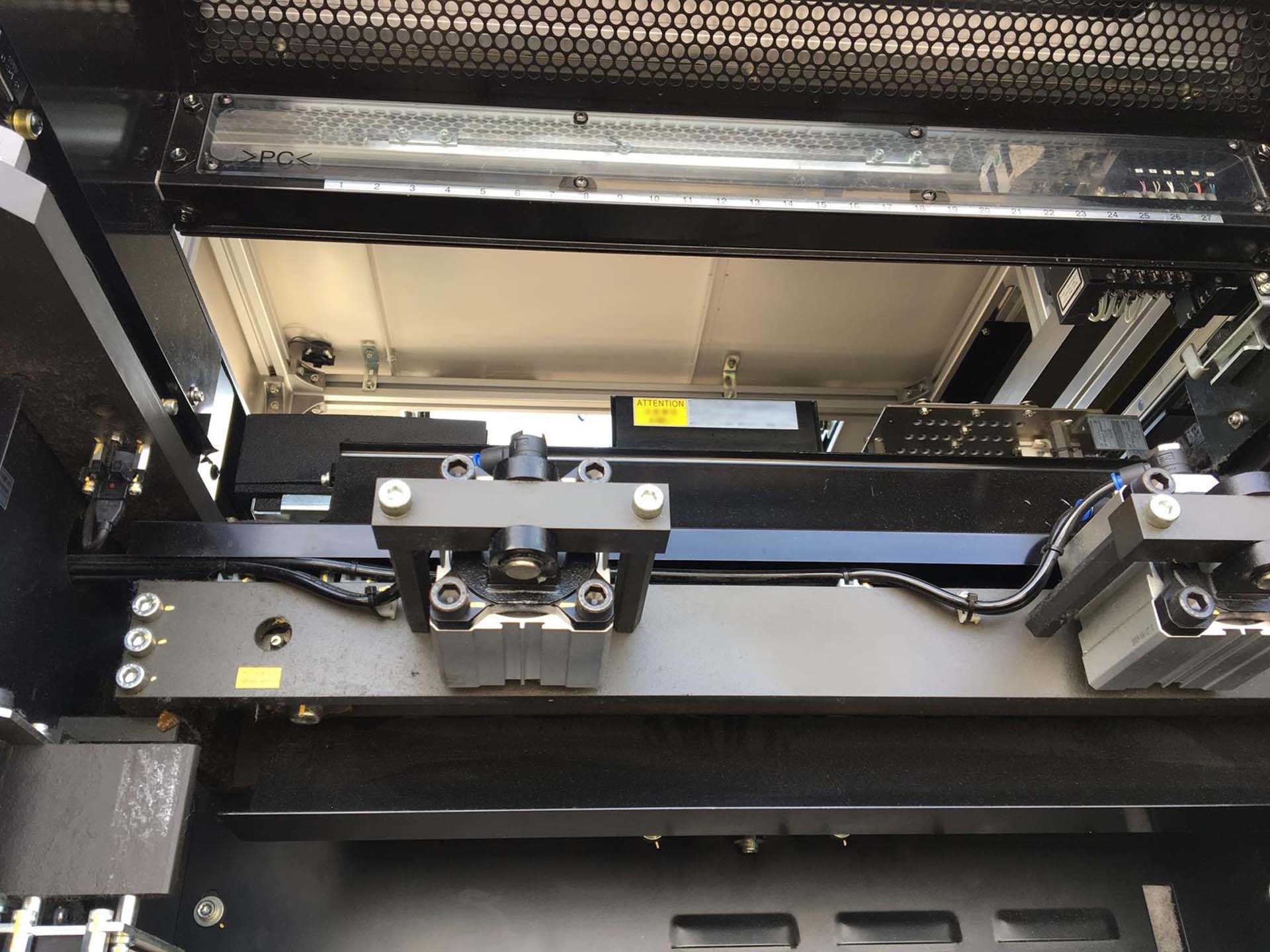

(12+12) Nozzle heads

Rear rail fixed

Left to right

No nozzles

(48) Holders

X/Y Servo drivers

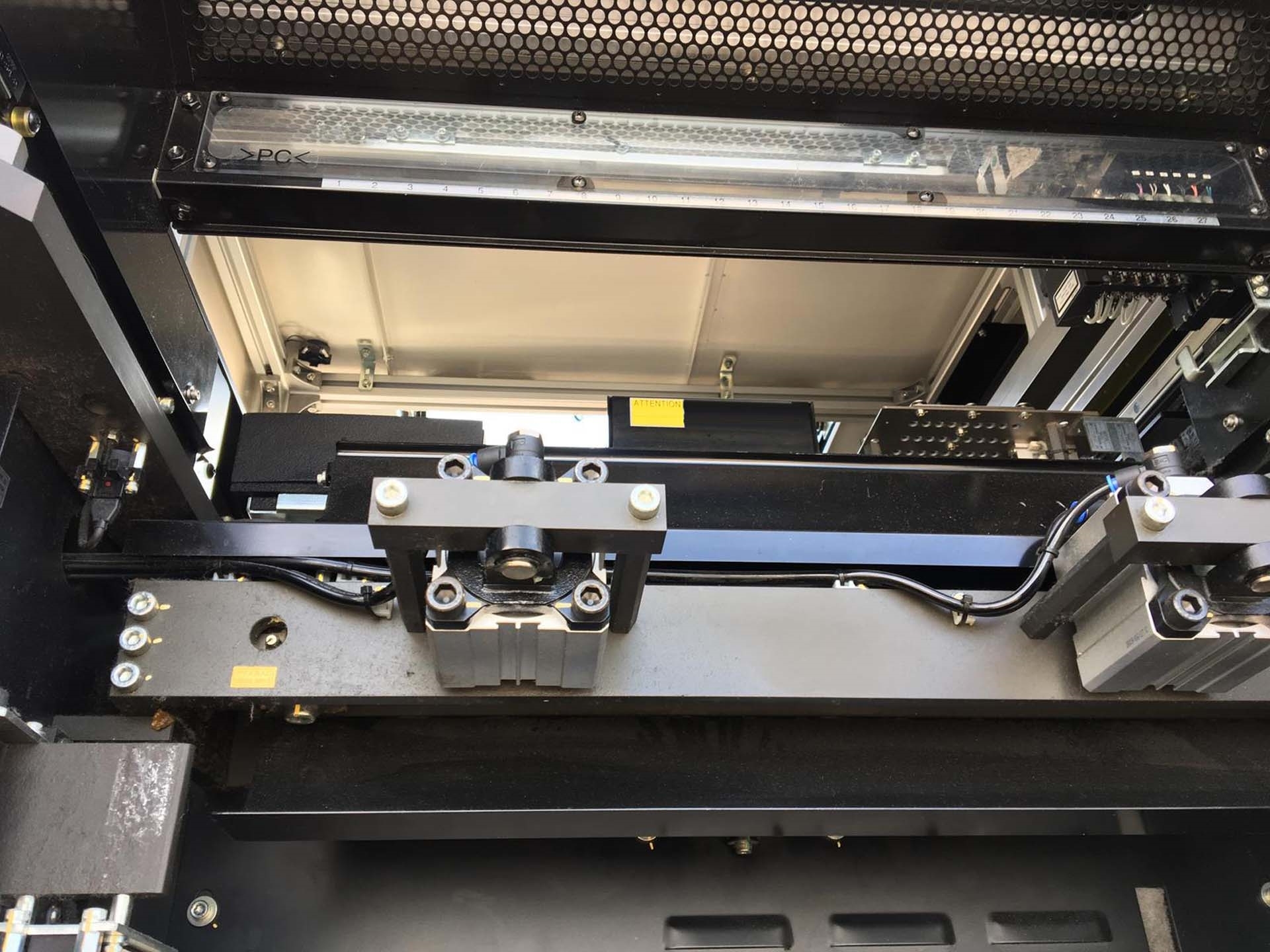

Height component thickness sensor

(4) Nozzle changers

(4) Camera units

(2) AF/BF Camera unit with side light

PCB Sensors

PCB Stopper

CPU Unit with cards

Missing parts:

Cover

(4) Scrap boxes

PCB Support pins

2009 vintage.

PANASONIC CM602-L is a state-of-the-art PC board assembly and manufacturing equipment designed to meet the most demanding requirements in terms of precision, flexibility and automation. With the capability to handle up to 2 independent production lines with 4 SPI combinations, the system can make PC boards of almost any size and complexity with the highest degree of accuracy, speed and reliability. The unit was designed with the philosophy of user-friendliness in mind, with an easy to read graphical user interface (GUI) allowing the control of all processes on the production line. A wide array of programmable settings allows the user to tailor the machine to their specific project needs, with features such as pick-and-place positioning and separate adjustability of each nozzle. This ensures the production of PC boards of the highest quality with the most efficient workflow possible. PANASONIC CM602L also comes with various integrated safety features, which can detect abnormal production conditions and CAE operation if required. Mode changing can be done quickly and easily thanks to a convenient and flexible pick-and-place tool and an effective design process. The asset also features an energy saving feature, allowing it to reduce power consumption when not in use. CM 602L model utilizes a wide range of components from various vendors, and is designed to work with all common PCB surface finishes. This includes resistivity and resistance measurements, allowing users to confirm solder joint quality at the point of production. The equipment can also be equipped with hot-oil, air-cooled, super-cooled and infra-red type soldering systems for different types of PC board assembly. In addition to its core features, CM 602 L also comes with various advanced options. This includes an integrated laser inspection system, providing a full 3D scan of even the most complex boards to ensure 100% accuracy. This unit is highly sophisticated and contains a variety of inspection and statistical monitoring options for quality control. Overall, CM 602-L is a highly advanced PC board assembly and manufacturing machine that offers users unparalleled precision and flexibility while ensuring the highest quality in production. The range of components and integrated features make it one of the most advanced and reliable systems on the market today.

There are no reviews yet