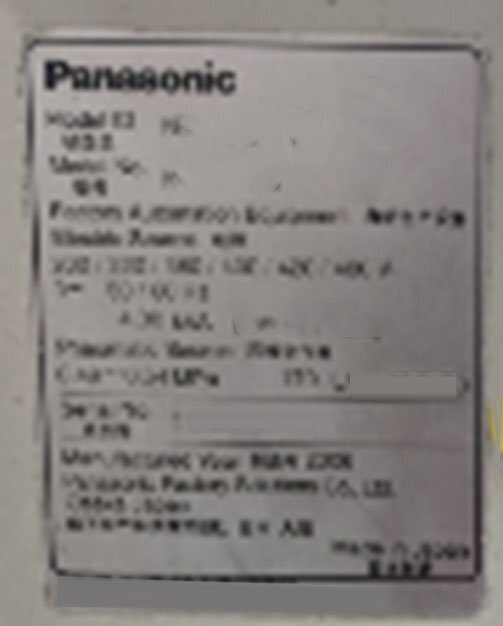

Used PANASONIC CM602-L #9351267 for sale

URL successfully copied!

Tap to zoom

ID: 9351267

Vintage: 2006

Chip mounter

Single lane

C Type

Head: 8/3

(3) Feeder carts

2006 vintage.

PANASONIC CM602-L is a leading PC board assembly and manufacturing equipment. It is a highly integrated and automated manufacturing system that provides maximum flexibility and high-efficiency production of high-quality PCB assemblies. The unit consists of a single work zone that can simultaneously accommodate up to four processing machines — one placement machine, two soldering machines, and one surface mounting machine — alongside four feeder stations, one parts bin station, an array of bottom-side processing stations, a depanelizer board station, and two collection tables. All machines and stations are configured with an easy-to-operate user interface. The placement machine is designed for precision placement of components up to 0201-inch size with up to 600,000CPH (Chips Per Hour) placement speed. It also contains a laser sensor that checks for proper placement of components before and after assembly and maintains optimal accuracy levels. The soldering machines feature advanced laser soldering technology for high-density circuit assemblies, and provide real-time optical recognition of solder joints for improved quality management. Features such as digital signal processing and a stationary laser optics machine ensure fast and precise soldering for a wide range of components. The automatic surface mounting machine is capable of performing multiple side placement and suitable for a wide range of components, including chip resistors, chip condensers, chip ICs, QFPs, SOICs, and HCPS. This machine also offers low-temperature soldering, allowing for the individual soldering of high-density packages. The integrated bottom-side processing stations feature a double-side feeder chassis, allowing double-side placement of components. The cassette tool offers component transportation capabilities between different bottom-side process stations, while the magazine tube asset is capable of handling tiny components up to 0.4-mm-dia. The depanelizing board station can easily adjust the parameters for production of PCBs of different sizes, and supports processes such as trimming, scoring, routing, punching, and bridging. The two collection tables provide an efficient method of collecting and sorting the assembled boards. PANASONIC CM602L PC Board Assembly and Manufacturing Model is an ideal choice for high-volume, automated production of PCB assemblies. Its precision components, advanced processing capabilities, and user-friendly interface provide top-quality results with maximum efficiency.

There are no reviews yet