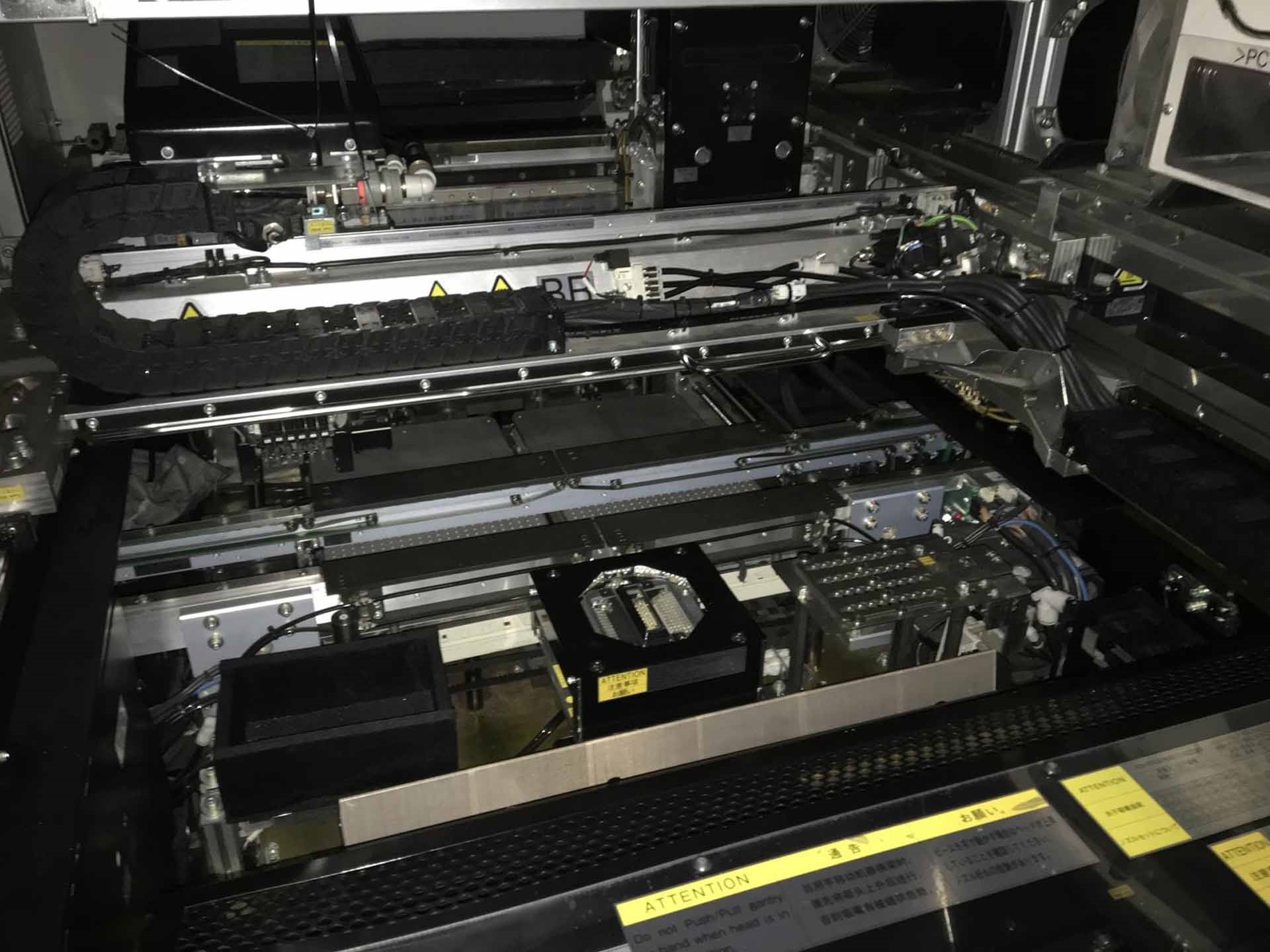

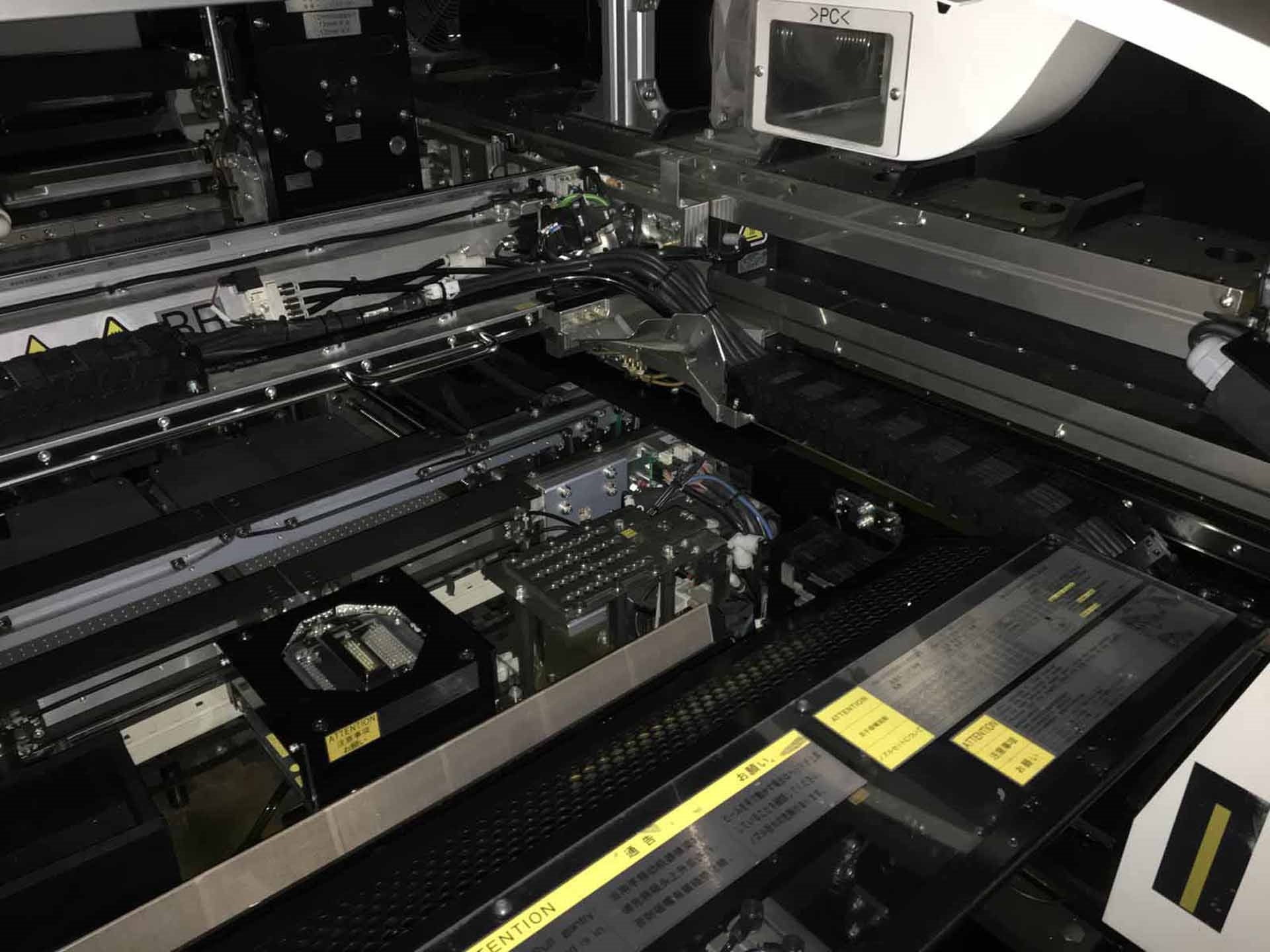

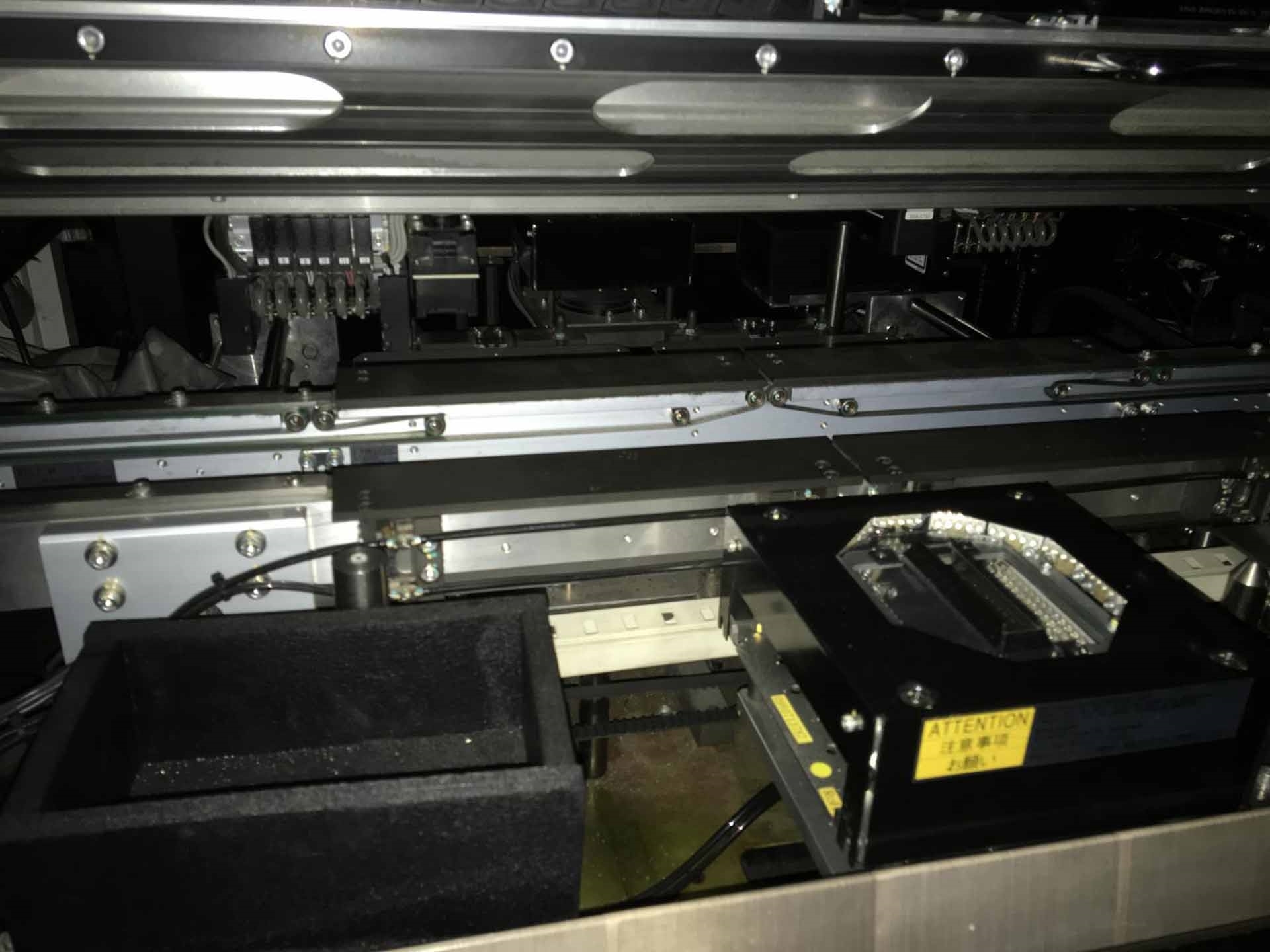

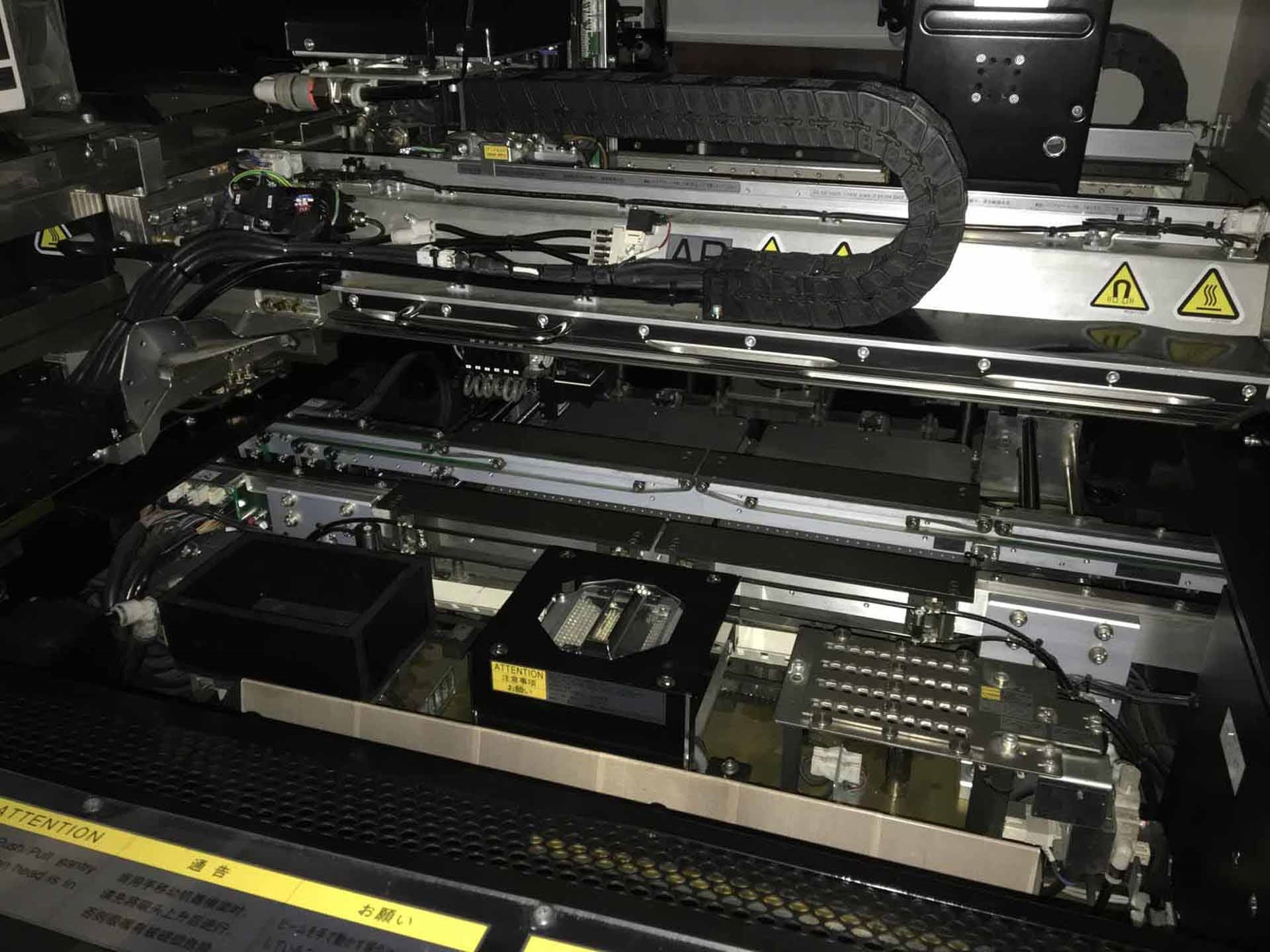

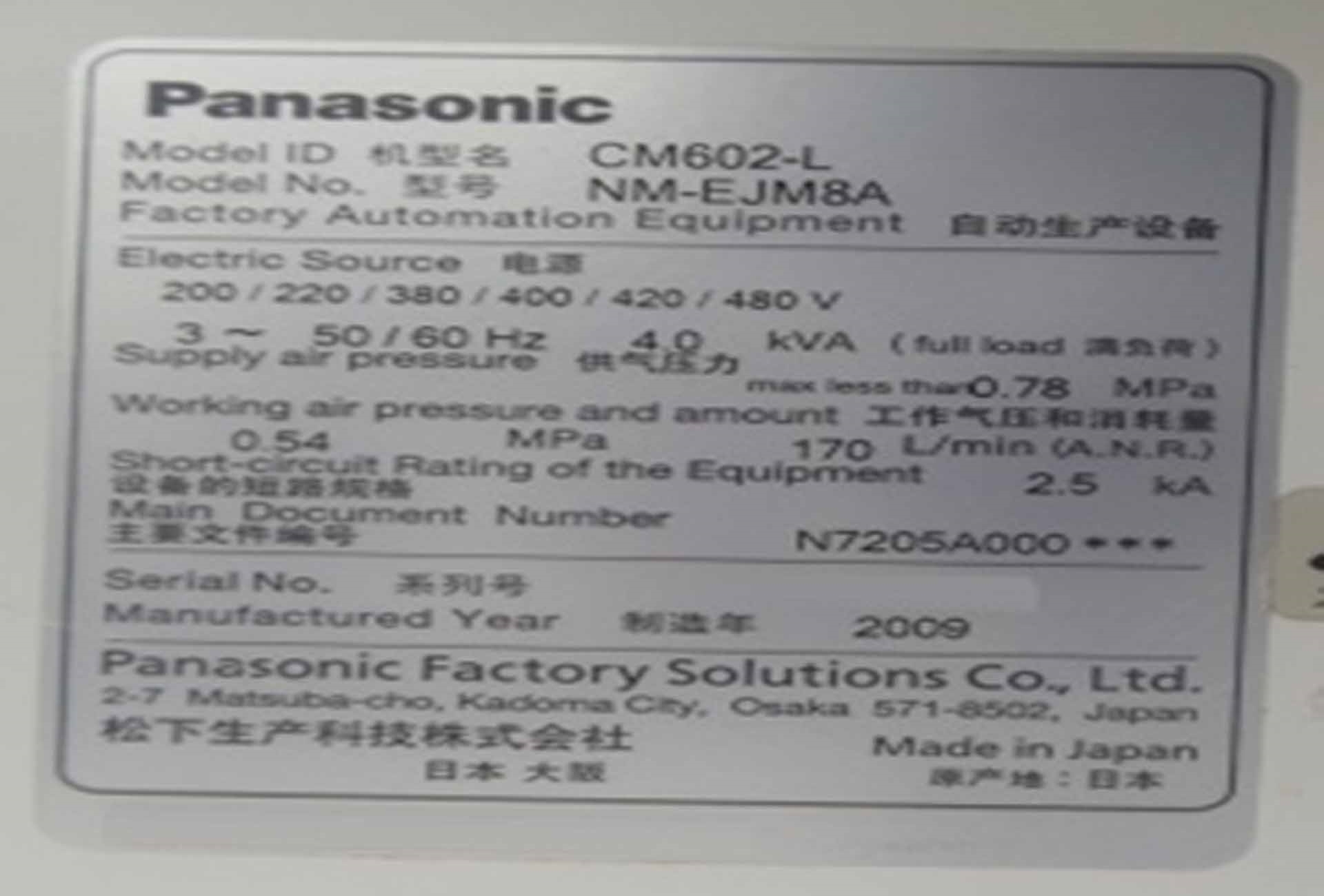

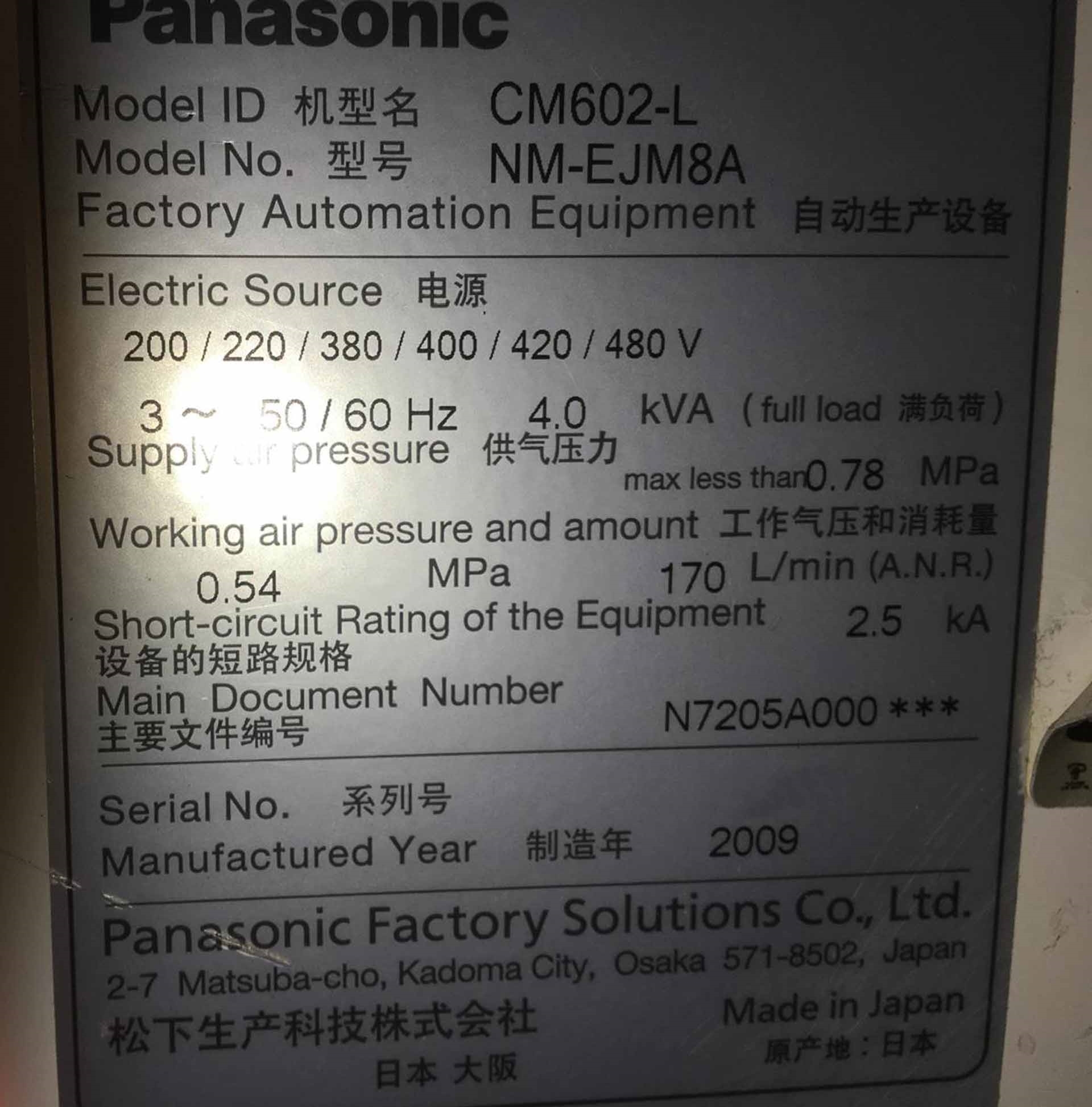

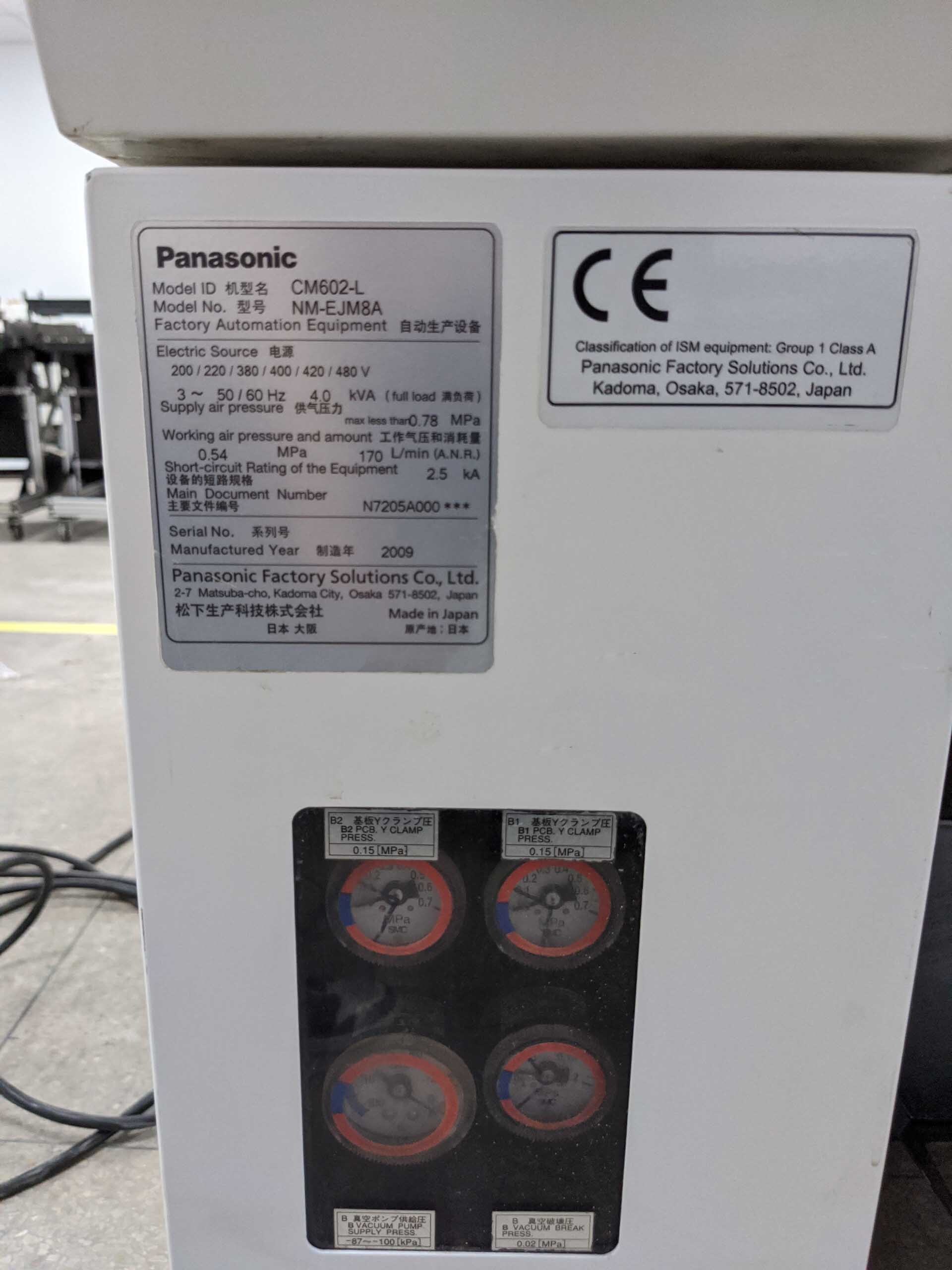

Used PANASONIC CM602-L #9388171 for sale

URL successfully copied!

Tap to zoom

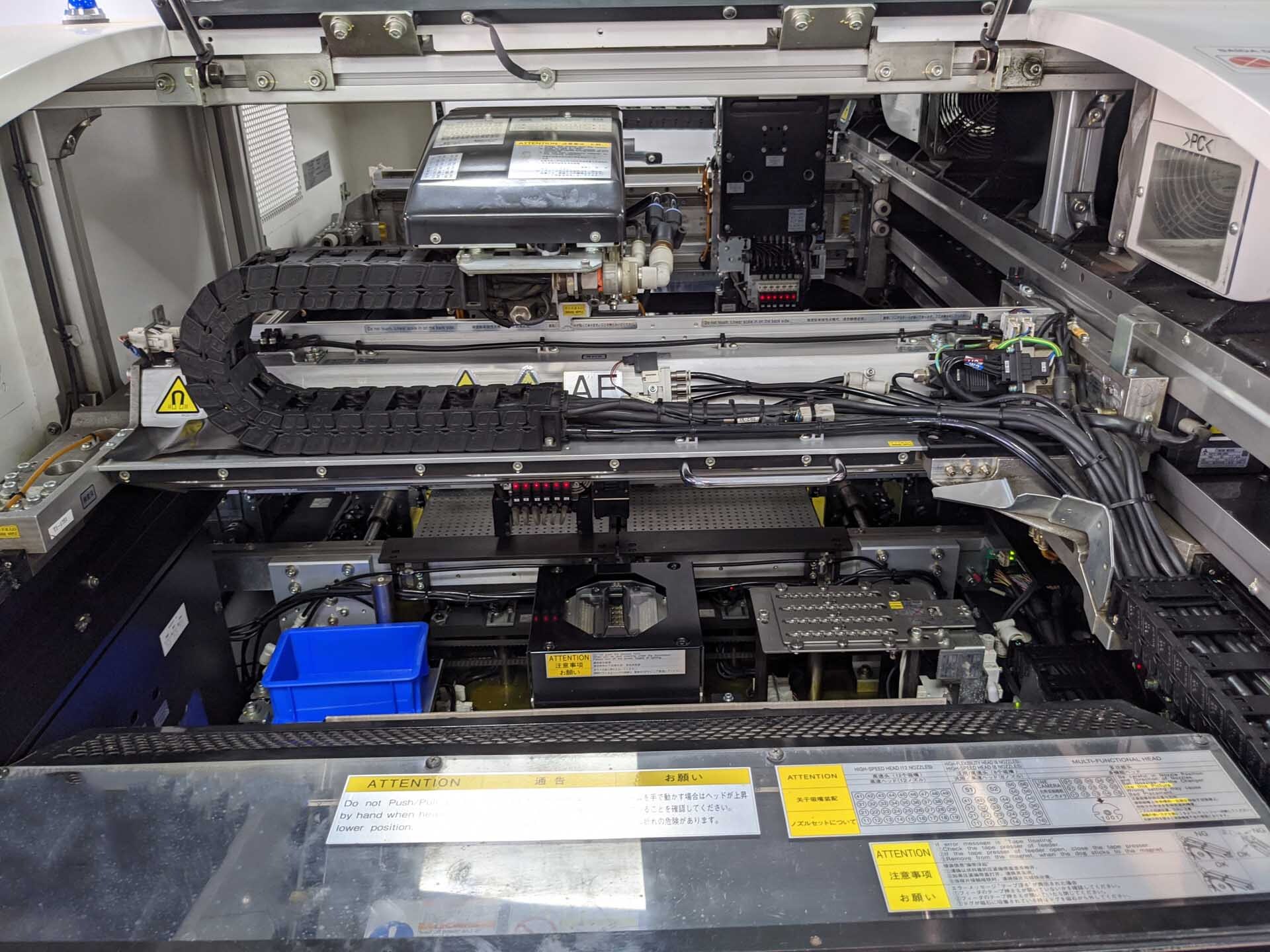

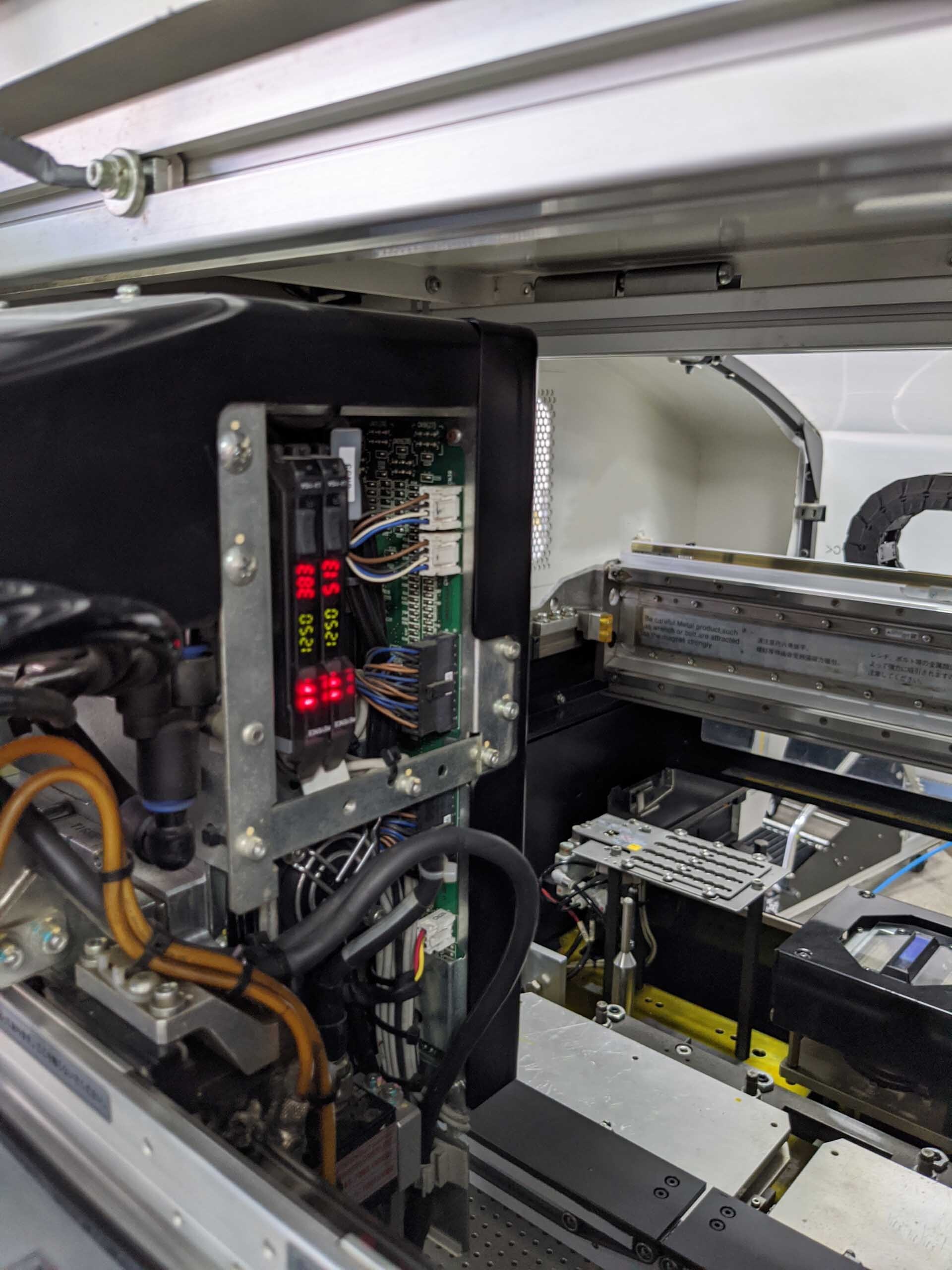

PANASONIC CM602-L is a sophisticated PC board assembly and manufacturing equipment that is able to quickly and accurately construct multiple layers of intricate circuits. It offers high-level functionality and flexibility while maintaining a low price point. At the heart of the system is a four-channel High-Speed Sequential PI (HSSPI) process, which is an automated process for dispensing, placing, and reflowing solder paste, components, and glue on a printed circuit board along exact specifications. This allows for a high degree of precision and accuracy for even the most challenging PCB designs. Additionally, targeted heating enables select parts of the PCB to be heated separately, which reduces heat exposure and improves overall yield. The unit is equipped with advanced visual tracking and process control technology, which helps to eliminate operator errors, reduce scrap, and improve throughput. The built-in error control machine displays a list of potential errors, allowing operators to quickly identify and address issues before they become costly production problems. In addition to the HSSPI process, PANASONIC CM602L is also equipped with multiple manufacturing processes. Among these are Pick & Place technology for precisely placing and mounting components on the PCB as well as an Automatic Optical Inspection (AOI) tool for visual quality assurance. The asset provides a total of 10 types of SPI programs and up to 33 types of AOI programs. This ensures that each board produced meets industry standards. CM 602L is a highly efficient model that is both cost-effective and easy to use. It provides superior performance while minimizing operator training, increasing throughput, and reducing waste. Its advanced features and flexible setup make it an ideal choice for any PCB assembly and manufacturing process.

There are no reviews yet