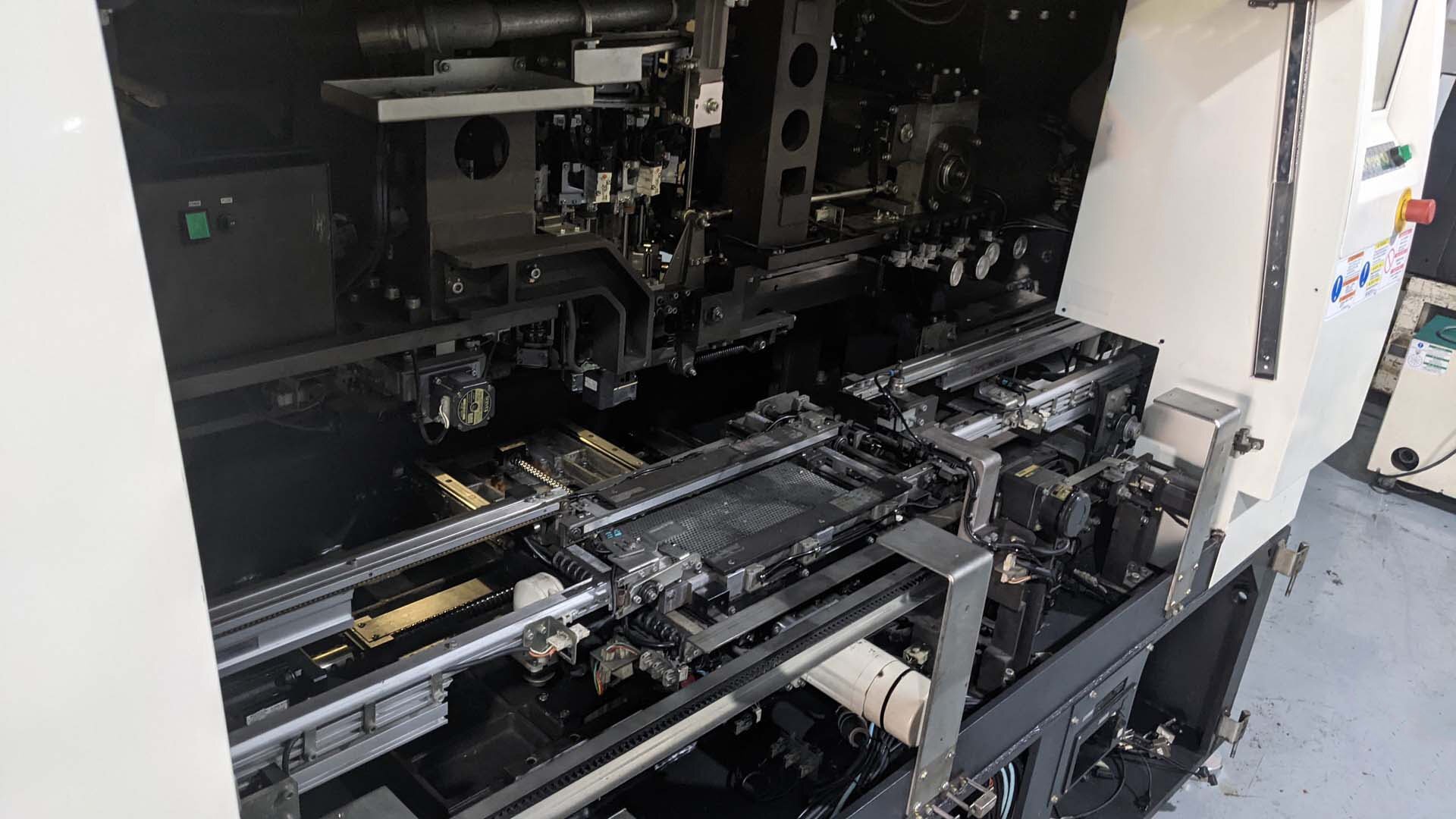

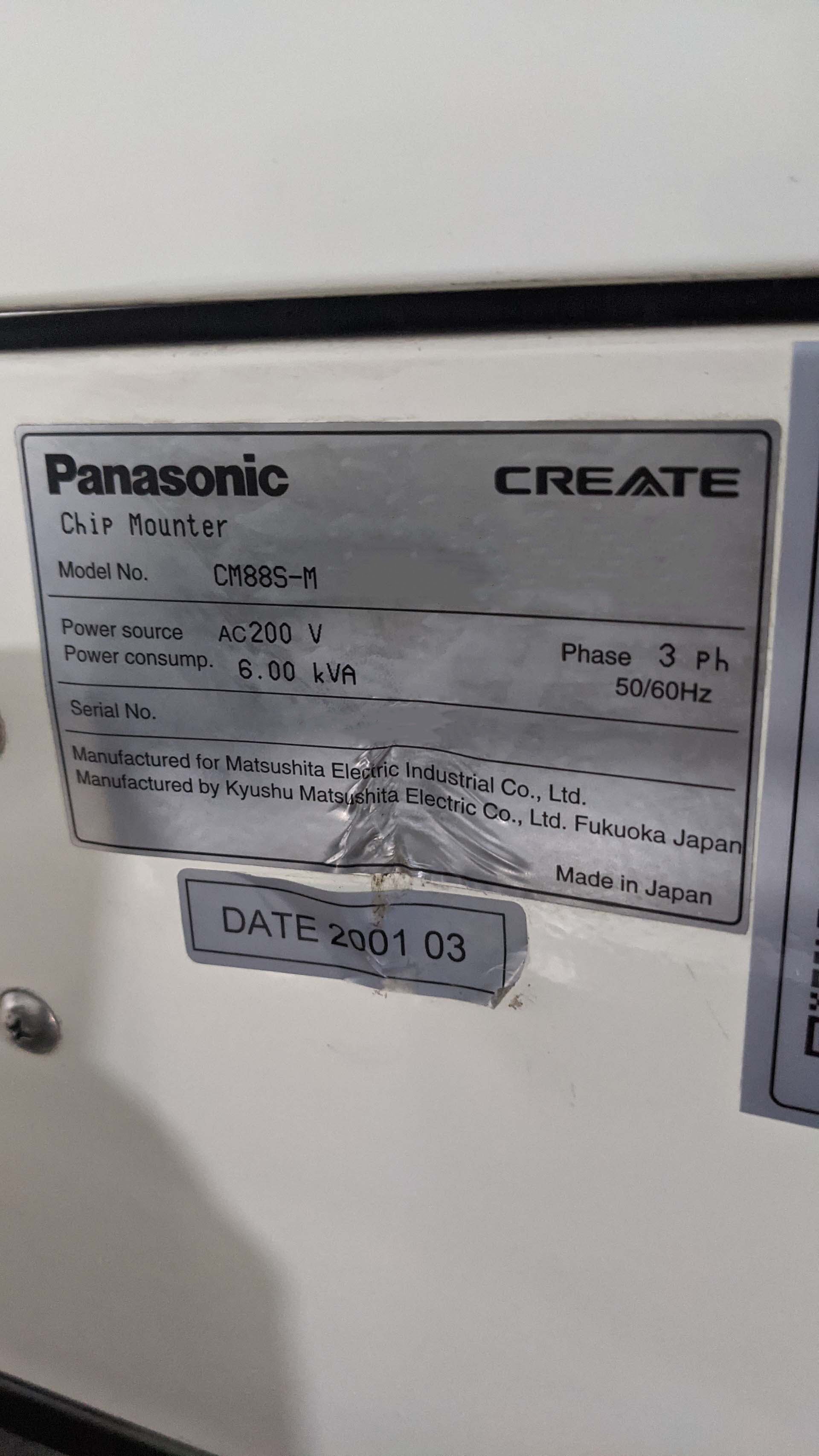

Used PANASONIC CM88S-M #9389374 for sale

URL successfully copied!

Tap to zoom

PANASONIC CM88S-M is a full featured PC board assembly and manufacturing equipment specifically designed to accommodate the needs of electronics engineering and manufacturing industries. The system offers a wide range of specifications, including an integrated board cleaning unit, a bank of automatic insertion machines with intelligent robotic features, an artificial vision machine, a fully automated surface mount device printing and pick-and-place tool, automatic component sorting, and automatic optical inspection. The Unit supports the integration of two or four machines with an automated vertical conveyor, and a heating and cooling tunnel. It offers the complete set of board assembly manufacturing capabilities including; surface mounting of components, placement of large plugs, wave soldering, selective soldering, insert component placement, flying probe testing, and automatic screen printing. The Unit uses a direct input barcode reader module to scan component information and manufacture boards with a higher precision and speed. The high speed feeders increase production speed and accuracy, while the intelligent conveyors move boards automatically from the unit to the cleaning and printing station. The surface mount device printing asset is capable of automatically aligning and printing up to 14 layers of components, with accuracy ensured by a smart marker model. CM88S-M is designed for optimal flexibility with options for manufacturing needs such as a bank of automatic insertion machines, an optical inspection equipment and an AI identified through-hole plus solder system. With its large number of available features, this unit can easily be integrated into existing lines. It is also designed to be easily serviced and adjusted for various board assembly and manufacturing needs. The machine is designed to be cost affective and the energy efficient equipment is low in maintenance and operates with low noise levels. PANASONIC CM88S-M is designed with a lightweight and compact structure, to allow configuration and reconfiguration options in order to obtain the optimal assembly solution. In addition to all of these, the tool is capable of delivering fully assembled boards at high speed. The boards are electronically tested and pass/fail results are reported directly to the host computer. The reporting asset records the serial numbers of the parts and assemblies for complete traceability. CM88S-M is a feature-rich PC board assembly and manufacturing model that provides users with the tools they need to rapidly and cost-effectively produce high-quality electronic boards in a reliable manner. It is the perfect choice for industries that require a fast, reliable, and cost effective PC board assembly and manufacturing equipment.

There are no reviews yet