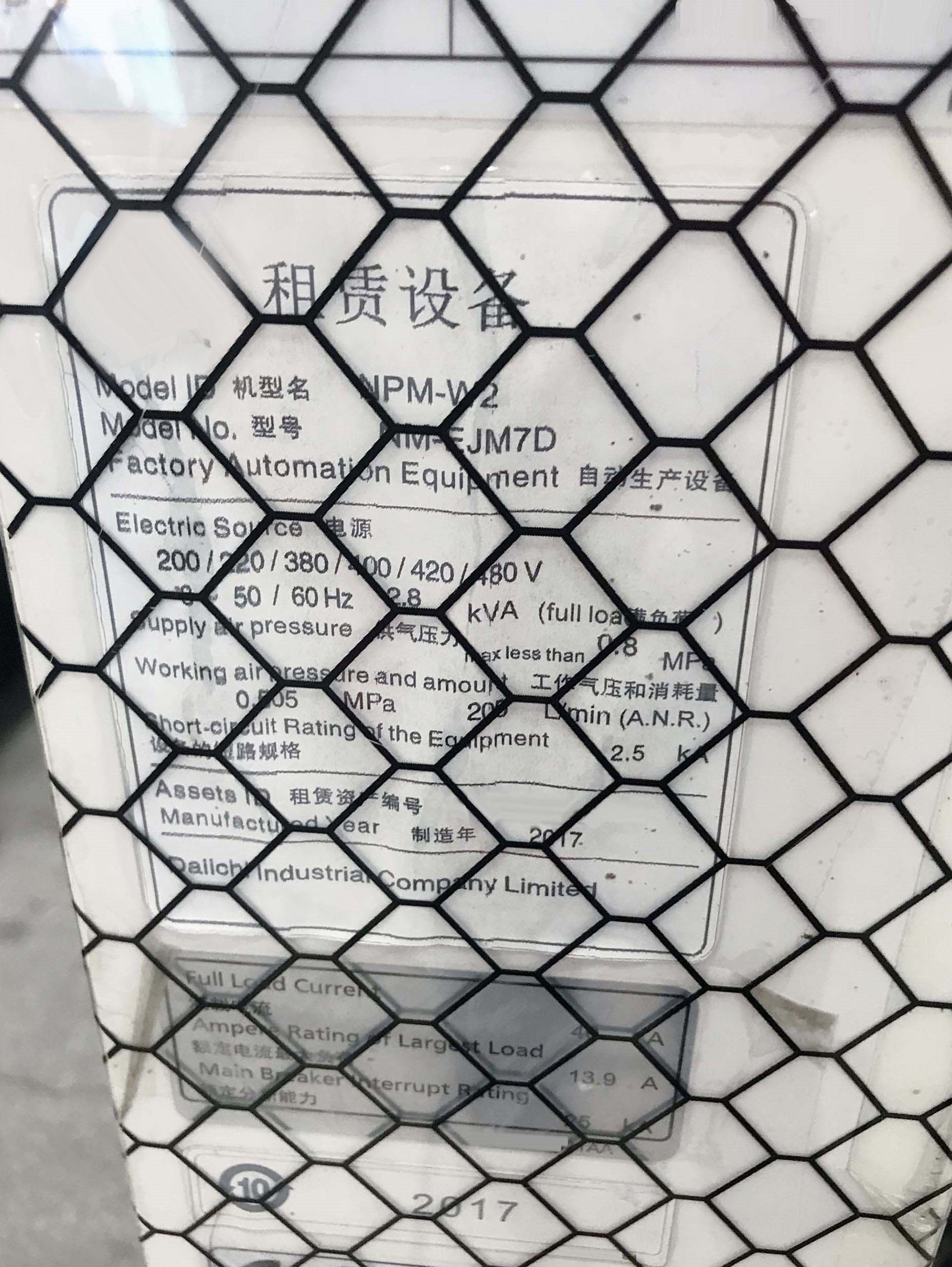

Used PANASONIC / DAIICHI NPM-W2 #9248627 for sale

URL successfully copied!

Tap to zoom

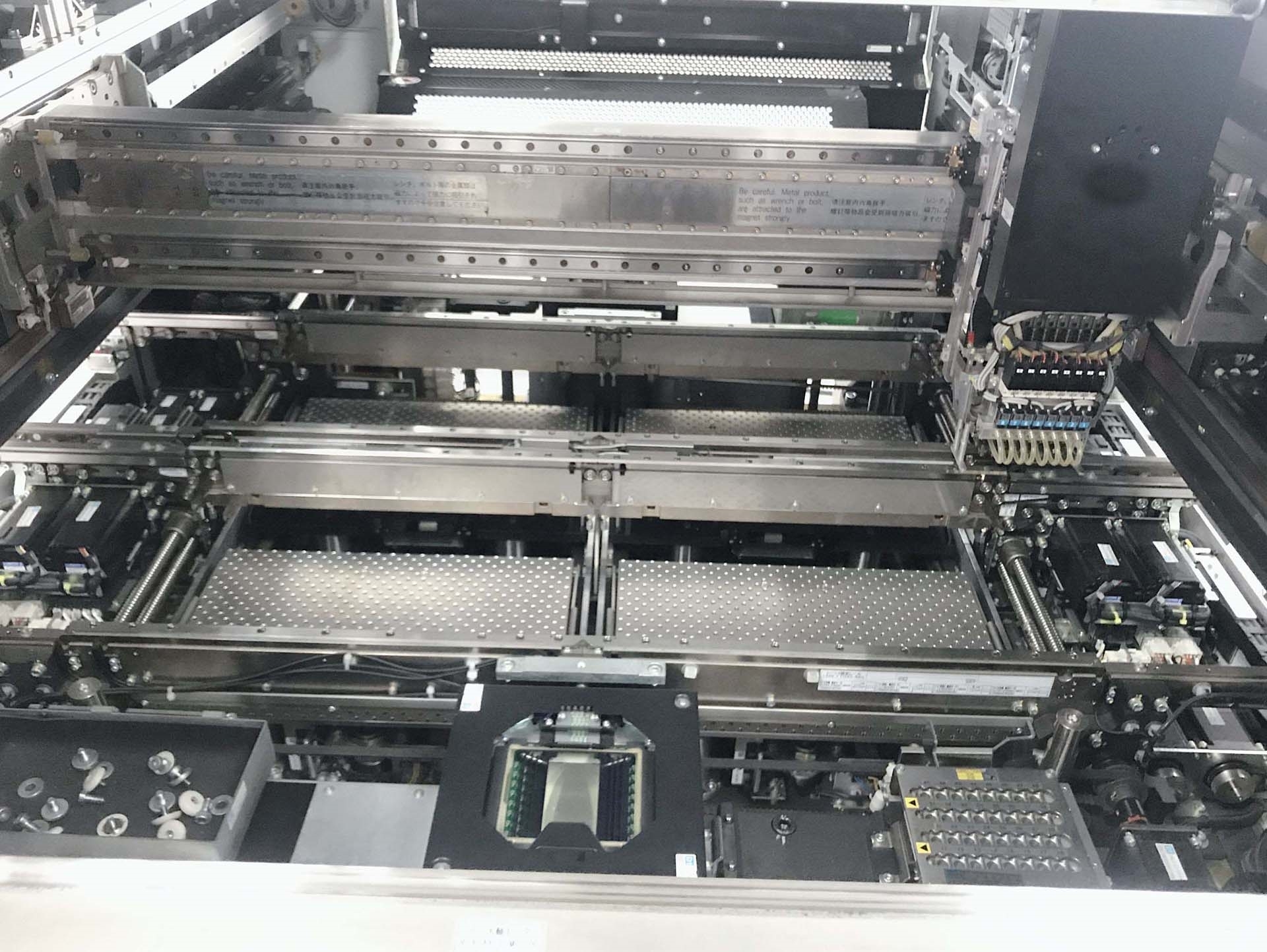

PANASONIC / DAIICHI NPM-W2 is an innovative pc board assembly and manufacturing equipment. The system is used in the production line of electronic components and provides increased efficiency, accuracy, and reliability. The unit is equipped with a variety of features that enable optimal production, such as a high speed polishing machine, an advanced SMT placement machine, and an DAIICHI NPM-W2 3D AOI inspection machine. The high-speed polishing machine is an automatic track-style polishing tool that uses a high-speed "MLPS" corner routing technique to cut and finish board edge profiles. This increases fabrication accuracy and productivity by allowing multiple boards to be cut at once. The advanced SMT placement machine assists in surface mount assembly. It accurately places components ranging in temperature, size, and weight. Furthermore, it has the capability to pick-and-place up to 3 levels, to "free-form adjust" or rotate the components, and to reduce airflow to 0. PANASONIC NPM-W2 3D AOI inspection tool is a highly capable collection of automated optical inspection tools designed to accurately measure and analyze defects in micro- and macro-hardware. It features 3D camera technology to inspect boards in 3D, as well as advanced image recognition algorithms which can detect even the tiniest of defects in production components. NPM-W2 asset is designed for maximum efficiency and reliability throughout the production process. Its sophisticated 3D AOI inspection model ensures that quality is maintained and defects are minimized. The advanced SMT placement machine and high-speed polishing machine increase production accuracy and speed. All components of the equipment are designed for maximum production, accuracy, and longevity with minimal maintenance.

There are no reviews yet