Used PANASONIC / DAIICHI NPM-W2 #9279493 for sale

URL successfully copied!

Tap to zoom

ID: 9279493

Vintage: 2017

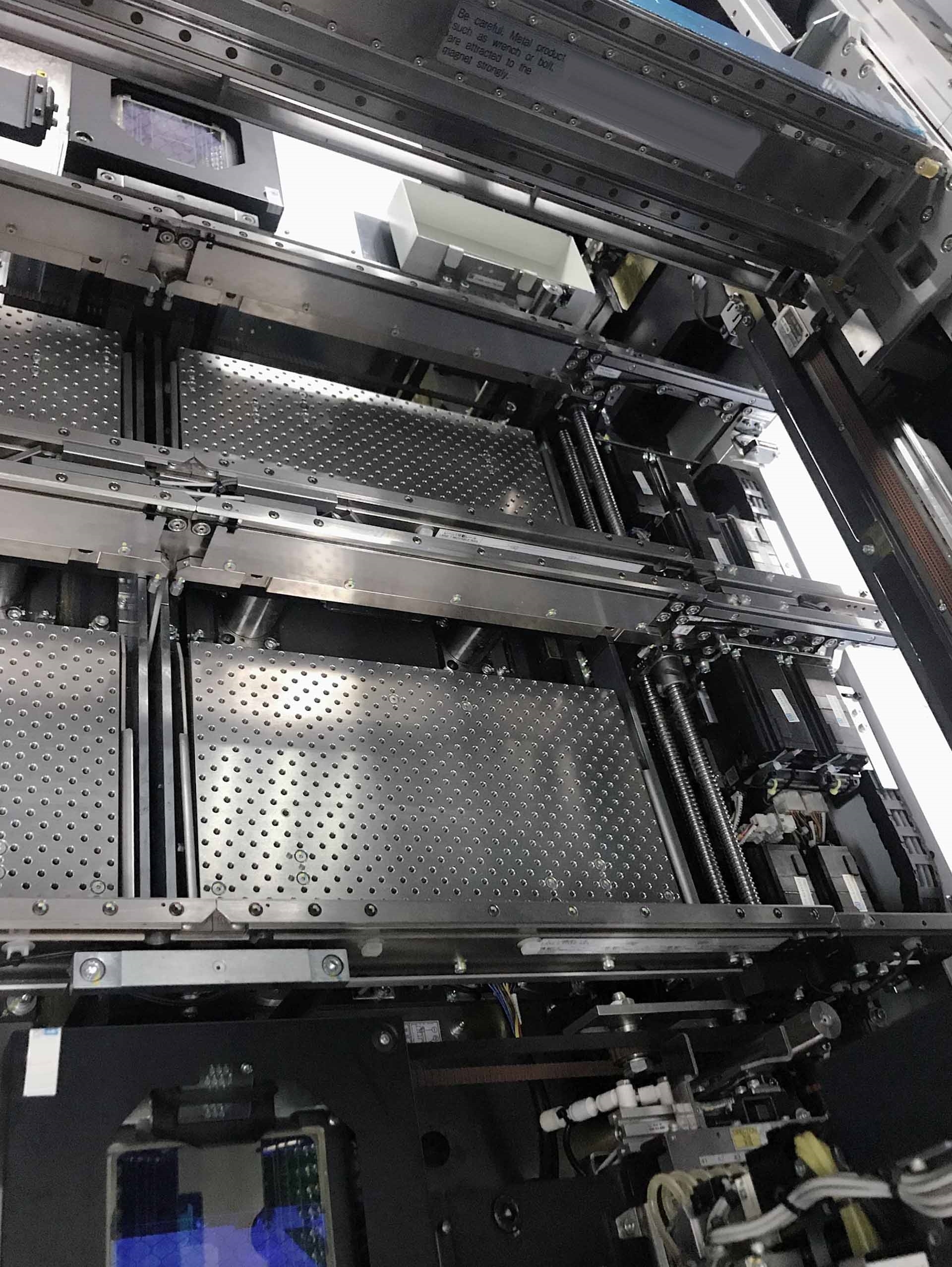

Pick and place machine

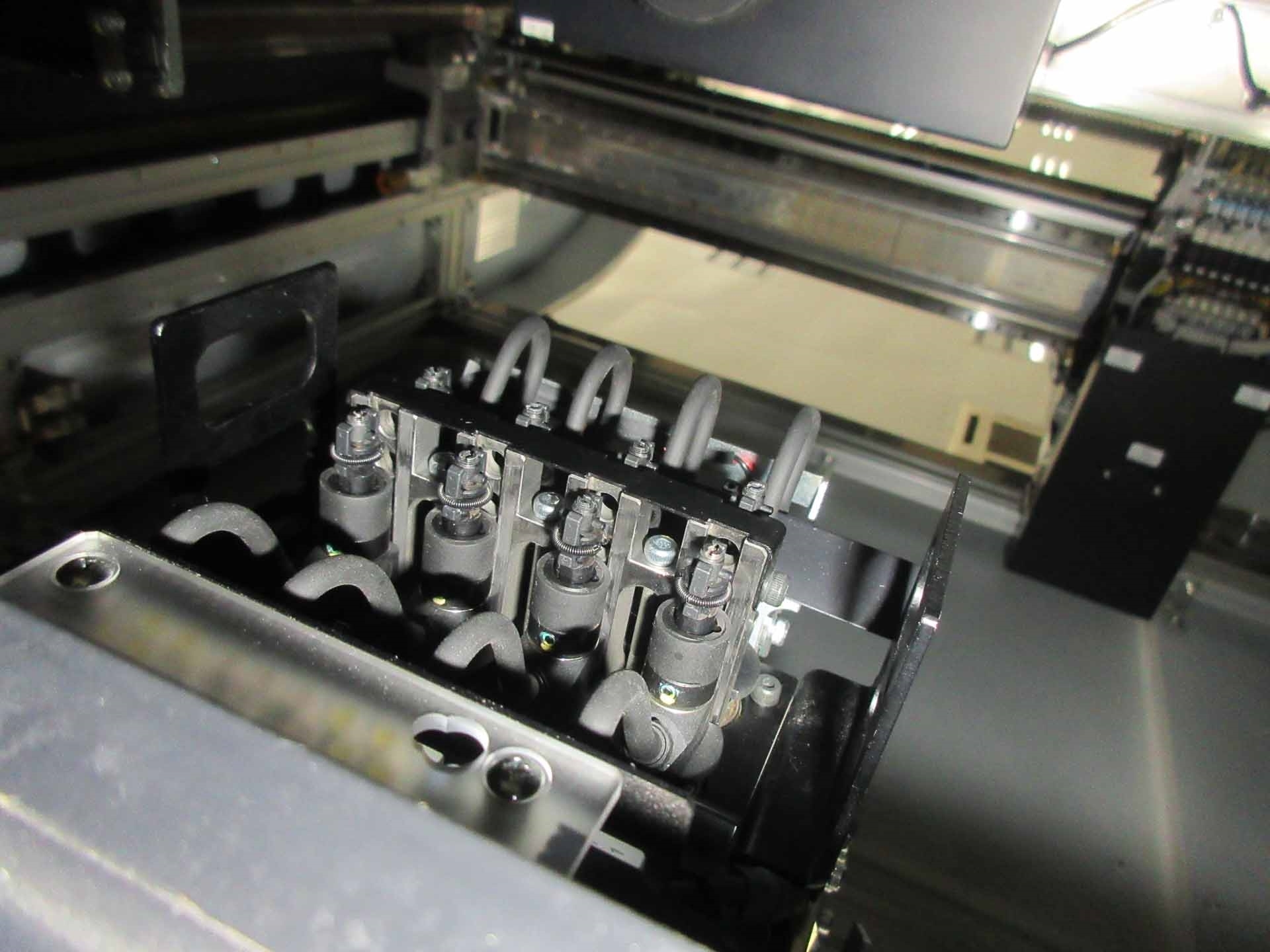

(16+8) Heads

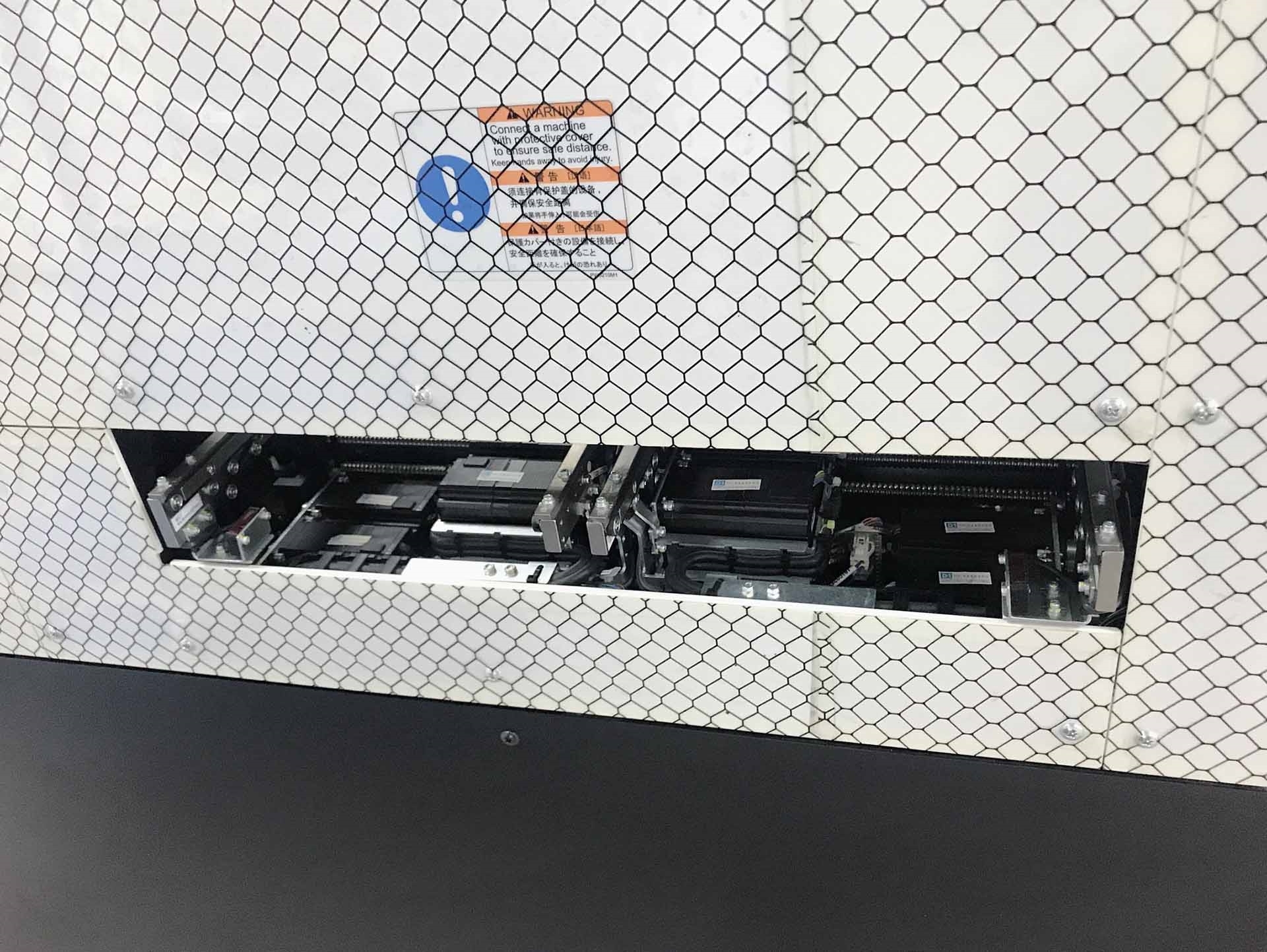

(2) Feeder carts

No tray

2017 vintage.

PANASONIC / DAIICHI NPM-W2 is a comprehensive PC board assembly and manufacturing equipment built for the most demanding electronic manufacturing environments. Featuring a wide range of integrated and expandable components, DAIICHI NPM-W2 allows for full configuration of a modern electronics manufacturing plant. PANASONIC NPM-W2 can be configured with up to four individual workstations, each with their own specialized equipment to manage different parts of the production process. For the PCB assembly line, an intuitive human-machine interface (HMI) allows for easy setup of components and production parameters, as well as efficient problem solving. PCB assembly is automated with SMT placement machines equipped with a dual-camera placement system, as well as six nozzle options for placement speed. For quality control, NPM-W2 is equipped with an automated optical inspection unit which detects and rejects defects in the production process. In addition to PCB production, PANASONIC / DAIICHI NPM-W2 also has automated production of solder pallets and others components. Using a high-speed spindle and multiple moving axes, DAIICHI NPM-W2 can produce a variety of parts to generate parts needed for assembly. It also includes a high-speed extractor for removal of component carriers and an inline reflow oven for accurate and speedy soldering. To efficiently handle material flow within the production area, PANASONIC NPM-W2 is equipped with a wide range of peripheral components. Automatic vision machine allow for precise components and material recognition, while an automatic X-ray tool is used for quality control. Further, an automatic pin-punch module supplements the SMT placement for additional creative solutions. An important part of any asset is the ability to track progress and manage production data. NPM-W2's advanced tracking model provides real-time production information to the user, making it easy to analyze and optimize production processes. To protect data integrity, the equipment features an integrated fault detection and correction system which ensures accurate traceability during production. PANASONIC / DAIICHI NPM-W2 is an all-in-one solution for the modern electronics production environment, providing a comprehensive and highly configurable platform for PCB manufacturing and assembly. Its combination of components and features allows for efficient and accurate production, while its tracking and control features allow for efficient analysis and optimization of production processes.

There are no reviews yet