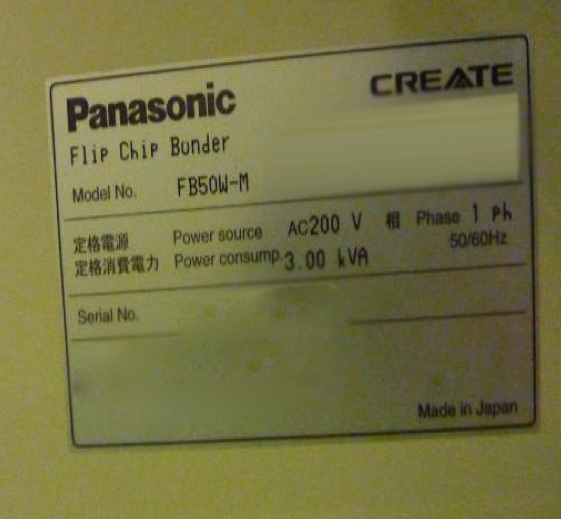

Used PANASONIC FB50W-M #9050428 for sale

URL successfully copied!

Tap to zoom

ID: 9050428

Vintage: 2008

Flip chip bonder

AC 200 V, 50/60 Hz, Single phase, 3 kVA

2008 vintage.

PANASONIC FB50W-M PC Board Assembly and Manufacturing Equipment is a light-weight, high-performance technology from PANASONIC that offers integrated microelectronic assembly and manufacturing processes. This system utilizes high-speed, precision-controlled movable blades to accurately position components on the printed circuit board. The boards are automatically transported to the assembly area where they are worked on by experienced and highly-trained operators. FB50W-M provides a variety of assembly and manufacturing processes including screen printing, pick-and-place of surface mount devices (SMDs), manual assembly, reflow, wave soldering, and more. The unit is designed for high throughput, with a maximum height of 50mm and a component pocket size of a maximum height of 10mm and a maximum area of 20mm. This high-speed, accurate machine is capable of processing up to 10,000 components per hour. In addition to its assembly and manufacturing capabilities, PANASONIC FB50W-M provides comprehensive traceability throughout each stage of the process. This allows for detailed documentation of the associated parts, components, and processes used to ensure the highest levels of quality. This tool includes numerous features to maximize efficiency including automatic print generation, color coding, data tracking, and various training options. FB50W-M is equipped with an automated image recognition camera that assists with the assembly and manufacturing process. This vision-inspection asset is used to track and monitor the quality and accuracy of parts, components, and processes. All components are preset for x and y position prior to being placed. The machine is capable of vis-inspection by shining a light on the parts to check for incorrect solder and bond angles. Overall, PANASONIC FB50W-M PC Board Assembly and Manufacturing Model is a light-weight, high-performance technology that allows users to quickly and accurately assemble and manufacture printed circuit boards. This comprehensive equipment offers several features such as automated print generation, color coding, and vision inspection that make it an ideal choice for microelectronic assembly and manufacturing processes. By its integration of automated processes and features, FB50W-M promises to meet the high demands of the industry with its reliability, accuracy, and high-throughput requirements.

There are no reviews yet