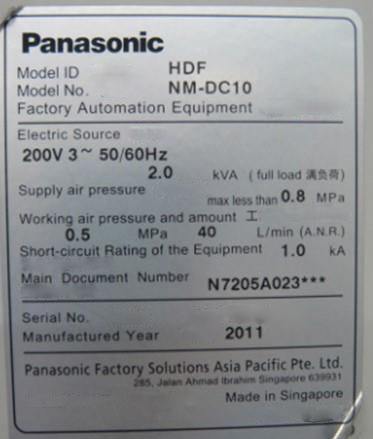

Used PANASONIC HDF NM-DC10 #9165806 for sale

URL successfully copied!

Tap to zoom

PANASONIC HDF NM-DC10 is a pc board assembly and manufacturing equipment designed for high-volume, high-throughput applications. It features automated component placement accuracy, highly accurate surface mounting and a wide range of features designed to ensure solid product assembly and reliable PC board production. HDF NM-DC10 offers an advanced, large-scale automated component placement system, with highly accurate results. This unit has precision feeders that can pick up components without any contact, helping to reduce damage and improve yield rate. It also offers a large variety of components to be assembled on a single board, providing flexibility to create even complex designs with ease. The machine offers highly accurate surface-mounting technology, which includes a 3-dimensional BGA placement head for more precise placement of components during the assembly process. Its conveyor tool can transport up to 7 substrates simultaneously at a transfer speed of 500mm/s, speeding up the production process. The asset also boasts an advanced edge-bending mechanism, ensuring an optimal contact between the board and the screws during PC board assembly. PANASONIC HDF NM-DC10 has a user-friendly software and control model, which allows for easy setup of components with an intuitive graphic interface. It also features a fast programming tool for quick setting of processing order and actual processing control. The equipment also offers intelligent alarm function and pass-through inspection capabilities, providing a high level of quality assurance. HDF NM-DC10 comes equipped with a maintenance stand-by function, which allows operators to quickly and easily change settings or parts when needed. It also offers a wide range of highly reliable peripheral parts such as an automated optical inspection system, which ensures high-quality inspection of components even in difficult-to-view positions. Overall, PANASONIC HDF NM-DC10 is an ideal pc board assembly and manufacturing unit for large-scale, high-volume applications. It offers quick and reliable component placement, highly accurate surface-mounting, and advanced edge-bending technology. Its user-friendly software and control machine makes it easy to set up and operate, and its powerful peripheral functions provide enhanced quality assurance.

There are no reviews yet