Used PANASONIC HDP V NM-DA00A #9115325 for sale

URL successfully copied!

Tap to zoom

ID: 9115325

Vintage: 1997

Dispenser

Flow direction: Right to Left

Front rail fixed

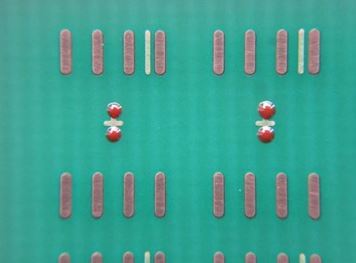

Heads: (2)

Nozzles: (3)

Tact: 0.08sec (when dispensed simultaneously)

1997 vintage.

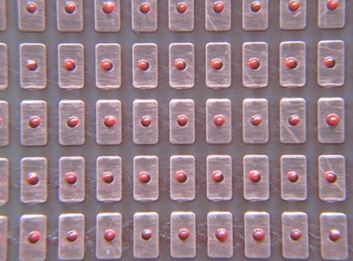

PANASONIC HDP V NM-DA00A is an advanced computer board assembly and manufacturing equipment designed to streamline and maximize the production of printed circuit boards (PCBs). With the capability to process and verify all types of circuit boards, HDP V offers a cost-effective and efficient approach. It is capable of supporting multiple configurations of robotics, sorting and source components, and it can be integrated into automated test and measurement systems. HDP V NM-DA00A integrates components, surface mount technology (SMT) and through-hole technology (THT) technologies, using a three-layer approach by incorporating a selection of routing, surface mount and fine-pitch components. This enables it to process even the most complex boards. With its intelligent data management and optimized production lines, the system can automatically allocate and organize the source components so that they are quickly loaded. Intelligent re-routing and intelligent updating of material lists allow the unit to avert potential production issues. The machine boasts fan-out capabilities and advanced handling of BGA/VFBGA packages, providing reliable stability and performance. Moreover, the tool is designed to provide powerful features and abilities, such as 'Pre-Calibration' that allows the quick and easy placement of components on the board. It is able to detect and report small defects, eliminating the need for manual inspection. All the data used in the placement process is managed to ensure accuracy during the manufacturing process. PANASONIC HDP V NM-DA00A is adaptable and capable of using external equipment, such as vision cameras, to confirm that components are in the correct position. Re-work capability is included for both SMT and THT processes and furthermore, the asset is capable of embedding bar codes, offering flexible automation when necessary. Overall, the model is easy to use and allows for faster and more efficient production. It allows for reliable, accurate and high-speed assembly, faster and more efficient production, higher yields and lower operating costs. Finally, the equipment is built to be safe and environmentally friendly, with minimal human intervention required.

There are no reviews yet