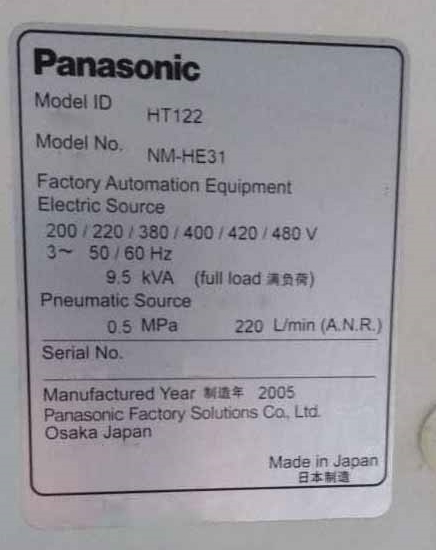

Used PANASONIC HT-122 NM-HE31 #9230013 for sale

URL successfully copied!

Tap to zoom

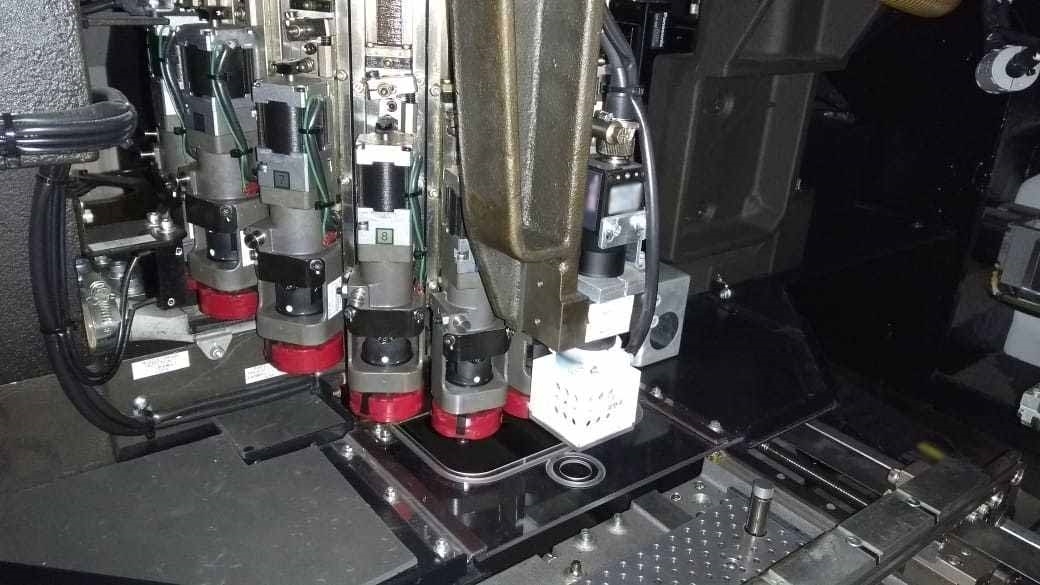

PANASONIC HT-122 NM-HE31 is a PC board assembly and manufacturing equipment that allows for efficient and cost-effective mass production of printed circuit boards. The system is designed to effectively handle all the known processes associated with printed circuit board assembly, including surface-mounting and through-hole mounting of components, as well as the efficient integration of manual and automated processes. The unit's main housing is constructed from heavy-duty steel frames for maximum durability, and is divided into two distinct sections. The first section contains the primary components of the machine, such as the placement head, machine controllers, camera controllers, and more. The second section houses the secondary components, such as the camera tables, additional Axis controllers, and additional tool motor controls. The asset's main feature is its placement head, which is designed to quickly and accurately mount components onto printed circuit boards. This high-speed head is driven by a 15-axis motor allowing for accurate placement of components as small as 0.2 mm in diameter on an 8 x 8 mm PCB. This head is compatible with both leaded and lead-free solder paste and features a precise powder dispenser for added accuracy. Additionally, the model is capable of handling both SMD and through-hole components. The machine's controllers are designed to quickly and accurately detect component placement discrepancies, making it an excellent choice for batch production of printed circuit boards. Additionally, this equipment features onboard teaching tools, including teachable alignment functions and the ability to select various board sizes and shapes. The system also offers visual verification at any point of the production process to ensure the accuracy of placement. For automated processes, HT-122 NM-HE31 can be teamed with automated machines such as the IP-3A3C for a complete turn-key solution. This machine utilizes a high-speed vision unit with on-board algorithms to inspect and verify each design component before completion. In addition to automated machine installs, PANASONIC HT-122 NM-HE31 also supports manual install processes, allowing for a deep integration of processes. In conclusion, HT-122 NM-HE31 offers a reliable, efficient, and cost-effective solution to the challenge of mass production of printed circuit boards. Its fast placement head enables it to accurately mount components as small as 0.2 mm in diameter on an 8 x 8 mm PCB. Moreover, its heavy-duty steel construction ensures outstanding durability and reliability. Furthermore, the machine is fully compatible with automated and manual processes, making it a powerful turn-key solution to PC board assembly and manufacturing.

There are no reviews yet