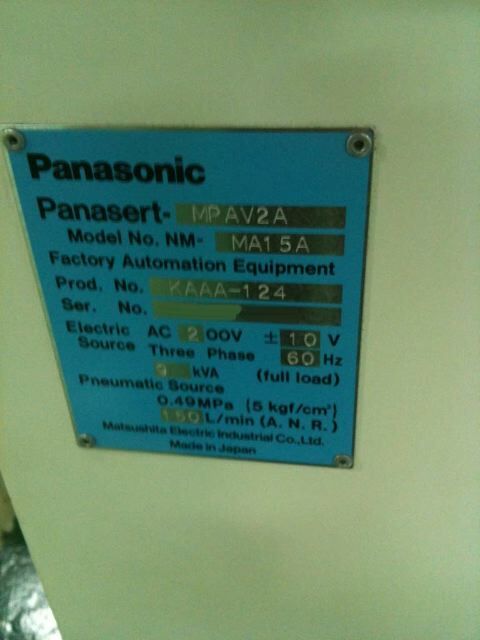

Used PANASONIC MPAV2A NM-15A #103087 for sale

URL successfully copied!

Tap to zoom

ID: 103087

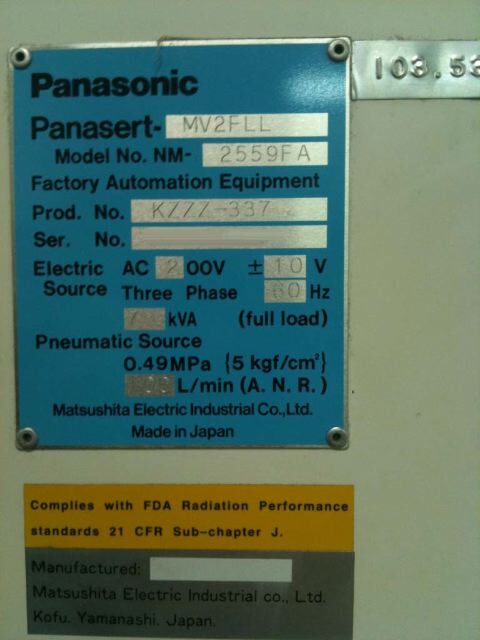

machine with PANASONIC MV2F NM-2559FA Chip Shooter Package

(15) 8mm Feeder capacity

Right to Left to Front flow

Without Tray

1999 vintage

PANASONIC MV2F NM-2559FA Chip Shooter

(50) 8mm Feeder capacity

Right to Left to Front flow

1996 vintage.

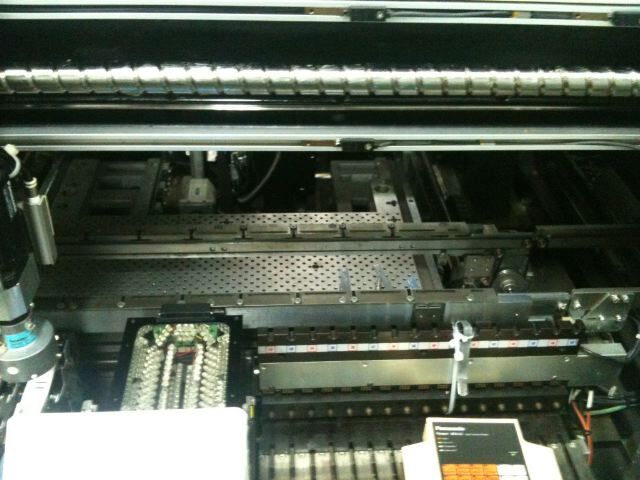

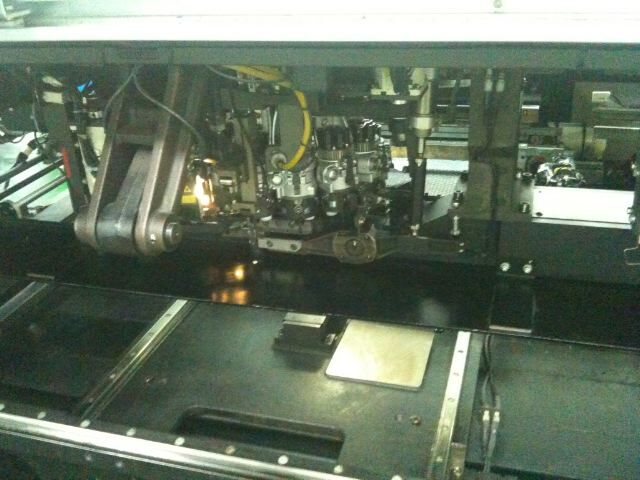

PANASONIC MPAV2A board assembly and manufacturing equipment is one of the most advanced solutions for assembling, programming and testing printed circuit boards. This system does it all - from the assembly to the final product testing. It is designed for flexibility and efficiency in industrial production environments. The MPAV2A has a fixed assembly area that consists of an operator's work surface, a large working area for handling electronic components, and a multiple-band wave soldering machine. It also contains a press fit mechanization area for surface-mount connectors and contact-type components. The wave soldering machine is equipped with an integrated fluxer and is programmed for a wide range of wave parameters. The unit also has a programming area which provides a high-speed solution for programming the PCBs with customer-specific designs. The programming unit includes a Flash memory writer, programmer and machine control software. Furthermore, the PCBs can be tested quickly and accurately using the tool's framework. The MPAV2A asset is compatible with a wide variety of automatic insertion, soldering and programming machines. It also has an extensive range of potential configuration options that allow it to be customized to meet the needs of individual production lines. For automated processes, the MPAV2A is also compatible with a wide range of robotic tools and peripheral equipment. This model is designed to be scalable and can be configured to maintain quality production from smaller to larger orders. To ensure accuracy, the MPAV2A utilizes a model-based verification equipment to check the PCB assembly for defects or damage before and after each stage of the production process. This system can also be used to update the model definitions for future batches of the product, ensuring product consistency among all batches. The MPAV2A is a comprehensive unit for debugging, assembly and manufacturing of PCBs that can streamline the production process and improve efficiency. With its flexibility and range of automated solutions, the MPAV2A can be used to handle even the most demanding PCB production demands.

There are no reviews yet