Used PANASONIC MV #165285 for sale

URL successfully copied!

Tap to zoom

ID: 165285

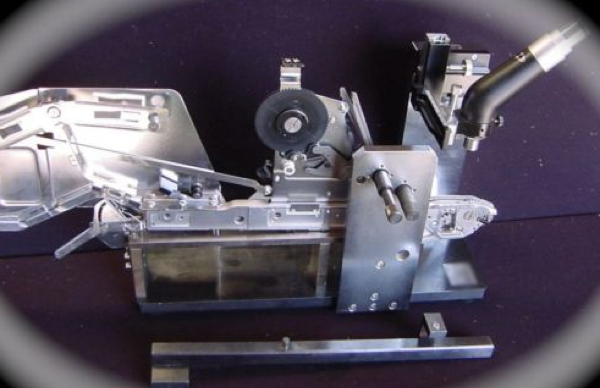

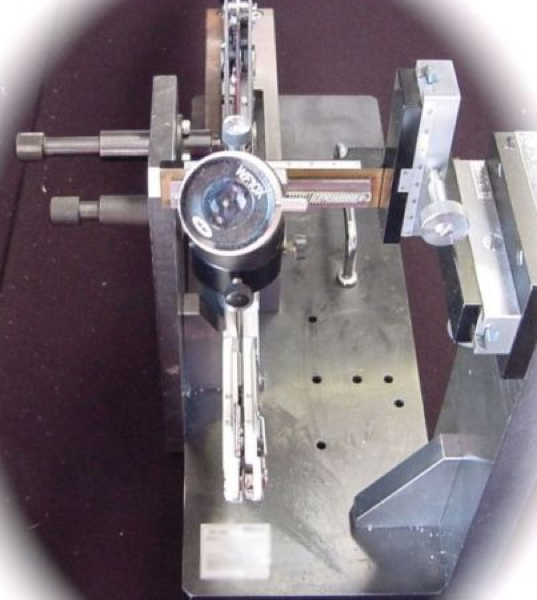

Feeder calibration unit

Specifications:

Inspectable Part Cassette: Standard, Thin, and Double. 8 - 24 mm width tape

For MPA type cassettes

Dimensions- 200(w)x520(l)x380(h)mm

Mass- 10 kg.

PANASONIC MV is a high-precision and fully automated PC board assembly and manufacturing equipment.This system is designed to provide optimized assembly production lines and high-speed prototyping processes for complex electronic products. It can perform a variety of assembly processes, including surface mounting technology (SMT), chip-on-board (COB), and flip chip soldering. The core component of the unit is MV model Auto-Loader. This is responsible for automatically positioning, loading and unloading the PC boards into position for the soldering process. The Auto-Loader, along with the X-Y Buffers, provides efficient and accurate placement of components on the boards to ensure superior solder joint quality. The machine also features a multi-image selection process (M-Select) for board level assembly along with an optimized process for routing, pasting and masking. The M-Select process allows for selecting the most suitable image for each process based on the layout of the components. This ensures accurate processing and protects components from damage. The tool also offers a wide range of intelligent control systems for optimal board assembly and processing. These include integrated vision systems for the inspection of various aspects of the board such as component placement, soldering quality and paste printing. The asset also features an offset tracking model (OT-Track) and thermocouple monitoring (TC) to ensure the accuracy of temperature control during the soldering process. Additionally, the equipment also includes a range of robotized inline processing functions such as robotic polishers, convection ovens and wave soldering. In terms of maintenance and operation, PANASONIC MV offers a comprehensive suite of diagnostic and monitoring capabilities. The system includes an inbuilt pre-production test unit (PST) which can ensure the quality of components and detect any potential fault lines during the production process. Additionally, the machine also provides a range of monitoring tools such as logging, alarms and data report for preventative maintenance and troubleshooting. Overall, MV offers industry-leading precision and reliability for PC board assembly and manufacturing. Its innovative technologies and intelligent control systems guarantee superior quality and cost-efficiency. With its excellent performance and robust safety measures, PANASONIC MV is an ideal solution for high-quality and efficient production processes.

There are no reviews yet