Used PANASONIC MV #32333 for sale

URL successfully copied!

Tap to zoom

ID: 32333

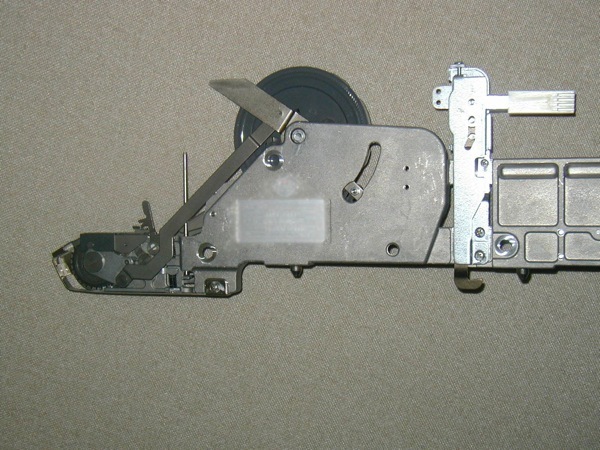

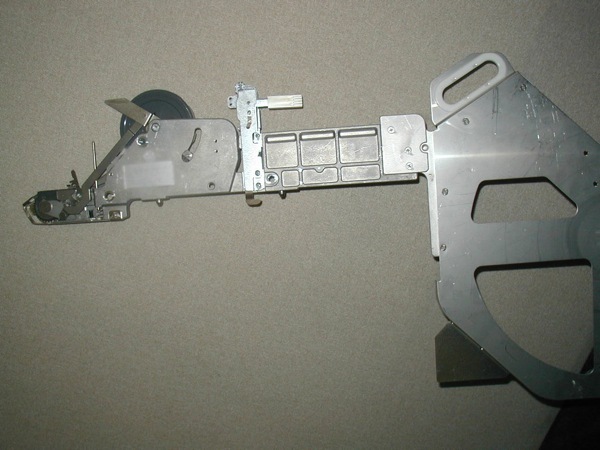

Lot of Feeders:

PANASONIC MVIIF: 8X4mm, K-Type, 15" Reel, XL, Emb. P/N: 10496 145

PANASONIC MVIIF: 32X16mm, K-Type, 15" Reel, XL, Emb. P/N: 10224 37400

PANASONIC MVIIF: 12X4mm, K-Type, 15" Reel, XL, Emb. P/N: 20267 000.

PANASONIC MV is a state-of-the-art PC board assembly and manufacturing equipment that provides a complete workflow solution for the production of printed circuit boards. It is designed to provide superior quality, speed, accuracy and cost-effectiveness for all your PCB assembly needs. MV features an automated inspection system that is capable of inspecting parts on all layers in one pass, ensuring high quality components and boards. It uses advanced 3D AOI technology and high-speed vision cameras to quickly detect errors and defects on both sides of a PCB. The unit also features built-in adjustment capabilities for compensating for any inconsistencies in the circuit board components. PANASONIC MV machine also features a fully integrated die attach robot, providing precise placement of components. The die attach robot is equipped with "high speed vision" which quite literally "sees" defects and prevents them from being fitted onto the PCB. This ensures that the circuit boards are produced to the highest standards, while maintaining high yields. MV also includes an advanced rework station, capable of performing even the most delicate manual processes in a controlled environment, while providing the user with an intuitive interface. PANASONIC MV tool offers a wide range of customizations to meet customer-specific requirements. It is capable of handling both SMT and through-hole processes, and can be easily configured for both single and multiple-PCB assemblies. The asset also integrates seamlessly with most popular software packages to allow for automation and traceability of the entire production process. MV is designed to maximize productivity and reliability. It features user-friendly software that enables easy integration, reduces setup times and shortens lead times. The model is designed for reliability, efficiency and accuracy, allowing for quick and accurate production. PANASONIC MV also features multiple quality control features such as ESD protection, temperature regulation and vibration reduction, further increasing the quality and durability of the product. In summary, MV is a versatile, cost-effective and reliable PC board assembly and manufacturing equipment that enables easy integration and automates the entire production process. It is equipped with advanced vision systems, automated inspection and adjustment capabilities, tight-tolerance components, and intuitive user interfaces. PANASONIC MV provides superior quality and speed, perfect for any PCB manufacturing needs.

There are no reviews yet