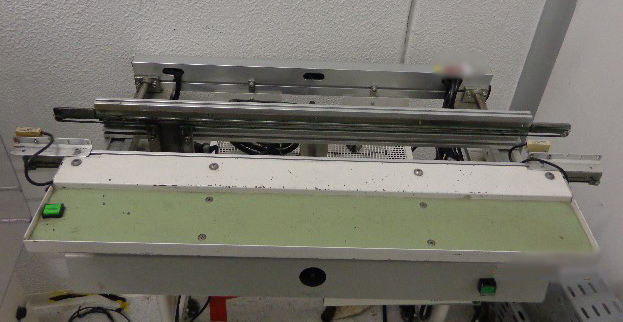

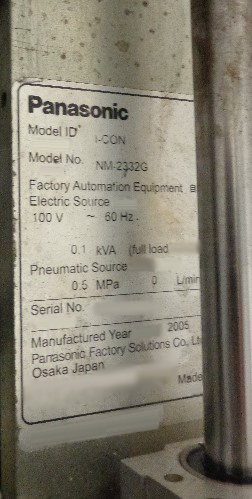

Used PANASONIC NM-2332G #9177391 for sale

URL successfully copied!

Tap to zoom

PANASONIC NM-2332G is a PC board assembly and manufacturing equipment that provides rapid and accurate assembly, testing and repair of circuits. It is designed to meet the demands of modern production lines and is ideal for low- to medium-volume circuit board assembly applications. The system features modular components that can be configured to meet various production requirements and process challenges. NM-2332G offers high-speed component insertion and a fast assembly rate. Intelligent vision and placement systems enable materials to be accurately positioned to tolerances down to a micron. Added precision comes from its advanced thermal camera unit which accurately registers component locations. As well as assembly, PANASONIC NM-2332G features automated testing capabilities, providing quality control assurance. It offers visual inspection, areal coverage X-ray imaging and precision test point probing. To ensure full traceability of every board, NM-2332G can store data, including order information, pass/scrap information, applied components and fault codes. This data can be retrieved for the identification and logging of non-conforming products. The machine is designed for easy serviceability, maintenance and flexibility in order to keep downtime to a minimum. Modular components can be replaced without need for machine recalibration. PANASONIC NM-2332G can also be configured to work with a wide variety of components and material types, giving manufacturers greater freedom to meet a variety of production requirements. For quality assurance and improved operator and product safety, NM-2332G includes an eddy-current testing tool and high-precision entry control unit. An ergonomic design - with adjustable overhead illumination - also makes it easy for operators to work in a comfortable and productive environment. Overall, PANASONIC NM-2332G is an advanced PC board assembly and manufacturing asset that offers rapid component insertion, reliable testing, and scalable production flexibility. Its advanced component recognition model and traceability records ensure product quality and reliability. With its configurable components and automated testing capabilities, this equipment can provide manufacturers with important production advantages.

There are no reviews yet