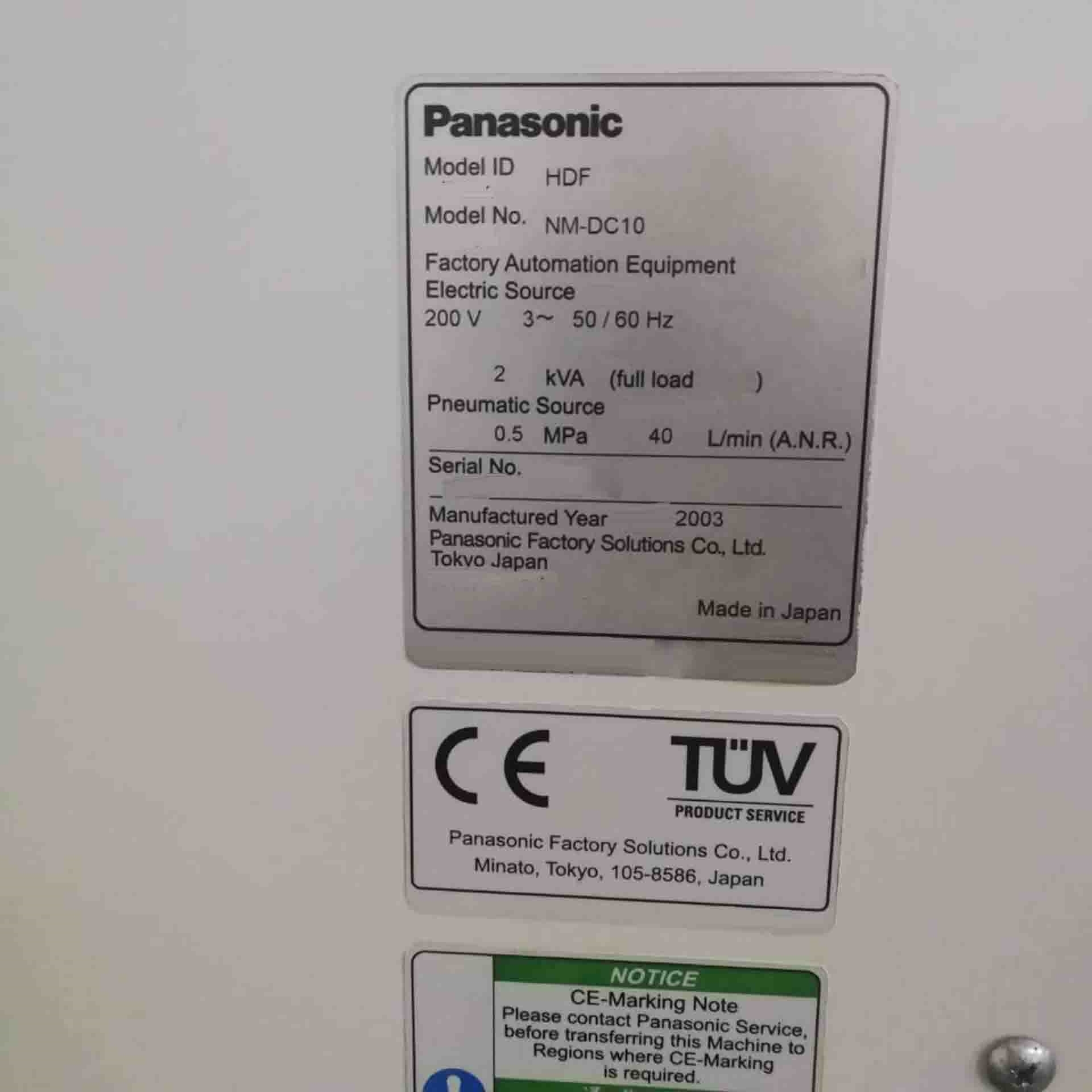

Used PANASONIC NM-DC10 #9203370 for sale

URL successfully copied!

Tap to zoom

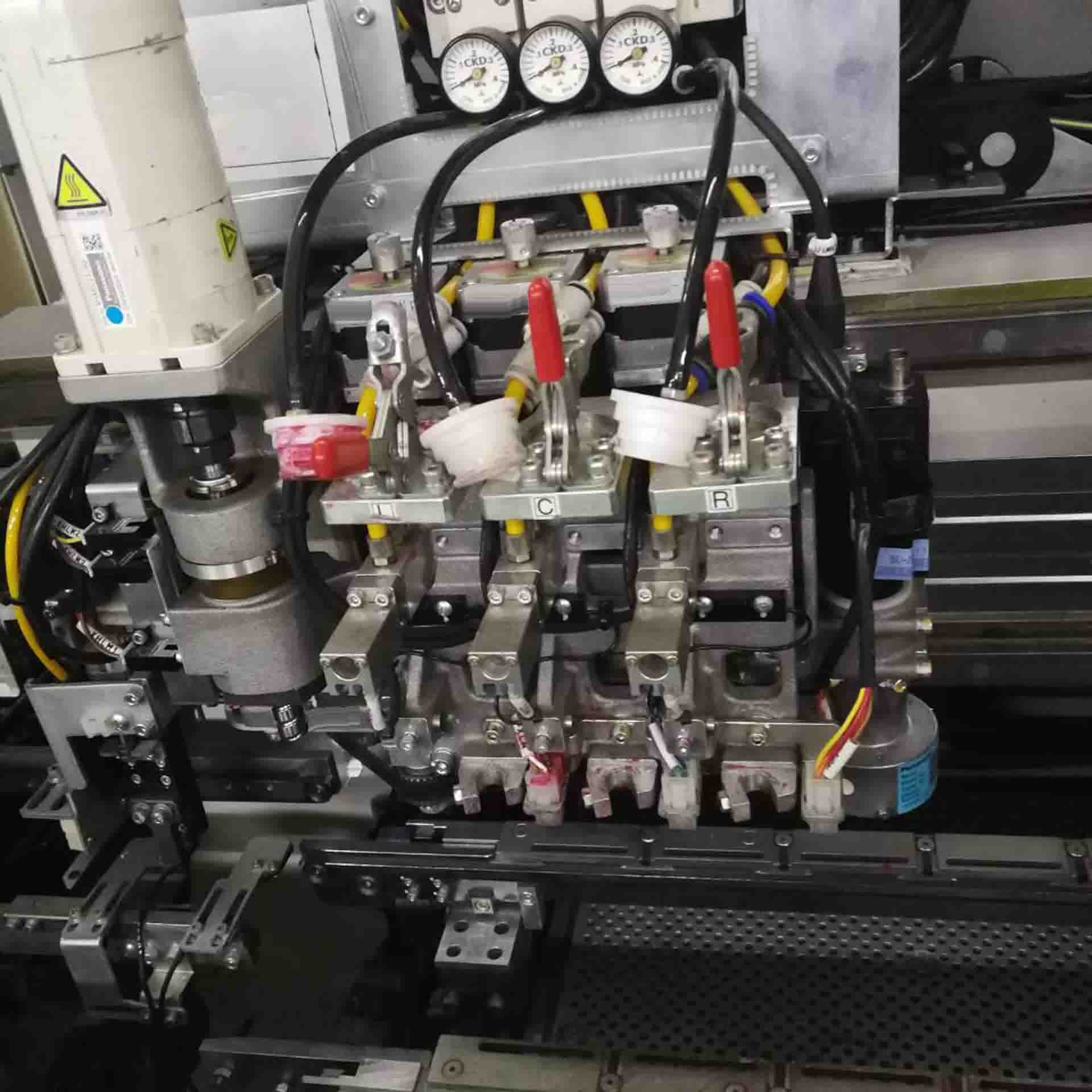

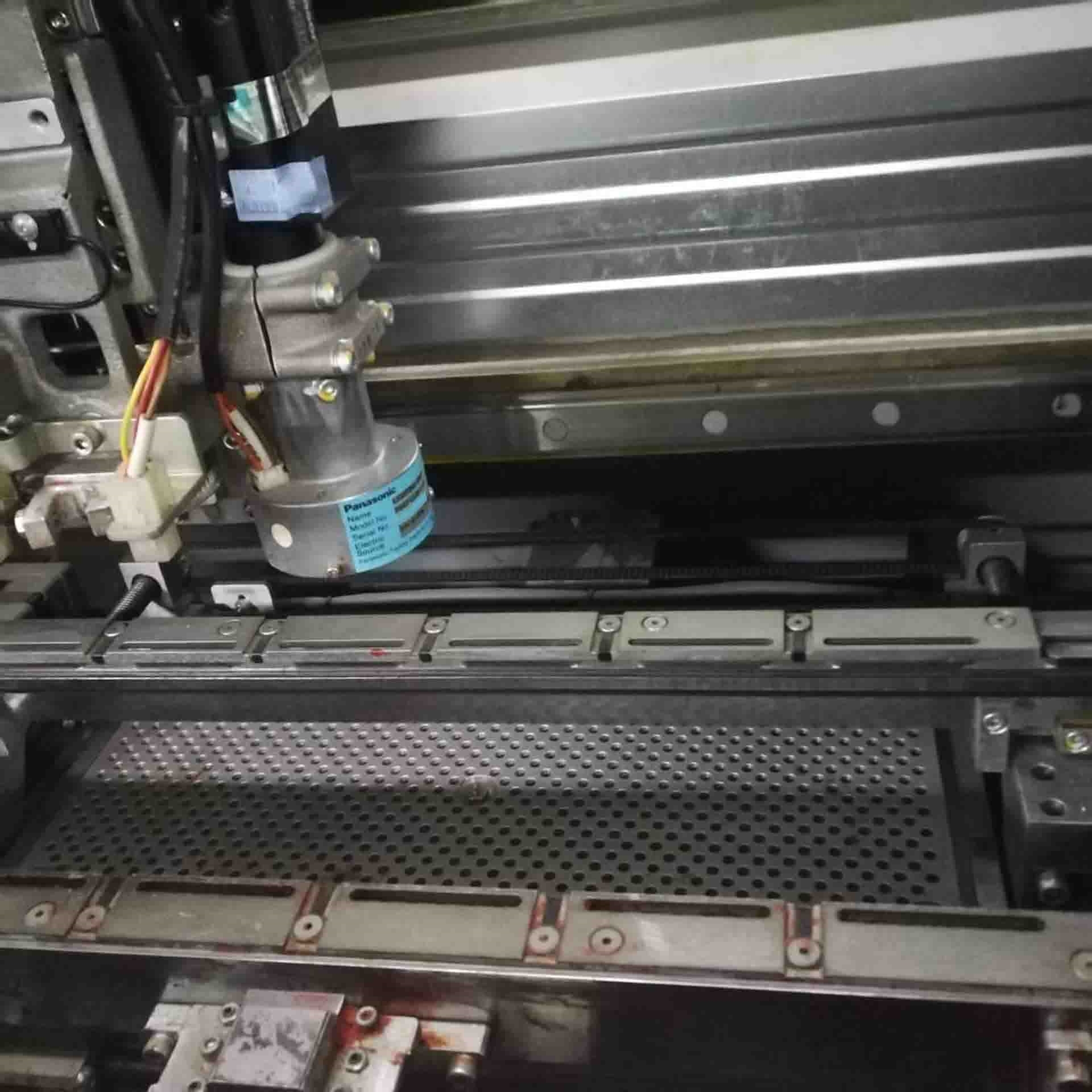

PANASONIC NM-DC10 is a state of the art PC board assembly and manufacturing equipment designed for medium- to high-volume production environments. It is able to significantly reduce throughput times, while also increasing the quality and accuracy of the produced product. NM-DC10 system consists of two main components, an AOI (Automated Optical Inspection) unit and a placement machine. The AOI machine on PANASONIC NM-DC10 can detect the presence and detect possible defects in printed circuit boards, including missing and wrong components, incorrect pad shapes, incorrect component height, and overprint. The AOI tool is able to detect potential defects up to a resolution of 0.2mm and has a maximum total cycle time of 1s, ensuring a highly efficient and accurate product inspection. The placement machine component of NM-DC10 asset is composed of a pre- and post-print process placement machine and a high-speed pick-and-place head. The pre- and post-print process placement machine is capable of placing a wide range of surface mount components, including chip components, lead frame type components, and odd-form components. It can assemble PCBs with a maximum of 20,530 parts per hour at a placement accuracy of 0.02-0.05mm accuracy. The high-speed pressure head of the placement machine can accurately place components at speeds up to 20,000 parts per hour. It is capable of picking and placing components ranging from 0201-34mm, from 0.15mm square chips and 2mm leaded components to large BGA and QFN packages. This enables PANASONIC NM-DC10 to produce highly reliable PCBs with excellent long-term performance. NM-DC10 can be programmed to run a variety of production test jobs. It is equipped with an integrated IO controller for data transfer and its own dedicated server for monitoring and controlling the production process. It supports Ethernet communication, with its own built-in browser-based user interface, to allow for remote setup or troubleshooting of the model. Overall, PANASONIC NM-DC10 is an ideal solution for medium- to high-volume production of printed circuit boards. Its high-speed placement machine and AOI inspection equipment guarantees fast and reliable PCB assembly, while its customizable software and range of peripherals allows for easy setup and maintenance. It is the perfect solution for companies seeking to streamline their PCB manufacturing process.

There are no reviews yet