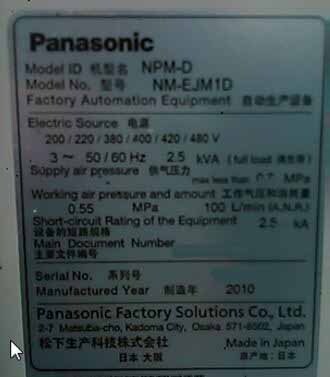

Used PANASONIC NPM-D #9161200 for sale

URL successfully copied!

Tap to zoom

PANASONIC NPM-D is a PC Board Assembly and Manufacturing equipment designed to meet the demands of advanced manufacturing. This production system uses an array of technologies to facilitate a complete digital manufacturing process. NPM-D combines standardized PC board assembly, optimization of process parameters, and manufacturing with operational flexibility. The unit is composed of a main unit and production modules including loaders, unloaders, and transfer devices; all of which are integrated for true machine optimization. The main unit is composed of the Process Control, Clock Control, and Feeder Control. The Process Control unit is built to manage all processes of the production line, such as program start, board registration, feeder management, programming of process parameters, management of machine tasks, data collection, and board unloading. The Clock Control unit is the command tool designed to control, monitor, and coordinate all of the activities of the asset. The Feeder Control unit is the part that configures and manages the parameters needed for the loading and unloading of PC board feeders. This model uses an efficient multi-axis deployment for precision pick-and-place operations and supports automatic registration, feeder loading, alignment, and data management for optimized product throughput. PANASONIC NPM-D also provides production modules that increase the flexibility and range of functions of the equipment. The Vision measurement unit provides 3D viewing, enabling more accurate in-line inspections. The PLC system assists with machine tasks, and can be connected to other machines or components on the production line, providing a comprehensive and efficient unit. Furthermore, the machine also uses smart printers and splitters to maximize production efficiency, and handles multiple product sizes and types. NPM-D is an extremely advanced PC Board assembly and manufacturing tool that enables full automation and optimization of the manufacturing process. It is equipped with a range of powerful features and advanced technologies to ensure the highest level of repeatability, performance, and accuracy for even the most complex manufacturing tasks. With its intuitive user interface, delivered expectations of production rates, and enhanced quality, this asset is an invaluable tool for efficient and reliable production.

There are no reviews yet