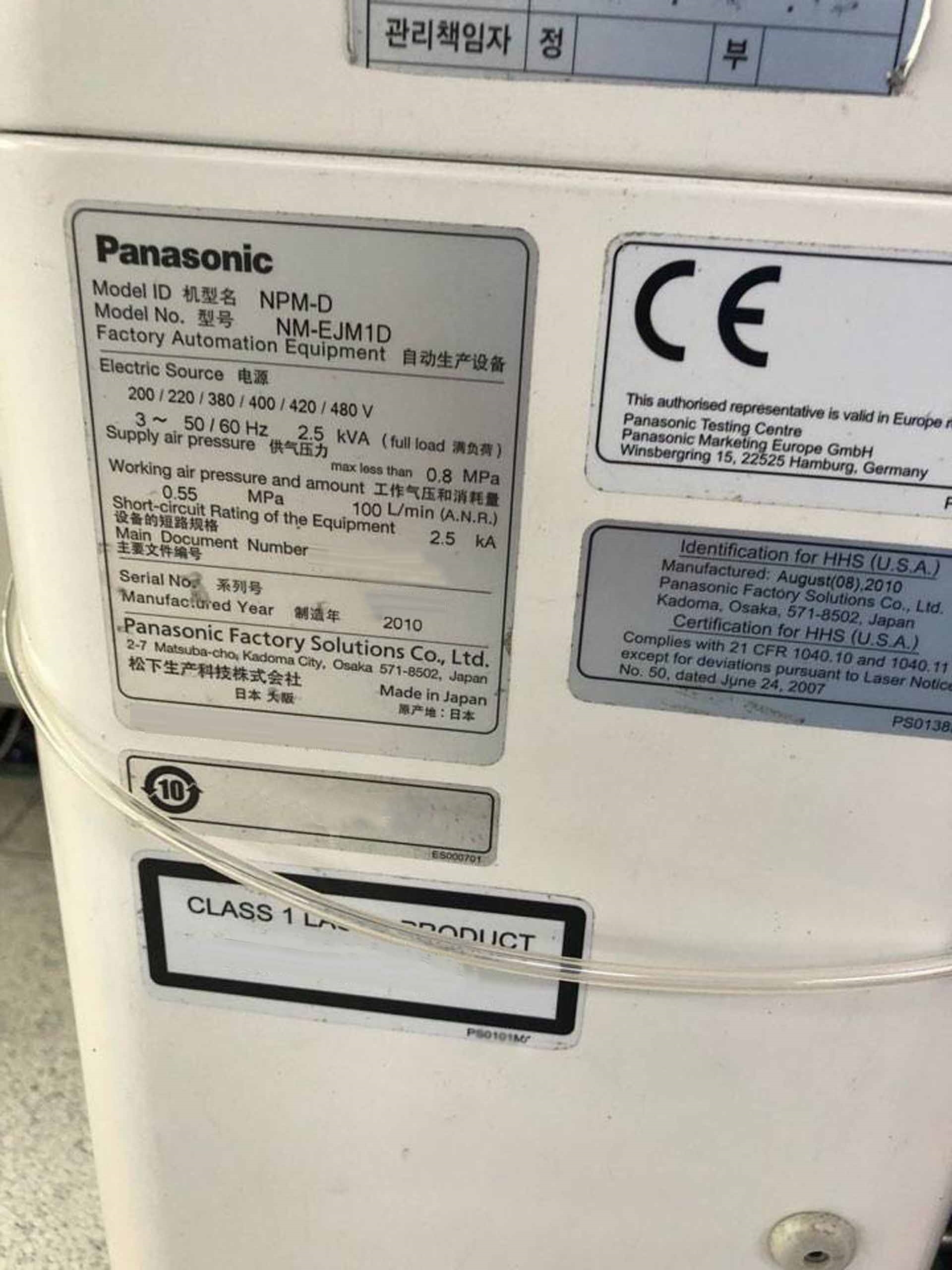

Used PANASONIC NPM-D #9219066 for sale

URL successfully copied!

Tap to zoom

PANASONIC NPM-D is a PC board assembly and manufacturing equipment designed to maximize automation and flexibility, allowing for the production of customer specific orders with the highest level of quality, cost-effectiveness, and speed. NPM-D accommodates up to 14 production modules, each uniquely designed to handle various parts that assemble into a printed circuit board. Each module utilizes a combination of advanced technologies including conveyor systems, 3D laser tracking and vision systems, robots, machine vision systems, and machine learning algorithms to quickly and accurately assemble components onto theboard layout. PANASONIC NPM-D also comes with a modernized software package to manage the entire manufacturing process. This includes the ability to set up customer order-specific production parameters, monitor production progress, and track parts and board progress. The software also offers real-time simulations to diagnose problematic components and make changes before they become an issue. This system is equipped with a wide range of features, such as rapid placement accuracy, to quickly place pieces and apply manual solder. It also includes automatic sorting capabilities to segregate components. NPM-D is also capable of performing various advanced techniques such as chip shooting, pin insertion, seaming and tinning. There are multiple camera systems on the unit that provide quality control clips of the task performed and allow for in-depth diagnostics of issues. Additionally, PANASONIC NPM-D can perform online part verification and test process programs as well as provide statistical process control. The machine is designed to provide a continuous flow of data from the line so that online problem solving can be done. The data can also be used for predictive maintenance, which will help optimize the production process and make adjustments to maximize throughput. NPM-D is an advanced tool that integrates the latest technologies to provide the highest level of accuracy, speed, and efficiency in PCB assembly and manufacturing. With the use of its advanced features, the ability to manage customer-specific orders, and the advanced software capabilities, it is able to maximize cost-effectiveness while also ensuring quality control and high product yields.

There are no reviews yet