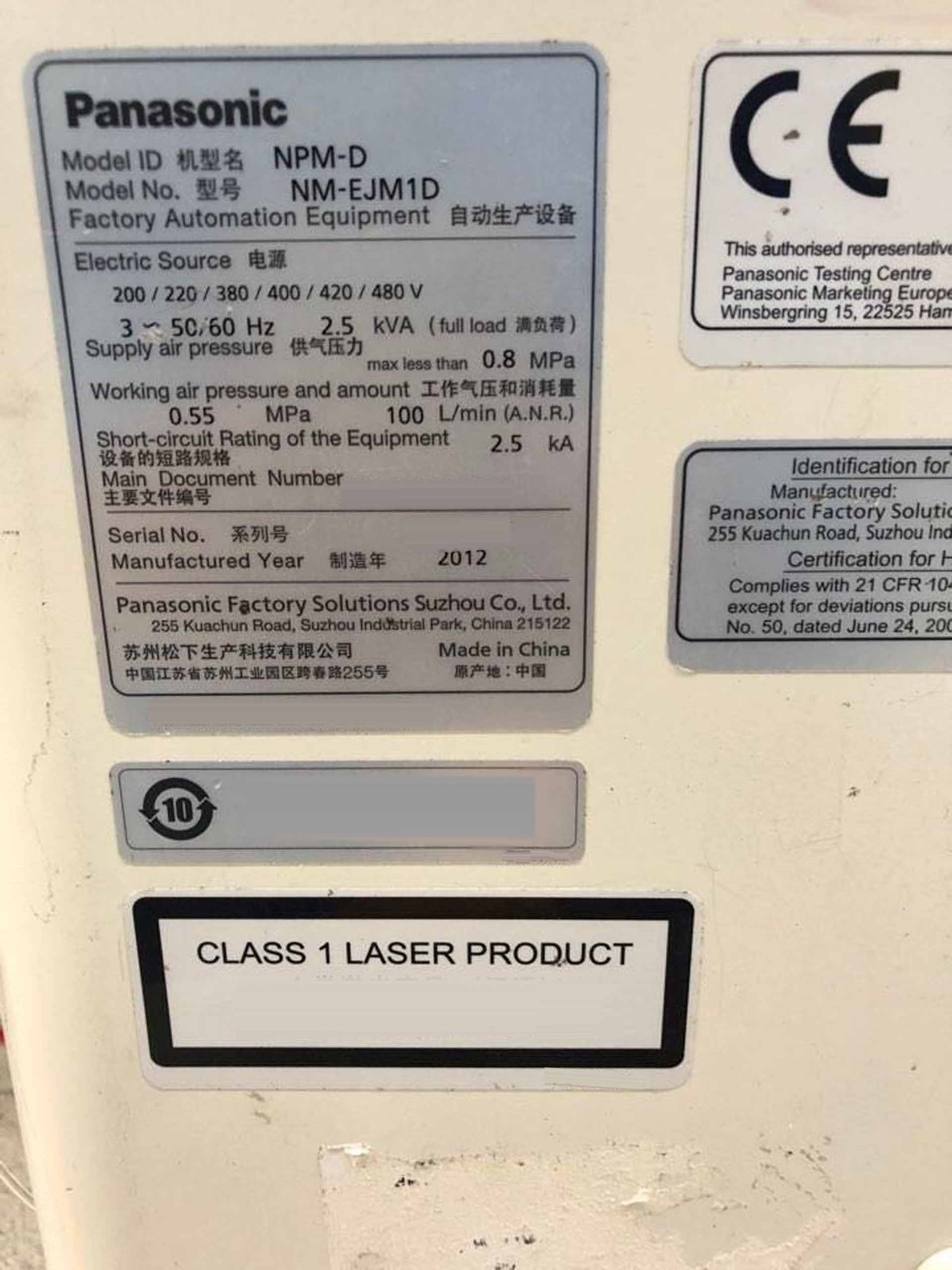

Used PANASONIC NPM-D #9219070 for sale

URL successfully copied!

Tap to zoom

PANASONIC NPM-D is a pc board assembly and manufacturing equipment, developed and manufactured by PANASONIC. This system makes use of advanced and integrated hardware and software technologies in order to automate the entire process of assembly and manufacturing of printed circuit boards (PCBs). NPM-D unit is designed to simplify the overall productivity, enabling a shorter time to market for electronic products, while reducing production costs. The core of the machine consists of three basic components - the pick and place module, the transport tool and the inspection asset. The pick and place module is a fully automated component assembly module, which uses vacuum nozzles to accurately and precisely place components on the circuit board. It can detect the type and size of components and place them in the exact predetermined location to ensure a high degree of accuracy in production. The transport model moves the PCBs from one station to another, and is capable of detecting and removing components that have failed inspection. Finally, the inspection equipment uses advanced image processing and 3D x-ray imaging to detect defects, and also to check the surface condition, solder joints and any other visible defects on the PCB. In addition to these three core components, PANASONIC NPM-D system also makes use of other hardware and software components to provide the customers with complete solutions. These include integrated vision systems and digital imaging, as well as special modules for programming and testing of the board, and other auxiliary equipment. NPM-D unit also offers a wide variety of user support and remote maintenance options, including remote diagnostic functions, central control systems and a variety of other options. The machine also enables quick and easy replacement of parts, providing high levels of stability and reliability. Overall, PANASONIC NPM-D is a complete solution for PCB assembly and manufacturing, offering users with an efficient and cost effective means of manufacture, as well as ensuring quality and reliability. The tool allows companies to reduce the time to market for their electronic products, while simultaneously reducing production costs.

There are no reviews yet