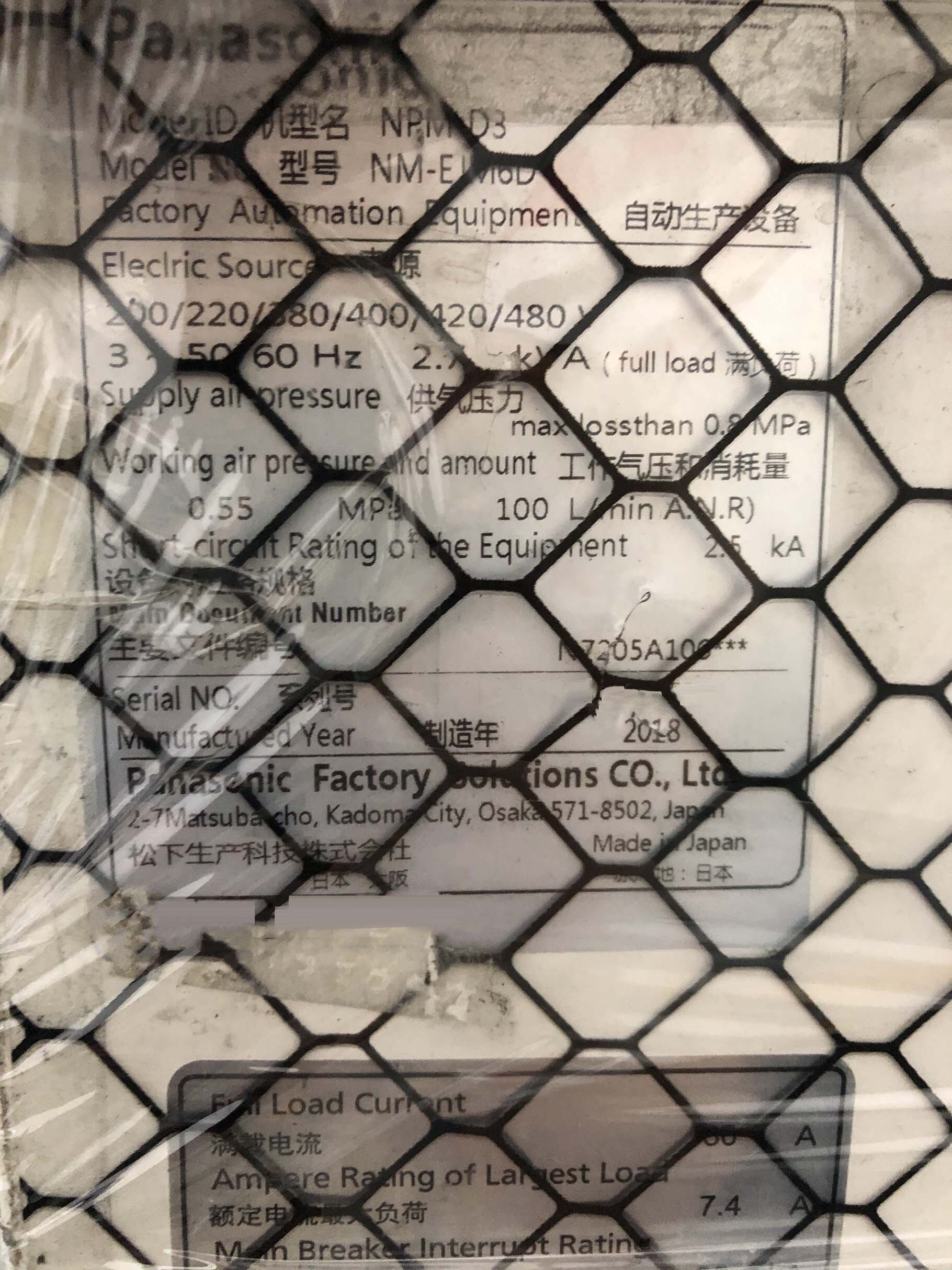

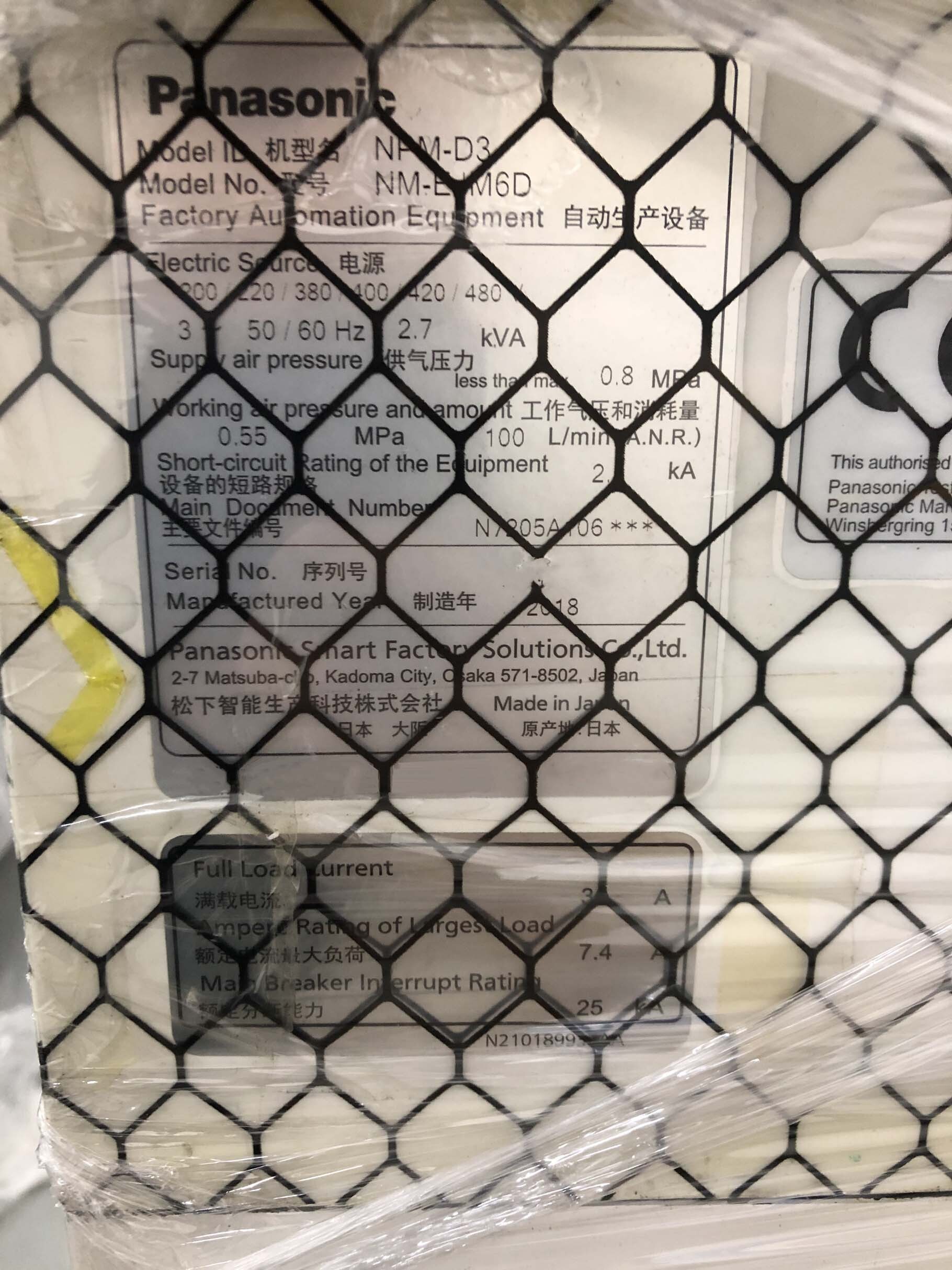

Used PANASONIC NPM-D3 #9261925 for sale

URL successfully copied!

Tap to zoom

ID: 9261925

Placement machines

Dual lane

(16) Nozzles

NPM Basic module

Feeder cart (Front / Rear side)

(16) Nozzle heads with nozzle changer (Front side - light weight type)

N610081683AA Feeder cart (Front side)

(16) Nozzle heads with nozzle changer (Rear side - light weight type)

N610081683AA Feeder cart (Rear side)

Multi recognition camera (Type 1) front side

Multi recognition camera (Type 1) rear side

PCB Transfer conveyor

N610152186 Safety alliance cable (Left)

N6101290024AA Safety alliance extension cable (Left)

N610152I87 Safety alliance cable (Right)

N6101290024AA Safety alliance extension cable (Right)

2018-2019 vintage.

PANASONIC NPM-D3 is a PC board assembly and manufacturing equipment designed to streamline the production process by automatically handling the entire board placement process from start to finish. The system utilizes advanced technologies such as vision unit inspection and servo-driven placement systems to accurately and quickly place components on a PCB. The vision machine inspection is used to validate and identify electronic components on the PCB. This includes inspecting the component's size, shape, polarity, presence of solder, and orientation. The tool is equipped with a high-resolution color camera to enable detailed component inspection and to detect errors early in the production process. The servo-driven placement systems use a multi-axis drive mechanism to quickly put components in their proper location on a PCB. This asset can feed multiple components simultaneously and uses an advanced feeder control algorithm to ensure reliable and accurate placement. The model is compatible with a variety of component types including ICs, capacitors, resistors, inductors, connectors, and pneumatics. It supports a wide range of component sizes, shapes, and rotation angles and can handle components up to 12.5mm in length and 3.5mm in height. The equipment is highly customizable and can be integrated into existing factory automation systems. It is designed to integrate with popular equipment such as automatic wire bonding and laser depaneling systems, and the high-speed component placement is compatible with high-speed production rates. The system is designed for easy maintenance and features user-friendly setup and operation. The user interface is intuitive and self-explanatory, and it can be connected to a network for remote monitoring and access. The unit also has built-in safety features to ensure proper operation and operator safety. PANASONIC NMP-D3 is an advanced PC board assembly and manufacturing machine specifically designed to improve quality and reduce time and costs associated with the production process. The tool's vision asset inspection, servo-driven placement systems, and user-friendly interface make it an ideal choice for any PCB assembly operation.

There are no reviews yet